Efficient preparation process of thickening agent

A preparation process and thickener technology, which are applied in the field of high-efficiency preparation technology of thickeners, can solve the problems of poor air removal effect in the thickener, influence the use effect of the thickener, easy introduction of external air, etc., so as to shorten the total stirring time. Duration, accelerated overflow, good quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

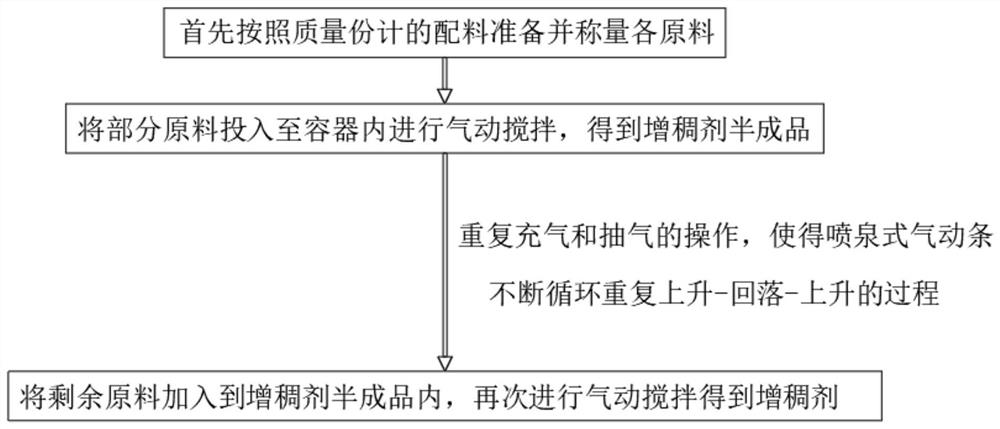

[0044] see figure 1 , a high-efficiency preparation process of a thickener, the thickener includes the following ingredients in parts by mass: 12 parts of polyvinyl alcohol resin, 13 parts of diisocyanate, 11 parts of paraffin wax, 4 parts of antioxidant, 8 parts of dispersant, polyethylene 7 parts of diol, 1.5 parts of chain extender, 2.5 parts of graphene powder, and its preparation process comprises the following steps:

[0045] S1, first prepare and weigh each raw material according to the ingredients in parts by mass;

