Patents

Literature

51results about How to "Guaranteed continuous processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

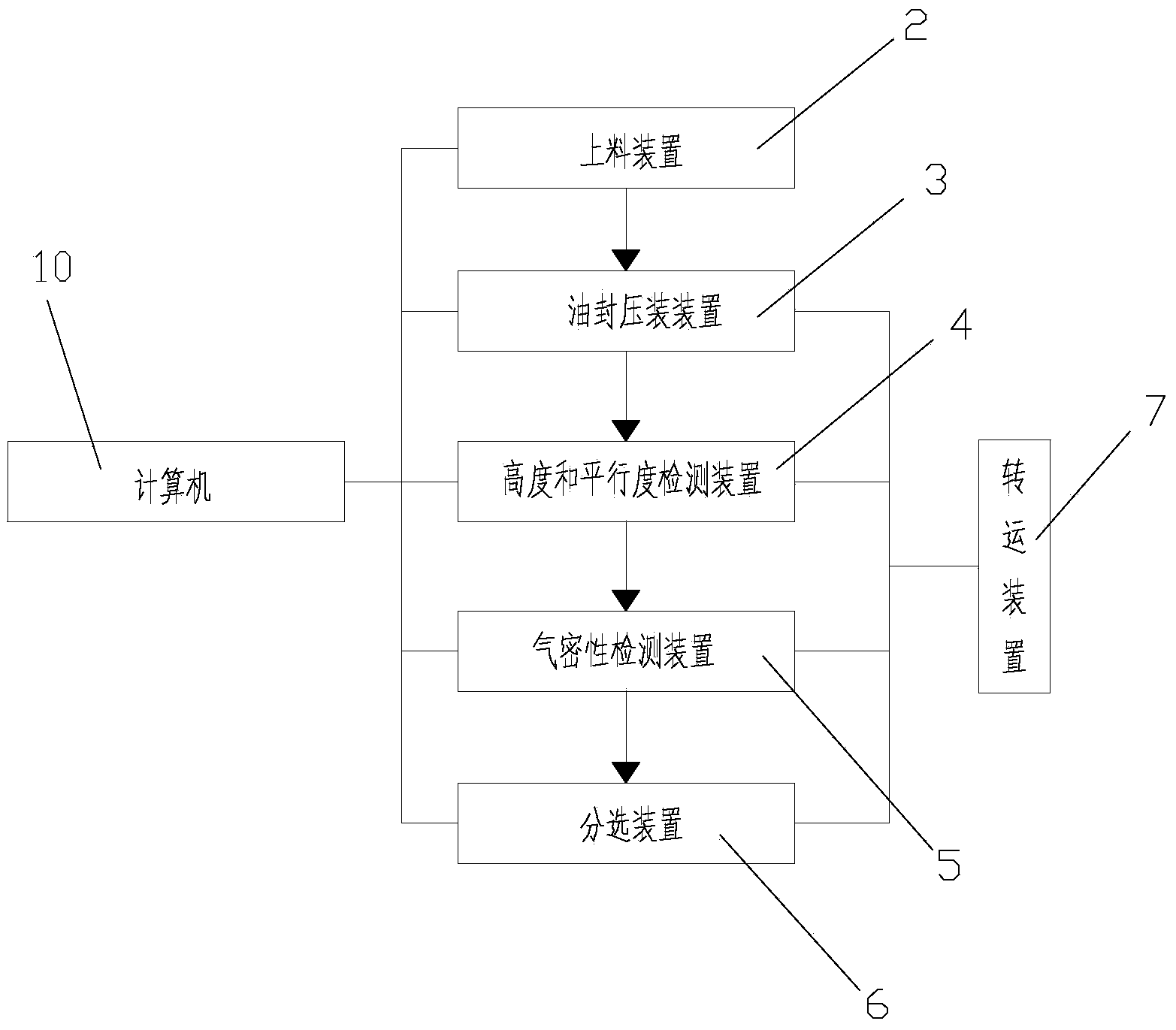

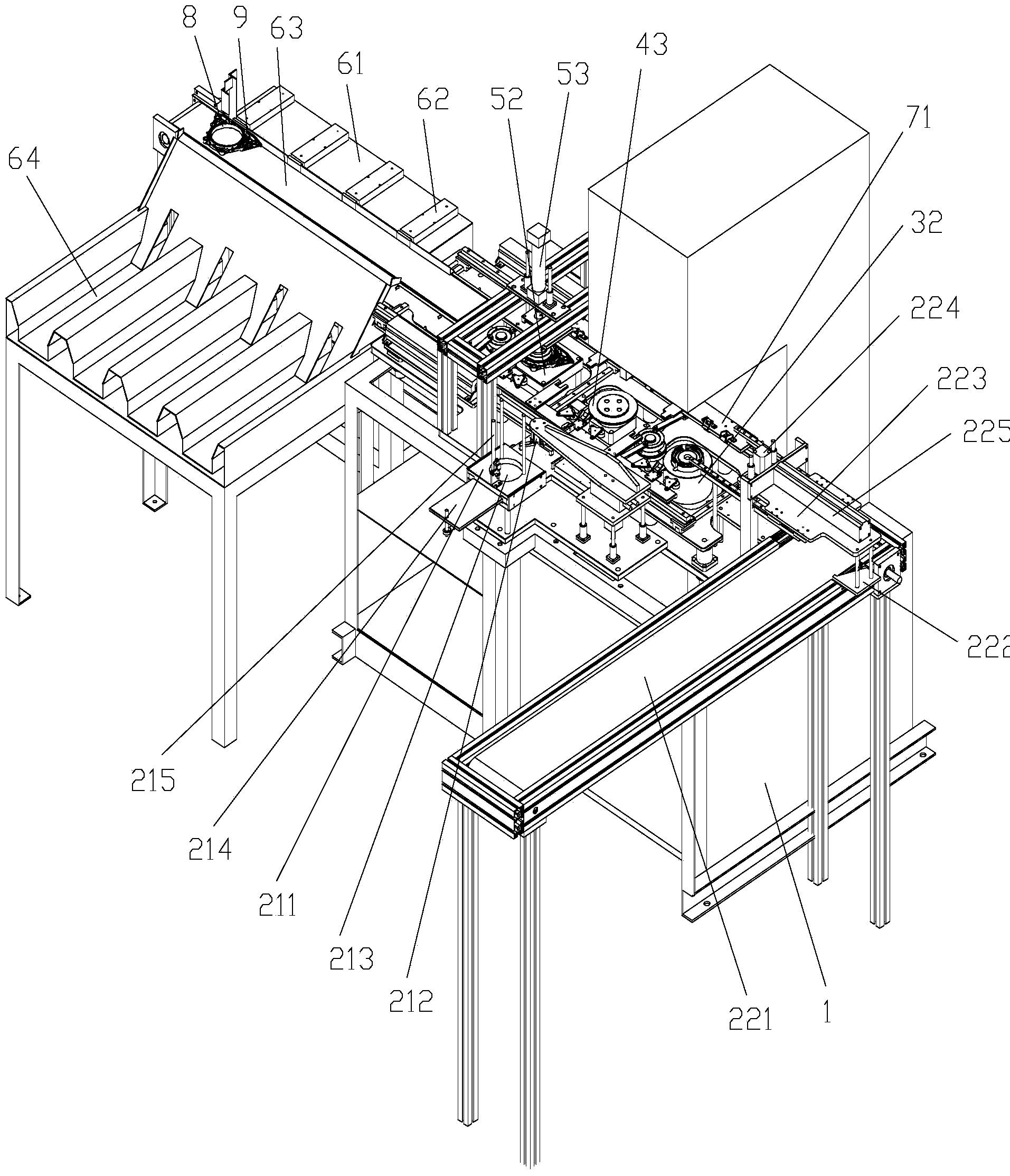

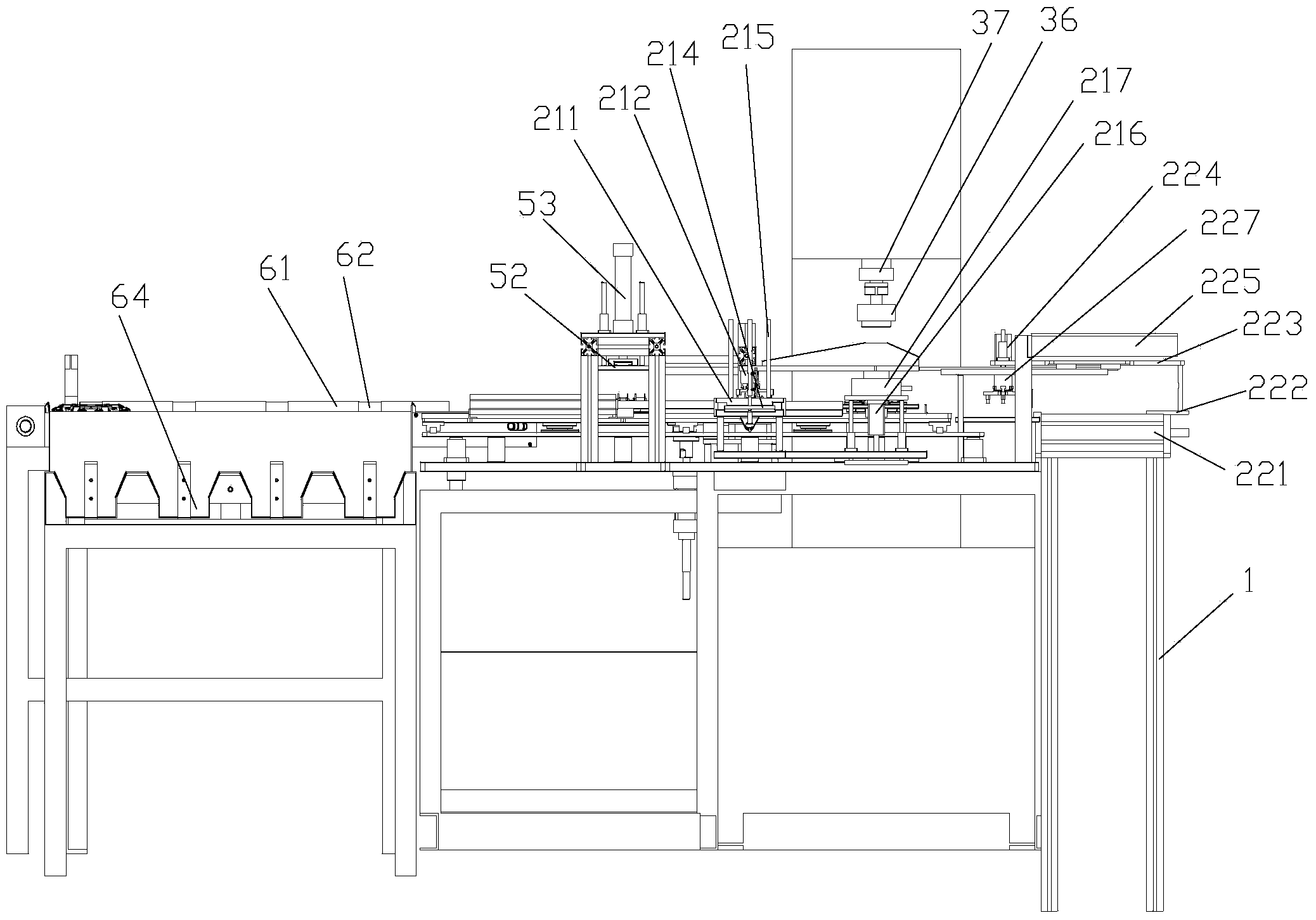

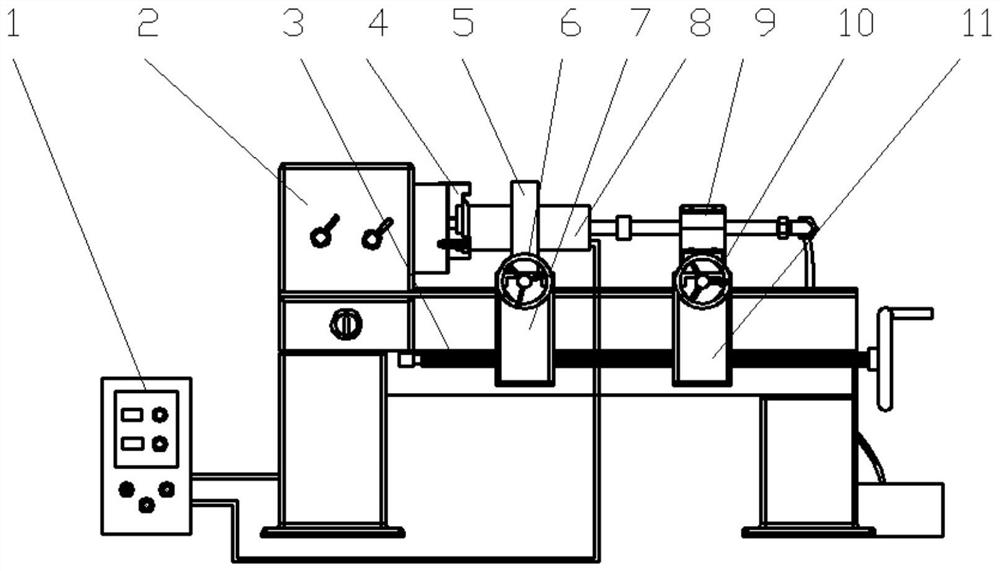

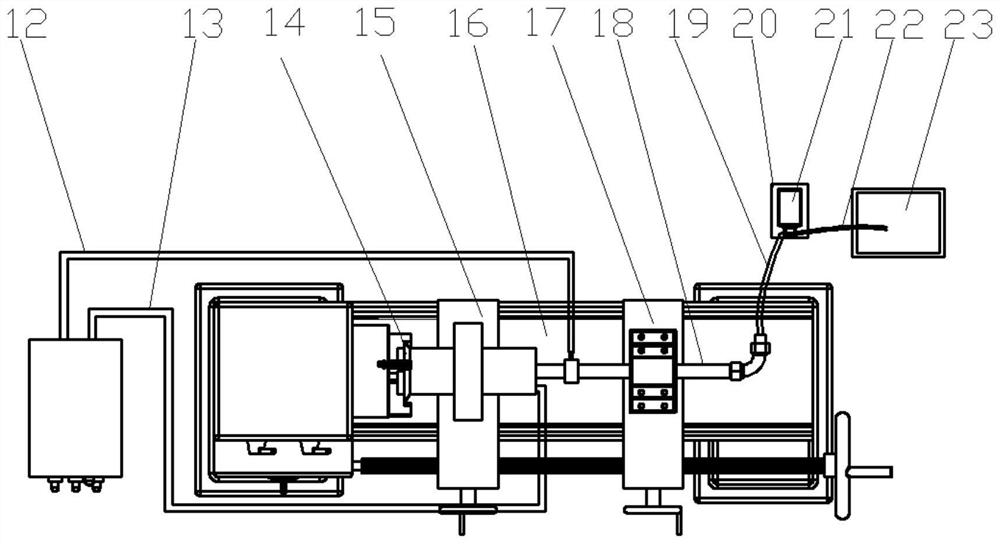

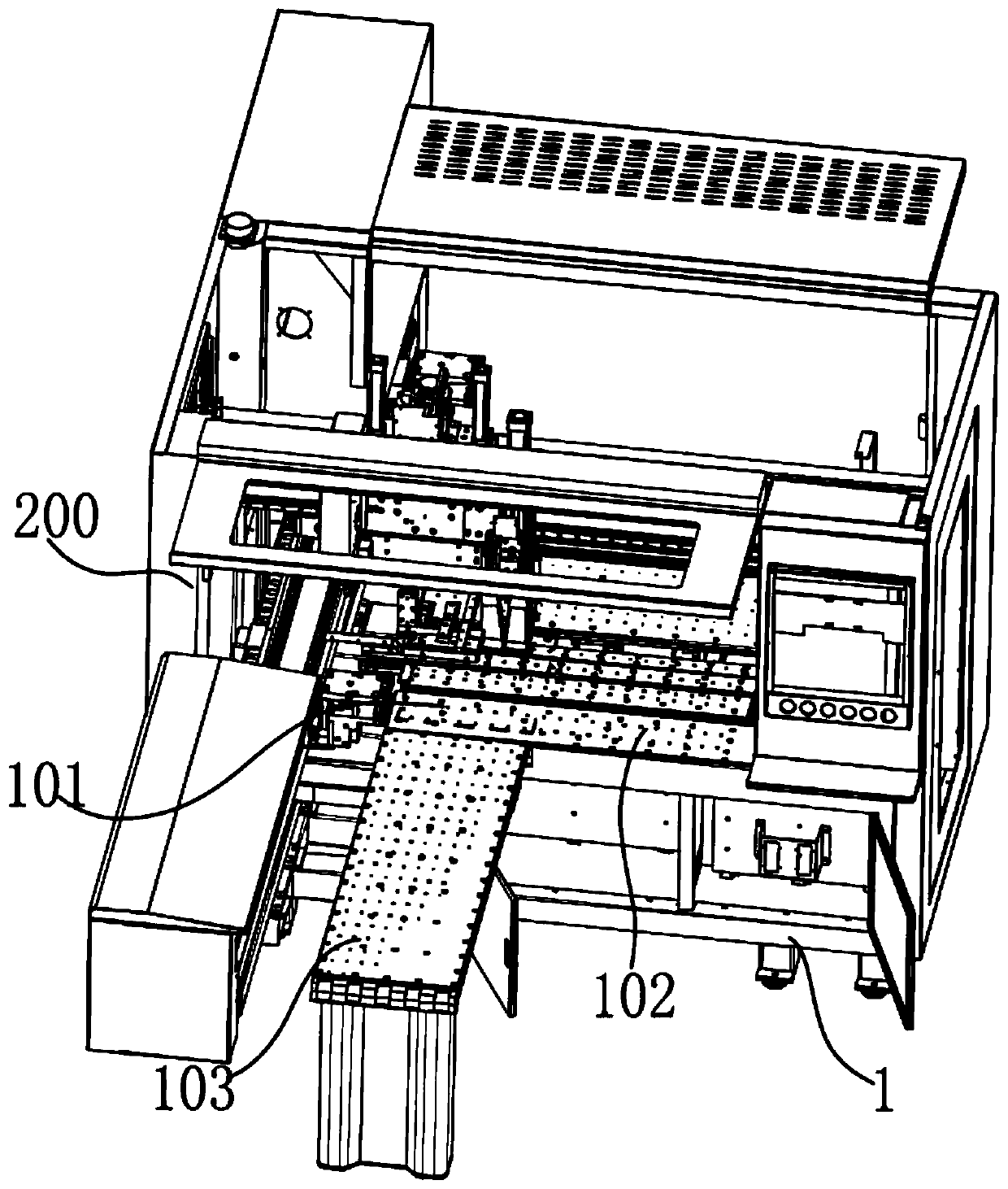

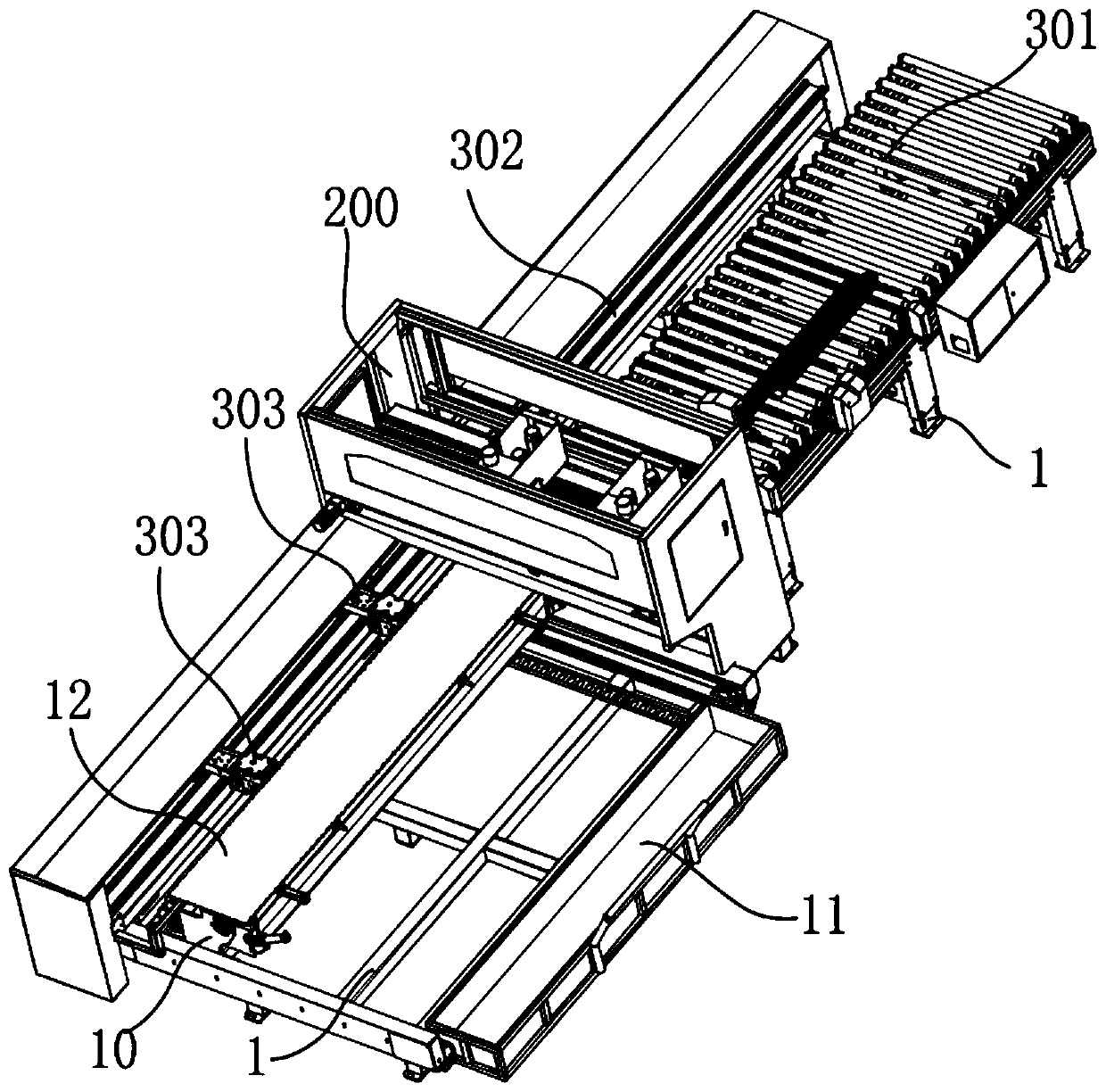

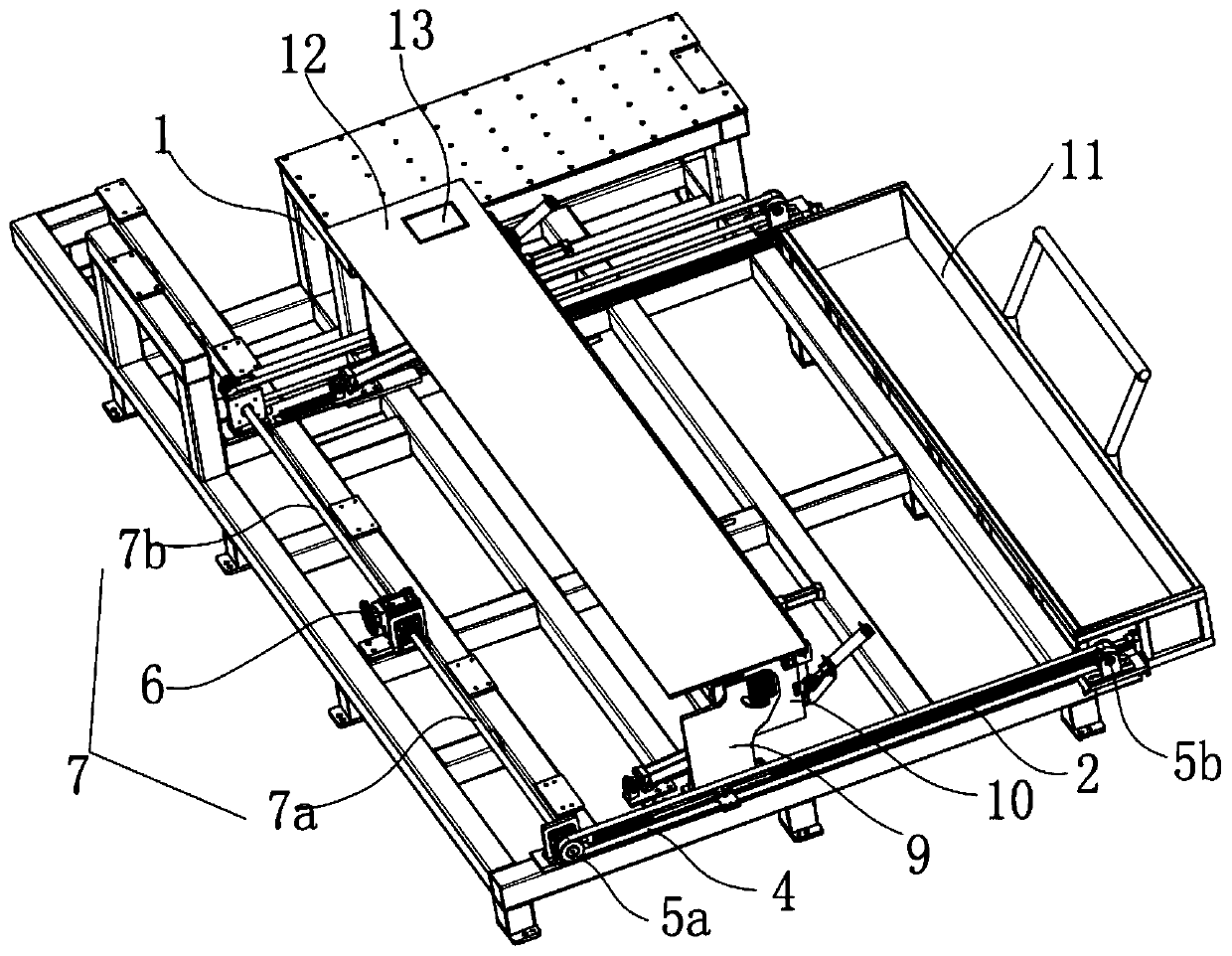

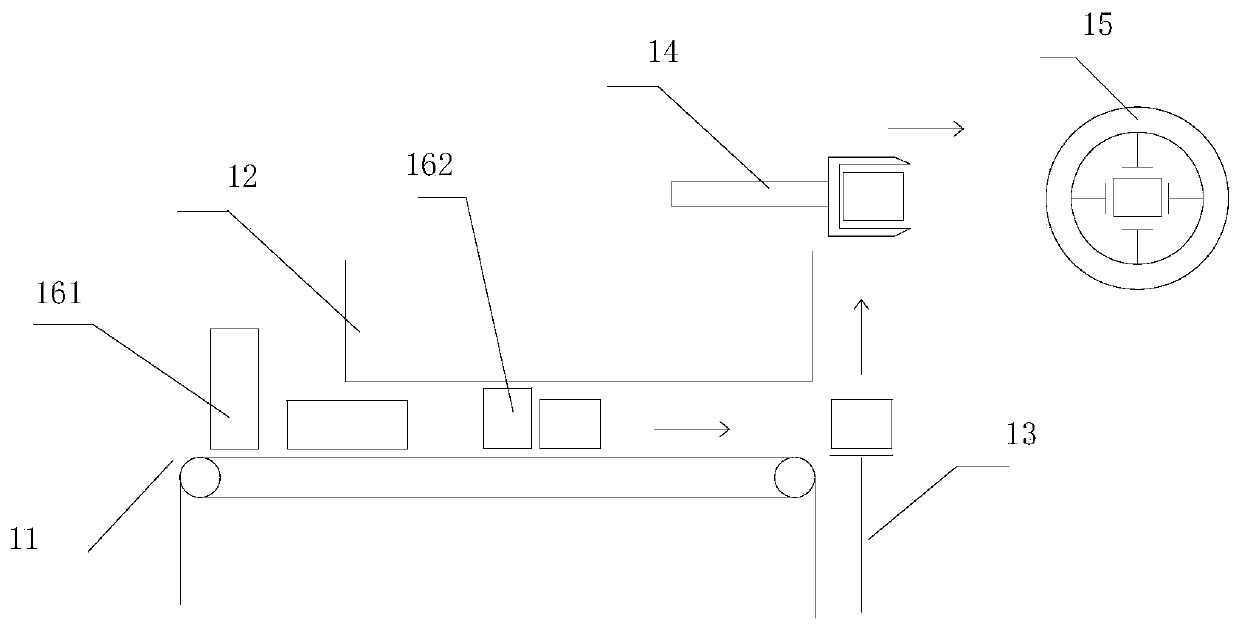

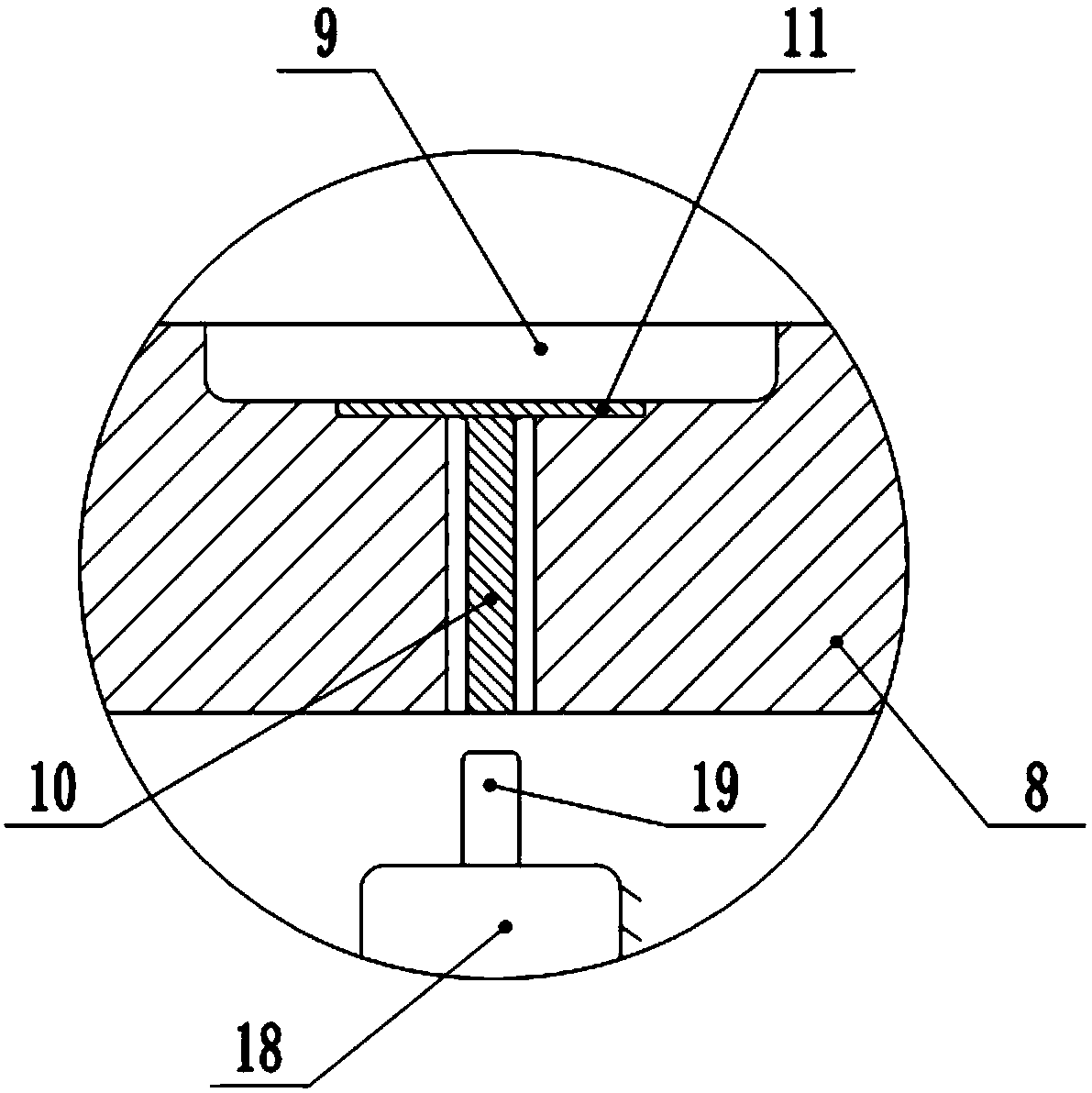

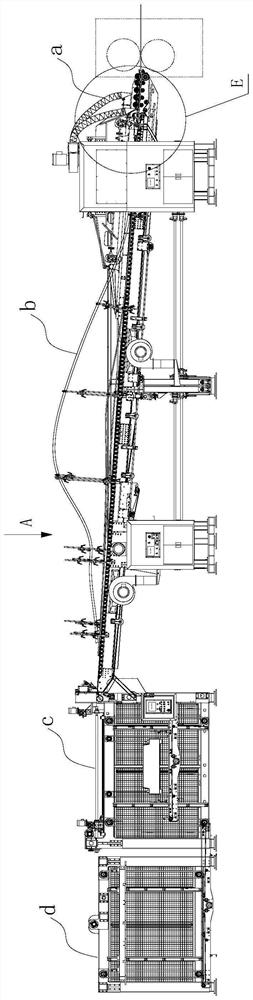

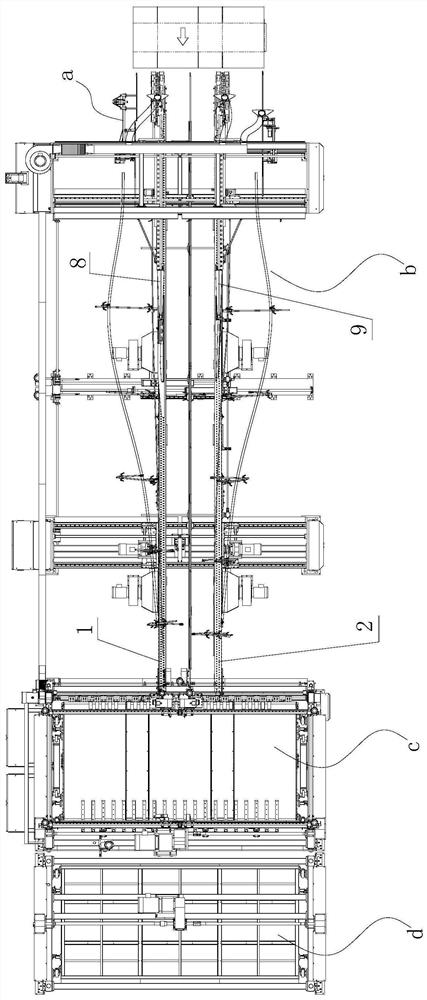

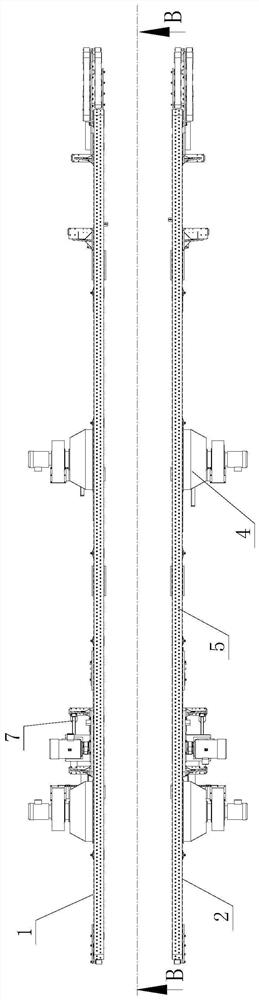

Oil seal press fitting detection production line

ActiveCN103447800AReduce labor intensityHigh degree of automationMeasurement of fluid loss/gain rateUsing optical meansProduction lineEngineering

The invention relates to an oil seal press fitting detection production line. The production line comprises a feeding device, an oil seal press fitting device, a height and parallelism detection device, an airtightness detection device, a separation device and a transfer device in sequence, wherein the feeding