Beer waste liquid biological treatment method

A technology for biological treatment and beer waste liquid, which is applied in biological water/sewage treatment, food industry waste water treatment, filtration treatment, etc. It can solve the problems of inability to adapt to beer waste liquid, no sewage treatment, etc., to achieve efficient treatment and reduce excessive consumption. , strengthen the effect of separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

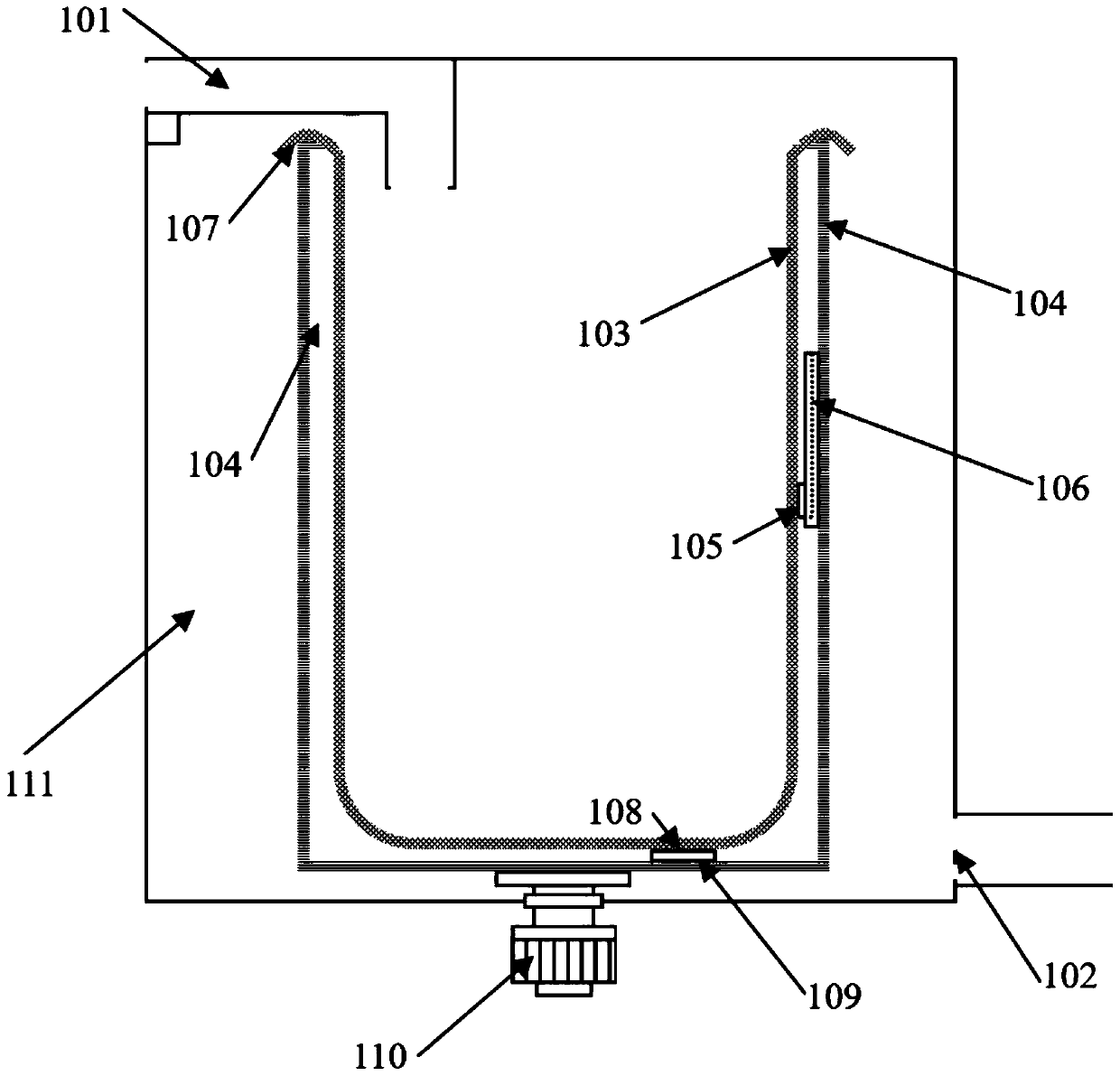

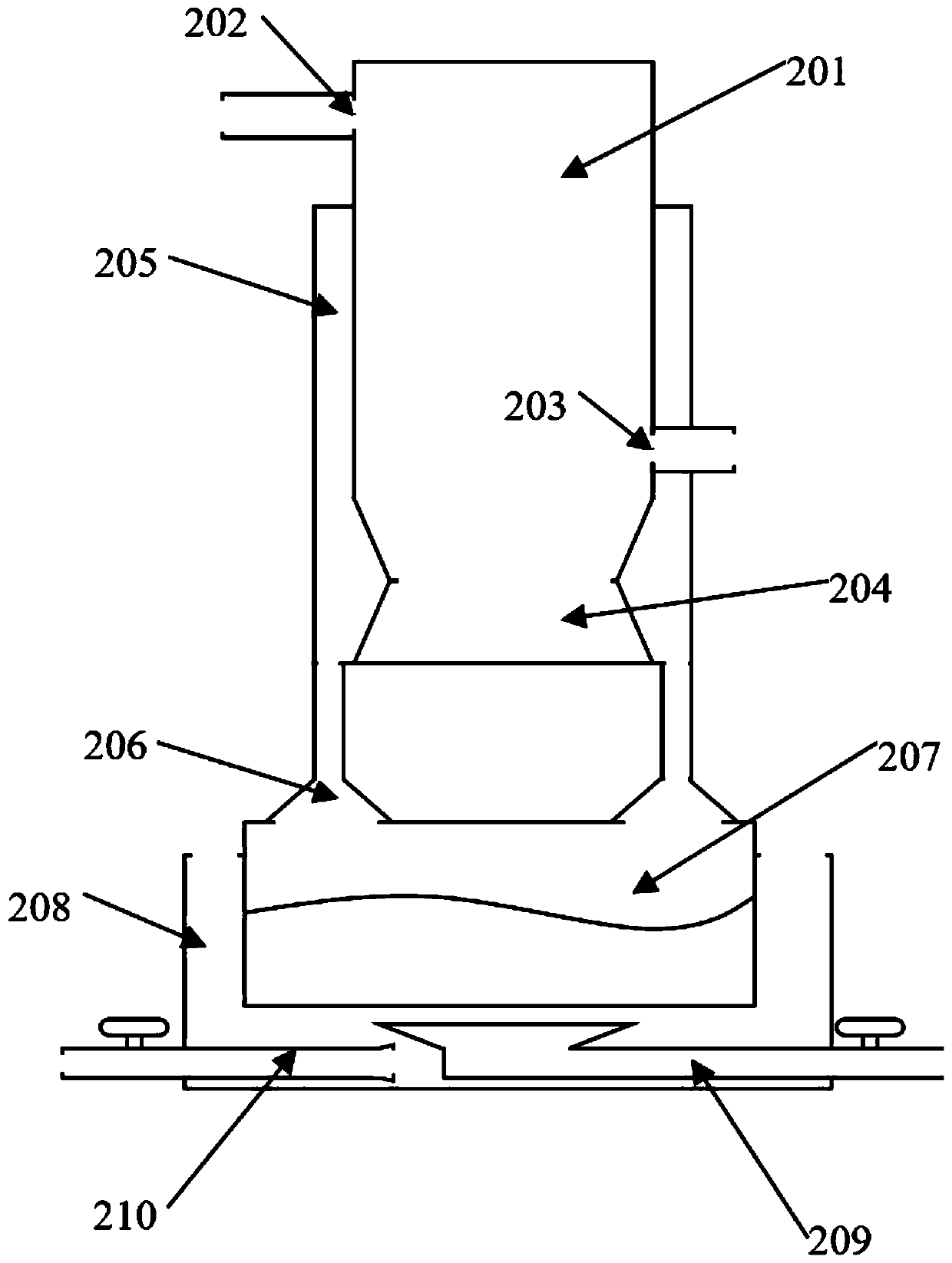

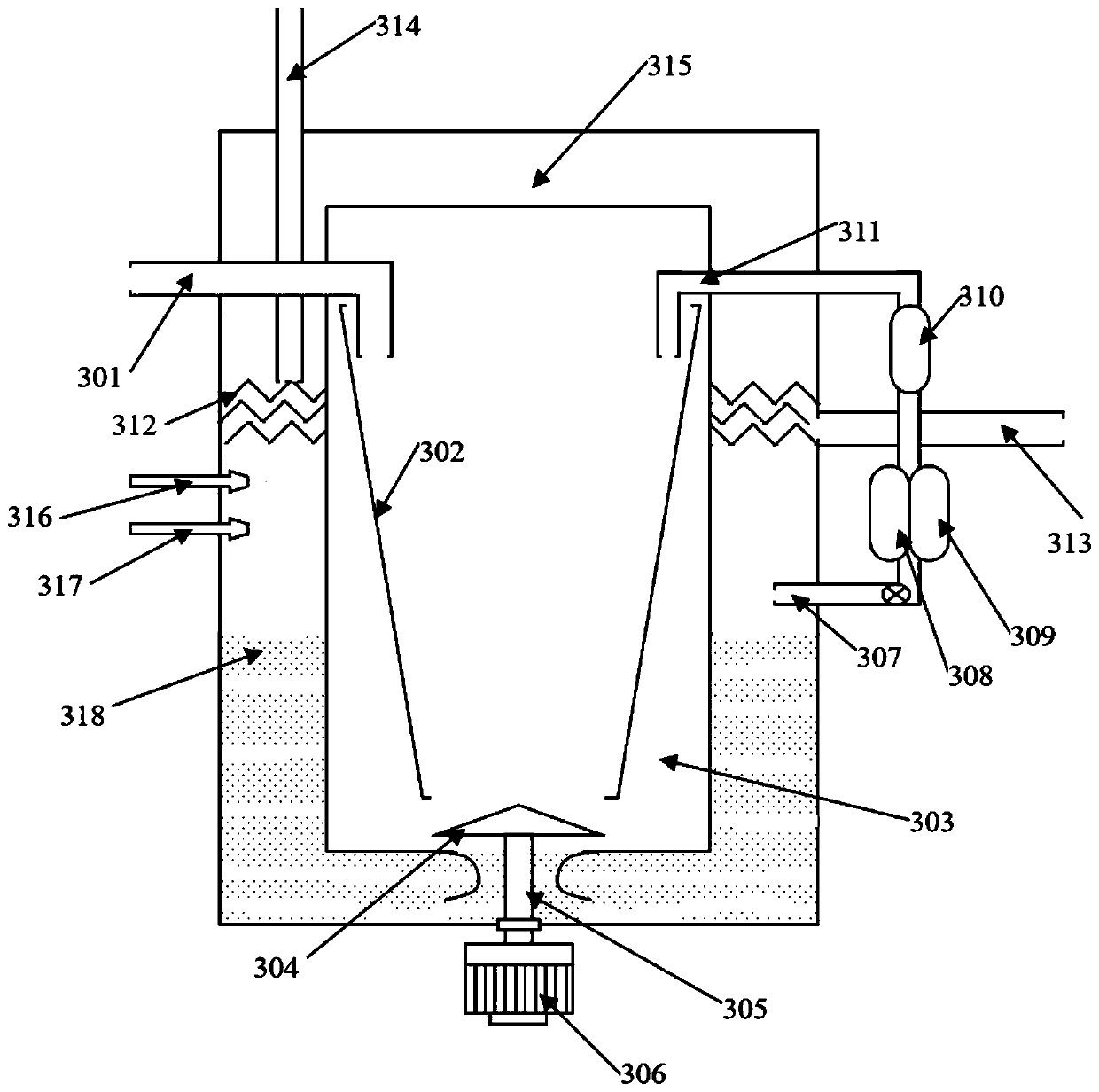

[0041] Further explanation in conjunction with accompanying drawings: as Figure 1 to Figure 8 The shown beer waste liquid biological treatment device, including impurity removal device ( figure 1 ),heating equipment( figure 2 ), anaerobic treatment unit ( image 3 ), biological contact oxidation chamber ( Figure 4 and Figure 6 ), filter adsorption chamber ( Figure 8 ) and membrane bioprocessing chamber ( Figure 7 ).