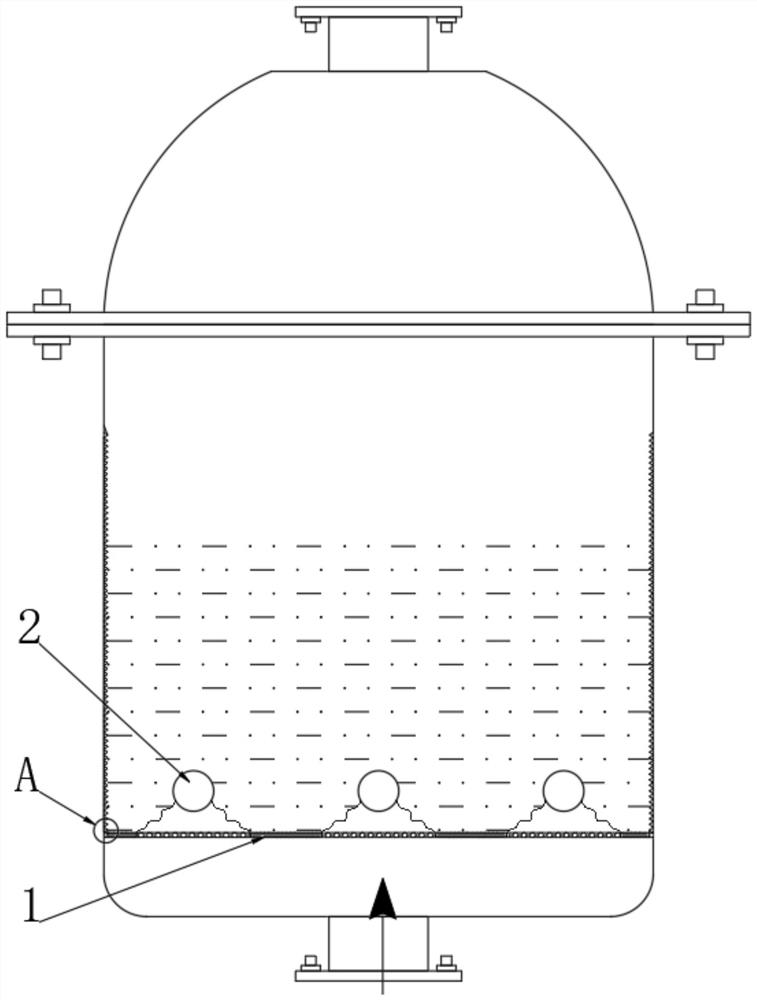

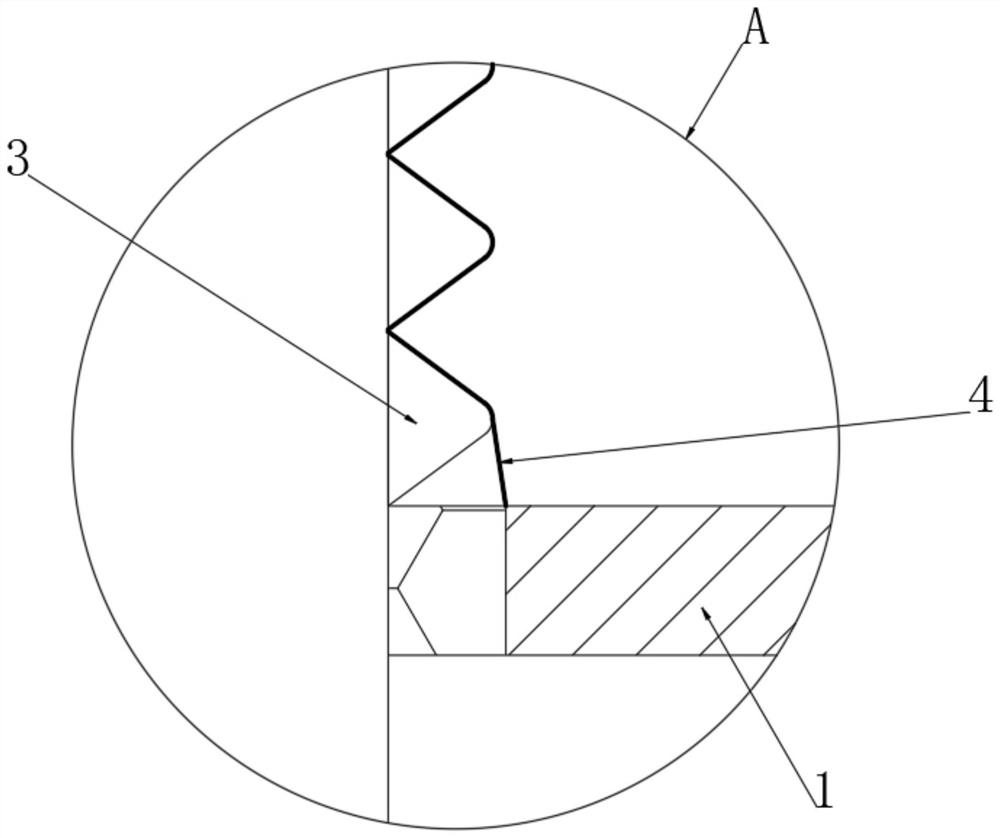

[0046] S2. Remove the chain extender and graphene powder, put other ingredients into the container, and perform pneumatic stirring in a heating environment to obtain a thickener semi-finished product. The pneumatic stirring specifically includes the following operations:

[0047] S21. Quickly inflate air from the bottom of the container, so that the fountain-type pneumatic bar 2 is quickly lifted up;

[0048] S22. Quickly extract the charged gas to make ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com