Optional type medicine processing crushing device

A crushing device and medicine technology, applied in grain processing, etc., can solve problems such as different crushing degrees, increased costs, and unguaranteed quality of finished products, and achieve the effects of reducing equipment costs, ensuring crushing quality, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

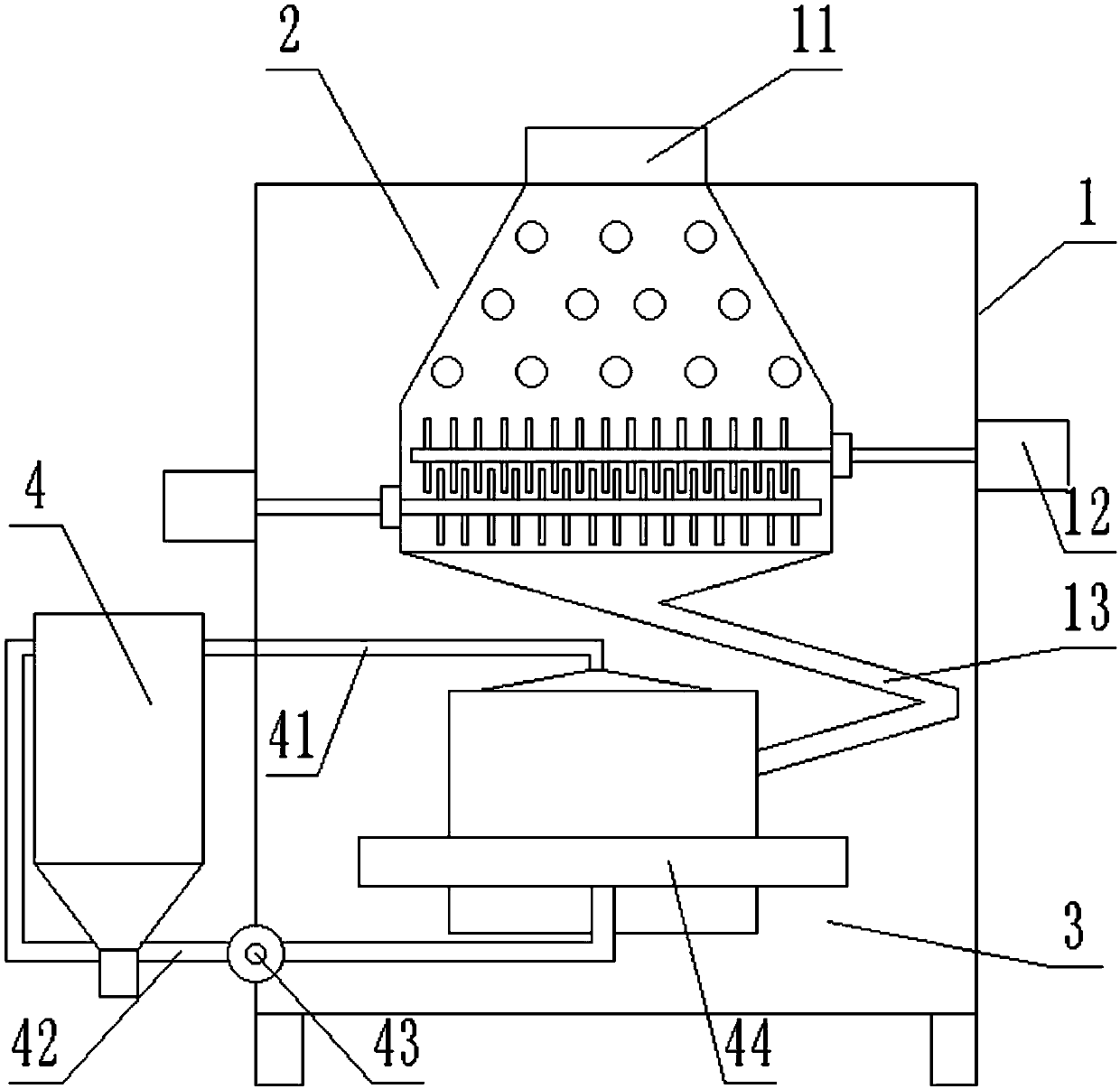

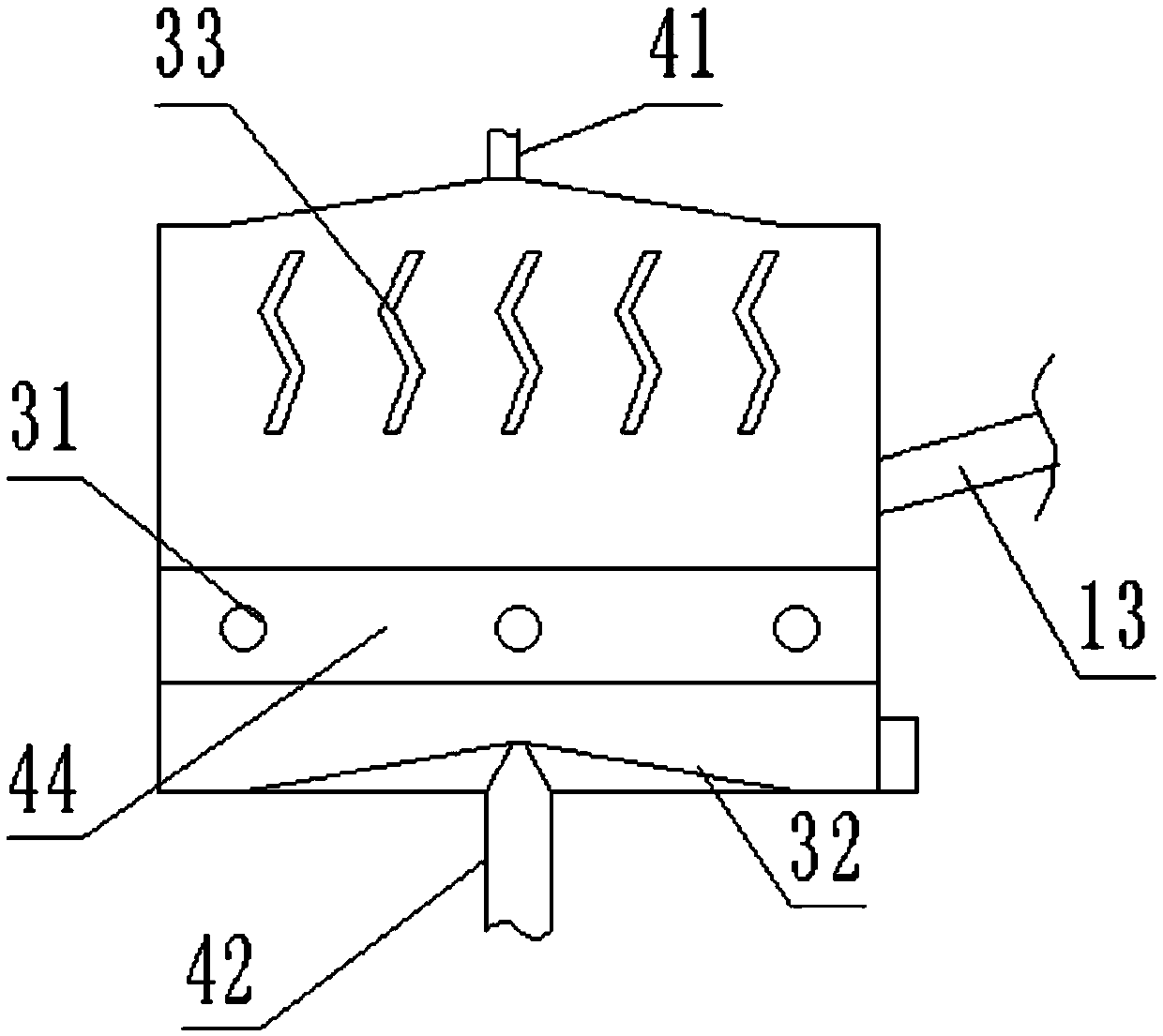

[0020] see Figure 1-3 , a self-selected drug processing and crushing device, including a main box body 1, a coarse crushing chamber 2 is provided inside the main box body 1, and a feeding port opened on the top surface of the coarse crushing chamber 2 and the top surface of the main box body 1 11 is connected, and the coarse crushing chamber 2 is used to preliminarily crush the pharmaceutical raw materials entering the main box 1 through the feed port 11. The main box 1 is also provided with an airflow crushing chamber 3, and the airflow crushing chamber 3 is located in the coarse crushing chamber. The bottom of the chamber 2 is connected through the rotary connecting pipe 13. The connection between the rotary connecting pipe 13 and the coarse crushing chamber 2 is located at the bottom of the coarse crushing chamber 2, and the connection between the rotary connecting pipe 13 and the airflow crushing chamber 3 is located on the side of the airflow crushing chamber 3. The rota...

