Environment-friendly industrial sewage rapid acidification treatment device

A technology for industrial sewage and acidification treatment, applied in anaerobic digestion treatment, grain treatment and other directions, can solve the problems of inability to stir, discharge sewage can not be evenly discharged, and the overall treatment effect is not very good, and achieves convenient and economical manual operation. human effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

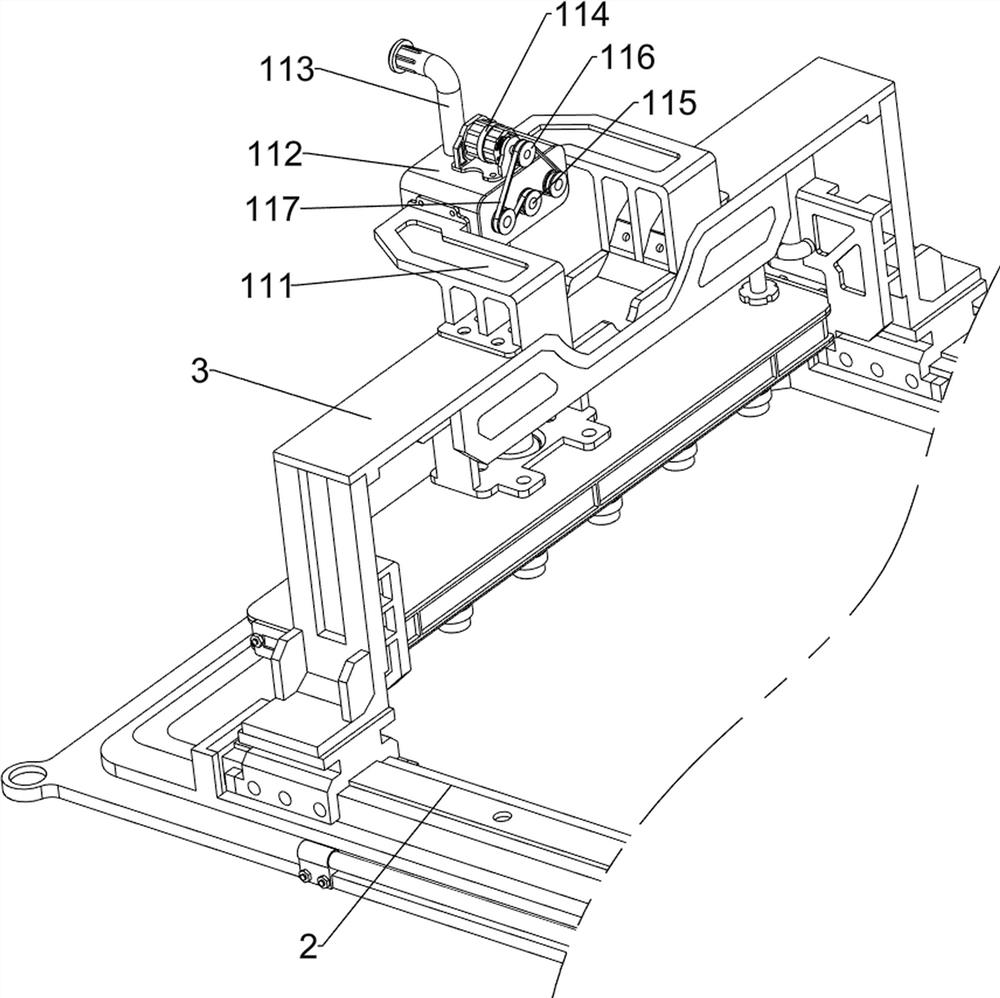

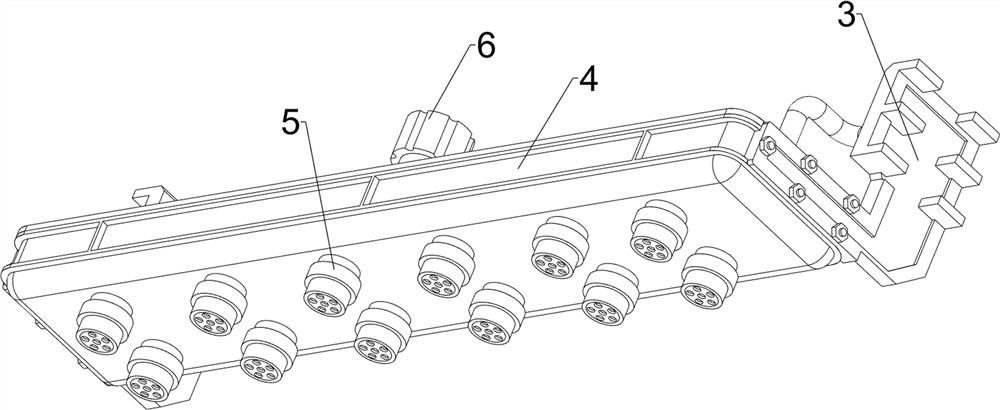

[0042] An environmentally friendly industrial sewage rapid acidification treatment device, such as Figure 1-8 As shown, it includes a first mounting seat 1, a rodless cylinder 2, a connecting frame 3, a first water tank 4, a spray head 5, a first connecting pipe 6, a water pump 7, a communication pipe 8, a sliding assembly 9 and a rotating assembly 10. A rodless cylinder 2 is installed on the top, front and rear sides of a mounting seat 1, a connecting frame 3 is connected between the piston parts of the rodless cylinder 2 on both sides, and a first water tank 4 is connected to the lower part of the connecting frame 3, and the bottom of the first water tank 4 The left and right sides are connected with a plurality of nozzles 5 at even intervals. The nozzles 5 are used to spray out sewage. The nozzles 5 on both sides are symmetrically arranged. The top of the first water tank 4 is connected with a first connecting pipe 6 in the middle. A water pump 7 is installed in the middle...

Embodiment 2

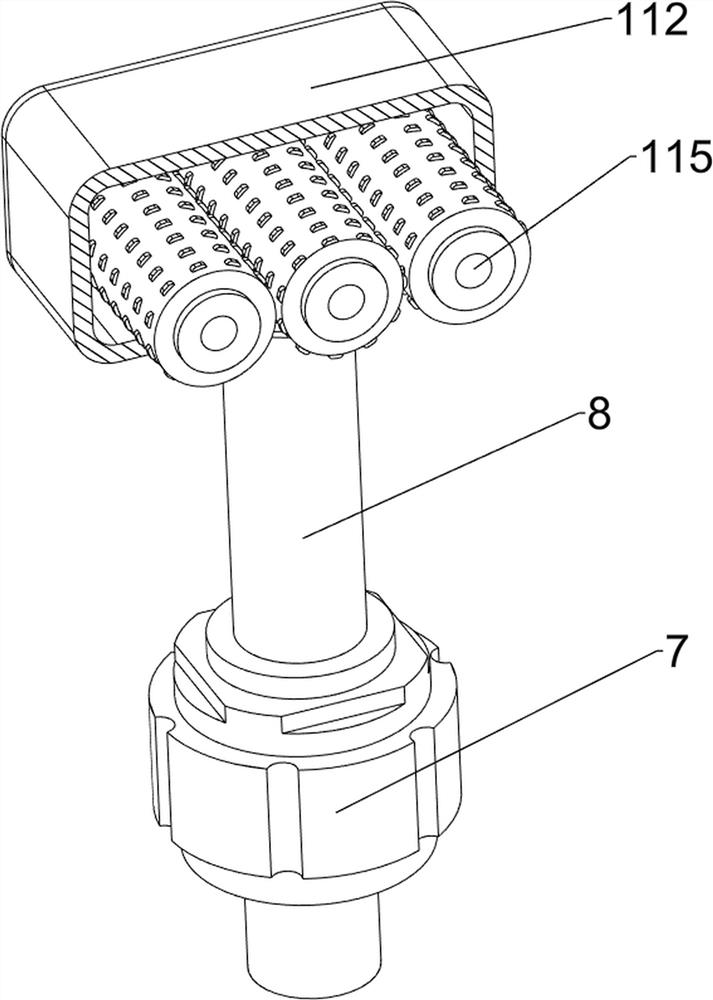

