Waste collecting device of numerical control machining equipment for wood machining

A technology for processing equipment and waste collection. It is used in wood processing tools, manufacturing tools, bark area/debris/dust/waste removal, etc. It can solve problems such as high labor intensity, increased equipment failure safety accidents, and slow collection speed. , to achieve the effect of improving processing efficiency and reducing equipment failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

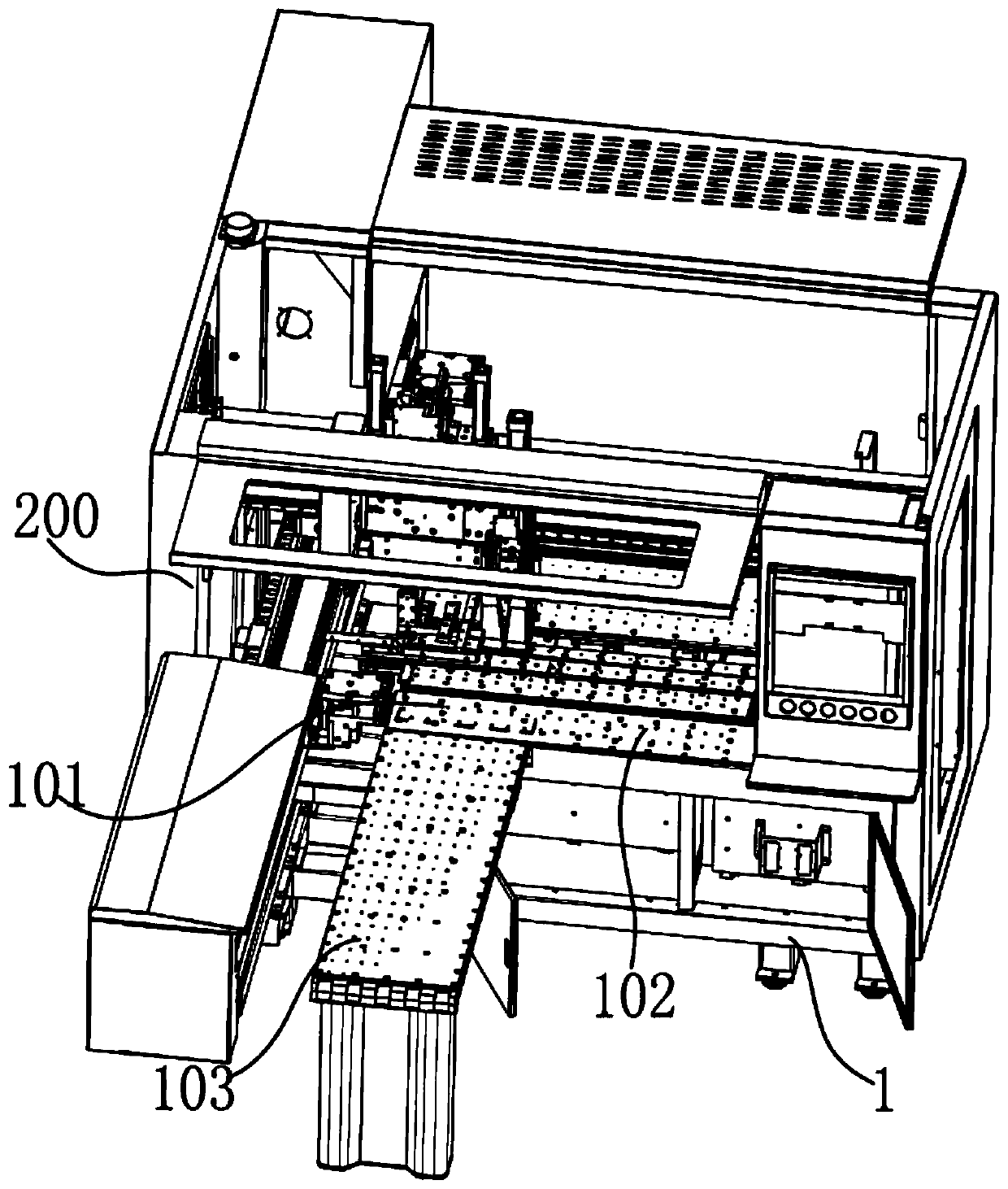