device, the oil seal press fitting device, the height and parallelism detection device, the airtightness detection device, the separation device and the transfer device are subjected to whole-process control of a computer respectively. According to the oil seal press fitting detection production line, computer integrated control is adopted, so that the automation degree is high, the detection accuracy is high, the machining efficiency is greatly improved, the labor intensity of workers is reduced, the parallelism, the height, the verticality and the airtightness of a product are guaranteed, and the defective rate of the product is reduced.

Owner:常州朗博密封科技股份有限公司

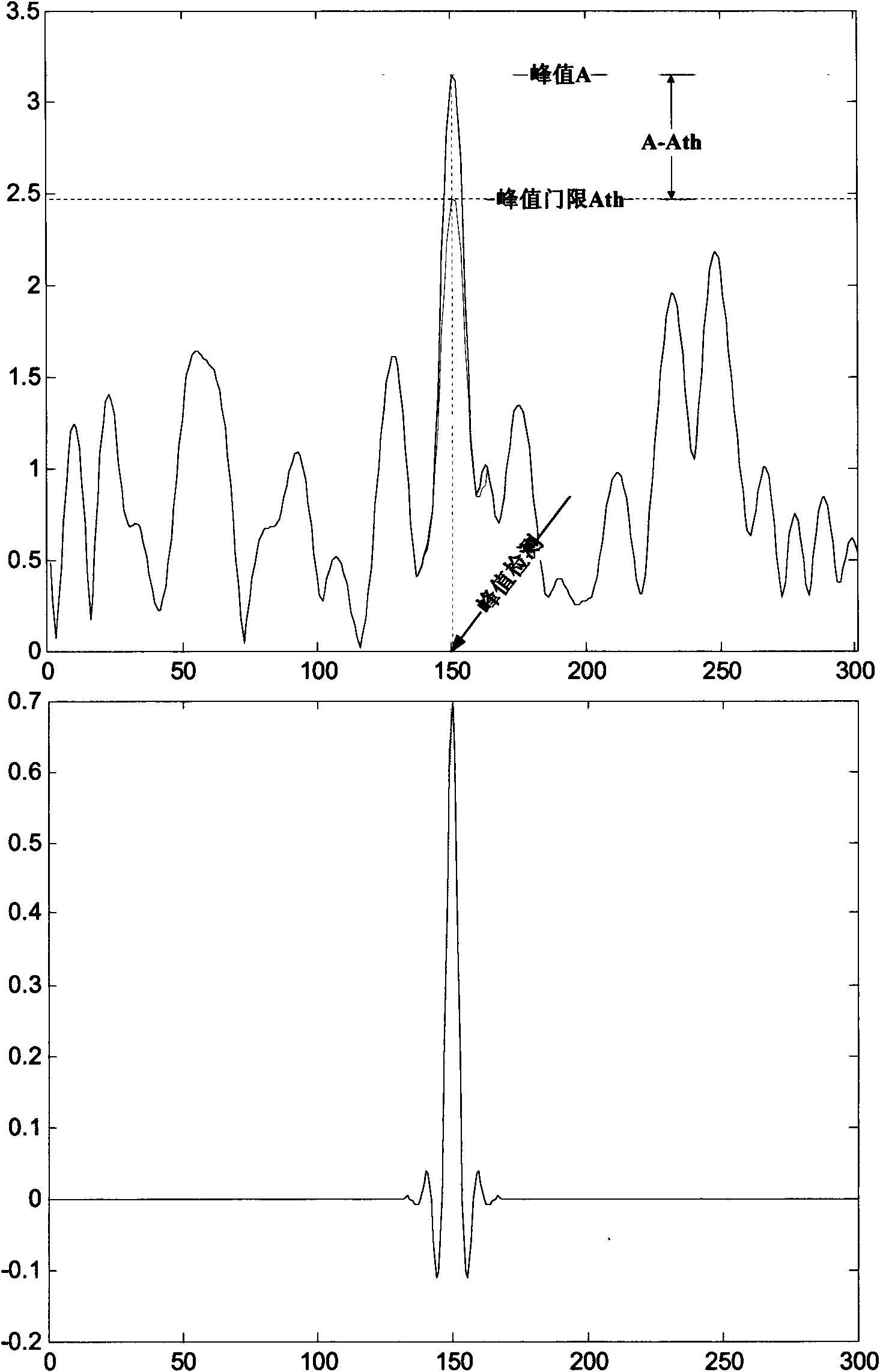

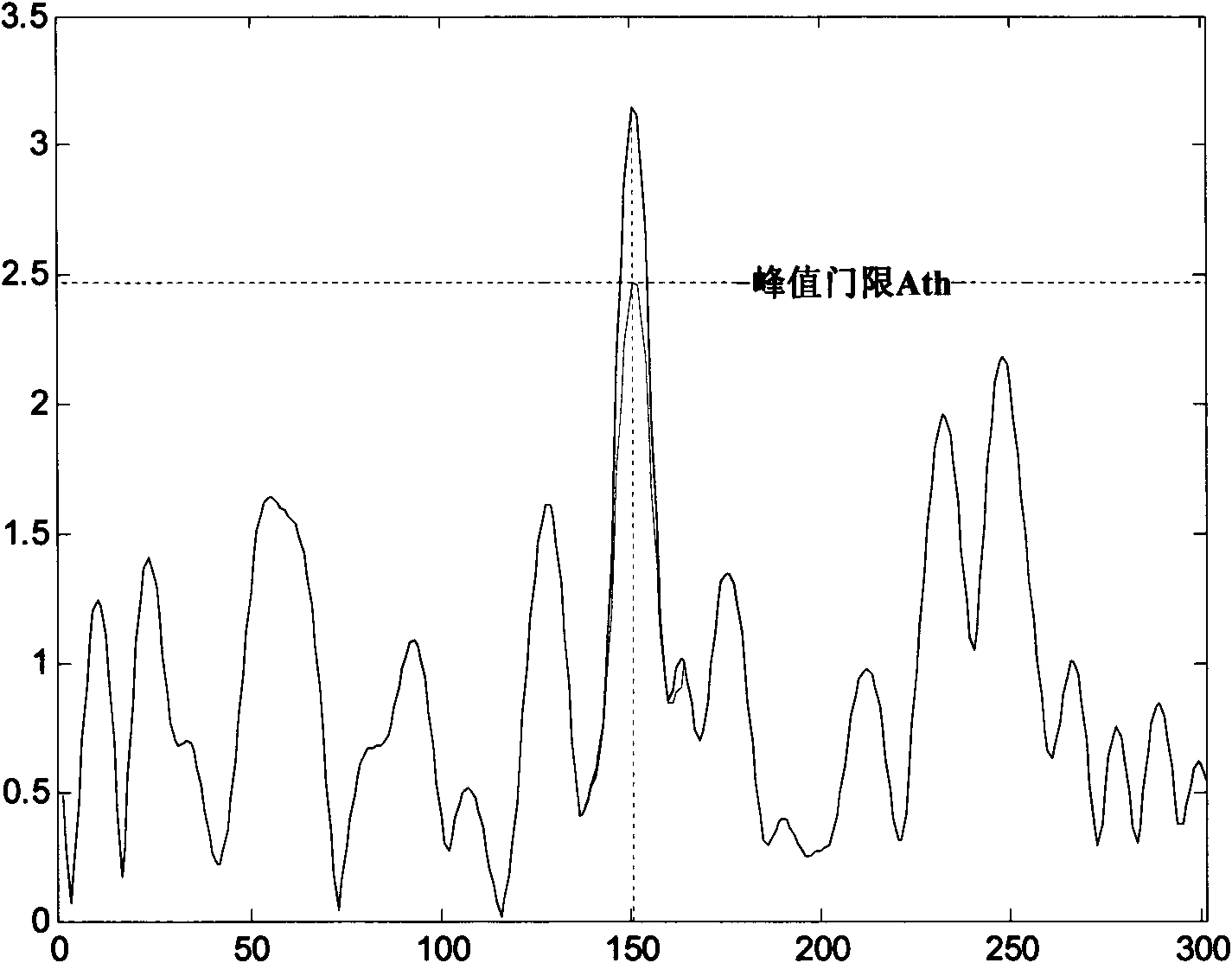

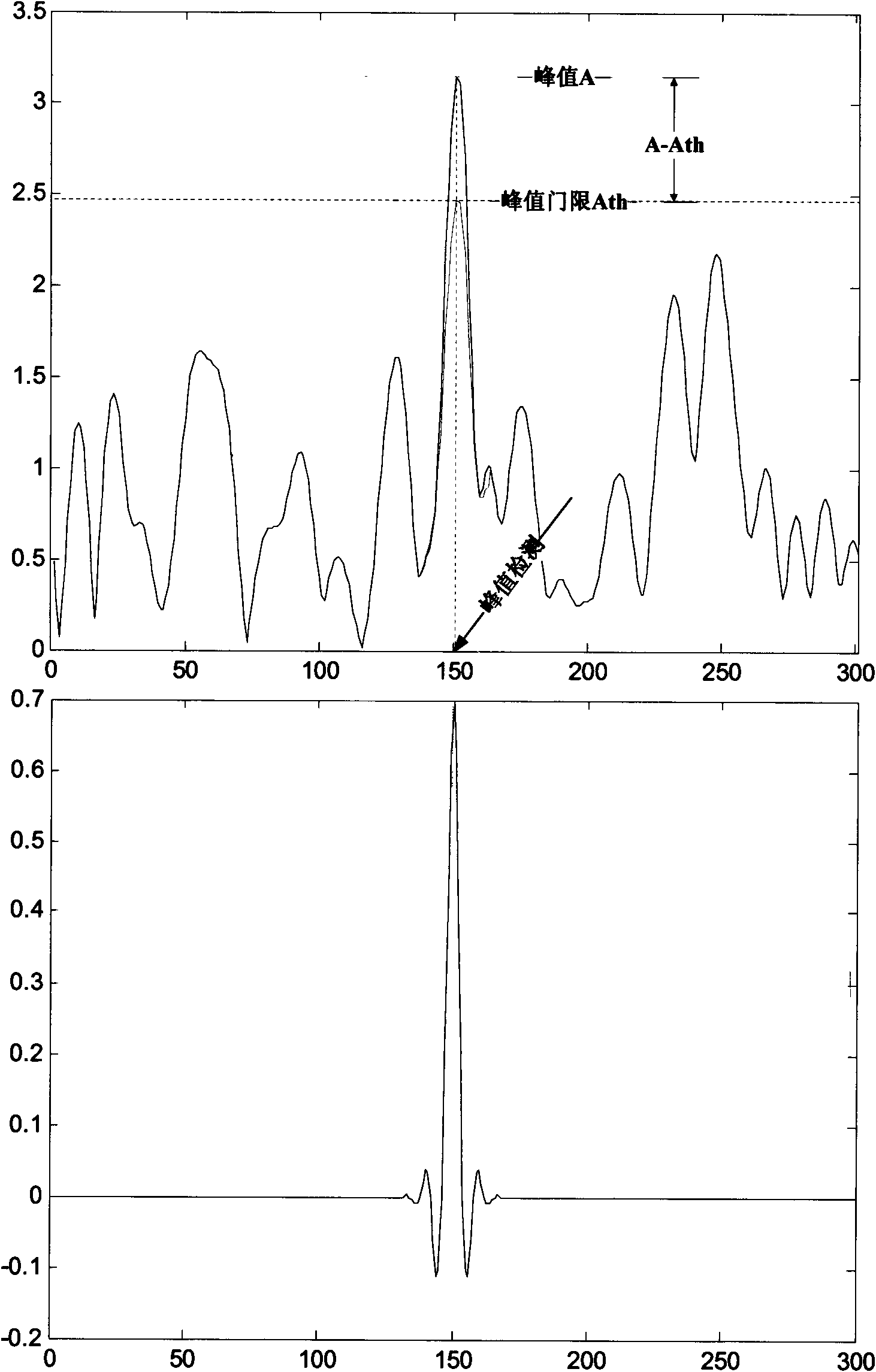

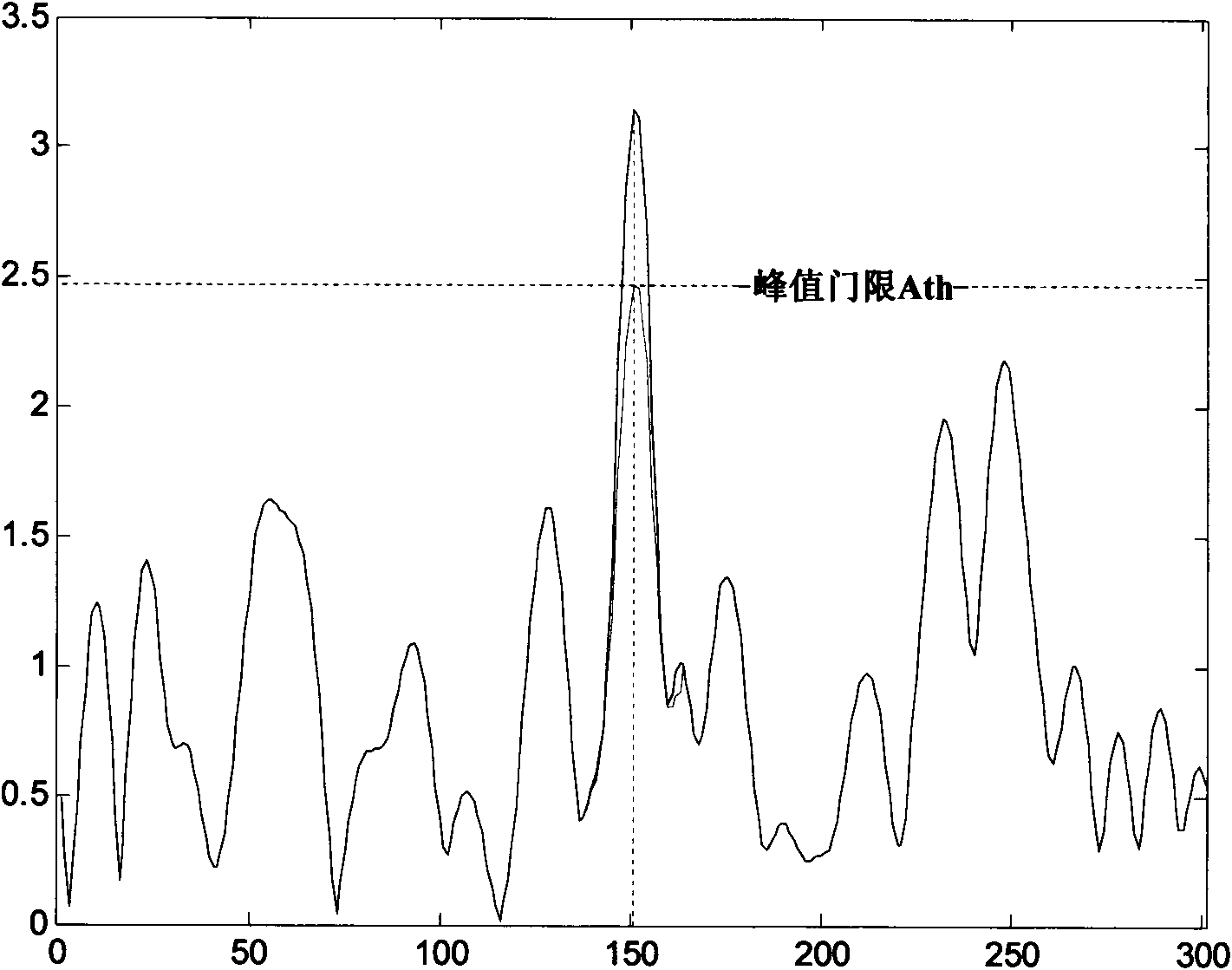

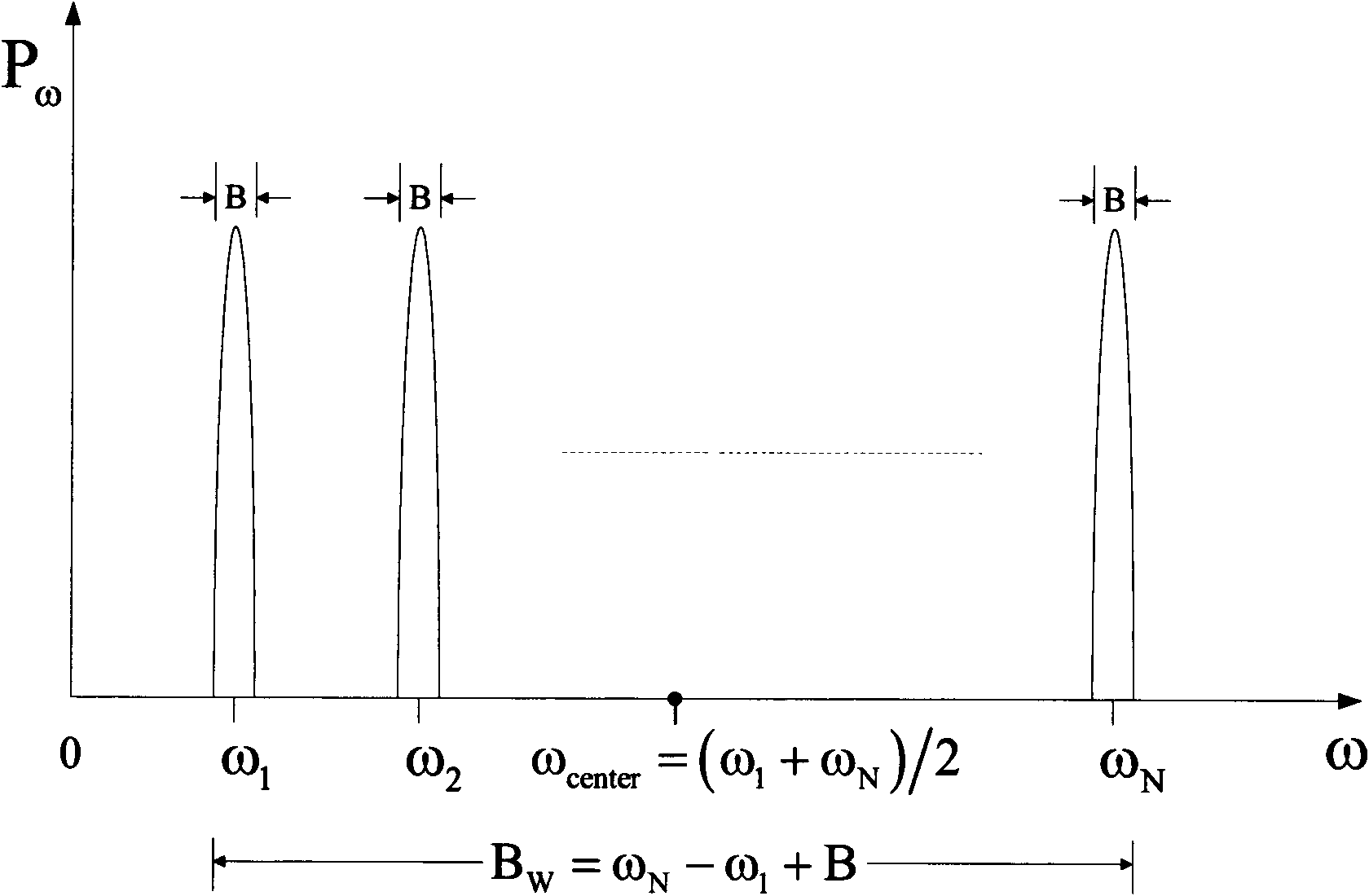

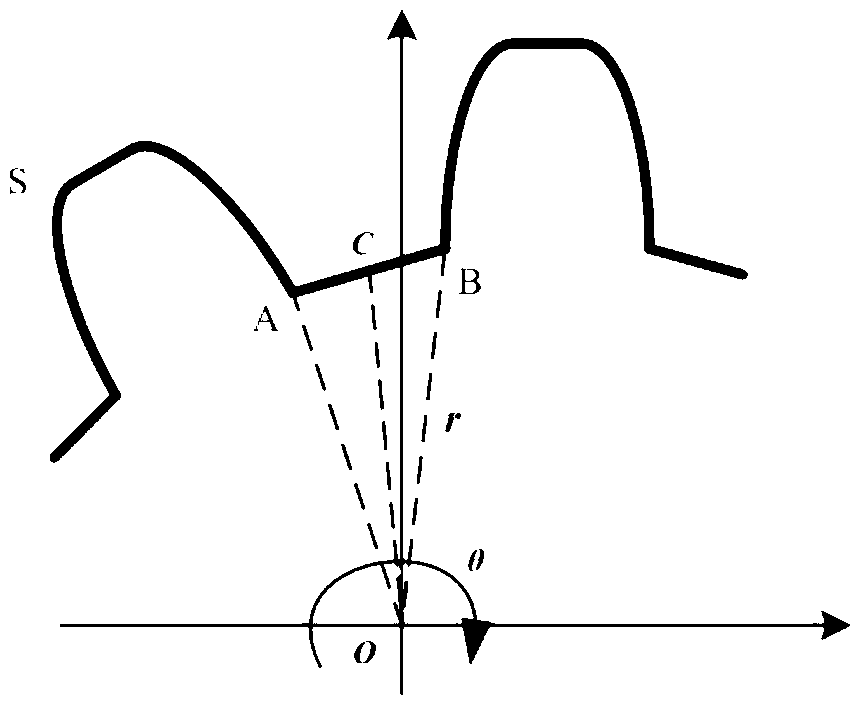

Peak clipping method for multi-carrier frequency hopping communication system

InactiveCN101651653ASuitable for programmingGuaranteed continuous processingMulti-frequency code systemsTransmitter/receiver shaping networksFrequency spectrumCarrier signal

