Full-automatic conveying-belt-type vacuum steam blanching equipment

A conveyor belt, fully automatic technology, used in the preservation of fruits/vegetables by bleaching, food preservation, fresh fruit and vegetable preservation, etc., can solve the problem of affecting the working efficiency, working energy consumption and service life of vacuum pumps, and cannot meet the requirements of batch continuous operation. , the degree of automation and low production efficiency, to achieve the effect of good blanching effect, simple structure and reduced processing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with accompanying drawing, and its content is explanation of the present invention rather than limitation:

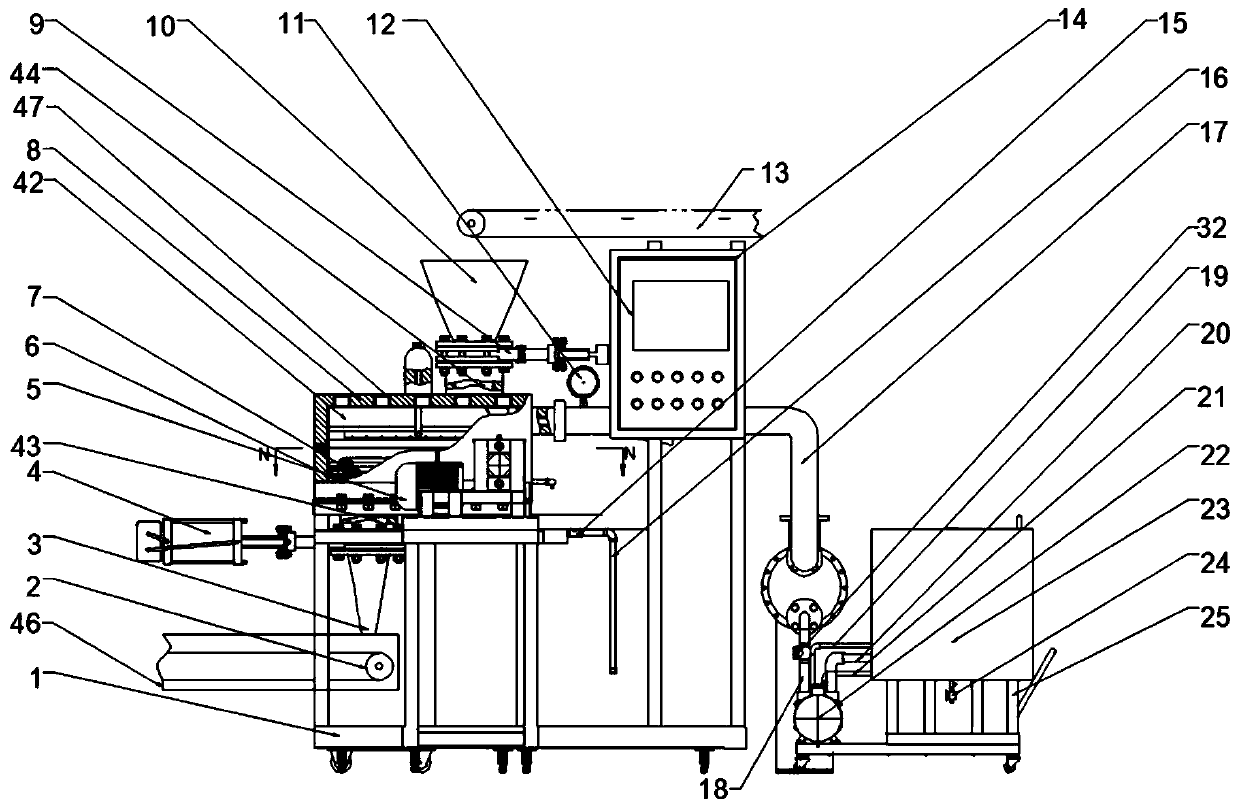

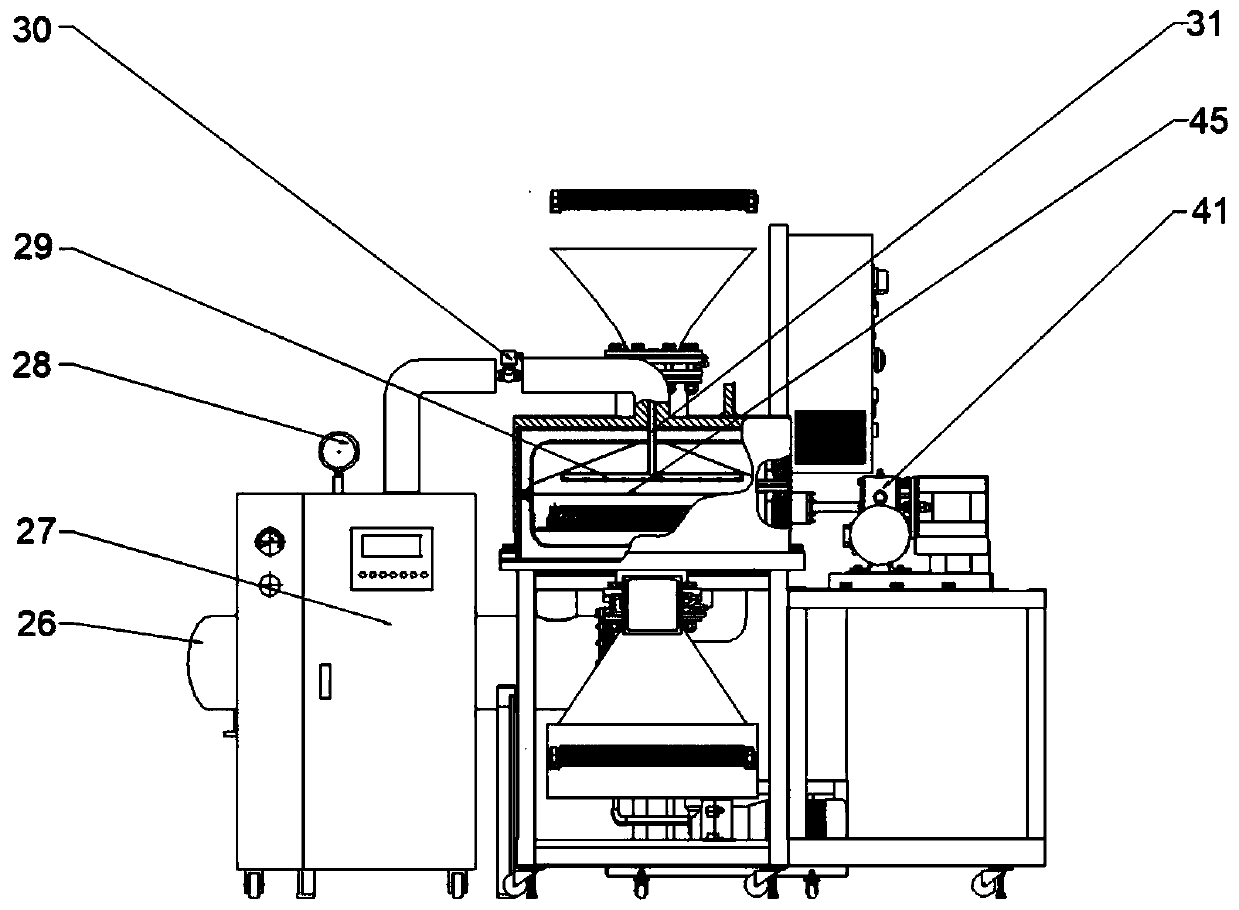

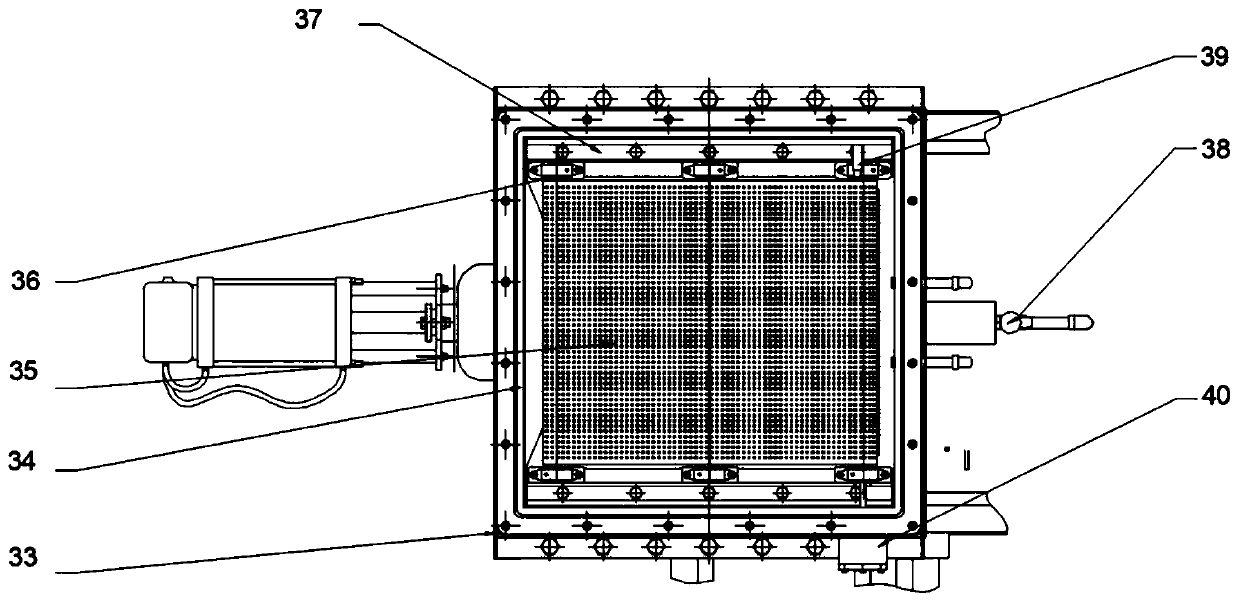

[0036] Such as figure 1 , figure 2 , is the automatic conveyer-belt vacuum steam blanching equipment of the present invention, such as image 3 , the pressure-bearing shell 34 is fixed on the frame 1, and the overall structure is a square cavity. The pressure-bearing shell 34 adopts a double-layer structure, and the inner layer is made of stainless steel with a thickness of 4-8 mm, and the structure adopts reinforcing ribs 46 Reinforced, the reinforcing rib 46 is selected from No. 6 channel steel, the outer layer is a stainless steel skin 33, and the middle of the inner and outer layers is filled with thermal insulation material with a thickness of 40-120mm. The inner chamber of the pressure-bearing shell 34 is a blanching chamber 42, For the place of pulsating blanching processing, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com