Box pasting and folding device for ultra-large type corrugated paper printing linkage line

A folding device, corrugated paper technology, applied in packaging, papermaking, transportation and packaging, etc., can solve the problems of large corrugated board size, difficult manual operation and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

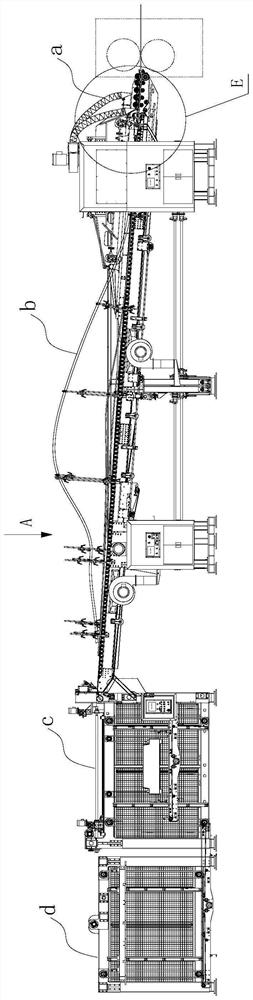

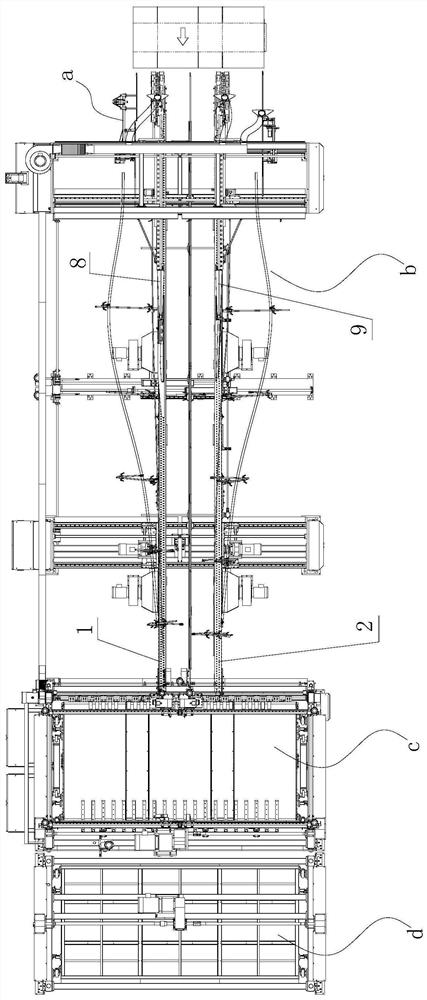

[0051] In this embodiment, a kind of paste box folding device for super large corrugated paper printing linkage line, such as figure 1 or figure 2 As shown, it includes the gluing part a, the folding part b, the counting and discharging part c and the pressing part d connected in sequence. In this device, the input end of the folding mechanism is externally connected to the printing and die-cutting part of the super-large corrugated paper printing linkage line, that is, after the cardboard is printed and die-cut, it enters the device for gluing, folding, counting, discharging, and pressing, and finally presents The super large corrugated paper printing linkage line is sent out in a stacked form.

[0052] The specific structure of the above-mentioned parts is as follows:

[0053] 1. Folding box department

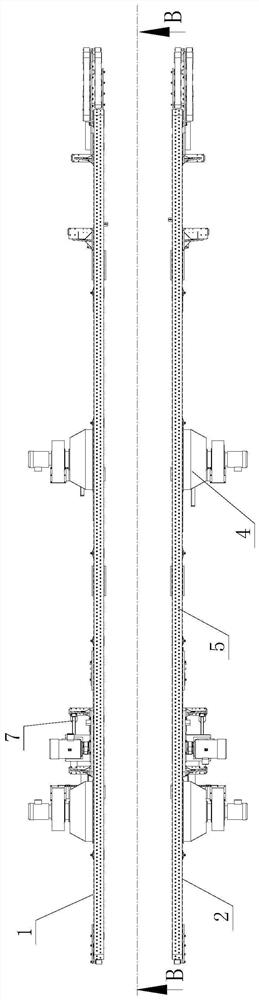

[0054] The box folding section includes a cardboard conveying mechanism and a folding mechanism. Along the cardboard conveying direction, the gluer section and the foldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com