The invention discloses a peak clipping method for a multi-carrier frequency hopping communication system, which is characterized by comprising the following real-time steps: (1) judging whether the signal bandwidth in the present moment is changed or not relative to the previous moment, if so, executing the step (3), otherwise, executing the step (2); (2) calculating a frequency difference of thepresent system signal and a center frequency point in the previous adjacent moment, carrying out frequency shift on a filter by the frequency difference so that the center frequency point is consistent with the present system signal and skipping to execute the step (4); (3) reconstructing the filter demanded by the digital bandwidth, the center frequency point and a spectrum template meeting thepresent system signal and executing the step (4); (4) constructing a peak clipping pulse, aligning to a peak value of the system signal by a peak value in response to a filter pulse and subtracting the peak clipping pulse by the system signal. The peak clipping method for the multi-carrier frequency hopping communication system can self-adaptively adjust the filter coefficient for constructing thepeak clipping pulse according to the carrier frequency point change of the system, thereby ensuring that the peak clipping effect is better than a traditional process.

Owner:COMBA TELECOM SYST CHINA LTD

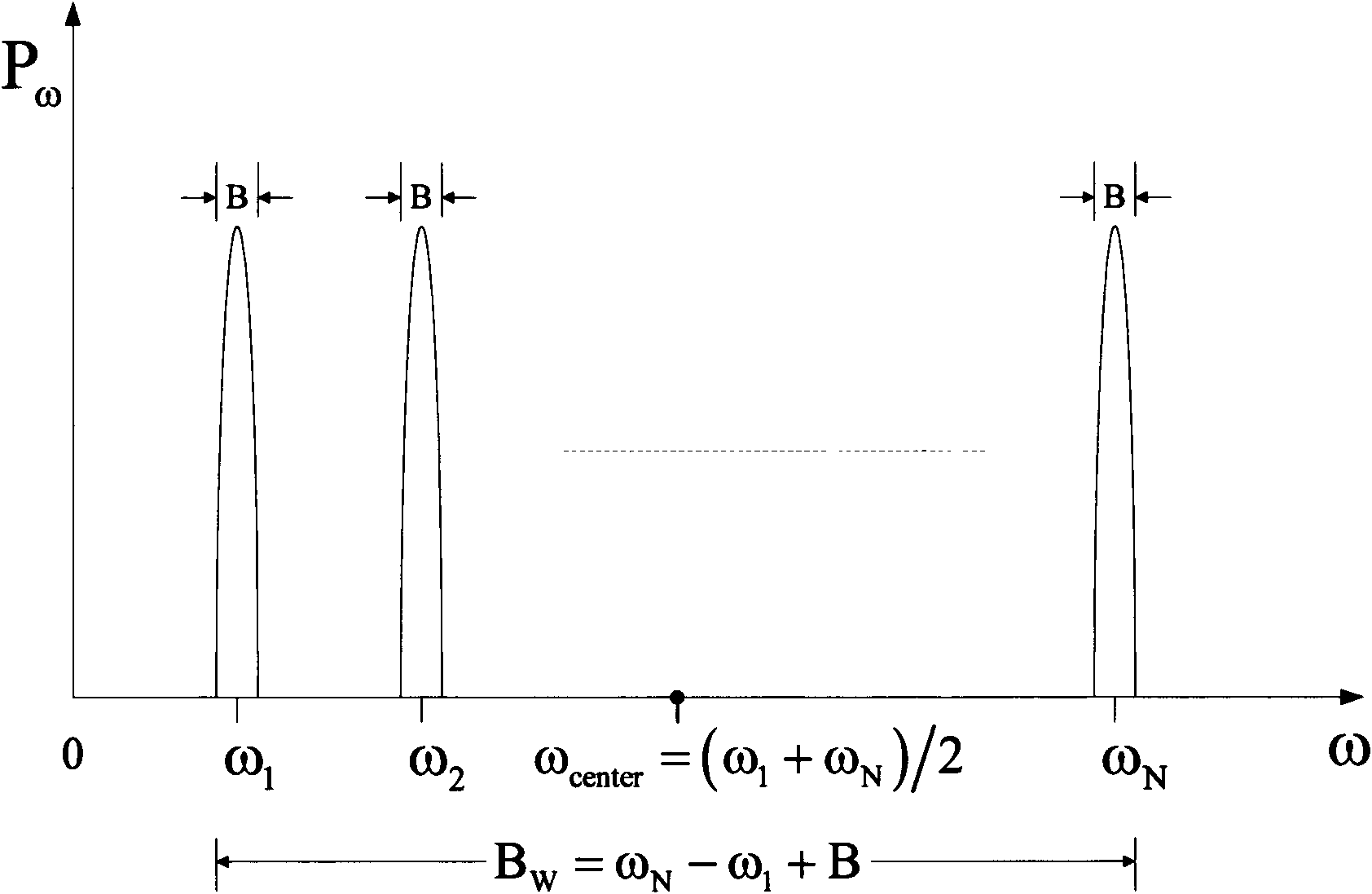

Table-lookup self-adapting peak-clipping method

ActiveCN101662450ASuitable for programmingImprove performanceMulti-frequency code systemsCommunications systemCarrier signal

The invention discloses a table-lookup self-adapting peak-clipping method. In the peak-clipping process of a frequency-hopping communication system, the coefficient of a filter is adjusted in time ina self-adapting way, and a peak-clipping pulse is accurately constructed to carry out effective peak-clipping processing on an input signal. The method comprises two steps: in a preliminary step, dividing the total bandwidth difference of the system into a plurality of bandwidth area sections, constructing a corresponding filter for any one bandwidth area section, obtaining the coefficient of thefilter and storing a data table characterizing a one-to-one correspondence relationship between all the bandwidth area sections and the coefficient of the corresponding filter; in the peak-clipping step, working out the corresponding element of a corresponding index sequence according to the signal bandwidth of the current time when changing the bandwidth of the system, and then further determining the coefficient of the corresponding filter according to the element. The invention can search a prestored data table according to the carrier wave frequency point change of the system, obtain the coefficient of the filter with proper matching with a current signal and adjust the filter used for constructing the peak-clipping pulse in the self-adapting way, thereby lowering the complexity degreeof the system and ensuring that the peak-clipping effect is better.

Owner:COMBA TELECOM SYST CHINA LTD

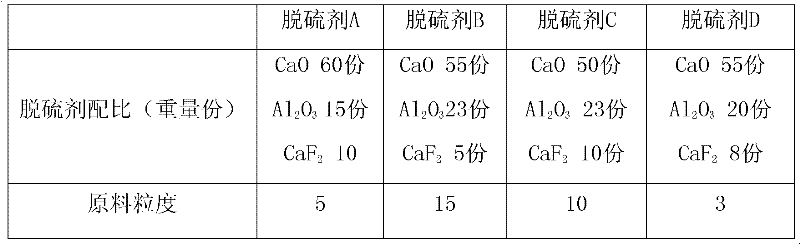

RH vacuum treatment desulfurizing agent used for non-oriented electrical steel, preparation method thereof, and desulfurizing method using same

InactiveCN102199687AGuaranteed electromagnetic performanceReduce iron lossElectrical steelRefractory

The invention relates to an RH vacuum treatment desulfurizing agent used for non-oriented electrical steel, a preparation method thereof, and a desulfurizing method using the same, belonging to the field of secondary refining of molten steel, so as to solve the problems that the RH vacuum treatment desulfurizing processes used for electrical steel in the prior art have serious erosion on refractory materials, high cost, slow melting speed and carburization risk to molten steel. The RH vacuum treatment desulfurizing agent used for non-oriented electrical steel is mainly composed of the following components: 50-60 weight parts of CaO, 10-25 weight parts of Al2O3 and 5-10 weight parts of CaF2. The invention also provides the preparation method of the RH vacuum treatment desulfurizing agent used for the non-oriented electrical steel, and the desulfurizing method using the RH vacuum treatment desulfurizing agent used for the non-oriented electrical steel. The RH vacuum treatment desulfurizing agent provided by the invention is mainly used for the RH vacuum treatment desulfurizing treatment of the non-oriented electrical steel.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +2

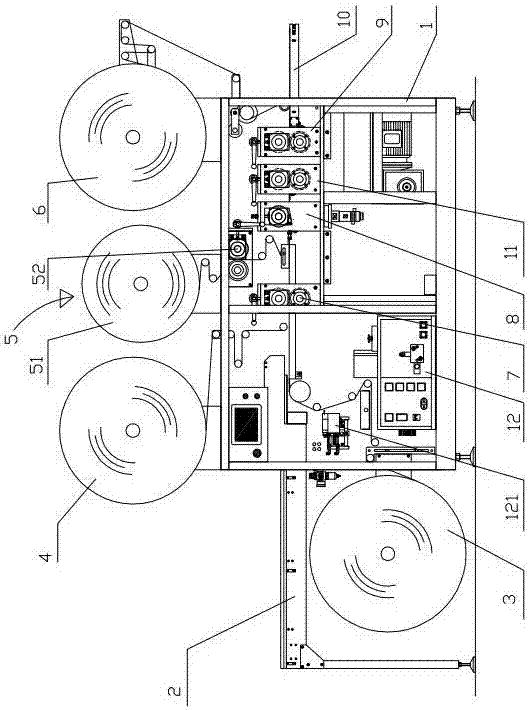

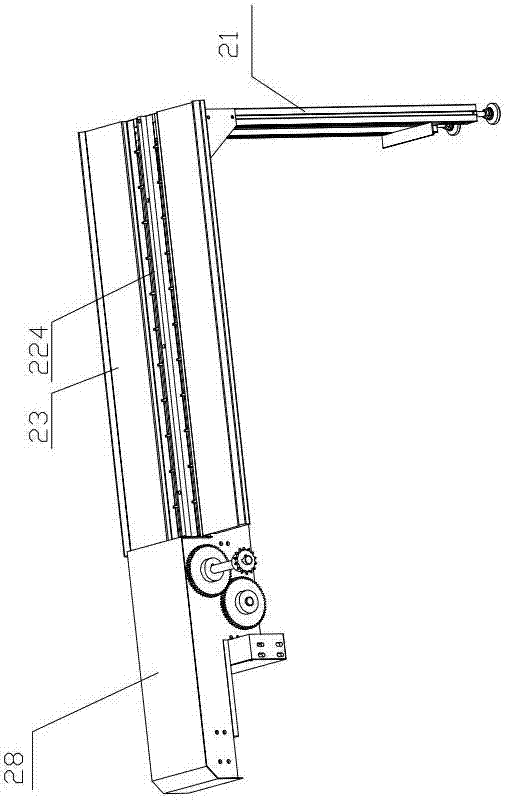

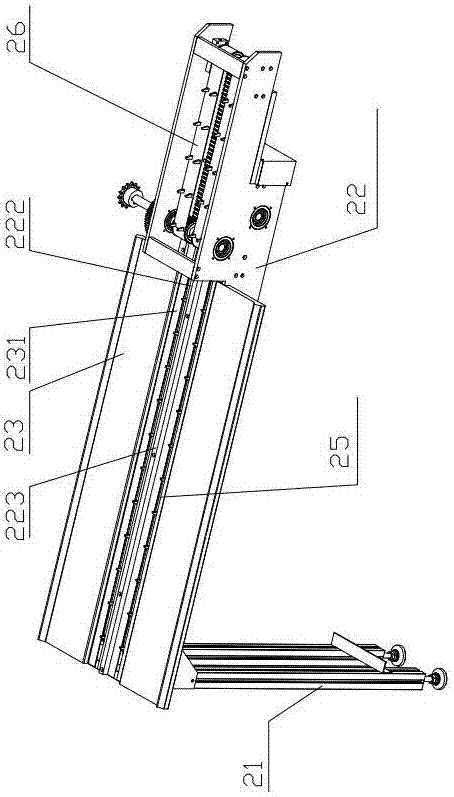

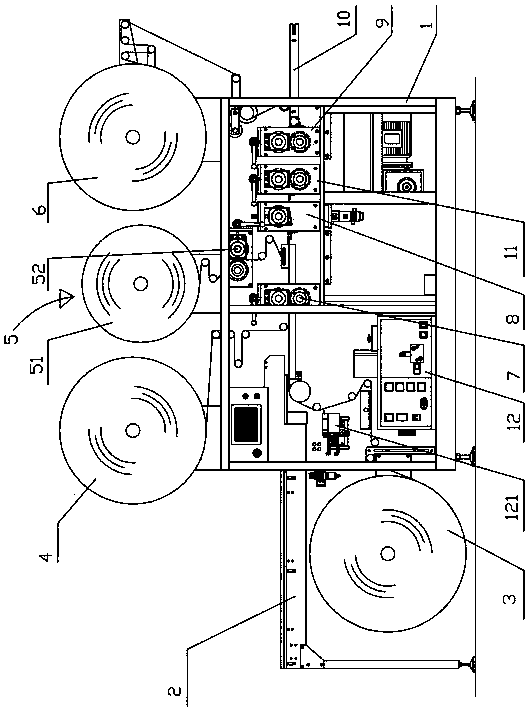

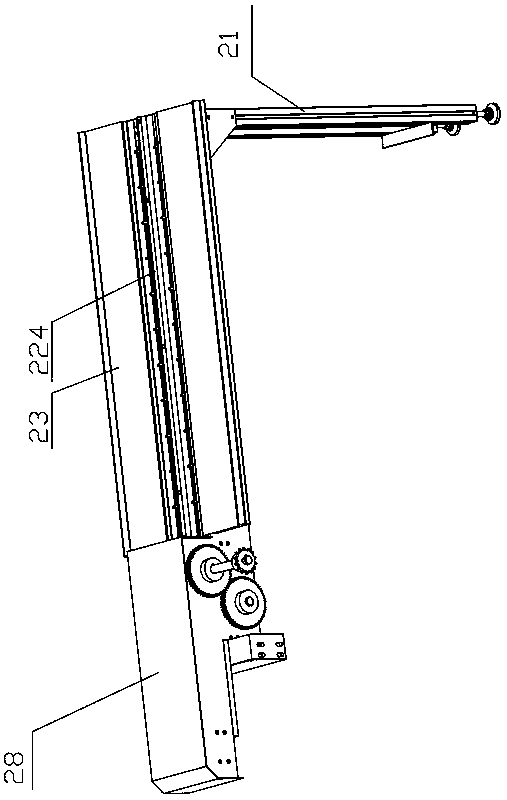

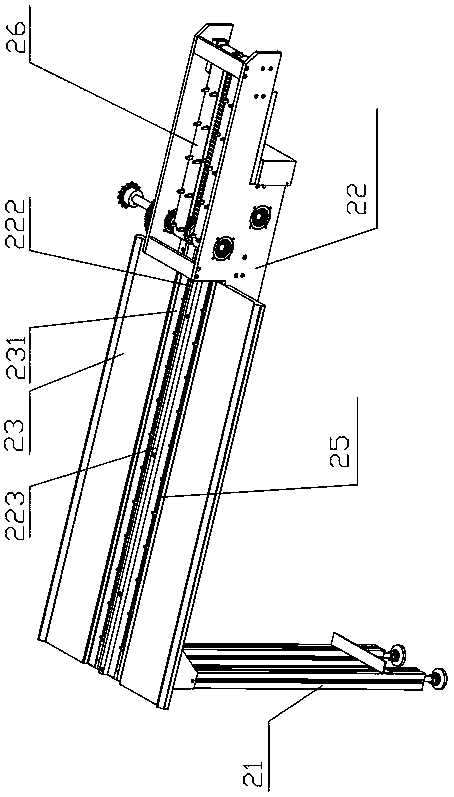

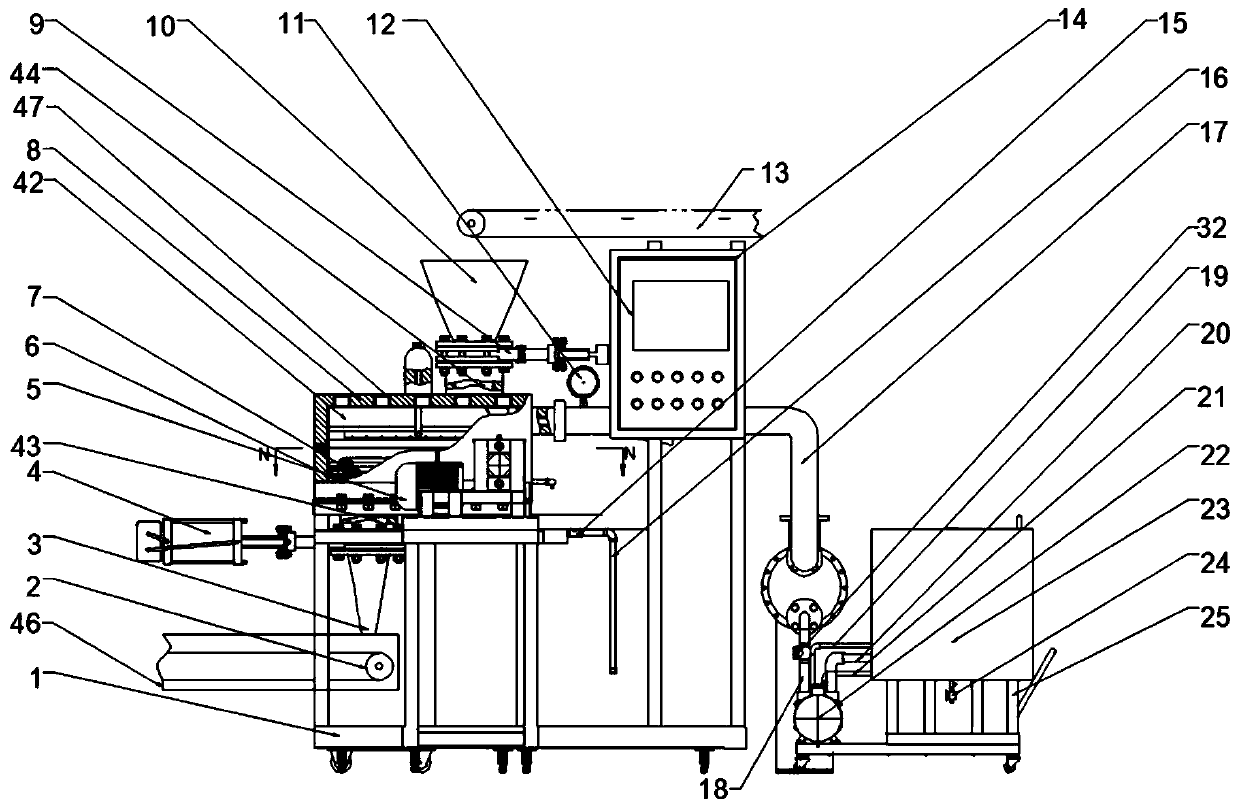

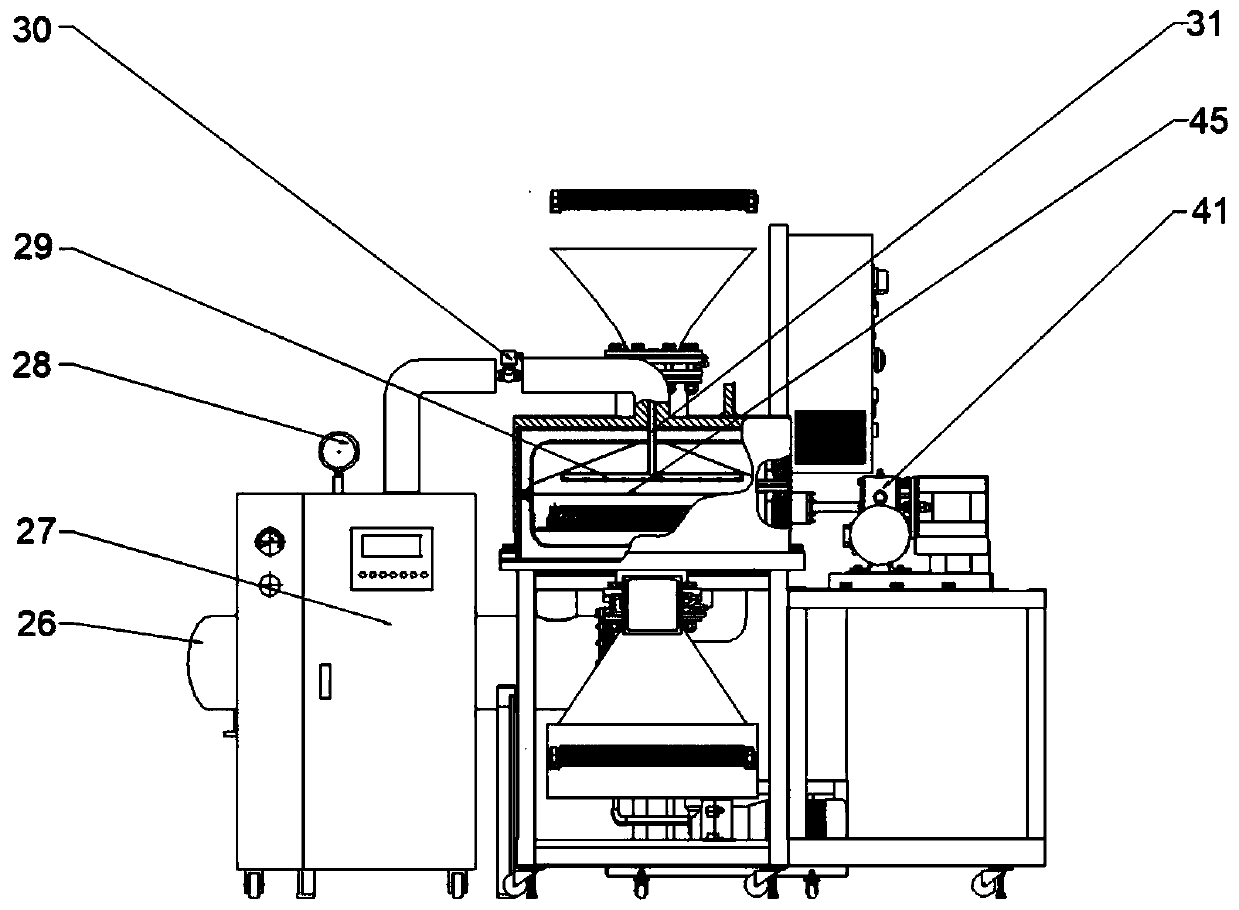

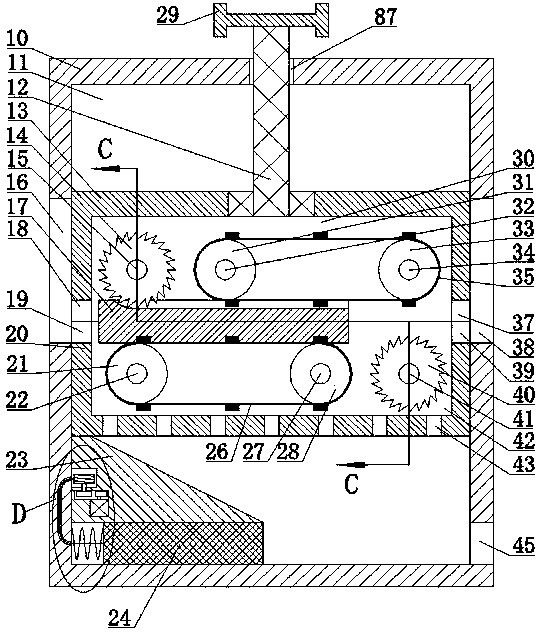

Steam eye mask packaging machine

The invention relates to a steam eye mask packaging machine. Problems that the existing eye mask machining process is low in production efficiency and poor in reliability and cannot carry out continuous machining are solved. The steam eye mask packaging machine comprises a frame, the frame is provided with a synchronous feeding device, a bottom film feeding device, an upper film feeding device, an ear hanging film forming device, a waste material gathering device, a sealing device, an ultrasonic bonding welding device, a finished product rolling cut device and a finished product conveyer belt. The upper film feeding device is arranged above the synchronous feeding device the discharging opening of the synchronous feeding device is arranged above the bottom film feeding device, and materials of the bottom film feeding device and the upper film feeding device sequentially pass through the sealing device, the ultrasonic bonding welding device and the finished product rolling cut device, and then are arranged on the finished product conveyer belt. The steam eye mask packaging machine is characterized by being simple in structure, convenient to maintain, small in occupied area, simple and convenient to control, long in service life and the like.

