System and method for purifying carbon dioxide

A carbon dioxide and adsorption tower technology, applied in the field of carbon dioxide purification systems, can solve the problems of the development and separation process of special membrane materials being in the development stage, the processing of chemical materials is difficult, and it is difficult to put into practical application, etc., to achieve high practical application value and ensure continuous processing. , the effect of promoting removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

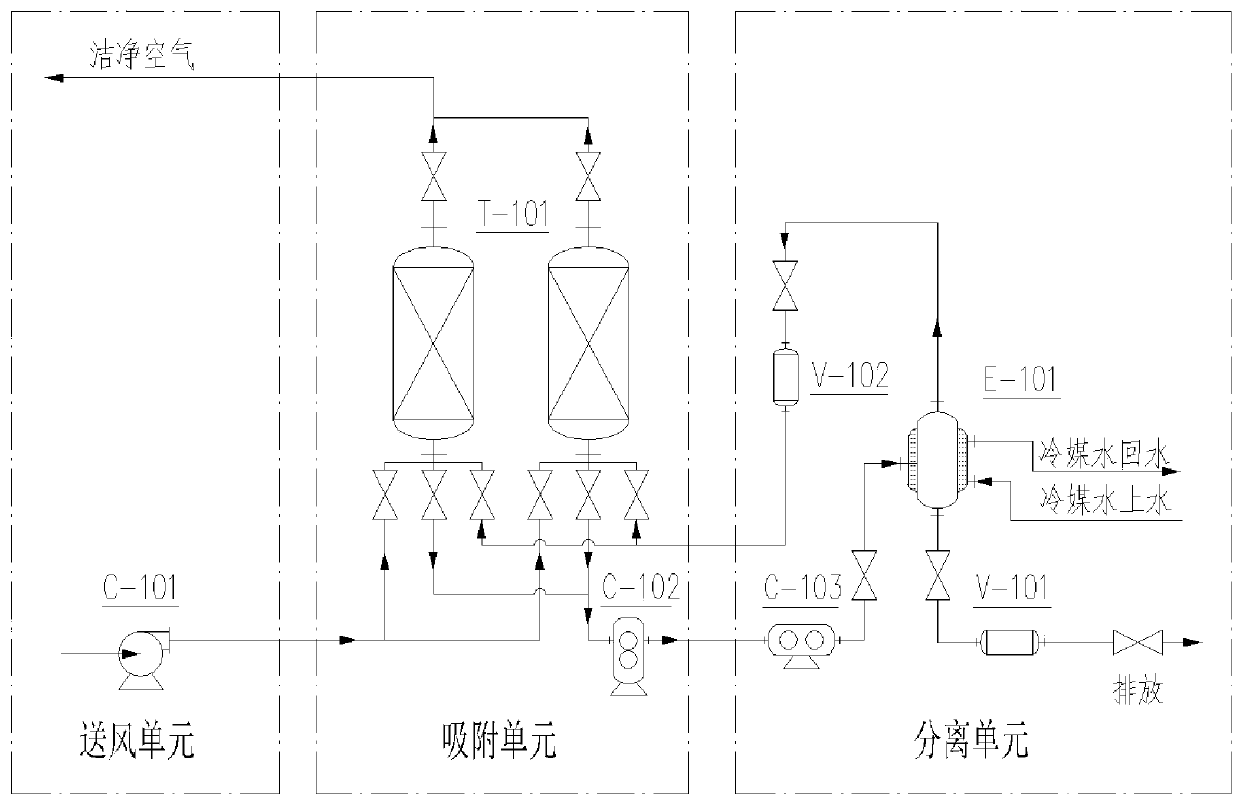

[0110] This embodiment provides a system for purifying carbon dioxide, the system includes an air supply unit, a microwave absorption and desorption unit, a separation unit and a control system connected in sequence;

[0111] The air supply unit includes: a centrifugal fan connected to the microwave absorption and desorption unit and an exhaust pipeline system respectively connected to the microwave absorption and desorption unit and the separation unit. valve;

[0112] The microwave adsorption and desorption unit includes: 8 adsorption towers arranged side by side with a total weight of 12kg and uniformly mixed 13x molecular sieve and ZSM-5 molecular sieve in a mass ratio of 2:1, and the upper end of the adsorption tower is connected to the air supply unit In the exhaust pipe system, the lower end is provided with the first branch, the second branch and the third branch, the first branch is connected with the air induction device in the air supply unit, and the second branch ...

Embodiment 2

[0116] This embodiment provides a system for purifying carbon dioxide. In the system, "the opening width of the rectangular waveguide gradually changes from 2.0mm to 4.0mm from top to bottom" is replaced by "the opening width of the rectangular waveguide increases from top to bottom". From 1.0mm to 6.0mm, all the others are the same as in Example 1.

Embodiment 3

[0118] This embodiment provides a system for purifying carbon dioxide. In the system, "the width of the opening of the rectangular waveguide gradually changes from 2.0mm to 4.0mm from top to bottom" is replaced by "the width of the opening of the rectangular waveguide is 0.5mm". mm", the rest are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com