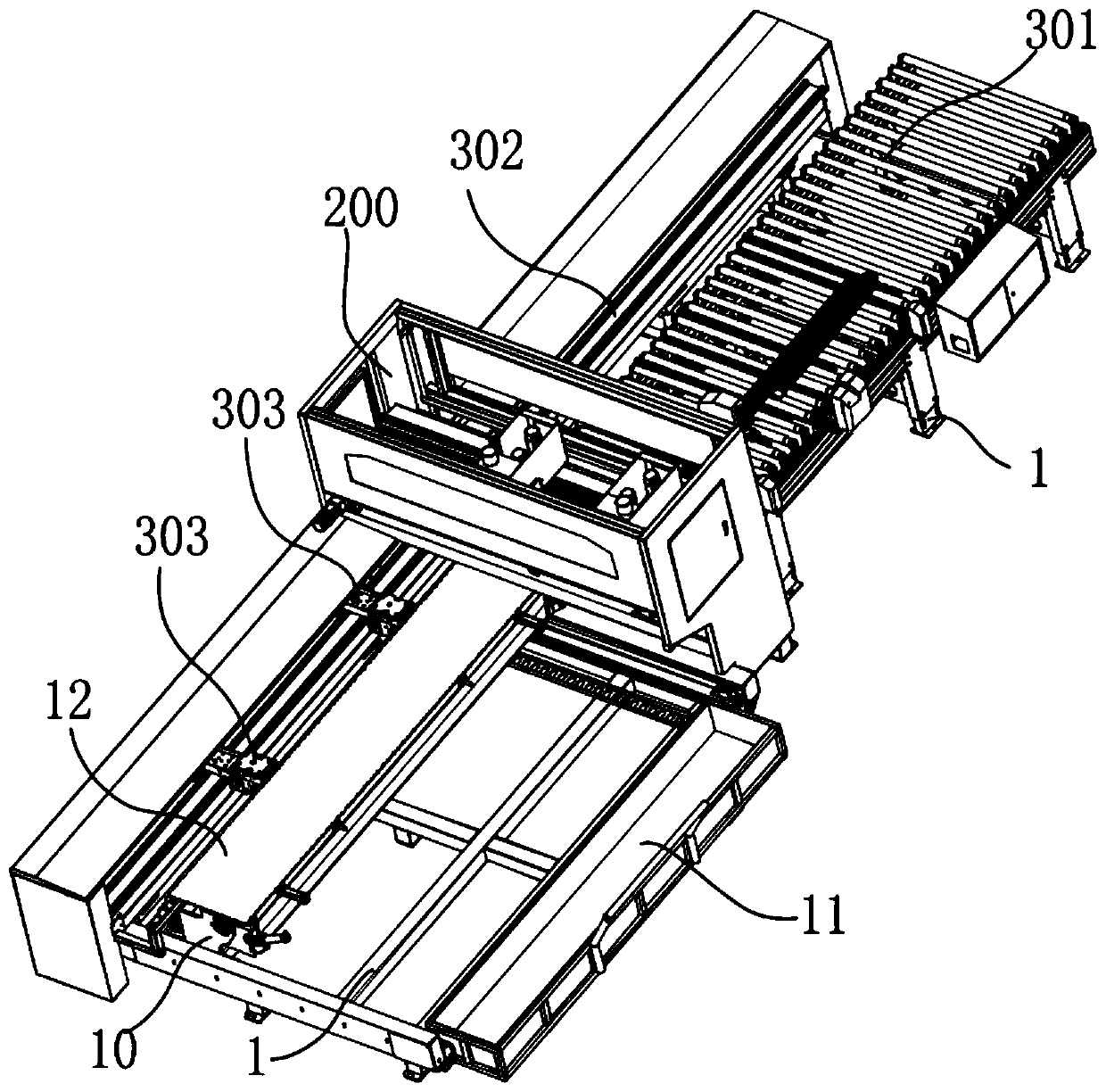

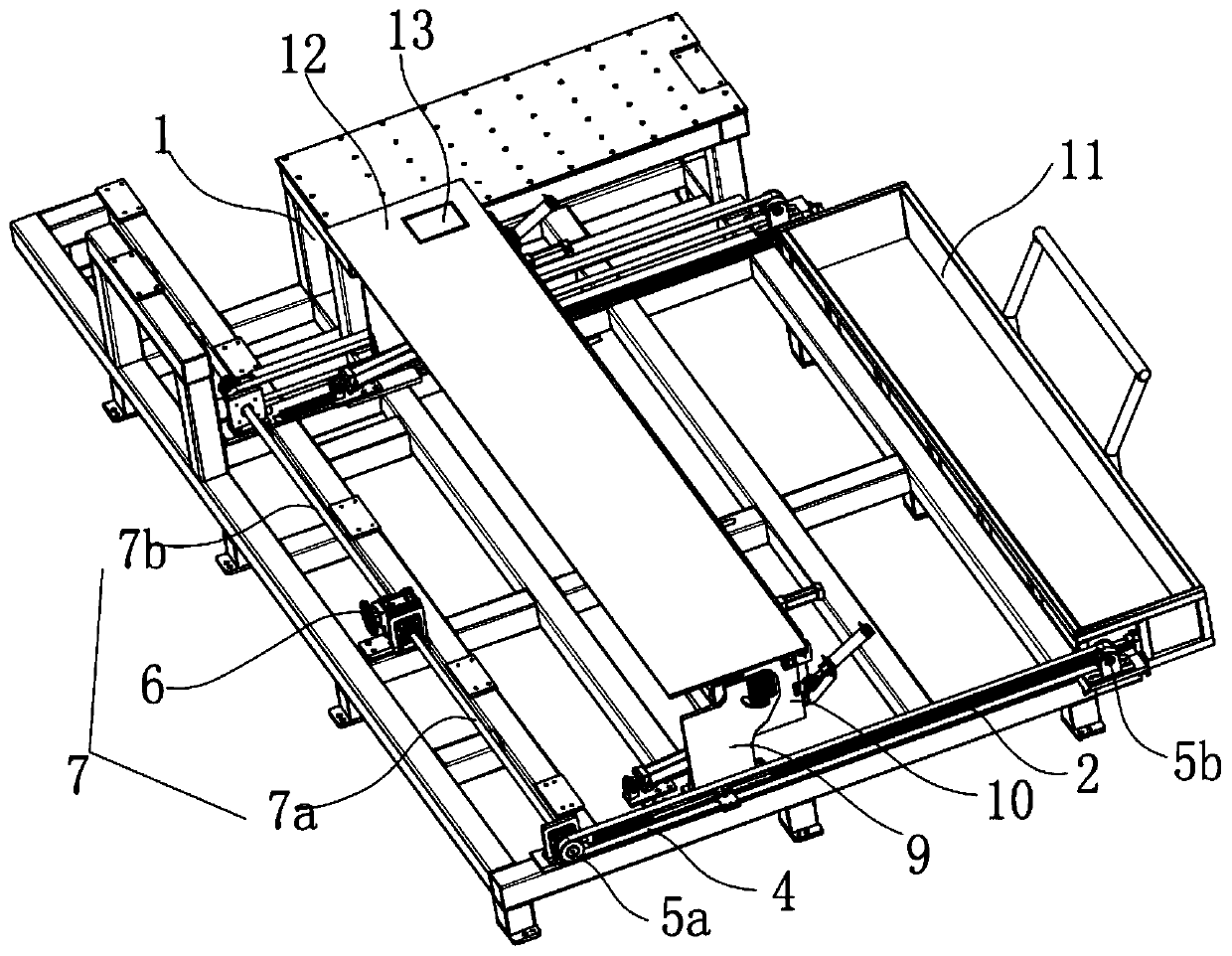

[0063] Such as figure 2 As shown, the numerical control processing equipment of the present invention includes a frame 1, a plate conveying mechanism, and a numerically controlled machine tool 200. The plate conveying mechanism is laid along the frame 1 in a straight line from the plate loading area to be processed to the finished plate blanking Area, the processing area of the CNC processing equipment is located in the middle area between the loading area and the unloading area of the plate conveying mechanism, that is, it is located below the CNC machine tool 200 . Wherein, the plate conveying mechanism includes a feed roller assembly 301 in the feeding area, a guide rail 302 and a clamp 303 arranged parallel to the plate conveying direction, and the clamp 303 is installed on the guide rail 302, so that the clamp 303 can move along the guide rail 302, and during processing During the processing of the plate, the clamp 303 clamps the processed plate 12 and moves the proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com