Owner:WENZHOU JIACHENG MACHINERY

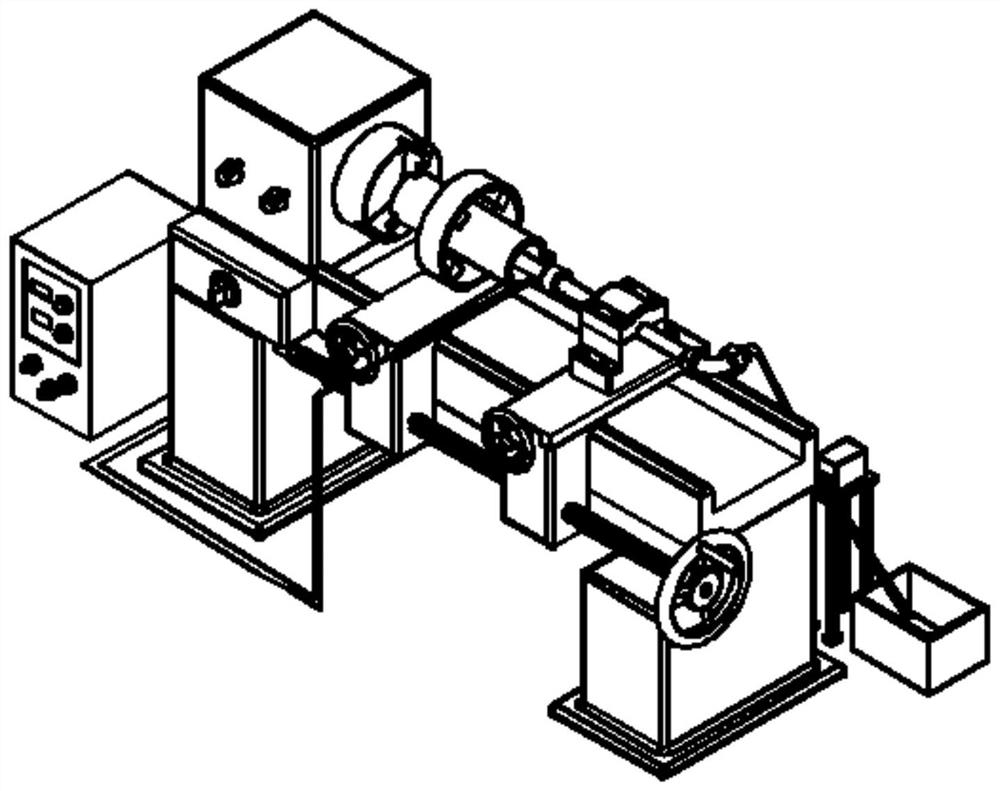

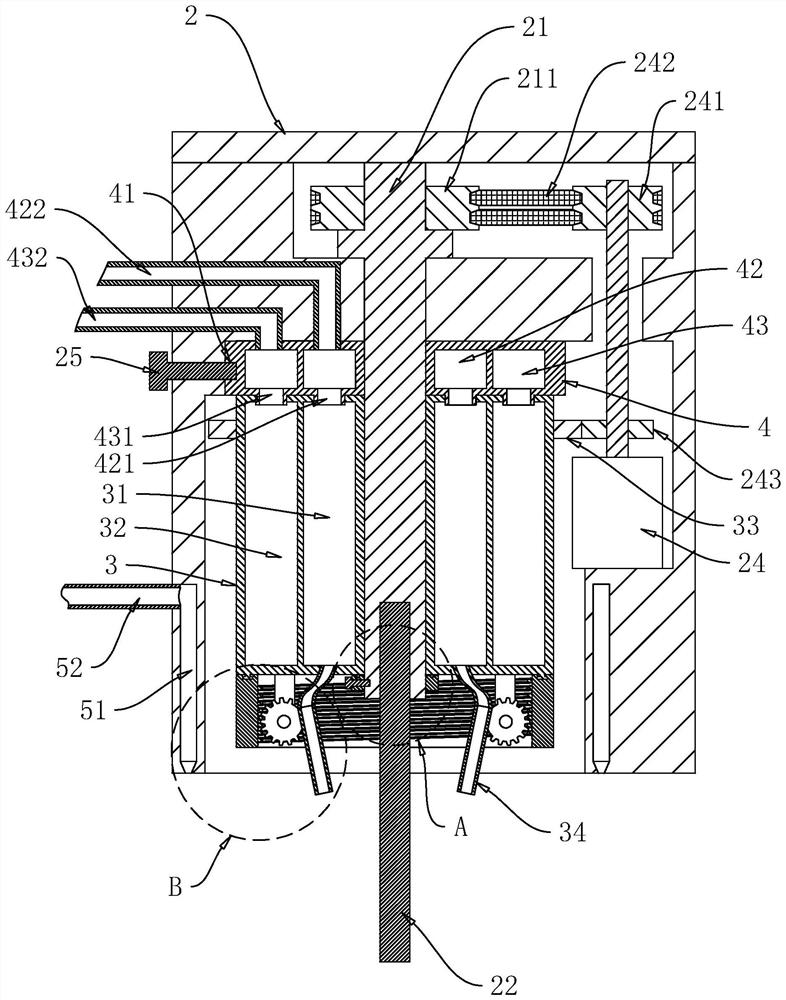

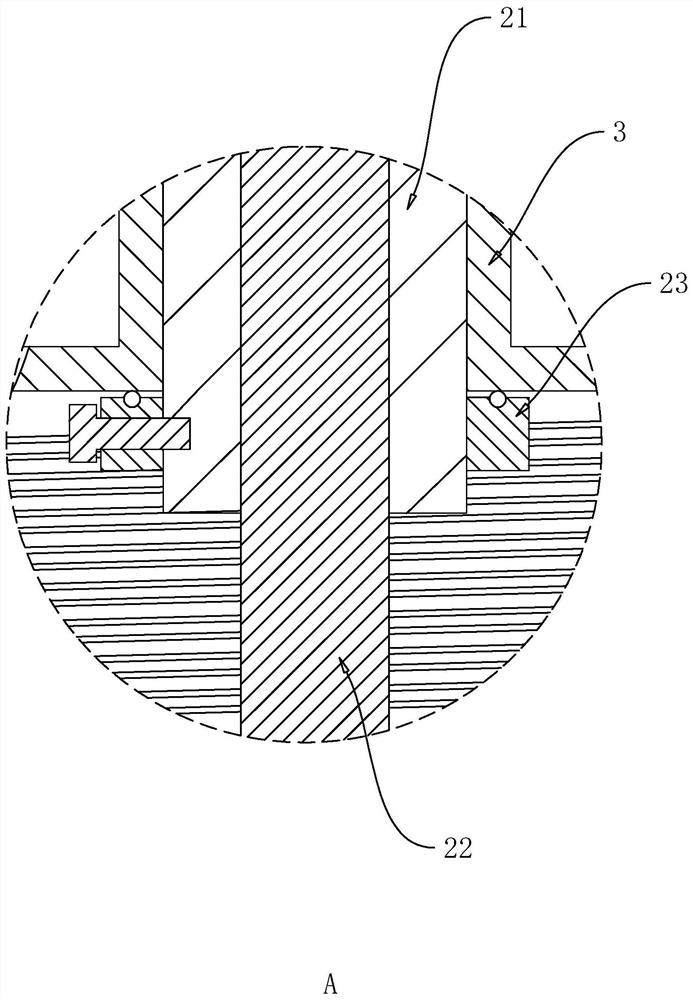

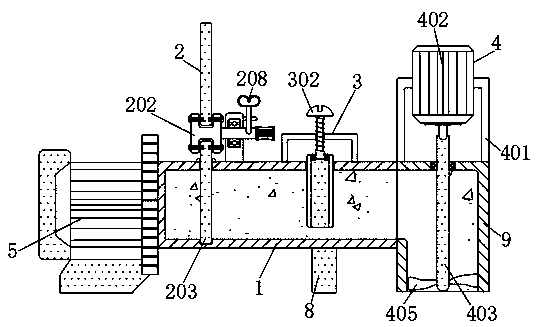

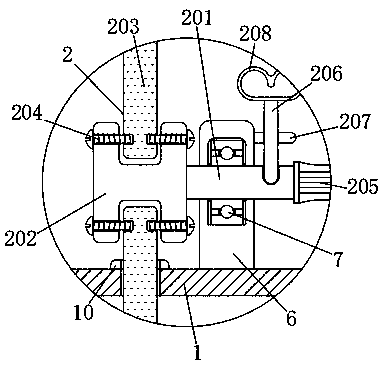

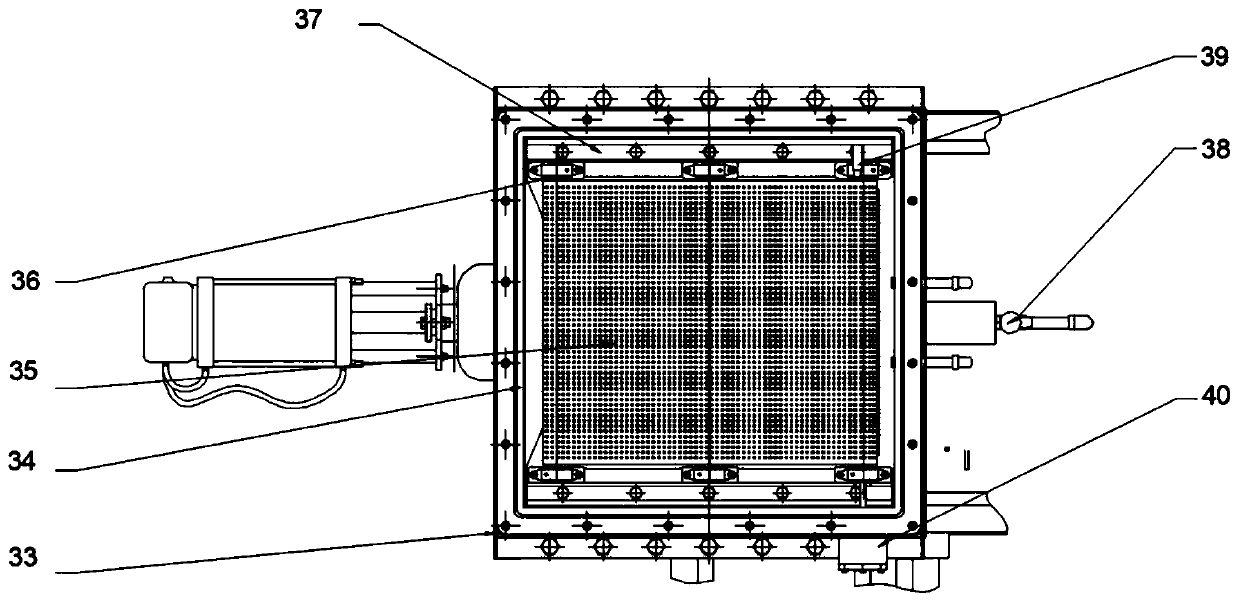

Electromagnet composite electrolysis type polishing device for inner wall of non-magnetic-conductive metal pipe and process

PendingCN112123031AReduce hardnessGuaranteed continuous processingEdge grinding machinesPolishing machinesElectrolytic agentPolishing

The invention aims to provide an electromagnet composite electrolysis type polishing device for the inner wall of a non-magnetic-conductive metal pipe and a process. The electromagnet composite electrolysis type polishing device comprises a machine tool, an electromagnet grinding device and an electrolytic polishing device, an electromagnet on the electromagnet grinding device sleeves a workpieceand can be driven by a first sliding table on the machine tool to move in the axial direction of the workpiece, electrolyte in the electrolytic polishing device is fed into the workpiece through a hollow copper pipe, and the hollow copper pipe can be driven by a second sliding table on the machine tool to move in the axial direction of the workpiece. The invention discloses an electromagnet composite electrolysis type polishing method for the inner wall of the non-magnetic-conductive metal pipe, the inner surface of the non-magnetic-conductive metal pipe can be subjected to finishing machining, the surface polishing quality of the workpiece can be improved, the service life of the workpiece can be prolonged, moreover, under the electrolysis condition, the grinding speed can be effectivelyincreased, and the working efficiency can be greatly improved.

Owner:UNIV OF SCI & TECH LIAONING

Steam Eye Mask Packaging Machine

The invention relates to a steam eye mask packaging machine. Problems that the existing eye mask machining process is low in production efficiency and poor in reliability and cannot carry out continuous machining are solved. The steam eye mask packaging machine comprises a frame, the frame is provided with a synchronous feeding device, a bottom film feeding device, an upper film feeding device, an ear hanging film forming device, a waste material gathering device, a sealing device, an ultrasonic bonding welding device, a finished product rolling cut device and a finished product conveyer belt. The upper film feeding device is arranged above the synchronous feeding device the discharging opening of the synchronous feeding device is arranged above the bottom film feeding device, and materials of the bottom film feeding device and the upper film feeding device sequentially pass through the sealing device, the ultrasonic bonding welding device and the finished product rolling cut device, and then are arranged on the finished product conveyer belt. The steam eye mask packaging machine is characterized by being simple in structure, convenient to maintain, small in occupied area, simple and convenient to control, long in service life and the like.

Owner:WENZHOU JIACHENG MACHINERY

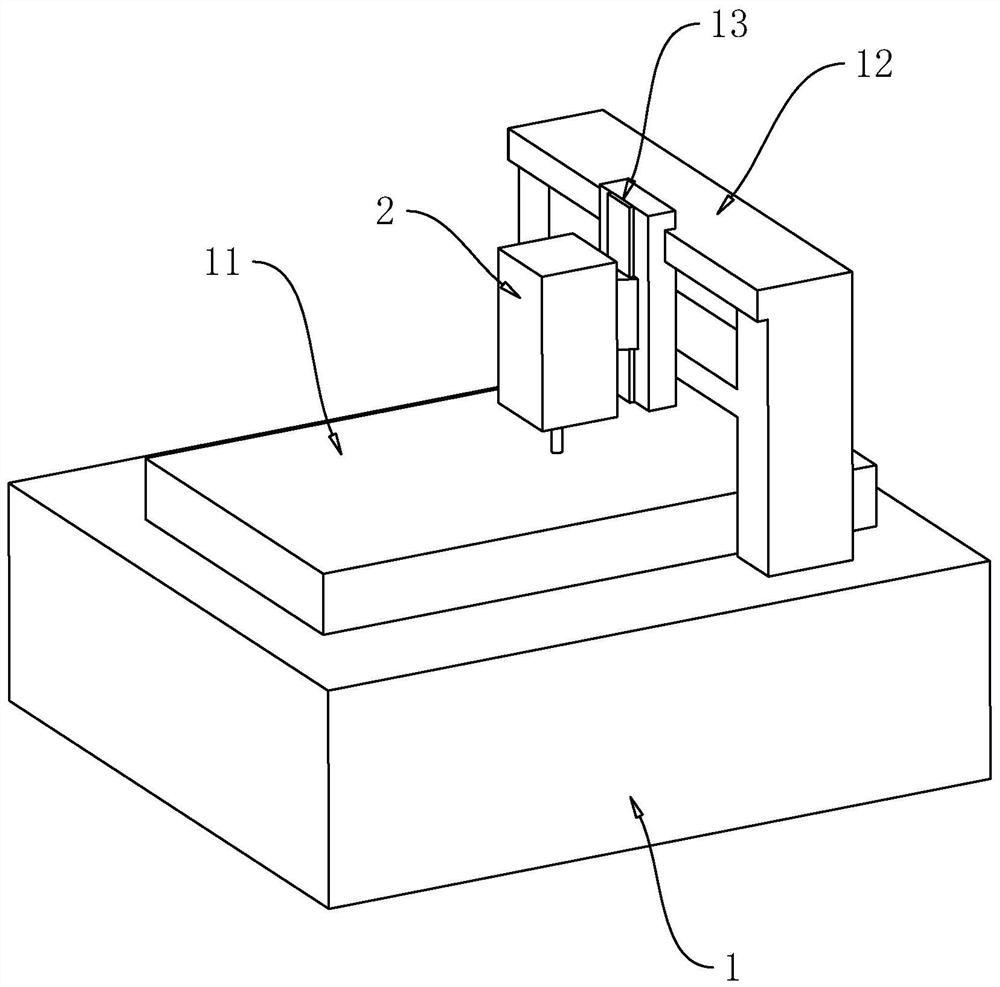

Numerical control engraving and milling machine

PendingCN112720052ACool evenlyGuaranteed continuous processingMaintainance and safety accessoriesNumerical controlTool bit

The invention relates to the field of numerical control machine tools, in particular to a numerical control engraving and milling machine. The numerical control engraving and milling machine comprises a spindle box, a vertically-arranged spindle is rotationally connected into the spindle box, a cutter is installed at the lower end of the spindle, a ring sleeve sleeving on the outer side of the spindle and rotationally connected to the spindle is arranged in the spindle box, liquid outlet cavities surrounding the spindle are formed in the ring sleeve, the spindle box is provided with a driving mechanism capable of driving the spindle and the ring sleeve to rotate at different rotating speeds, a plurality of liquid spraying pipes with nozzles facing the cutter are arranged on the lower side of the ring sleeve around the main shaft, and a liquid feeding pipes are connected between the liquid outlet cavities of the ring sleeve and the liquid spraying pipes. The numerical control engraving and milling machine has the advantages that the relative position of cooling liquid pipes and a tool bit is guaranteed, and the cooling effect is improved.

