Electroplating effluent recycling device and processing method thereof

A technology for electroplating wastewater and treatment method, which is applied in the fields of metallurgical wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can achieve the effect of realizing resource reuse, strong versatility and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

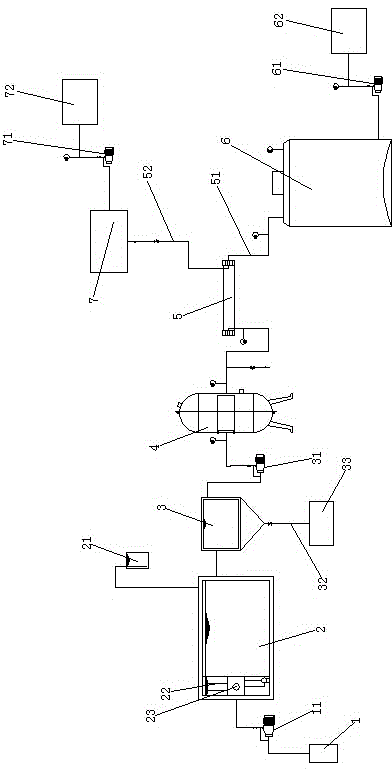

Image

Examples

Embodiment 1

[0040] A treatment method for electroplating wastewater recycling equipment, comprising the following steps:

[0041] Step 1: the electroplating wastewater in the wastewater storage tank 1 is pumped into the flocculation tank 2 under the action of the self-priming pump 11;

[0042] Step 2: In the flocculation tank 2, add a flocculant (polyglutamic acid of 2 g / L) through the flocculant dosing machine 21, and stir for 1 to 2 minutes to form a mixture, and send the mixture into the sedimentation tank 3;

[0043] Step 3: The mixture is precipitated in the sedimentation tank 3, the sediment is deposited in the lower part of the sedimentation tank 3, the liquid floats on the upper layer of the sediment, and the upper liquid is pumped into the quartz sand filter 4 for filtration;

[0044] Step 4: The filtered liquid is sent to the reverse osmosis membrane treatment equipment 5, the pure water outside the reverse osmosis membrane is sent to the pure water tank 6 through the pure water...

Embodiment 2

[0048] A treatment method for electroplating wastewater recycling equipment, comprising the following steps:

[0049] Step 1: the electroplating wastewater in the wastewater storage tank 1 is pumped into the flocculation tank 2 under the action of the self-priming pump 11;

[0050] Step 2: In the flocculation tank 2, add a flocculant (6g / L polyacrylamide) through the flocculant dosing machine 21, and stir for 1 to 2 minutes to form a mixture, and send the mixture into the sedimentation tank 3;

[0051] Step 3: The mixture is precipitated in the sedimentation tank 3, the sediment is deposited in the lower part of the sedimentation tank 3, the liquid floats on the upper layer of the sediment, and the upper liquid is pumped into the quartz sand filter 4 for filtration;

[0052] Step 4: The filtered liquid is sent to the reverse osmosis membrane treatment equipment 5, the pure water outside the reverse osmosis membrane is sent to the pure water tank 6 through the pure water pipe 5...

Embodiment 3

[0056] A treatment method for electroplating wastewater recycling equipment, comprising the following steps:

[0057] Step 1: the electroplating wastewater in the wastewater storage tank 1 is pumped into the flocculation tank 2 under the action of the self-priming pump 11;

[0058] Step 2: In the flocculation tank 2, add a flocculant (6g / L dehydrated polyferric sulfate) through the flocculant dosing machine 21, and stir for 1 to 2 minutes to form a mixture, and send the mixture into the sedimentation tank 3;

[0059] Step 3: The mixture is precipitated in the sedimentation tank 3, the sediment is deposited in the lower part of the sedimentation tank 3, the liquid floats on the upper layer of the sediment, and the upper liquid is pumped into the quartz sand filter 4 for filtration;

[0060] Step 4: The filtered liquid is sent to the reverse osmosis membrane treatment equipment 5, the pure water outside the reverse osmosis membrane is sent to the pure water tank 6 through the pure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com