Numerical control engraving and milling machine

A technology of engraving and milling machine and driving mechanism, which is applied in the direction of metal processing machinery parts, metal processing equipment, maintenance and safety accessories, etc. It can solve the problems of serious torsional loss, easy heat generation, and easy deviation from the main shaft, so as to ensure continuous processing and uniform Cooling and ensuring clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

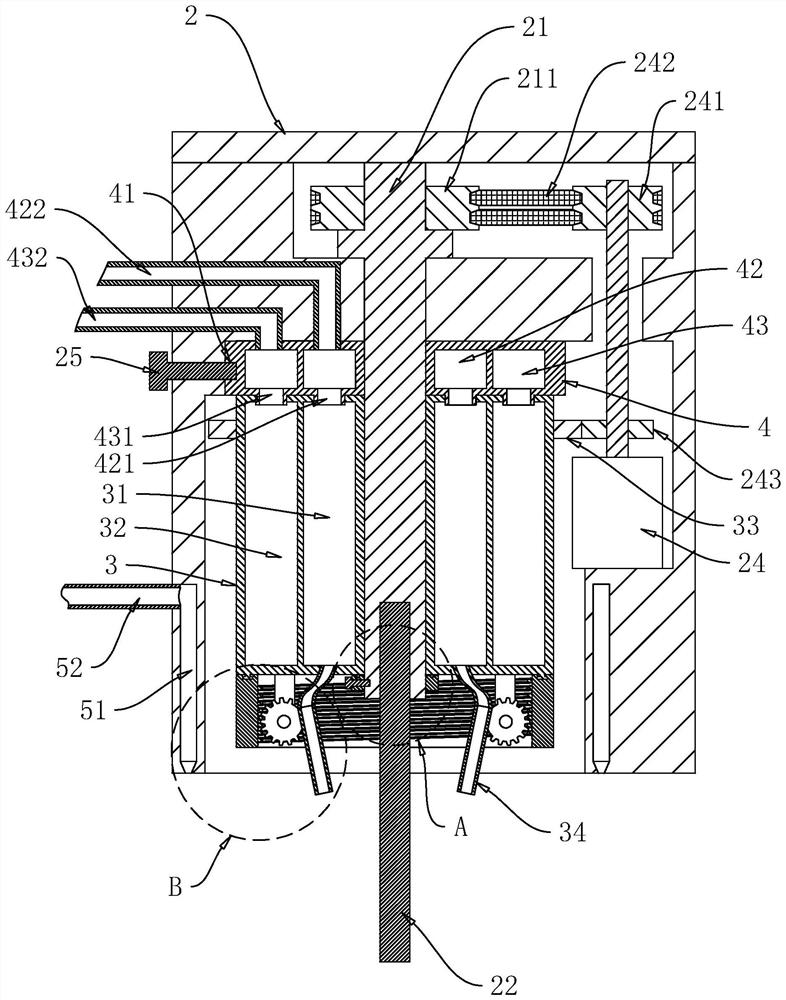

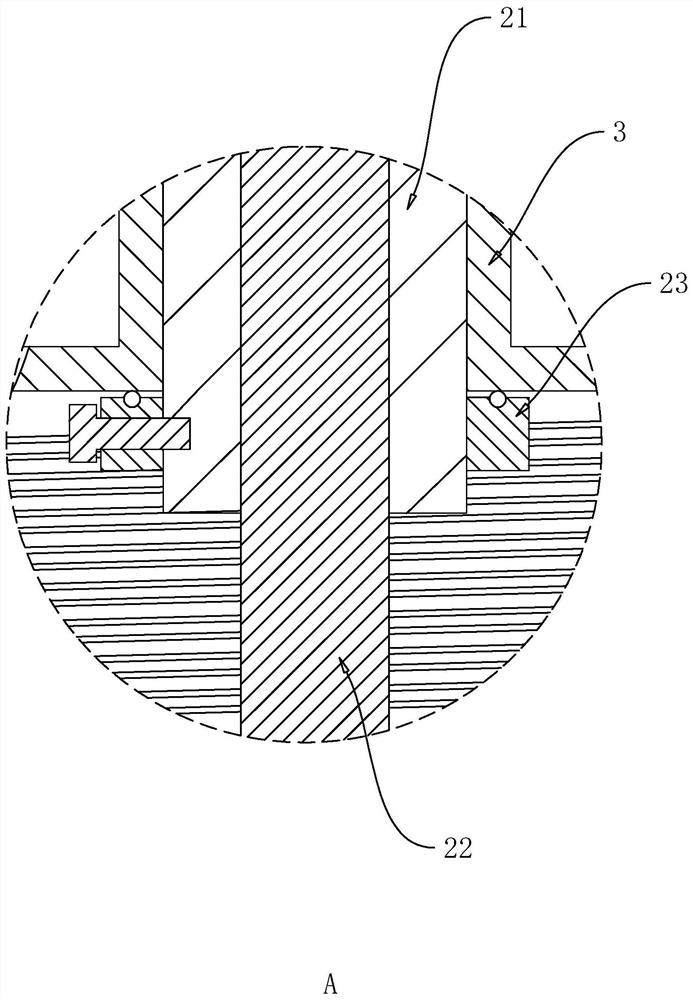

[0036] The following is attached Figure 1-5 The application is described in further detail.