Owner:青岛捷美达数控机械有限公司

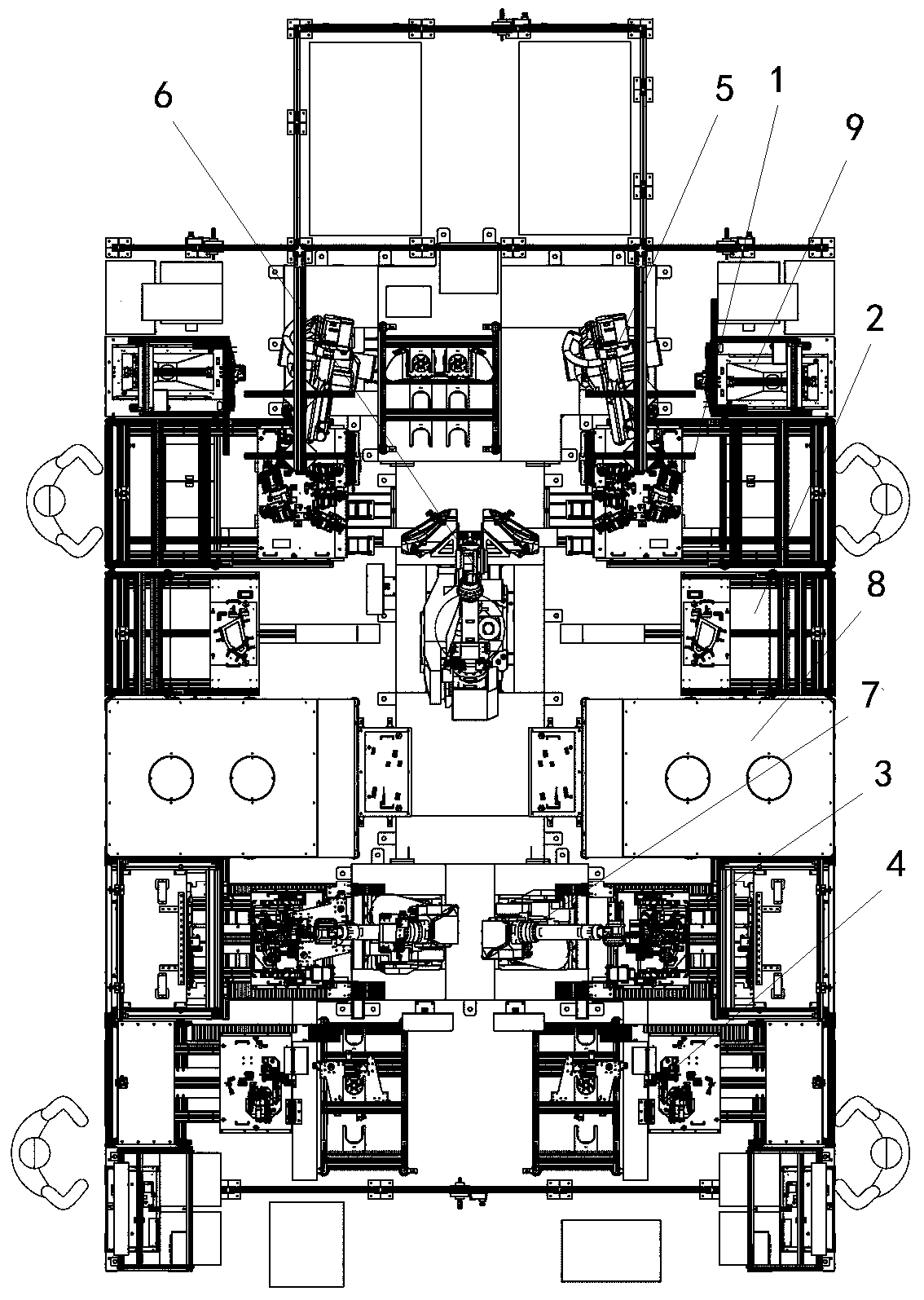

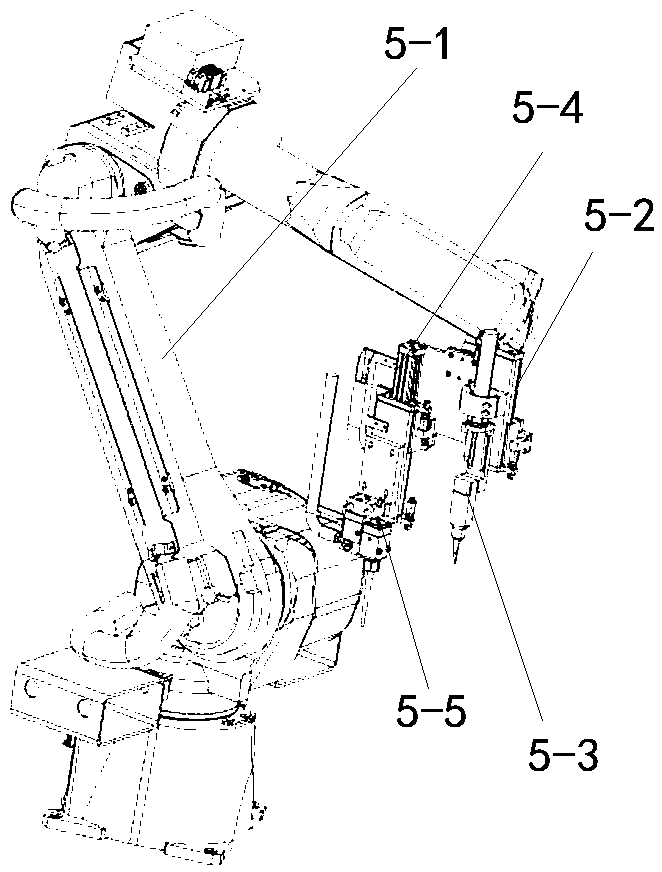

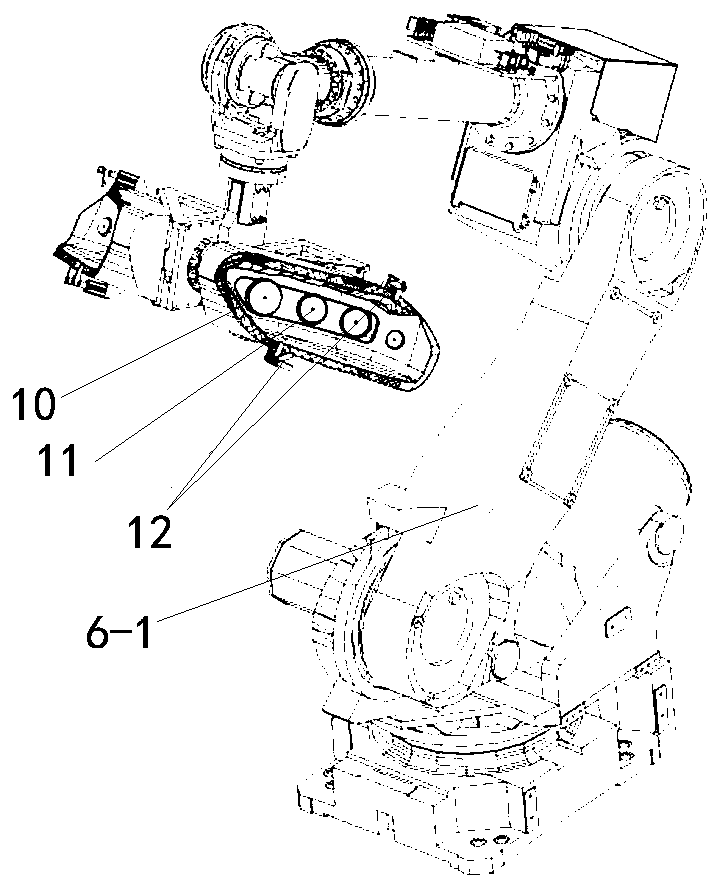

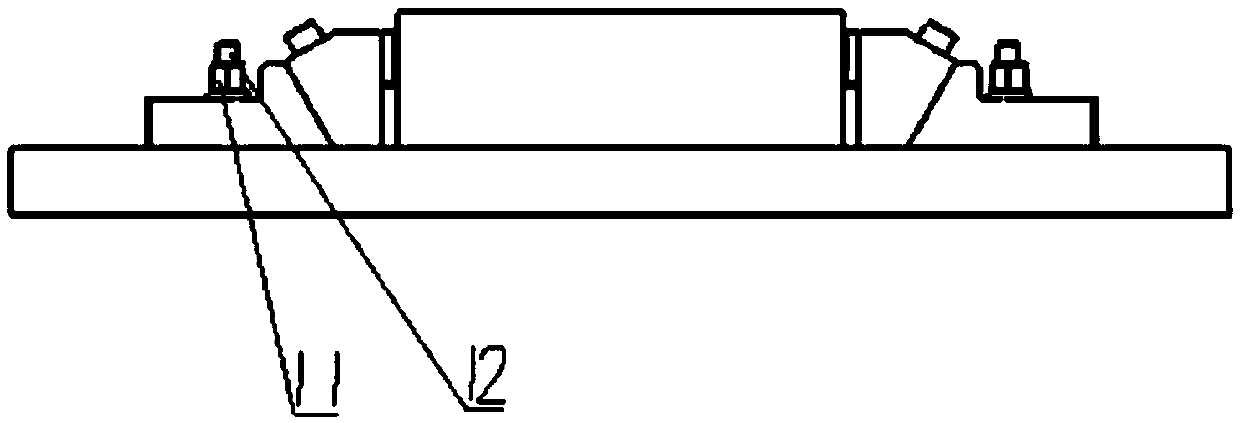

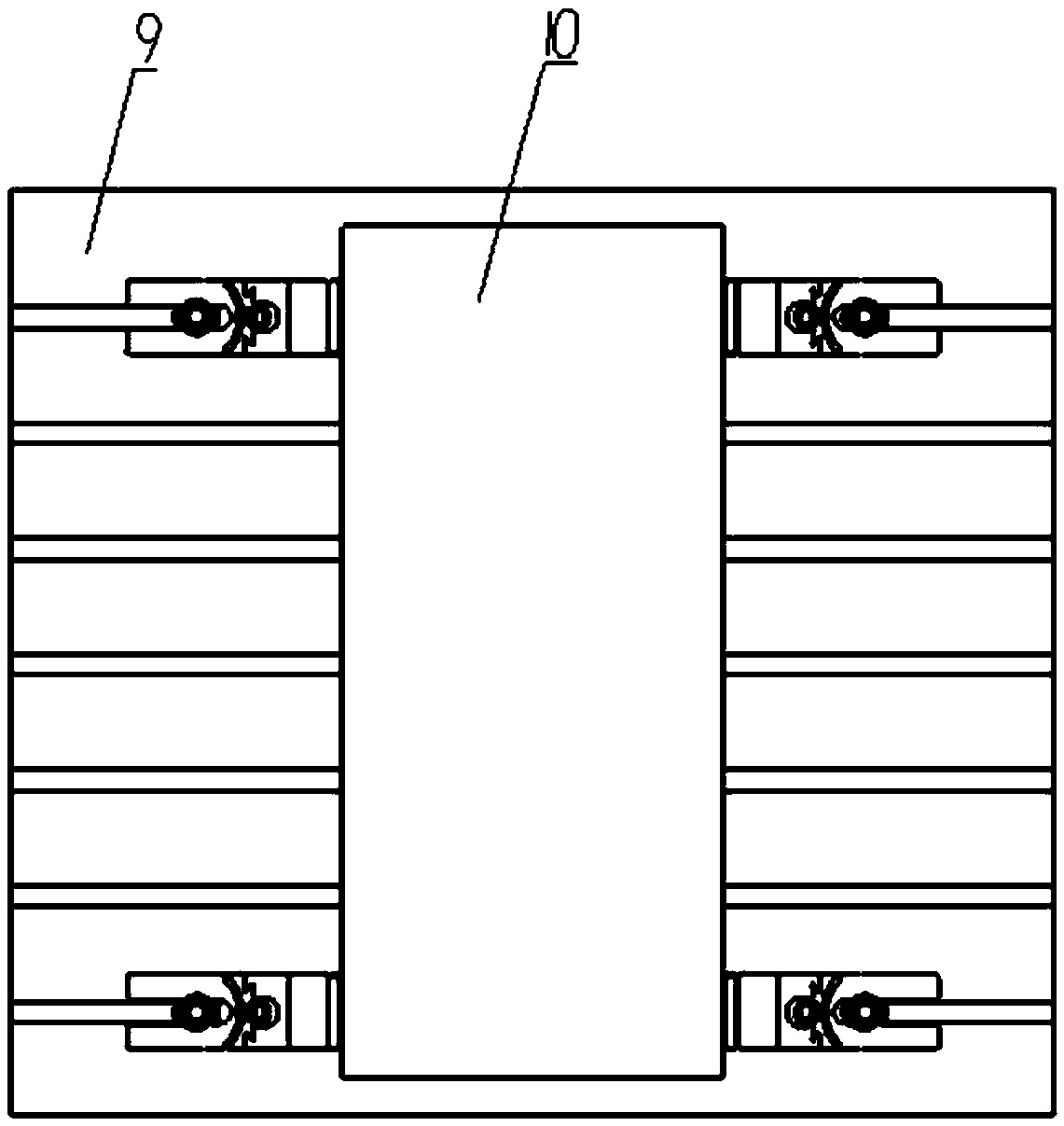

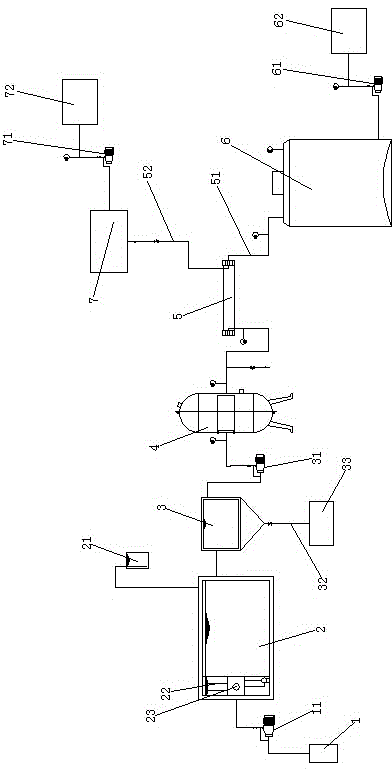

Car lamp intelligent assembly production line and production process

PendingCN108757674AGuaranteed continuous processingGuaranteed processing efficiencyMaterial gluingFluid-tightness measurementProduction lineProcessing cost

The invention relates to the technical field of car lamp processing, in particular to a car lamp intelligent assembly production line and a production process. The car lamp intelligent assembly production line can guarantee the machining efficiency and reduce the processing cost. The production line comprises a mask buckling station, a mask feeding station, a light type detection station, an airtight detection station, a gluing robot mechanism and a grabbing robot mechanism, and further comprises a glue drying station, the grabbing robot mechanism comprises a first grabbing robot mechanism anda second grabbing robot mechanism, the first grabbing robot mechanism is used for transferring a car lamp between the mask buckling station and the glue drying station, the second grabbing robot mechanism is used for enabling the car lamp to be transferred among the glue drying station, the light type detection station and the airtight detection station; the glue drying station comprises a glue-drying machine frame and at least two glue-drying tables, the glue-drying tables are provided with first car lamp locating tools, and the two sides of the glue-drying machine frame are provided with circulating conveying mechanisms respectively, and the two ends of the glue-drying tables are connected with the circulating conveying mechanisms. The invention further provides an intelligent assemblyproduction process of the car lamp.

Owner:WUXI ZHONGZHUO TECH

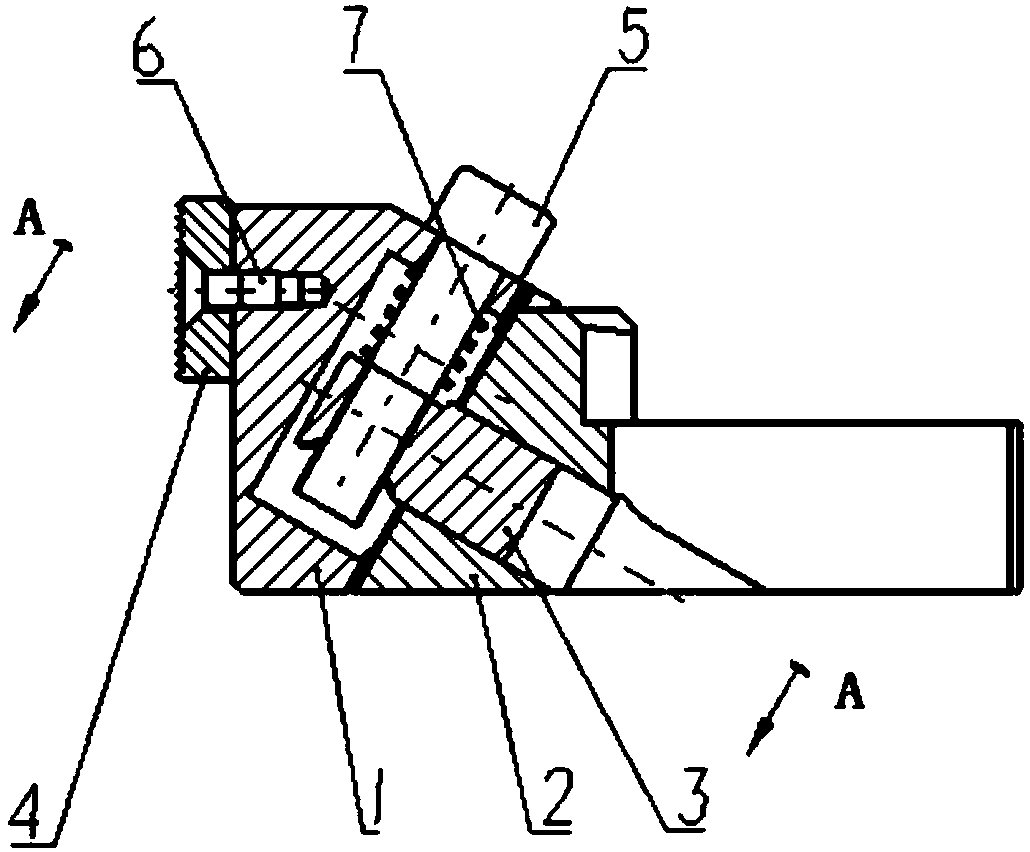

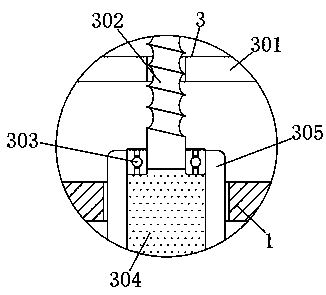

Thread self-locking lateral compressing mechanism

PendingCN109676412AAvoid dangerIncrease profitPositioning apparatusMetal-working holdersAviationSelf locking

The invention belongs to the field of machining process technological equipment of aviation and relates to a thread self-locking lateral compressing mechanism. The thread self-locking lateral compressing mechanism comprises a main body part, a T-shaped slot worktable, a nut with a shoulder and a T-shaped bolt; the main body part comprises a movable pressure head, a fixed body, a self-locking nut,a tooth-shaped pressure plate, a compressing screw, a sunk screw, a spiral compression spring and a cylindrical pin. The fixed body is provided with a U-shaped groove and is connected to the T-shapedslot worktable through the nut with the shoulder and the T-shaped bolt; a 60-degree dovetailed guide rail is arranged on the guide surface of the fixed body; a 60-degree dovetail groove is formed in the guide surface of the movable pressure head; the compressing screw and the self-locking nut are in threaded fit to form a thread self-locking mechanism; the spiral compression spring is arranged onthe compressing screw in a sleeving manner; the tooth-shaped pressure plate is arranged on the other side of the movable pressure head, is positioned through two cylindrical pins and is connected through one sunk screw. The thread self-locking lateral compressing mechanism compresses in two directions, so that the thread self-locking lateral compressing mechanism clamps reliably. The processing face is opened fully to achieve continuous processing, so that the utilization ratio of a machine tool is improved.

Owner:SHENYANG AIRCRAFT CORP

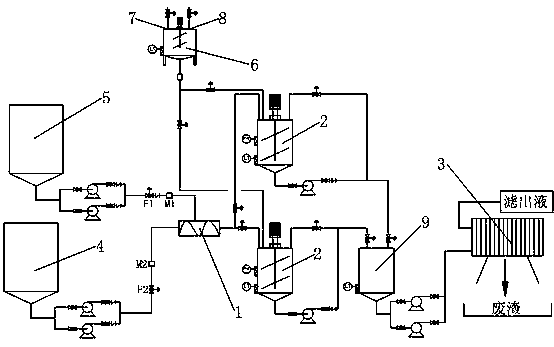

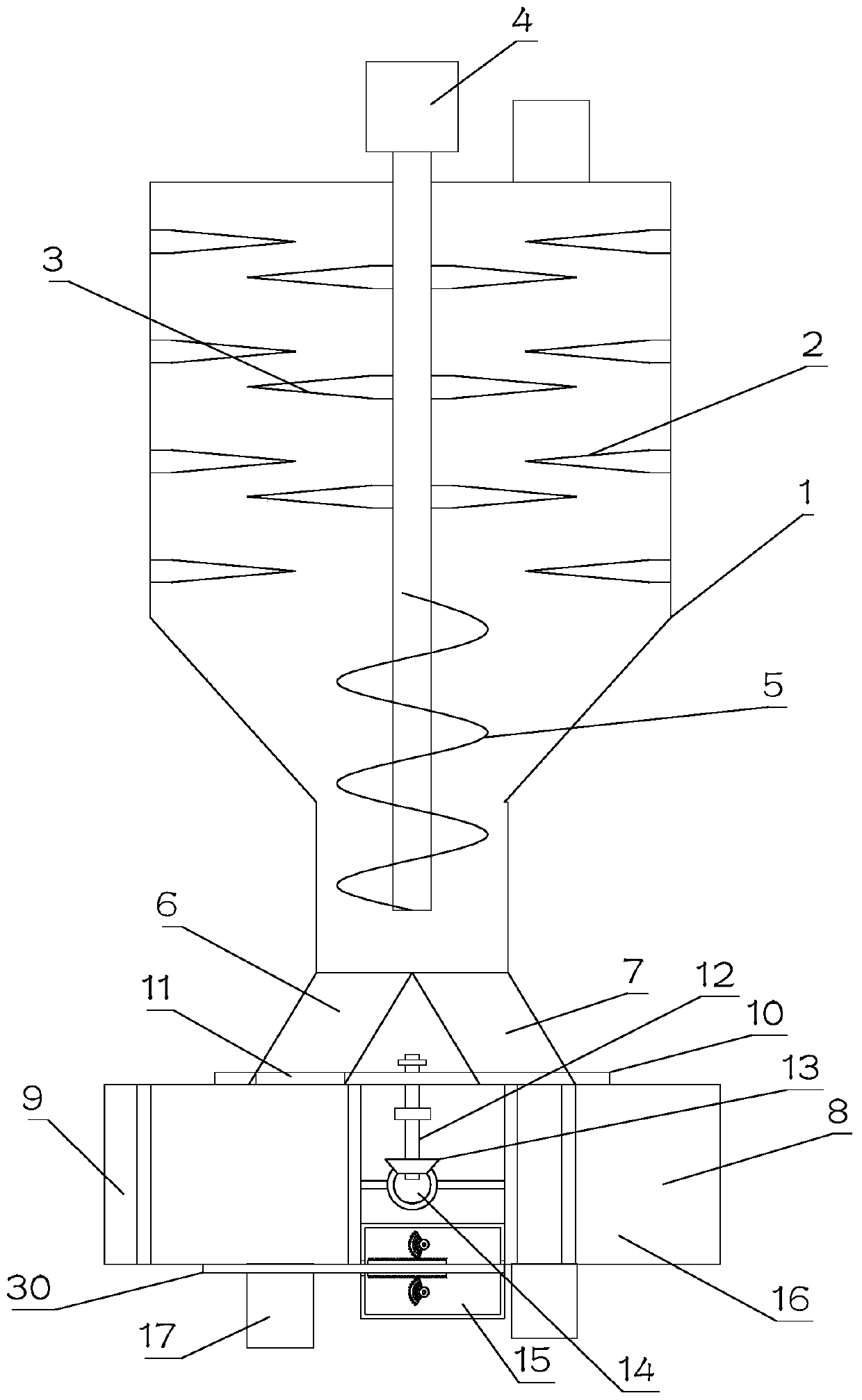

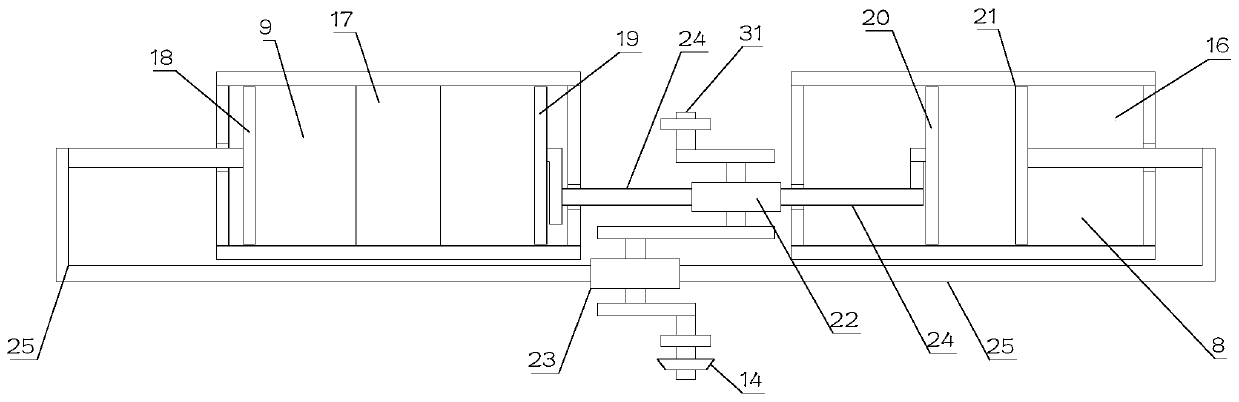

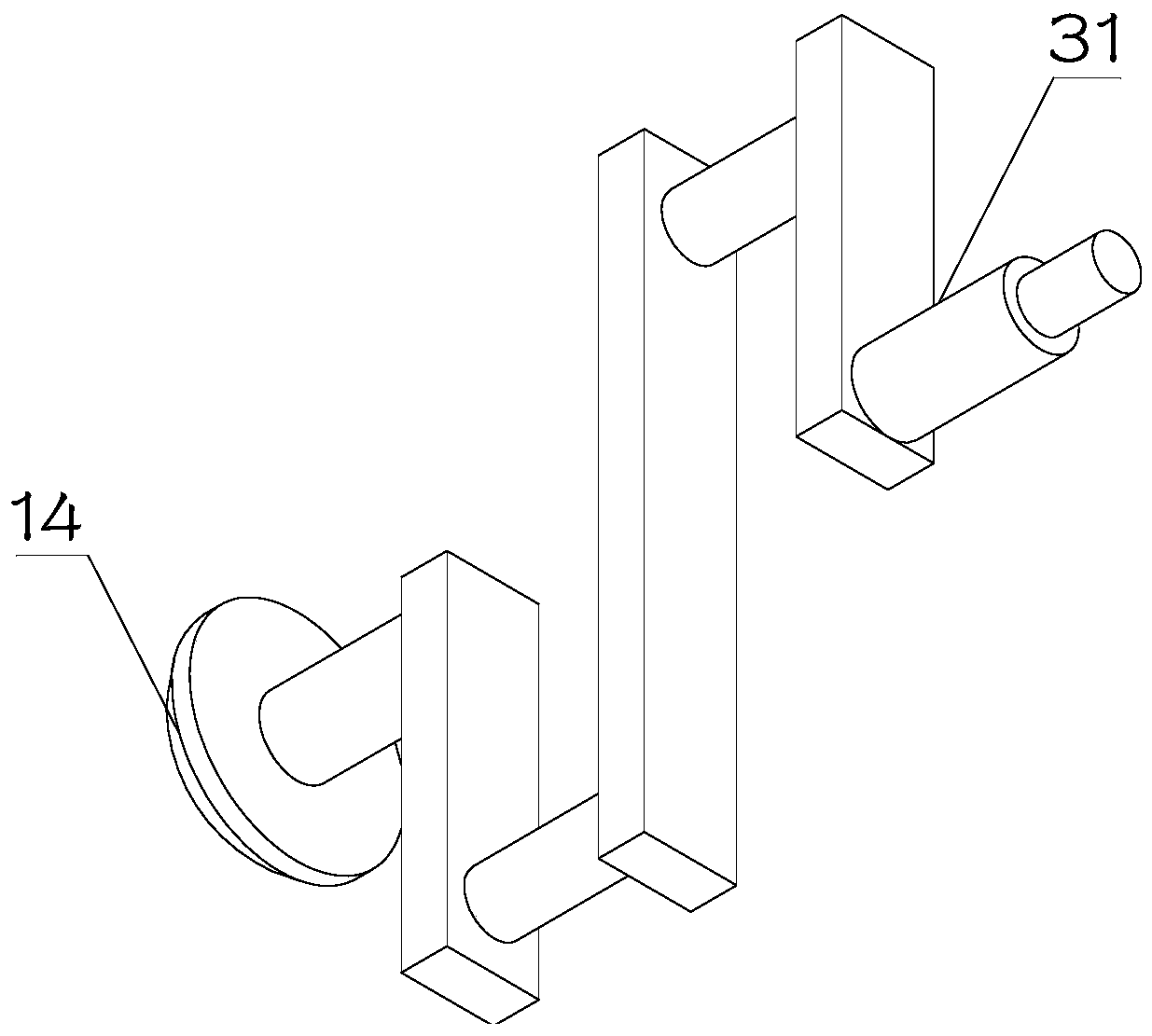

Electroplating effluent recycling device and processing method thereof

ActiveCN104692563AGuaranteed continuous processingSimple structureWaste water treatment from metallurgical processMultistage water/sewage treatmentFlocculationReverse osmosis

The invention discloses an electroplating effluent recycling device. The electroplating effluent recycling device comprises an effluent storage pond connected with a flocculation pond through a self-priming pump and a pipeline, the flocculation pond is connected with a settling pond through a pipeline, the settling pond is connected with a silica sand filter through a raw water lift pump and a pipeline, the silica sand filter is connected with a reverse osmosis membrane processing device through a pipeline, and the reverse osmosis membrane processing device is connected with a purified water tank through a purified water pipe and further connected with a concentrated water tank through a concentrated water pipe. A flocculant adding machine is arranged on the flocculation pond, and a sediment conveying pipe is arranged at the lower portion of the settling pond. The electroplating effluent recycling device is simple in structure, convenient to connect and low in input cost. According to an electroplating effluent recycling method, the electroplating effluent is flocculated through the flocculation pond, deposited through the settling pond and filtered through the silica sand filter to be processed through the reverse osmosis membrane processing device, purified water and concentrated water are obtained, the concentrated water is recycled, the purified water is collected and recycled, the recycling rate of the electroplating effluent can reach 60 percent, and resource reutilization is achieved.

Owner:TONGJI UNIV

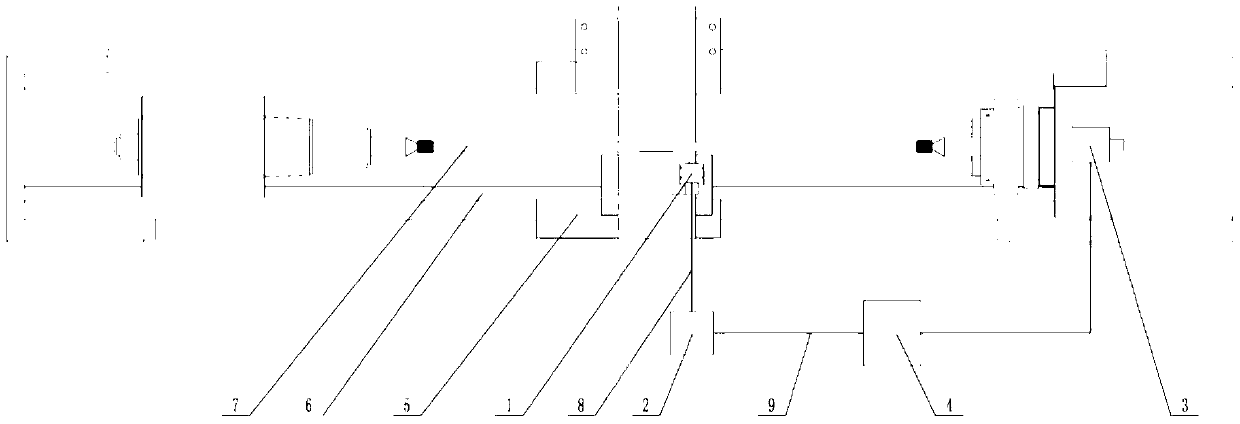

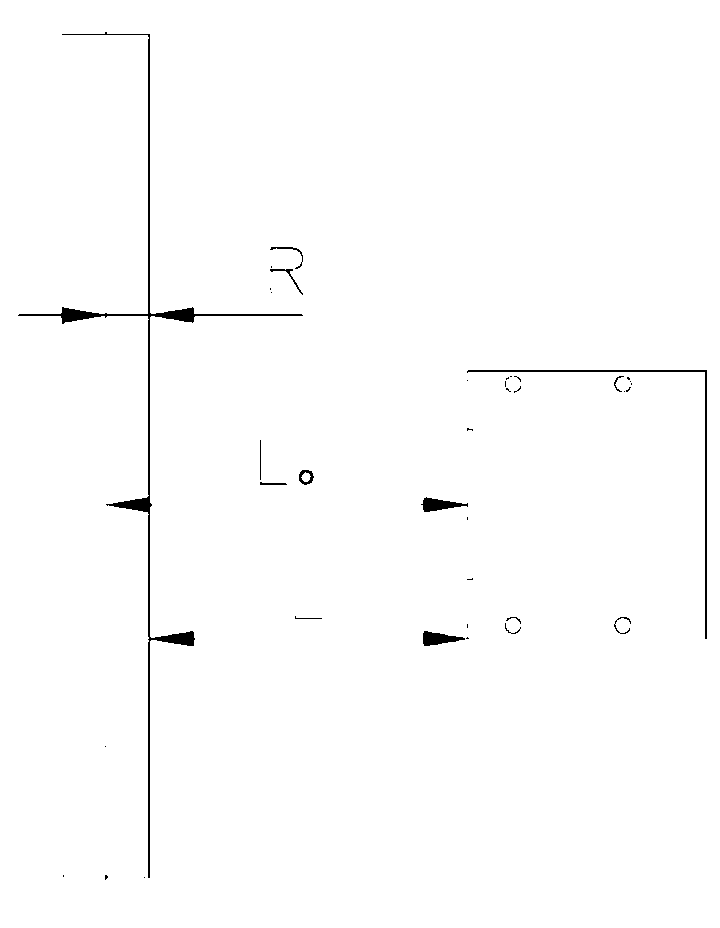

Method for measuring torsion shaft rolling characteristic parameter by using laser displacement sensor

InactiveCN103105129ASimple structureEasy to operateUsing optical meansMeasurement deviceNon contact measurement

The invention provides a method for measuring a torsion shaft rolling characteristic parameter by using a laser displacement sensor. The method is conducted on a machine tool and comprises the steps of setting a measuring device; demarcating through a testing bar, and measuring the distance L0 from the axis of the testing bar to a laser head; measuring the distance L' of points on the surface of a torsion shaft to the laser head at each moment, and using an encoder to record the corresponding angle value theta of each measuring point; through R=L0-L' obtaining the distance R of each measuring point of the torsion shaft to the axis of the torsion shaft, and then, storing each theta and corresponding R to (theta, R), and calculating the position of a tooth root of the torsion shaft according to the (theta, R). According to a measuring device established by the method, structure is simple and easy to implement, measuring method is easy to operate, and the requirement to automatic non-contacting measuring to the torsion shaft can be satisfied.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

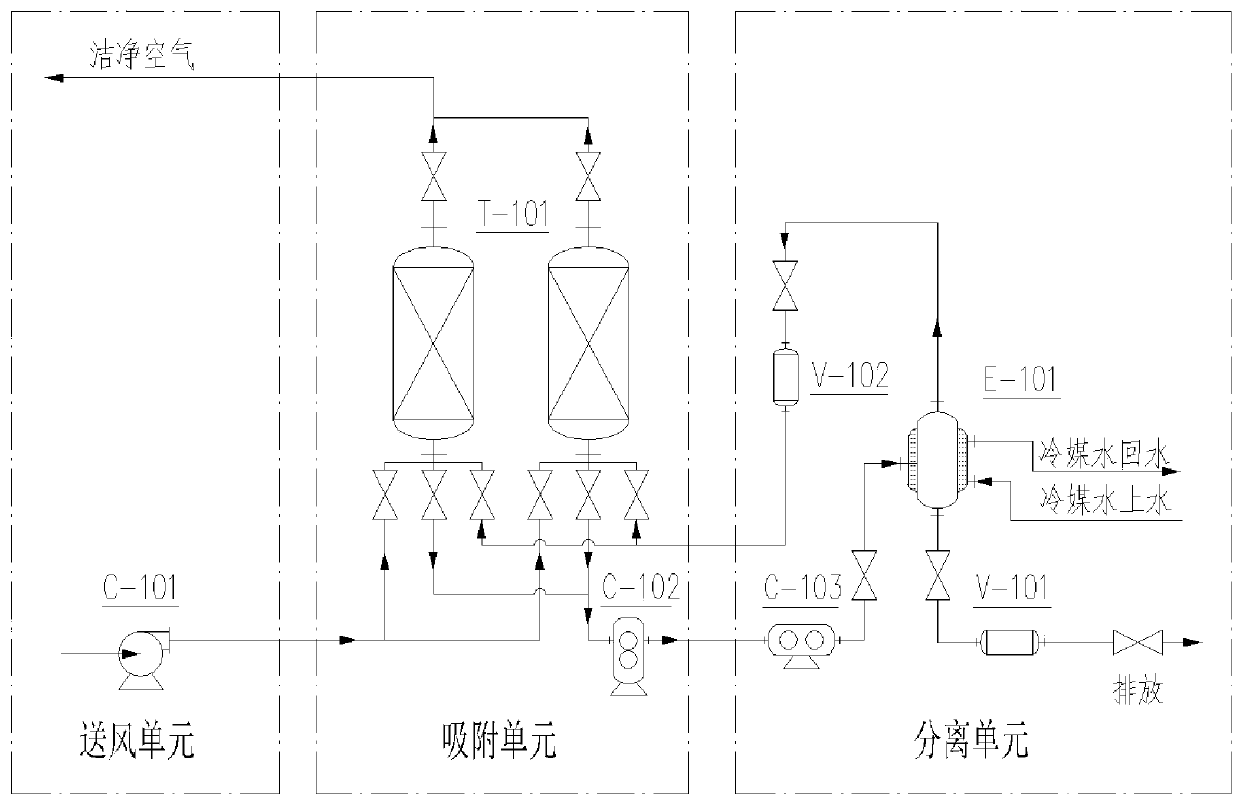

System and method for purifying carbon dioxide

PendingCN110813017AExtended service lifeAdsorption completeGas treatmentDispersed particle separationMicrowaveSeparation technology

The invention provides a system for purifying carbon dioxide. The system comprises an air supply unit, a microwave adsorption and desorption unit and a separation unit which are connected in sequence;the microwave adsorption and desorption unit combines an adsorption tower with a microwave heating device, and a waveguide tube extending into the adsorption tower is arranged on the microwave heating device, so that the regeneration efficiency of the adsorbent is greatly improved, the device size is small, and the service life of an adsorbent is long; according to the method for purifying the carbon dioxide by utilizing the device, an adsorption technology, a microwave heating regeneration technology and a condensation separation technology are combined, so that the desorption regeneration efficiency of the adsorbent is improved, the cycle operation time is shortened, the energy consumption is reduced, carbon dioxide with the volume concentration of 85% or more can be obtained, and the system and method have a relatively high practical application value.

