Removing device for COD in high-concentration alkaline wastewater

A high-concentration alkali and wastewater technology, applied in water/sewage treatment, water treatment parameter control, neutralized water/sewage treatment, etc., can solve problems such as difficult combustion, decreased filtration efficiency, and smaller filter gaps in the filter cake layer. Achieve the effects of ensuring continuous processing, delaying the decline in filtration efficiency, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

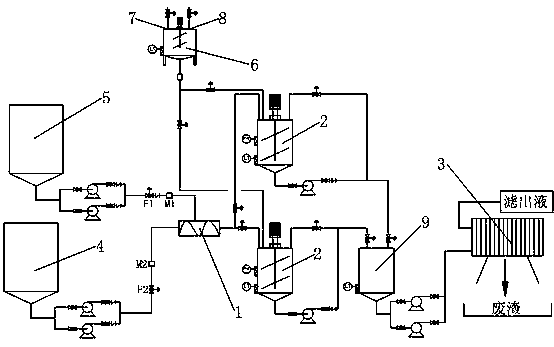

[0017] This embodiment proposes a COD removal device in highly concentrated alkaline wastewater, such as figure 1 As shown in the structure, the COD removal device includes an acid-base neutralization device 1, a reaction tank 2 and a filter press 3 connected in sequence, and the acid-base neutralization device 1 is connected with an alkaline waste water collection tank 4 and a plasticized water collection tank 5 , The reaction tank 2 is provided with a flocculant preparation tank 6, and the flocculant preparation tank 6 is provided with a flocculant inlet 7 and a carbon particle inlet 8.

[0018] In this embodiment, the acid-base neutralization equipment 1 adopts a static mixer, and a flow meter M1 and a regulating valve F1 are arranged on the connecting pipeline between the plasticized water collection tank 5 and the static mixer, and the connection between the alkaline waste water collection tank 4 and the static mixer A flow meter M2 and a regulating valve F2 are arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com