[0048] On the basis of Example 1, as figure 1 , 9 , Figure 10 , Figure 11 , Figure 12 and Figure 13 As shown, it also includes a crushing component 11, which is used to crush the agglomerated impurities doped in the sewage, and the crushing component 11 includes a second mounting seat 111, a second water tank 112, a second connection The pipe 113, the drive motor 114, the toothed roller 115, the first pulley 116 and the first flat belt 117, the top of the connecting frame 3 is connected with a second mounting seat 111, the second mounting seat 111 is connected with a second water tank 112, and the communication pipe 8 Connected to the second water tank 112, the communication pipe 8 is communicated with the inside of the second water tank 112, the top of the second water tank 112 is connected with a second connecting pipe 113, the top of the second water tank 112 is installed with a driving motor 114, and the driving motor 114 is located in the second connecting pipe O...

Embodiment 3

[0053] On the basis of Example 2, as figure 1 , Figure 14 , Figure 15 , Figure 16 and Figure 17 As shown, a blocking component 13 is also included, and the blocking component 13 is used to block the nozzle 5. The blocking component 13 includes a connecting frame 131, a support plate 132 and a rubber plate 133. The top left side of the first mounting seat 1 is connected with a The connection frame 131 is connected with a support plate 132 , the top of the support plate 132 is connected with a rubber plate 133 , and the top of the rubber plate 133 is in contact with the bottom of the nozzle 5 .

[0054] In the initial state, the rubber plate 133 can block the bottom of the spray head 5 to prevent the spray head 5 from spraying water. When the spray head 5 is no longer in contact with the rubber plate 133, the spray head 5 can spray water, thereby preventing the spray head 5 from spraying water. When the sewage is sprayed, the sewage is sprayed on the edge of the hydrolys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com