Owner:上海穗杉实业股份有限公司

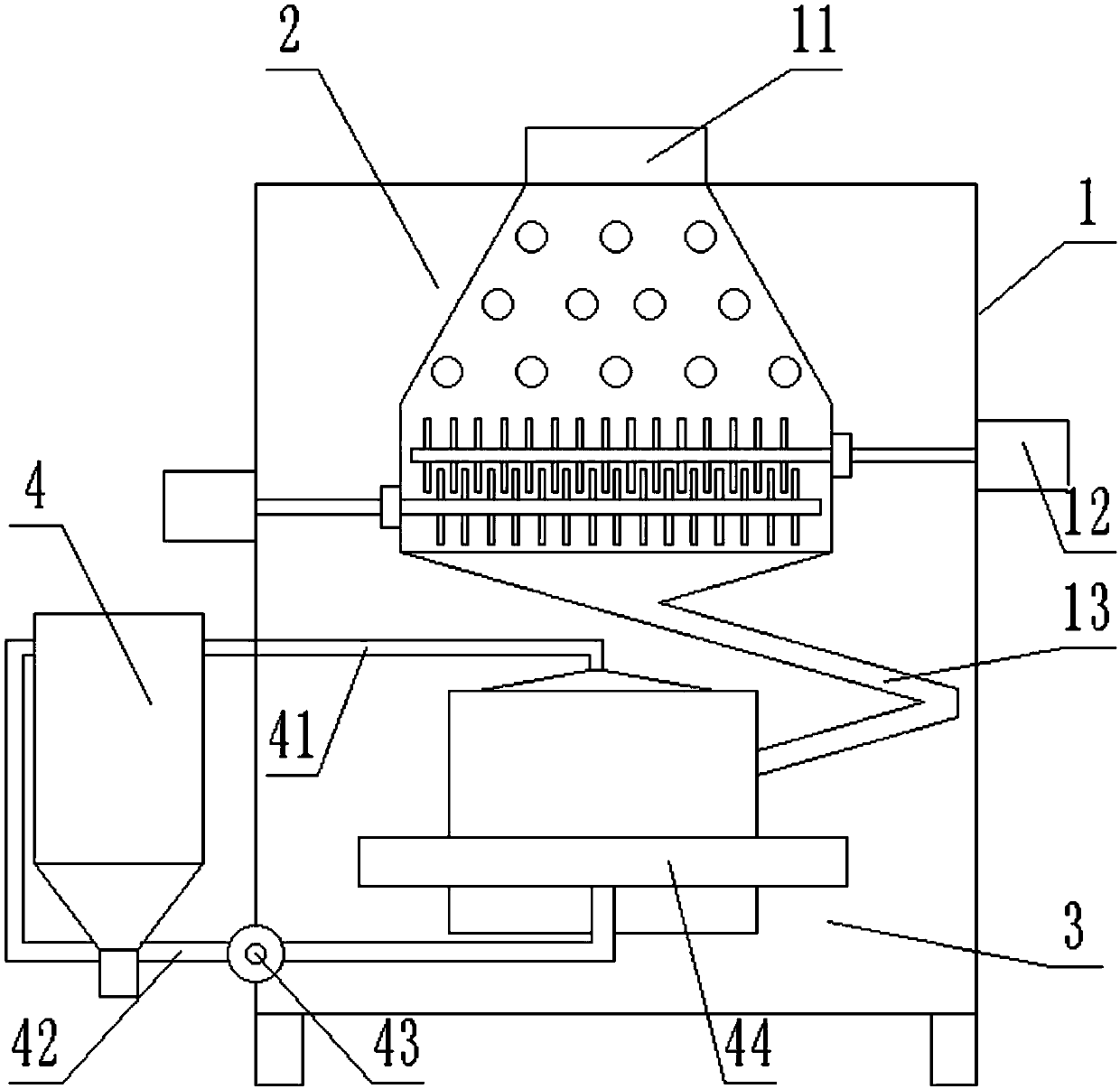

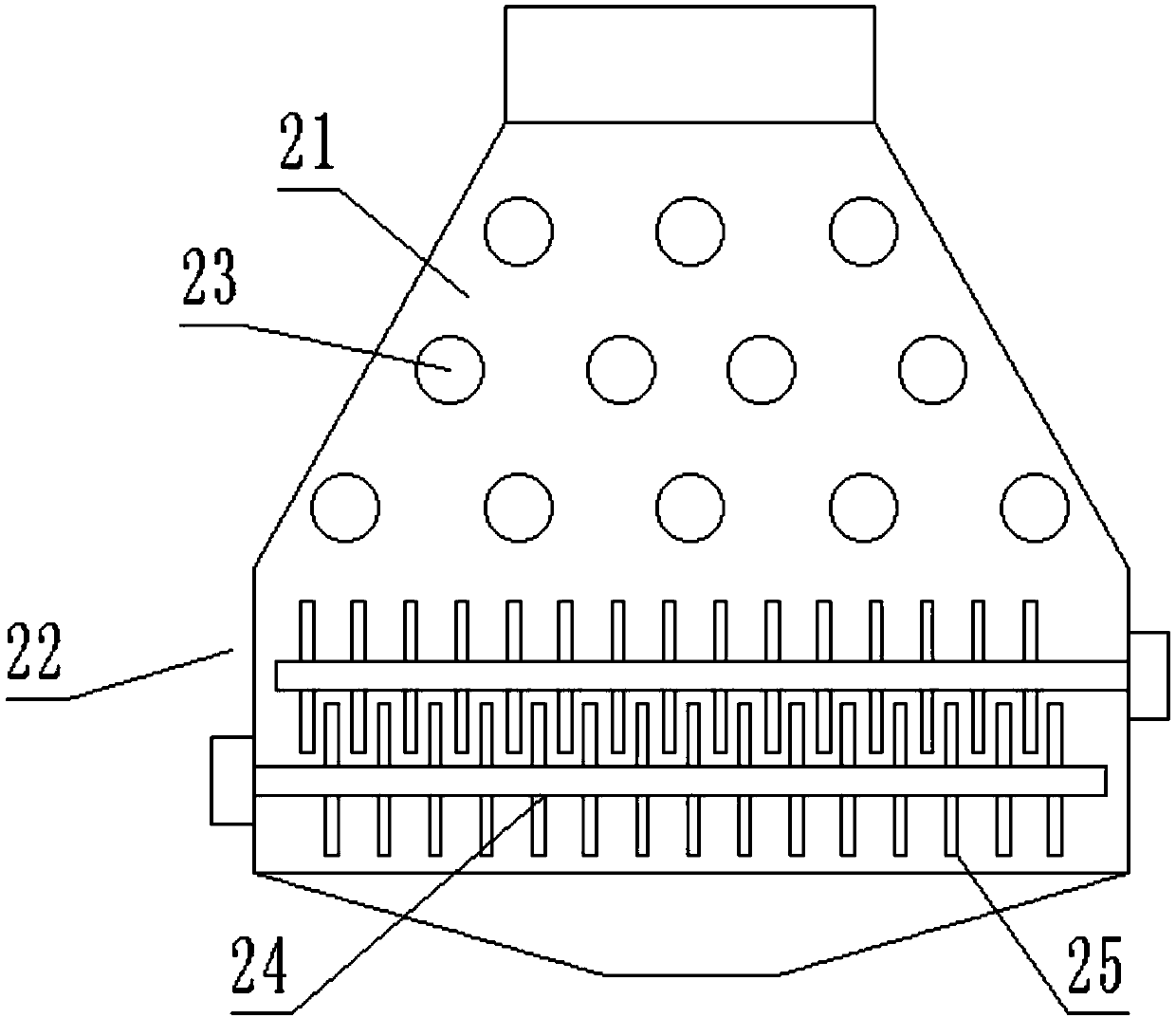

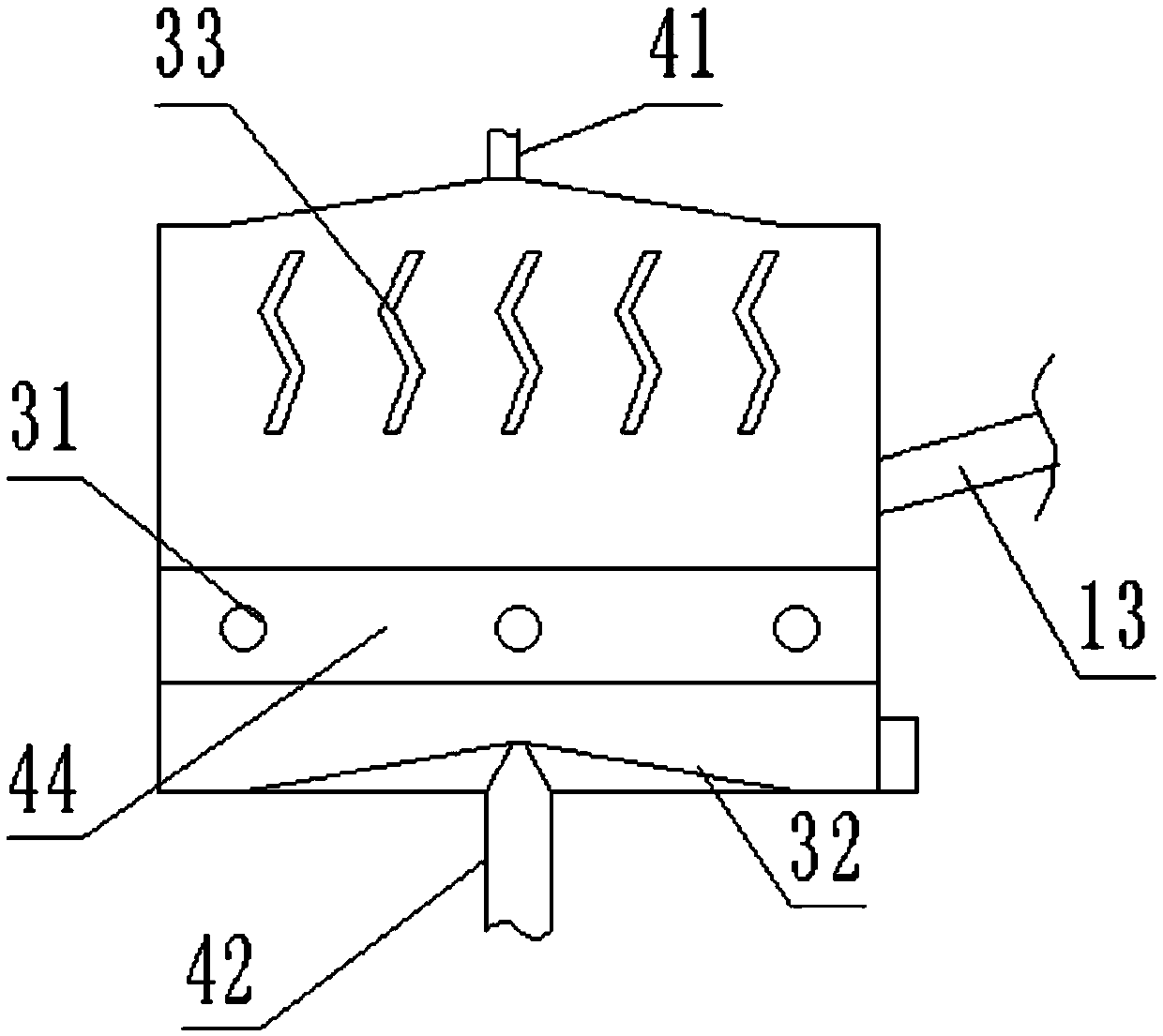

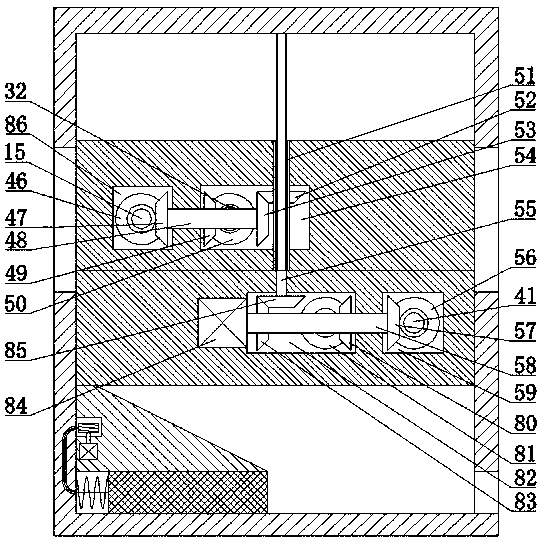

Optional type medicine processing crushing device

InactiveCN109604027AGuaranteed continuous processingGuaranteed crushing qualityGrain treatmentsEngineeringRaw material

The invention discloses an optional type medicine processing crushing device. The optional type medicine processing crushing device comprises a main box body, the main box body is internally providedwith a rough crushing cavity, the top of the rough crushing cavity communicates with a feeding port formed in the top surface of the main box body, the main box body is further internally provided with an air flow crushing cavity, the air flow crushing cavity is located under the rough crushing cavity and communicates with the rough crushing cavity through a rotation connecting pipe, and the connecting position of the rotation connecting pipe and the rough crushing cavity is located at the bottom of the rough crushing cavity. According to the optional type medicine processing crushing device,the main box body is internally provided with the air flow crushing cavity with a plurality of sorting plates, in the air flow crushing process, crushing and powder collecting can be carried out through air flow generated by a strong-wind fan, automatic screening can be carried out through the sorting plates, the condition that raw materials which are not crushed completely are processed continuously is ensured, and the overall crushing quality of finished products is ensured; and the rotation connecting pipe is connected with the rough crushing cavity, shearing crushing is carried out beforeair flow crushing, and the air flow crushing efficiency is improved.

Owner:SHANDONG TUMOR HOSPITAL

Waste collecting device of numerical control machining equipment for wood machining

PendingCN111438776AAvoid Splash SituationsDoes not affect work continuityBark-zones/chip/dust/waste removalNumerical controlWood machining

The invention discloses a waste collecting device of numerical control machining equipment for wood machining. The waste collecting device comprises two collecting boxes, namely a first collecting boxand a second collecting box; the first collecting box is a movable collecting box mechanism and comprises a first collecting box body, a box base, a rack, a driving mechanism, a guiding mechanism, adischarging mechanism and a control component, wherein the driving mechanism and the guiding mechanism are installed on the rack, a top face of the first collecting box body is open and serves as a machining table, and the discharging mechanism is connected with each of the first collecting box body and the box base and used for controlling the first collecting box body to discharge waste; and thedriving mechanism is used for controlling the first collecting box body to move back and forth through the guiding mechanism so that the first collecting box body can move back and forth between a machining area and a waste discharging end away from the machining area, and the second collecting box is arranged at the waste discharging end and used for collecting waste conveyed and discharged by the first collecting box body.

Owner:佛山帕拉斯数控装备制造有限公司

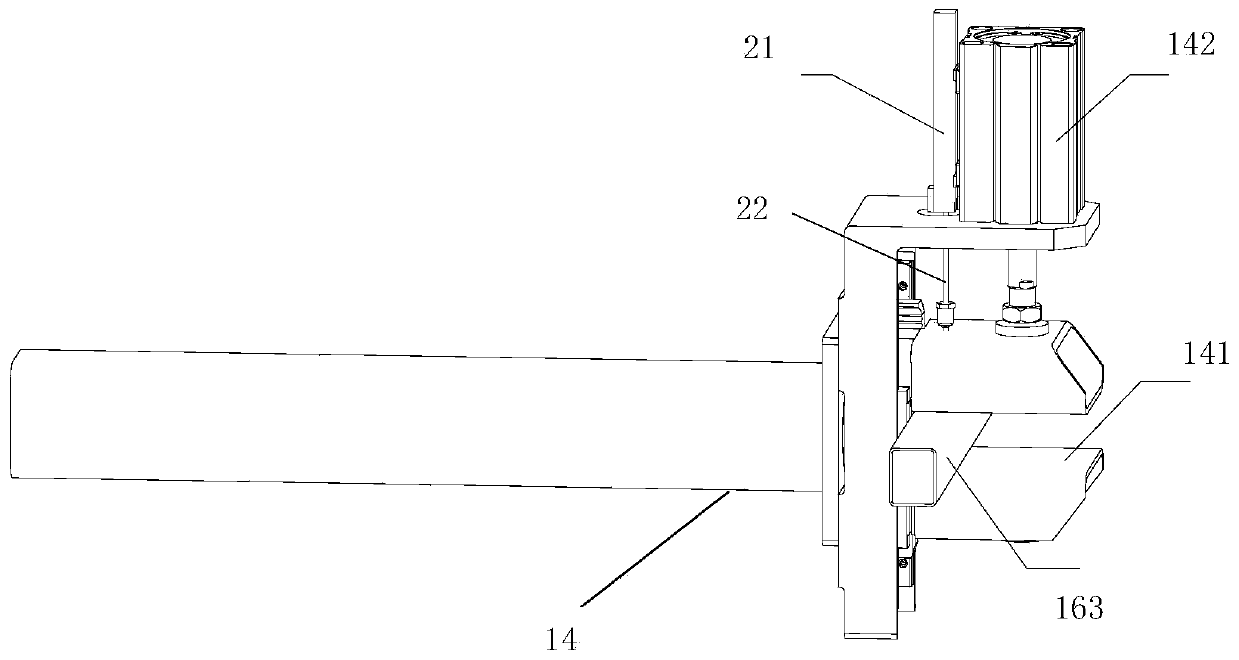

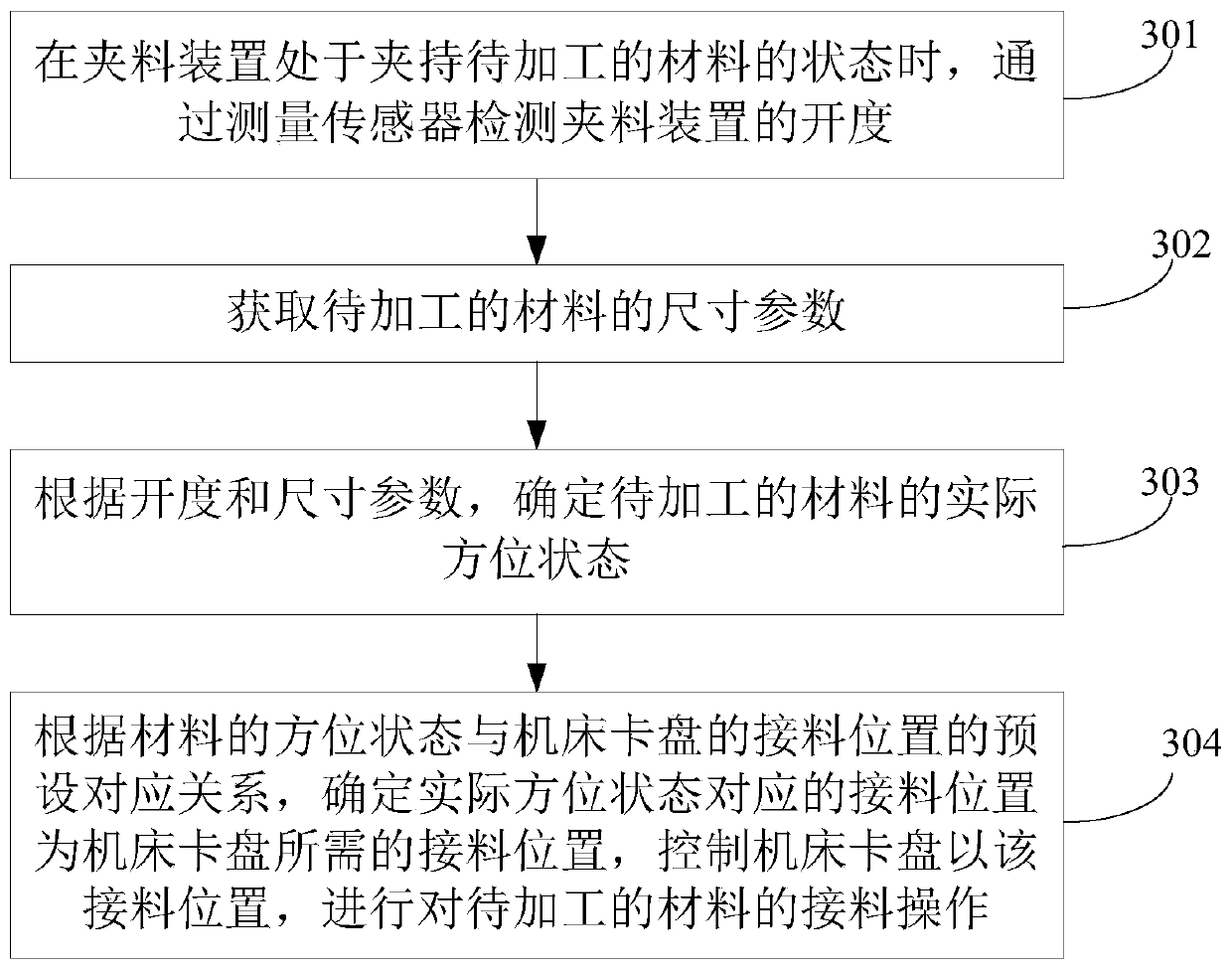

Automatic loading method and device, storage medium and automatic loading control device

ActiveCN109909603AReduce restrictionsContinuous and stable feedingLaser beam welding apparatusEngineeringMachine tool

The invention discloses an automatic loading method and device, a storage medium and an automatic loading control device. A measuring sensor is arranged on a feeding mechanism, and when a clamping device is in the state of clamping the material to be machined, through the measuring sensor, the opening degree of the clamping device is detected; the size parameter of the material to be machined is obtained; according to the opening degree and size parameters, the actual orientation state of the material to be machined is determined, accordingly, according to the preset corresponding relation between the orientation state of the material and the receiving position of a machine tool chuck, and the machine tool chuck is controlled to carry out receiving with the receiving position correspondingto the actual orientation state; through the scheme, limiting on the orientation state of the material clamped in the clamping device is greatly reduced, the device can achieve continuous stable loading for easy dialing material with the large long and short side difference or the difficult dialing material with the small long and short side difference, through the scheme, continuous stable loading can be achieved, the loading success rate and loading efficiency can be improved, and continuous machining is ensured.

Owner:HANS LASER TECH IND GRP CO LTD +1

Forming method of toriconical head

InactiveCN103522018AThe process is clear and smoothImprove securityPressure vesselsSafety coefficientBiomedical engineering

The invention discloses a forming method of a toriconical head. The method includes the following steps of raw material preparation, first lineation, first cutting, welding, edge rolling, correction, secondary lineation, secondary cutting, measurement and defect detection. By means of the mode, according to the forming method of the toriconical head, the whole process is clear and smooth, continuous machining of the toriconical head can be guaranteed, the safety coefficient of the head is improved, operation is more convenient to achieve, and the use process is safer.

