Method for recovering sulfur in industrial by-product sulfur-calcium slag by fixed bed

An industrial by-product, fixed bed technology, applied in chemical instruments and methods, sulfur preparation/purification, sulfur compounds, etc., can solve problems such as environmental pollution, land occupation by titanium gypsum, loss of titanium gypsum, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with specific examples.

[0024] A method for recovering sulfur in industrial by-product sulfur-calcium slag in a fixed bed, characterized in that it comprises the following steps in sequence: the industrial by-product sulfur-calcium slag is mixed evenly with a sulfur increasing agent, and then added to a fast decomposer for countercurrent heat exchange reaction to obtain oxidation Calcium and sulfur dioxide flue gas; the sulfur dioxide flue gas is passed into the activated reduction bed for reaction to obtain sulfur vapor flue gas, and the flue gas is cooled to recover sulfur.

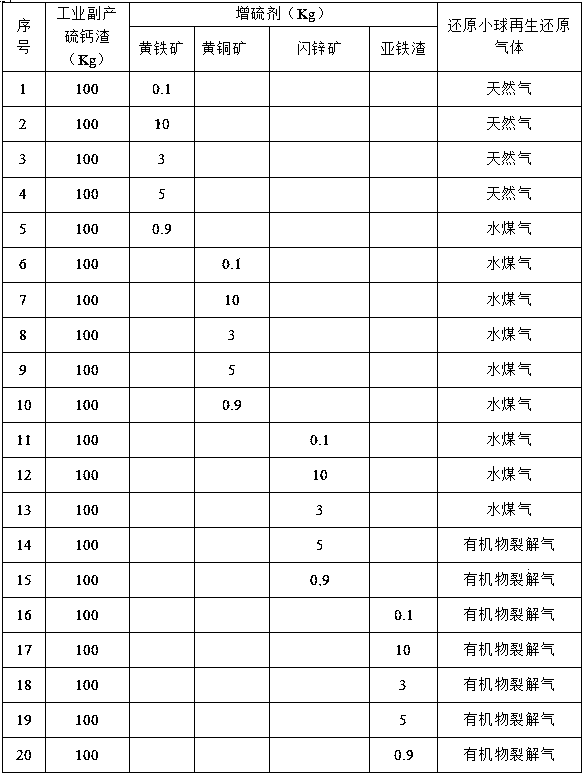

[0025] Table 1

[0026]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com