Embodiment 2

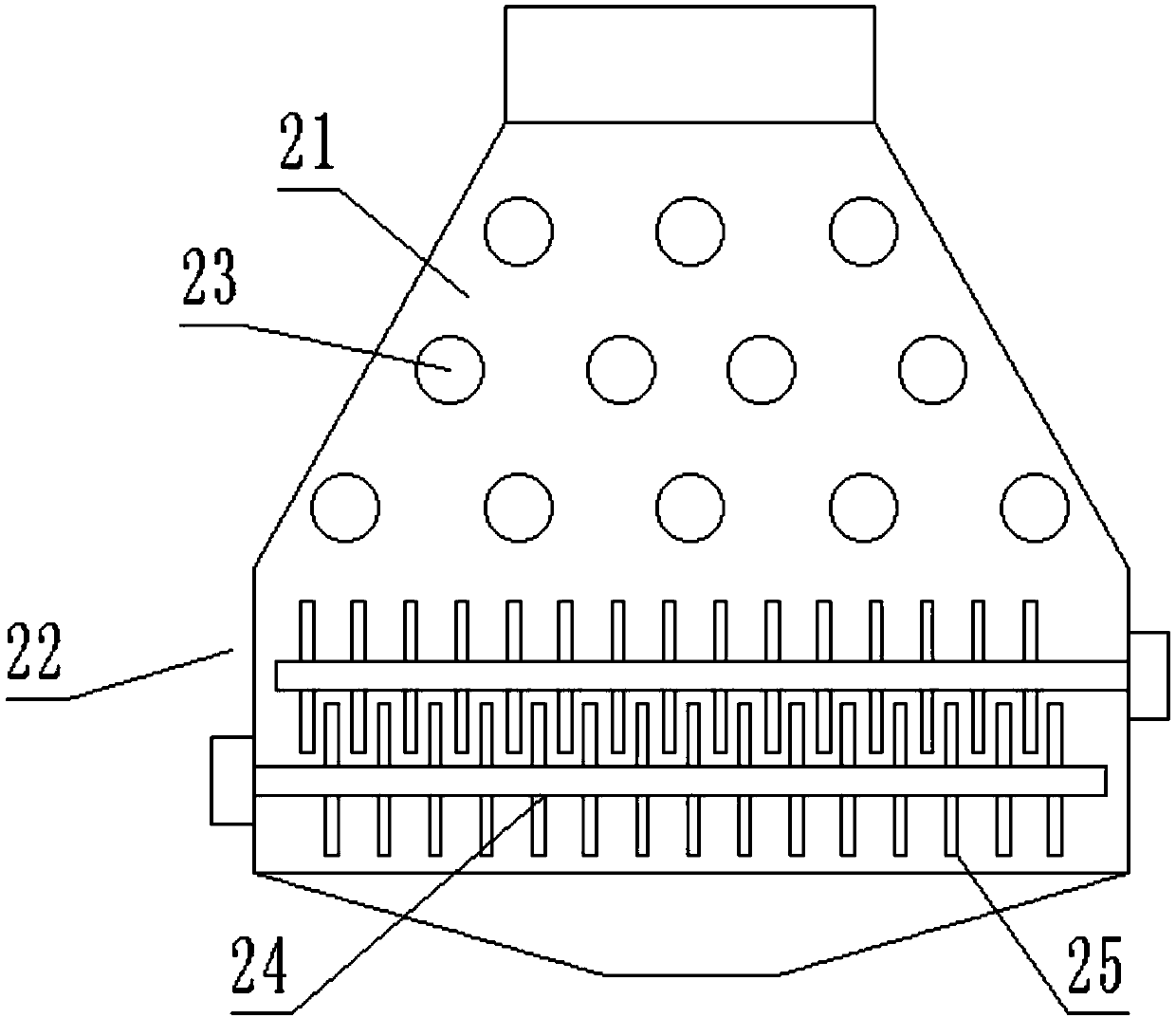

[0024] The difference from Example 1 is that in order to ensure that raw materials can be coarsely crushed more quickly and evenly, the coarse crushing chamber 2 includes an integrally formed equalizing part 21 and a crushing part 22, and the rotating shaft 24 is located at the crushing part 22 Inside, the equalizing part 21 is in the shape of opening up, and there are multiple striking rods 23 in the equalizing part 21. The multiple striking rods 23 are distributed in a conical shape. When the raw material enters, it will collide with the multiple striking rods 23. Irregular impacts make the raw materials evenly divided when they reach the pulverizing part 22, thereby speeding up the efficiency of coarse pulverization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com