Owner:WUXI XIZHOU END SOCKET MFG

Papermaking wastewater aeration device

InactiveCN110357281AReduce processing timeGuaranteed continuous processingWater treatment parameter controlTreatment using aerobic processesWastewaterTherapeutic effect

The invention discloses a papermaking wastewater aeration device, which comprises a transverse pipe, wherein the top of the transverse pipe is fixedly connected with a wide plate; the inner wall of the wide plate is fixedly connected with a first bearing; the inner wall of the first bearing is provided with a filtering mechanism; the left side of the transverse pipe is fixedly connected with an aerator; and the right side of the top of the transverse pipe is provided with an opening and closing mechanism. According to the papermaking wastewater aeration device, the problem that the existing papermaking wastewater aeration device cannot quickly combine oxygen with wastewater during operation is solved through an agitation mechanism, so that microorganisms can quickly obtain dissolved oxygen, the wastewater treatment time is reduced, and the treatment effect is ensured; and the problem that a filter screen for filtering oxygen is inconvenient to replace is solved through the filtering mechanism, the papermaking wastewater aeration device does not need to be stopped during replacement, the wastewater is continuously treated, and the wastewater pollution is reduced, and the problem that the input amount of the oxygen cannot be controlled is solved through the opening and closing mechanism during replacement, so that the oxygen waste is avoided, and the practicability is improved.

Owner:福建华闽特种纸科技股份有限公司

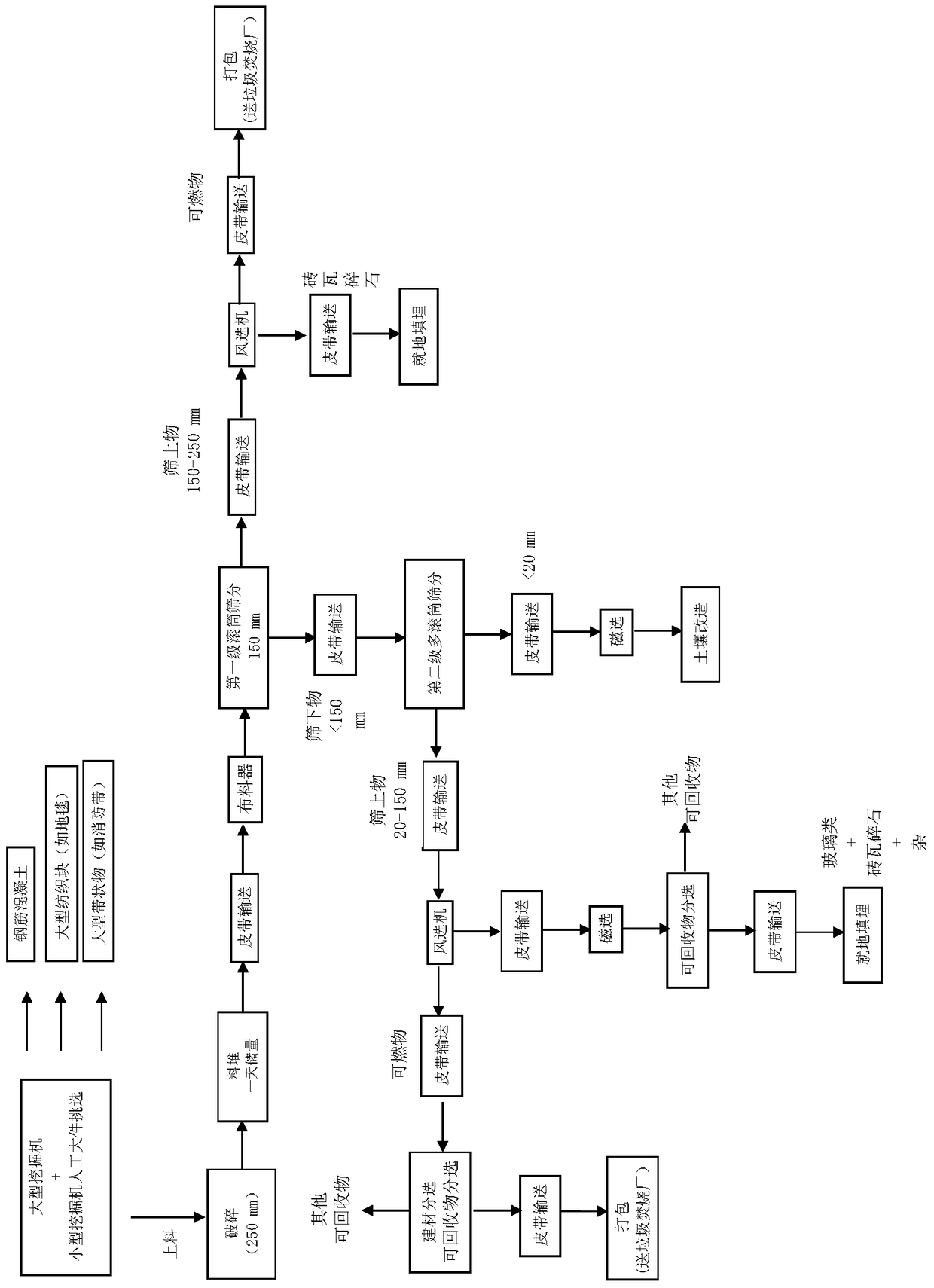

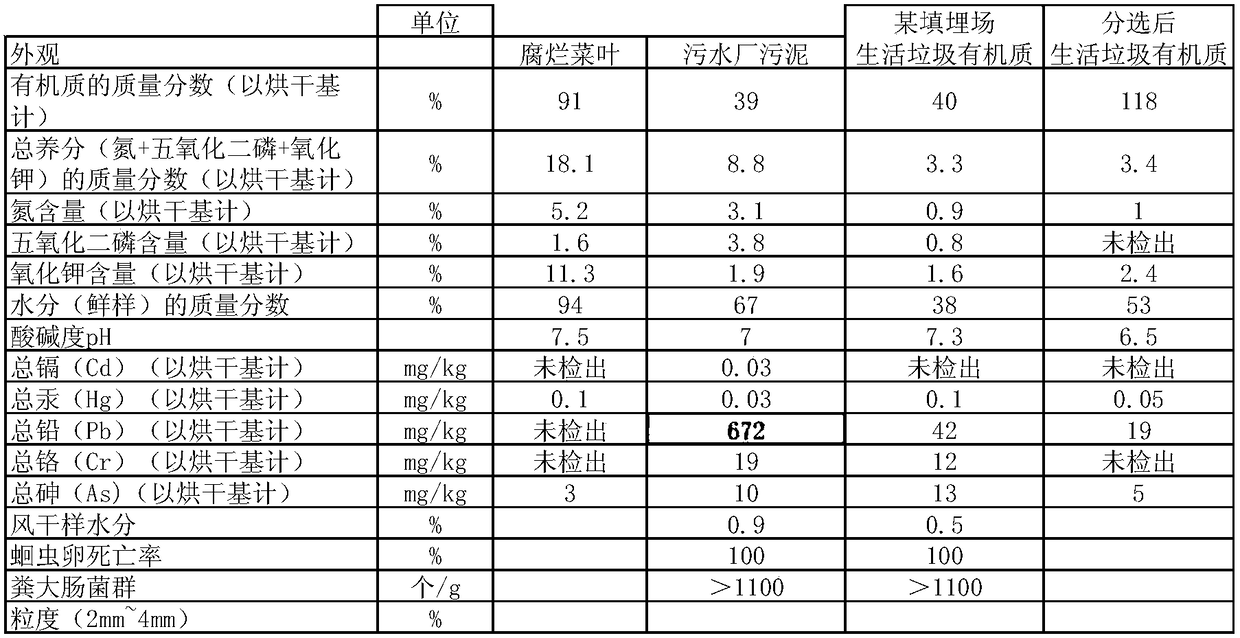

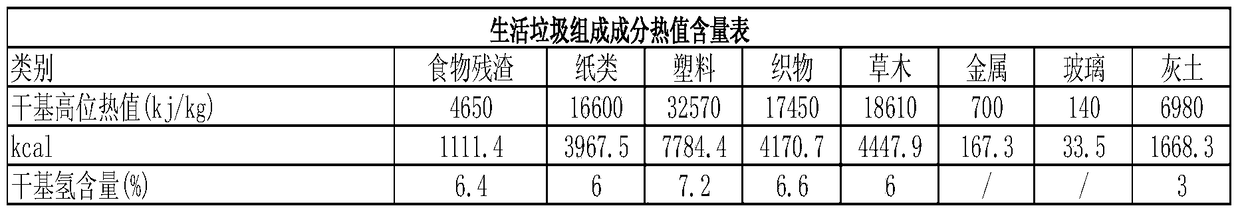

Land Reuse Treatment Methods for Waste Landfills

ActiveCN104874598BGuarantee large-scale same-day processing tonnageThe purpose of ensuring landfill reuseSolid waste disposalContaminated soil reclamationSoil treatmentLand resources

The invention discloses a land reuse processing method of a refuse landfill. The land reuse processing method of the refuse landfill comprises the steps of re-excavating, cleaning and treating the whole landfill, sorting humus soil, combustibles, recoverable substances, unrecoverable inorganic substances and dangerous and waste substances, transporting the humus soil to a soil treatment and desert treatment place, packaging and transporting the combustibles to a waste incineration power plant for incineration power generation, conducting harmless treatment and recovery on the recoverable substances, backfilling the unrecoverable inorganic substances in place, transporting the dangerous and waste substances to a dangerous and waste center and obtaining harmless land. The land reuse processing method has the advantages that the substances in the refuse landfill are re-smashed and sorted at a time, treatment scale, namely daily treatment tonnage can be ensured. After the landfill is treated and reused, a large amount of humus soil (nutritional soil) is obtained and can be used for planting woods, the woods absorb carbon dioxide and release oxygen, and atmospheric pollution and haze situation are improved. Land resources are reutilized, the arable land minimum in our country is guaranteed, and the land reuse processing method has immeasurable strategic significance.

Owner:中能润达环境工程有限公司

Removing device for COD in high-concentration alkaline wastewater

PendingCN107827278AGood removal effectGuaranteed continuous processingWater treatment parameter controlTreatment involving filtrationFlocculationActivated carbon

The invention discloses a removing device for COD in high-concentration alkaline wastewater. The removing device comprises an acid and alkali neutralization device, a reaction tank and a filter presswhich are sequentially connected, wherein an alkaline wastewater collecting tank and a plasticization water collecting tank are connected onto the acid and alkali neutralization device, a flocculant blending tank is arranged on the reaction tank, and a flocculant inlet and an activated carbon inlet are arranged on the flocculant blending tank. The high-concentration alkaline wastewater is treatedin an acid and alkali neutralization, flocculation and filter pressing combined manner, on one hand, the COD content of high-concentration alkaline wastewater with the COD content of about 50,000 mg / Lcan be decreased to 1,300-1,600 mg / L, then, the wastewater is sent to an environmental protection process for degradation treatment, the environmental protection pressure is reduced, on the other hand, waste residues obtained after filter pressing can be directly sent to a power department for incineration after being unloaded, and the energy cost is saved.

Owner:YIBIN GRACE +1

Continuous garbage treatment device

ActiveCN110560229AGuaranteed continuous processingGuaranteed crushing effectGrain treatmentsPressesEngineeringCrankshaft

The invention discloses a continuous garbage treatment device, and relates to the technical field of environmental protection equipment. The continuous garbage treatment device comprises a crushing main body, wherein a conveying pipe A and a conveying pipe B communicating with the crushing main body are arranged at an outlet at the bottom of the crushing main body; a self-rotating gate plate A isarranged at the bottoms of the conveying pipe A and the conveying pipe B; outlets of the conveying pipe A and the conveying pipe B respectively communicate with a compaction cavity B and a compactioncavity A inside a compression assembly; the gate plate A is rotatably mounted on the compression assembly; a pressing plate C and a pressing plate D which are mutually matched are arranged in the compaction cavity A; a pressing plate A and a pressing plate B which are mutually matched are arranged in the compaction cavity B; a crankshaft is rotatably mounted on the compression assembly; two connecting rod journals are arranged on the crankshaft; a rotating block B and a rotating block A are respectively and rotatably mounted on the two connecting rod journals; two connecting rods A are respectively mounted on the two sides of the rotating block A; and the other ends of the two connecting rods A are respectively hinged to the pressing plate A and the pressing plate D. By means of the continuous garbage treatment device, the continuous high-efficiency compaction of garbage is achieved.

Owner:泓欣环境集团有限公司

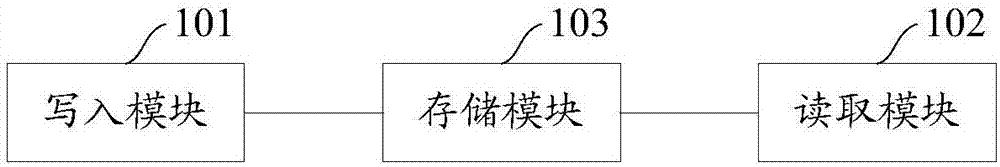

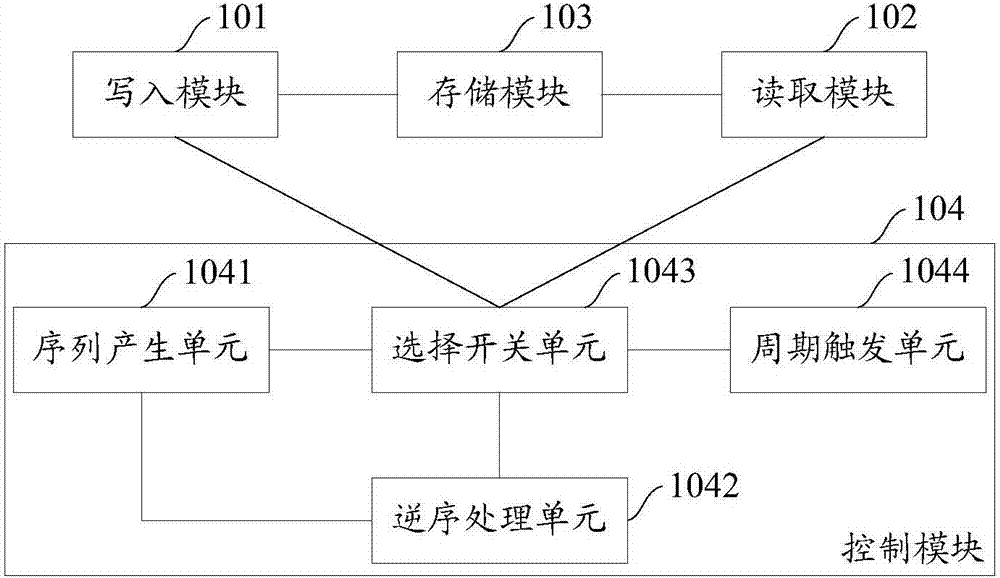

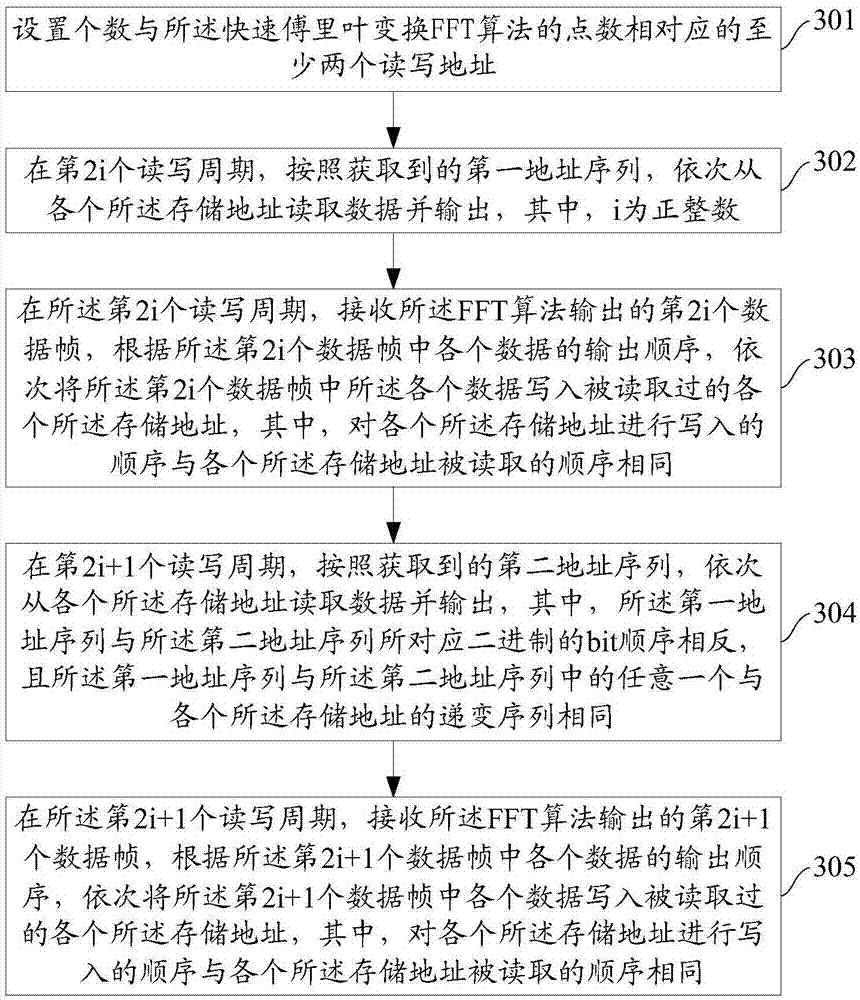

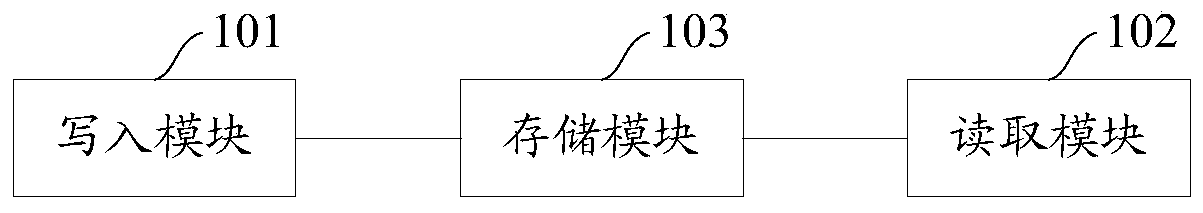

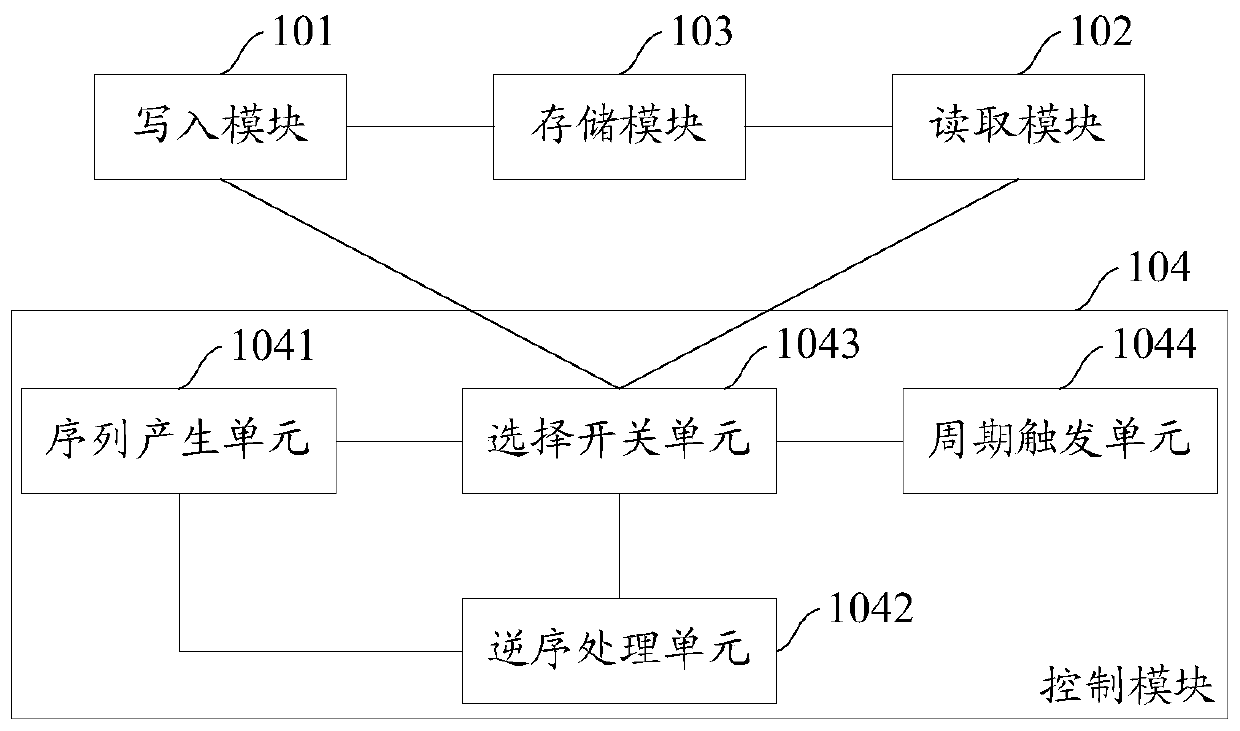

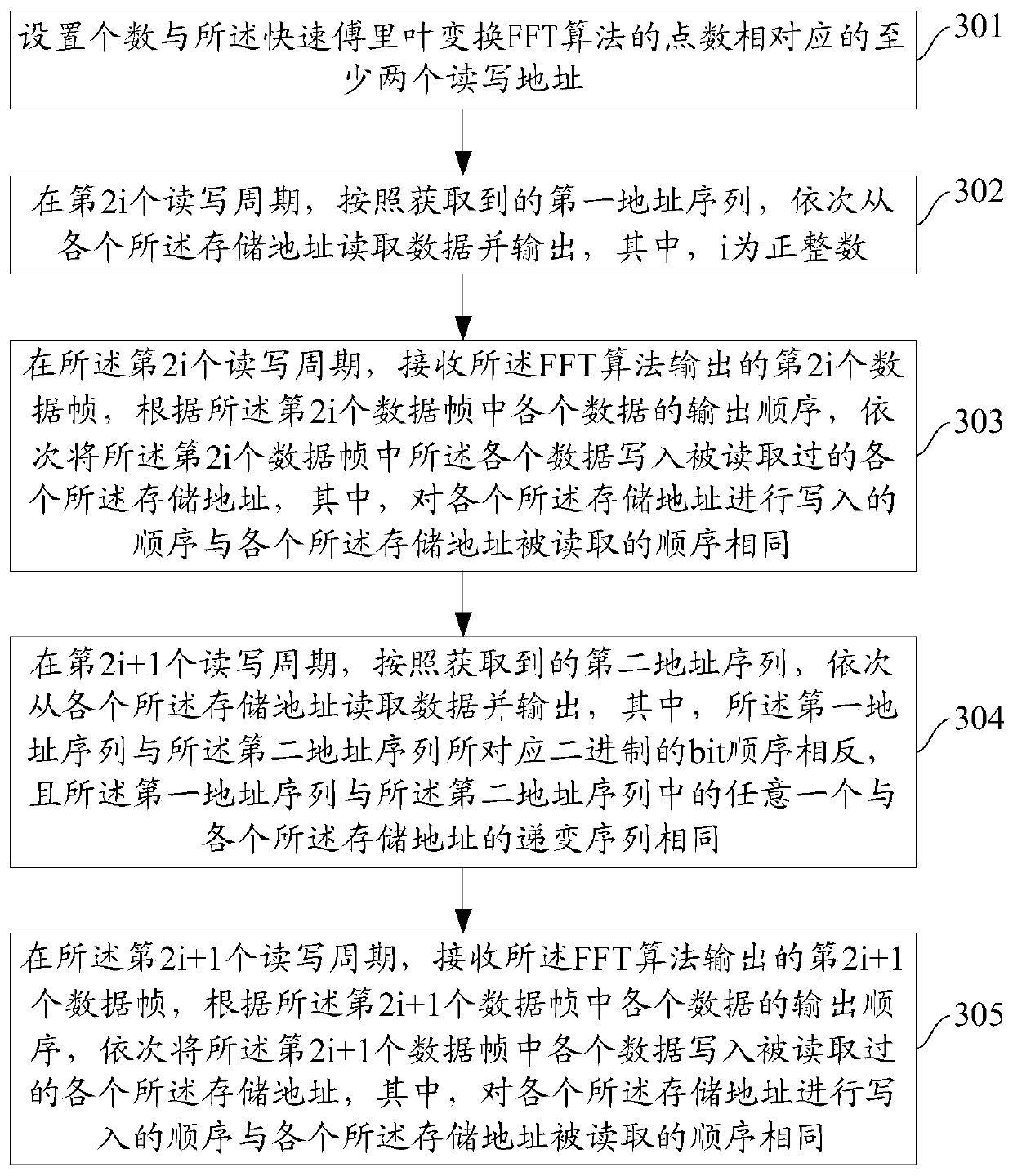

Processing device and method of fast Fourier transform algorithm output data

ActiveCN107391440AGuaranteed continuous processingComplex mathematical operationsFast Fourier transformComputer module

The invention provides a processing device and method of fast Fourier transform algorithm output data. The device comprises a writing module, a reading module and a storage module; storage addresses with the number corresponding to the points of the FFT algorithm are set in the storage module; the reading module is used for sequentially reading data from all the storage addresses according to the first address sequence and outputting the data in the 2i read-write cycle and sequentially reading data from all the storage addresses according to the second address sequence and outputting the data in the (2i+1) read-write cycle, wherein i is a positive integer, and the binary bit sequence corresponding to the first address sequence is opposite to that of the second address sequence; the writing module is used for sequentially writing all the data into all the storage addresses read by the reading module according to the output sequence of all the data in data frames output by the FFT algorithm. By means of the scheme, the FFT algorithm can be applied to running water application scenarios.