[0042] The impurity removal device described in this embodiment is provided with two, one is used to pretreat high-concentration waste liquid, and the other is used to treat low-concentration waste liquid. Each of the impurity removal devices includes a liquid inlet pipe 101, Liquid outlet 102 of impurity removal device, inner filter tank 103, outer rotary filter tank 104, inner tank side slider 105, outer tank side slide 106, inner tank top wall 107, inner tank bottom clamping block 108, outer tank bottom Clamping block 109, impurity removal device ...

Embodiment 2

[0050] The difference between this embodiment and embodiment 1 is that, as Figure 5 As shown, the scope of the oxygen-enriched chamber is further expanded to perform oxygen exposure treatment on a part of the first packing frame, that is, the oxygen-enriched chamber can further enable a part of the first packing frame to turn in and out during the rotation process. .

Embodiment 3

[0052] The flow of high-concentration waste liquid in the waste water flow of a brewery is 1000m 3 / day, the flow rate of low-concentration waste liquid is 3000m 3 / day, the beer waste liquid biological treatment method that adopts the beer waste liquid biological treatment device of embodiment 1 to carry out, concrete steps comprise:

[0053] (1) put a figure 1 The inner filter tank of the impurity removal device slides downward in the outer tank side slideway through the inner tank side slider, and the inner filter tank is clamped to the outer rotation through the clamping block at the bottom of the inner tank and the clamping block at the bottom of the outer tank. Inside the filter tank (the clamping block at the bottom of the inner tank and the clamping block at the bottom of the outer tank only limit their position by clamping, and the inner filter tank is not loaded, and the load bearing of the inner filter tank is carried out by the top wall of the inner tank), at thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com