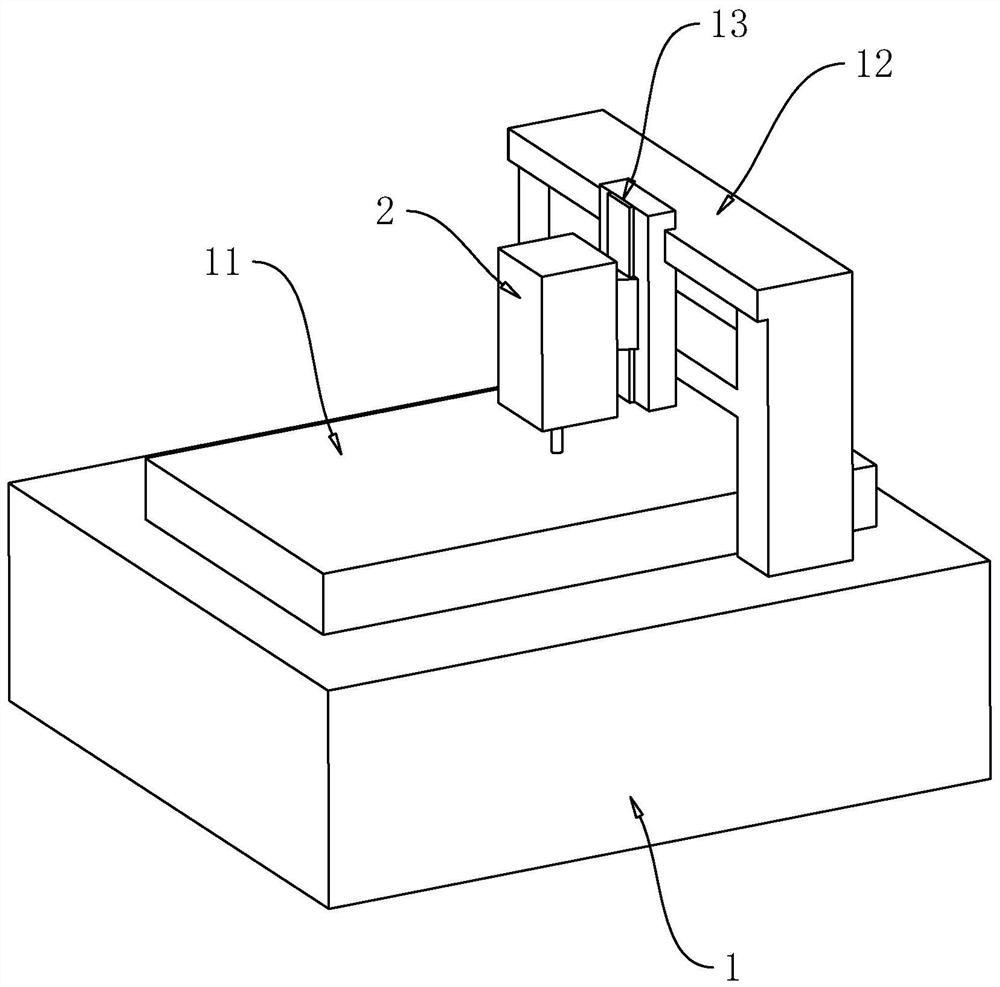

[0037] refer to figure 1, the embodiment of the present application discloses a numerical control engraving machine, including a base 1, a workbench 11 is arranged on the upper side of the base 1, and the upper side of the base 1 corresponding to the workbench 11 is horizontally provided with a length direction perpendicular to the length direction of the workbench 11. Crossbeam 12, both ends of crossbeam 12 are fixedly connected with sliding connection to base 1 and can reciprocate along the length direction of workbench 11, and crossbeam 12 is connected with movable frame 13 capable of reciprocating along its length direction, movable frame The upper vertical sliding of 13 is connected with the headstock 2 that can reciprocate in the vertical direction. During work, the crossbeam 12 reciprocates along the length direction of the workbench 11, the carriage 121 reciprocates along t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com