Owner:SUZHOU LANGCHAO INTELLIGENT TECH CO LTD

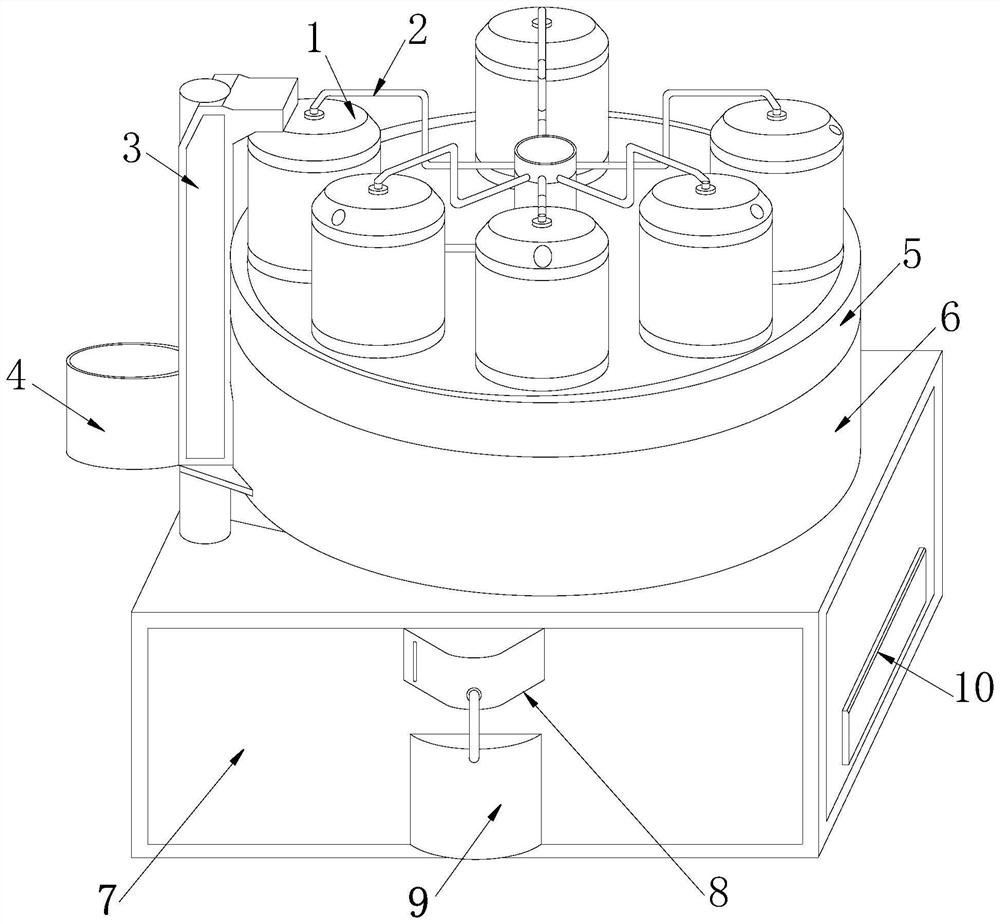

Efficient extraction equipment and preparation process for beautifying plant extract

InactiveCN112807740AReduce laborImprove processing productivityGas solvent extractionSolid solvent extractionProcess engineeringWaste material

The invention discloses an efficient extraction device and preparation process for beautifying plant extract, belonging to the technical field of extraction. According to main points of a technical scheme in the invention, the efficient extraction device comprises a distillation retort, wherein the tail end of the upper side of the distillation retort is fixedly connected with a distillation connecting pipe; the left end of the distillation retort is provided with a feeding end; the left end surface of the feeding end is fixedly connected with a discharging hopper; an upper end disc is fixedly connected to the bottom end of the distillation retort; a lower fixing disc is arranged at the bottom end of the upper end disc; a touch push plate is arranged at the tail end of the lower side of a discharging pipe; a rotating structure is formed between the touch push plate and the lower fixing disc; a groove is formed in the rear side of the touch push plate; a spring is connected to the rear side of the touch push plate; a rotating structure is formed between the spring and the touch pressing push plate; a waste chamber is arranged under the touch pressing push plate; and a communicating structure is formed between the waste chamber and the lower fixing disc. By means of the above structure, internal extracted materials can be conveniently discharged and stored, automatic discharging is achieved through the rotating structure, and the interior of the device does not need to be cleaned.

Owner:六安树袋熊生物科技有限公司

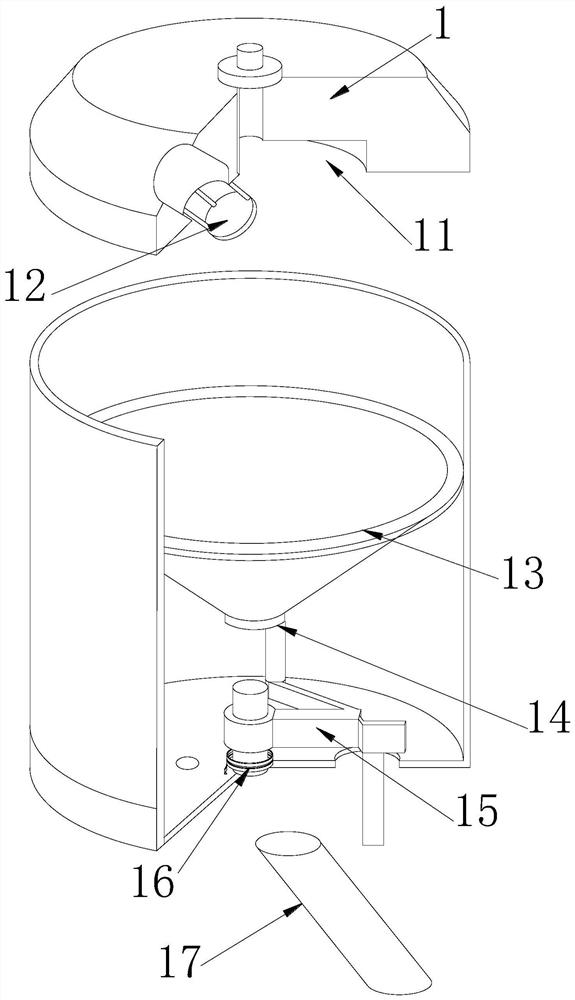

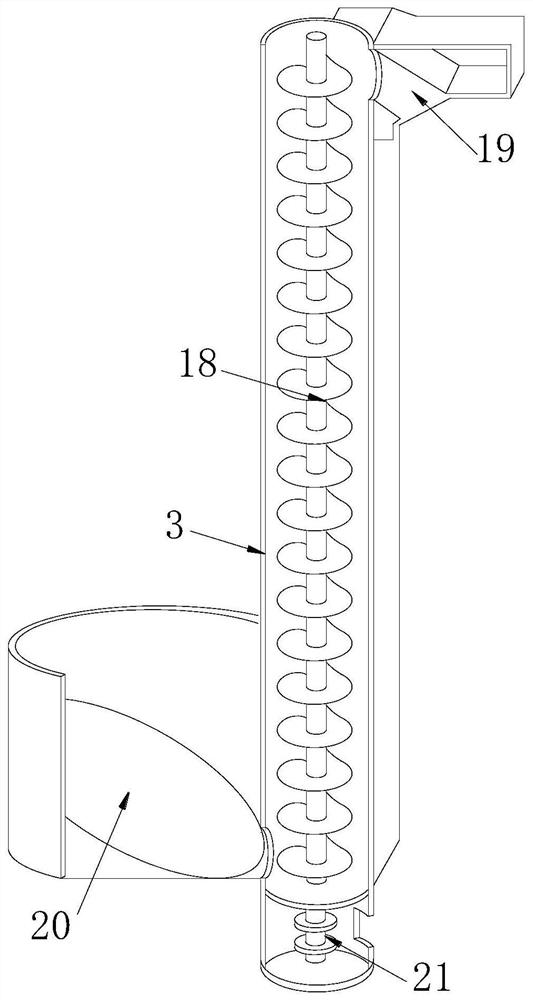

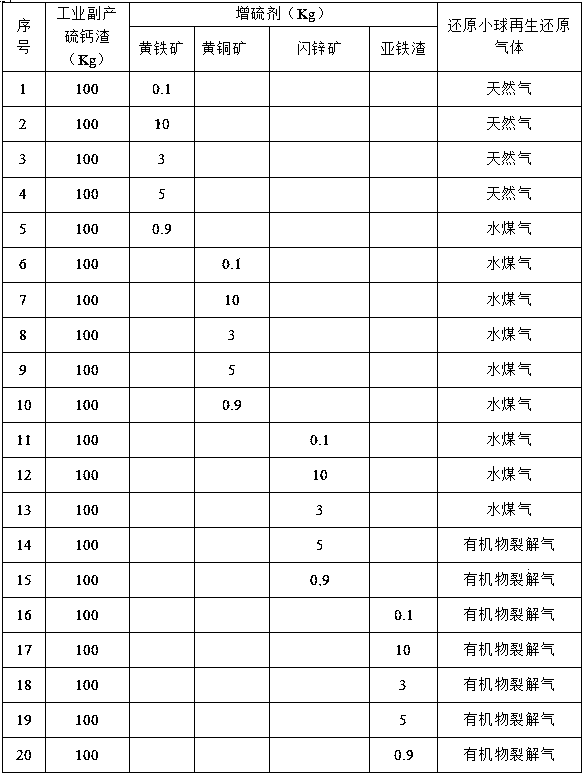

Method for recovering sulfur in industrial by-product sulfur-calcium slag by fixed bed

ActiveCN111453702AIncreased sulfur oxide contentImprove decomposition efficiencySulfur preparation/purificationSlagFlue gas

The invention discloses a method for recovering sulfur in an industrial by-product sulfur-calcium slag by a fixed bed, comprising the following steps of: uniformly mixing the industrial by-product sulfur-calcium slag with a sulfur increasing agent, and adding into a rapid decomposer to carry out countercurrent heat exchange reaction to obtain calcium oxide and sulfur dioxide flue gas; introducingthe sulfur dioxide flue gas into an activation reduction bed for reaction to obtain sulfur steam flue gas, and cooling the flue gas to recover sulfur. Compared with the prior art, the method has the characteristics of low production cost, high production efficiency and good product quality.

Owner:SOUTHWEAT UNIV OF SCI & TECH

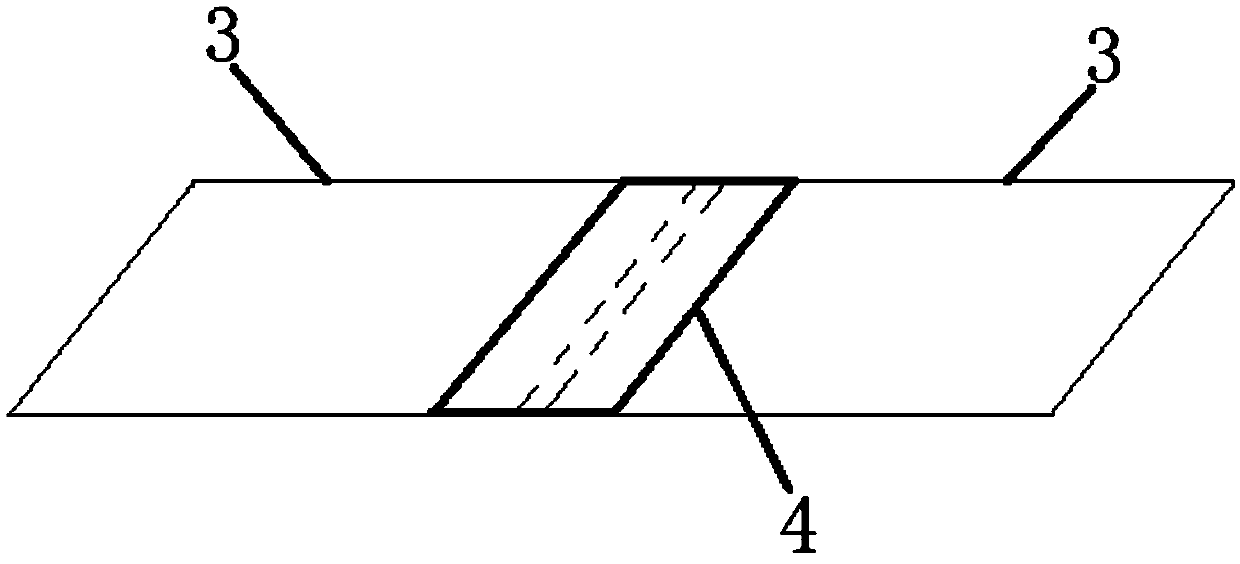

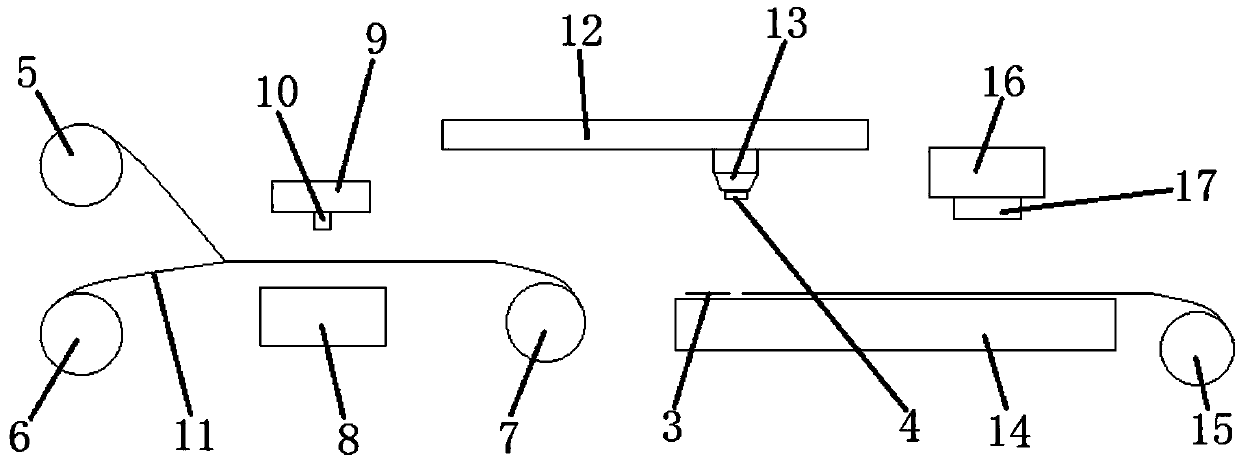

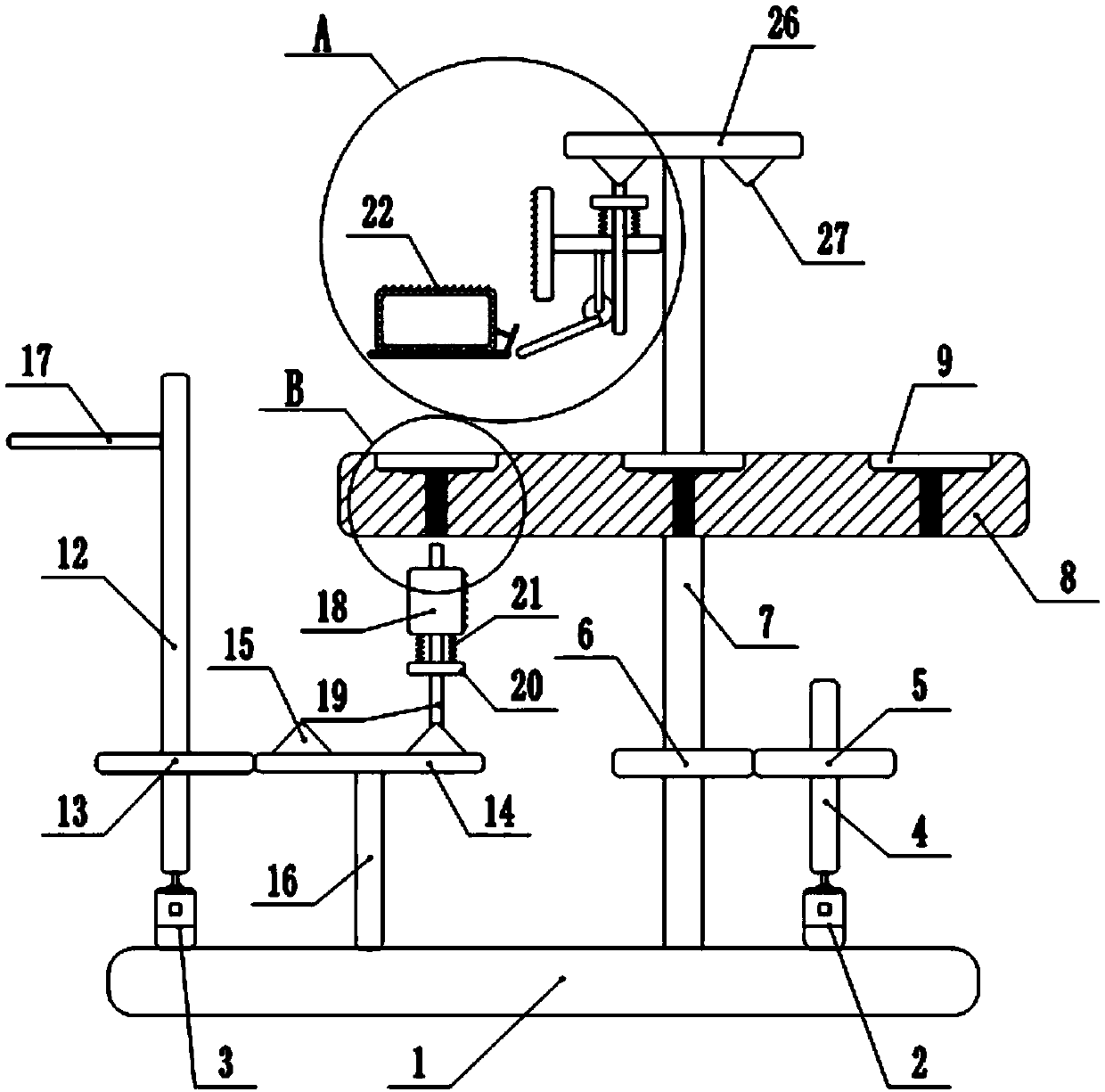

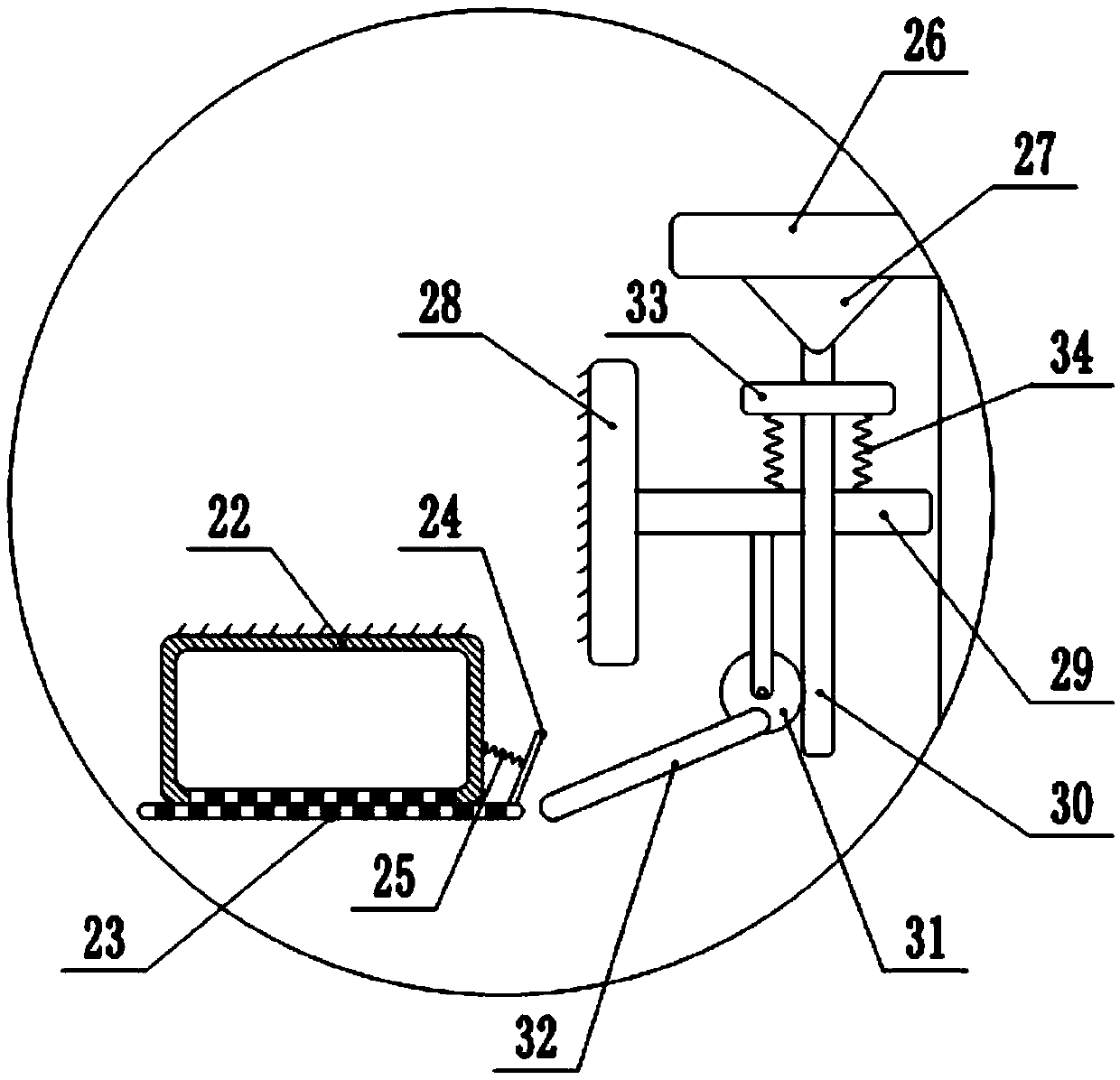

Processing device for splicing-type coil

PendingCN111377280AEasy accessAvoid Completely Disconnected SituationsArticle deliveryWebs handlingAdhesive beltSurface mounting

The invention relates to a processing device for a splicing-type coil. The splicing-type coil comprises a plurality of parallelogram belts sequentially connected end to end and a plurality of parallelogram tape arranged between every two adjacent parallelogram belts. The processing device comprises a tape cutting mechanism, a tape bonding mechanism and a belt conveying mechanism, and the tape bonding mechanism bonds each parallelogram tape in the tape cutting mechanism between every two adjacent parallelogram belts in the belt conveying mechanism. Compared with the prior art, in the processingdevice, the short side of each parallelogram belt and the curling direction form an included angle, the situation of complete disconnection during curling and storing is avoided, and normal taking and using of a follow-up automatic surface mounting machine are ensured; and each parallelogram tape in the tape cutting mechanism is bonded between every two adjacent parallelogram belts in the belt conveying mechanism through the tape bonding mechanism, continuous processing of the splicing-type coil is ensured, and the production efficiency is improved.

Owner:昊佰电子科技(上海)有限公司

White sugar addition equipment for food

InactiveCN109645532AGuarantee processing qualityGuaranteed continuous processingFood coatingAgricultural engineeringEngineering

The invention relates to the technical field of food processing and discloses white sugar addition equipment for food. The equipment comprises a rack, a base is fixedly connected to the rack, and a first motor and a second motor are fixedly connected to the base; a first rotation shaft is connected to the first motor, an incomplete gear is fixedly connected to the first rotation shaft, and a firstgear is intermittently meshed with the incomplete gear; a second rotation shaft is fixedly connected to the first gear, a feeding disc is fixedly connected to the second rotation shaft, and four feeding grooves are formed in the upper end face of the feeding disc; through holes are formed in the groove bottoms of the feeding grooves, supporting rods are slidingly connected with the interiors of the through holes, and trays are fixedly connected to the upper ends of the supporting rods; a third rotation shaft is connected to the second motor, a second gear is fixedly connected to the third rotation shaft and meshed with a third gear, and four first arc protrusions are arranged on the upper end face of the third gear; a limit block and a storage box are fixedly connected to the rack, and apush rod is slidingly connected to the limit block; a pushing assembly is arranged on the rack. The white sugar addition equipment for food has the advantage that white sugar is quantitatively and evenly added to cake-shaped food.

Owner:象山锦绣升平食品有限公司

Full-automatic conveying-belt-type vacuum steam blanching equipment

PendingCN110338213AReduce heating rateImprove work efficiencyFood processingFruits/vegetable preservation by heatingAutomatic controlSemi automatic

The invention discloses full-automatic conveying-belt-type vacuum steam blanching equipment and belongs to the technical field of agricultural product processing. An automatic control system controlsa steam generation system, a vacuum system, a drainage system and a material conveying device, steam is adopted for continuously blanching materials, and the equipment is simple in structure and reasonable in design and can be conveniently integrated with a processing production line; a waste heat recoverer is adopted for conducting waste heat recovery on the steam obtained after material blanching before the steam is pumped to a water ring vacuum pump, the waste heat is used for heating water introduced into the steam generation system, and the processing energy consumption is obviously lowered; in addition, the temperature increase speed of the water ring vacuum pump is lowered, and the working efficiency of the water ring vacuum pump is guaranteed. The problems are solved that existingvacuum pulse blanching equipment is in semi-automatic manual intermittent operation, the industrial continuous production demand cannot be met, the processing energy consumption is large, the production efficiency is low, and secondary pollution is easily caused.

Owner:SHAANXI UNIV OF SCI & TECH

Box pasting and folding device for ultra-large type corrugated paper printing linkage line

ActiveCN111605243AHigh-speed automatic productionIncrease productivityPaper-makingBox making operationsPaperboardManual handling

The invention discloses a box pasting and folding device for an ultra-large type corrugated paper printing linkage line. The box pasting and folding device comprises a box pasting part, a box foldingpart, a counting and discharging part and a press fit part which are connected in sequence. The box folding part comprises a paperboard conveying mechanism and a folding mechanism, and the box pastingpart and the folding mechanism are sequentially arranged above the paperboard conveying mechanism in the paperboard conveying direction. The counting and discharging part is connected with the outputend of the paperboard conveying mechanism, and the press fit part is connected with the output end of the counting and discharging part. The box pasting and folding device is designed aiming at the printing process of ultra-large type corrugated paper; after the printing and die cutting process is completed, the ultra-large type corrugated paper can directly enter a subsequent process to be subjected to box pasting, box folding, counting and discharging, press fitting and other processes; traditional manual operation can be replaced, the defect that a traditional printing linkage line can beonly suitable for small paperboard printing and cannot be suitable for large or ultra-large type paperboard printing, high-speed automatic production of the ultra-large type corrugated paper is achieved in cooperation with printing equipment, the production efficiency is improved, and the production safety is also improved.

Owner:GUANGZHOU KESHENGLONG CARTON PACKING MACHINE

Splicing board machining device

InactiveCN109968463AGuaranteed continuous processingImprove processing efficiencyProfiling/shaping machinesWood machiningEngineering

The invention discloses a splicing board machining device. The device comprises a machine shell, wherein a cutting sliding cavity is formed in the machine shell, and a cutting mechanism is arranged inthe cutting sliding cavity; the cutting mechanism comprises an upper cutting part and a lower cutting part which are arranged in the cutting sliding cavity in a sliding mode; and the upper cutting part comprises an upper cutter and upper cutting blades, wherein the upper cutting blades are symmetrically and fixedly arranged in the upper cutter. The device is more reasonable and ingenious in integral structure, and very convenient to install, maintain and overhaul; boards are continuously conveyed into the device through an upper conveying belt and a lower conveying belt so that it is guaranteed that the device can carry out continuous machining on the boards, and the board machining efficiency is improved; saw dust is conveyed out of the device uninterruptedly, so that subsequent operation is facilitated, and the operation environment of workers is improved; and the device has efficient automation in the use process, and has high use and popularization values.

Owner:嘉兴劲境电子商务有限公司

A device and method for processing output data of a fast Fourier transform algorithm

ActiveCN107391440BGuaranteed continuous processingComplex mathematical operationsComputer hardwareFast Fourier transform

The invention provides a processing device and method of fast Fourier transform algorithm output data. The device comprises a writing module, a reading module and a storage module; storage addresses with the number corresponding to the points of the FFT algorithm are set in the storage module; the reading module is used for sequentially reading data from all the storage addresses according to the first address sequence and outputting the data in the 2i read-write cycle and sequentially reading data from all the storage addresses according to the second address sequence and outputting the data in the (2i+1) read-write cycle, wherein i is a positive integer, and the binary bit sequence corresponding to the first address sequence is opposite to that of the second address sequence; the writing module is used for sequentially writing all the data into all the storage addresses read by the reading module according to the output sequence of all the data in data frames output by the FFT algorithm. By means of the scheme, the FFT algorithm can be applied to running water application scenarios.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com