Continuous garbage treatment device

A waste disposal device, continuous technology, applied in grain processing, presses, manufacturing tools, etc., can solve problems such as low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

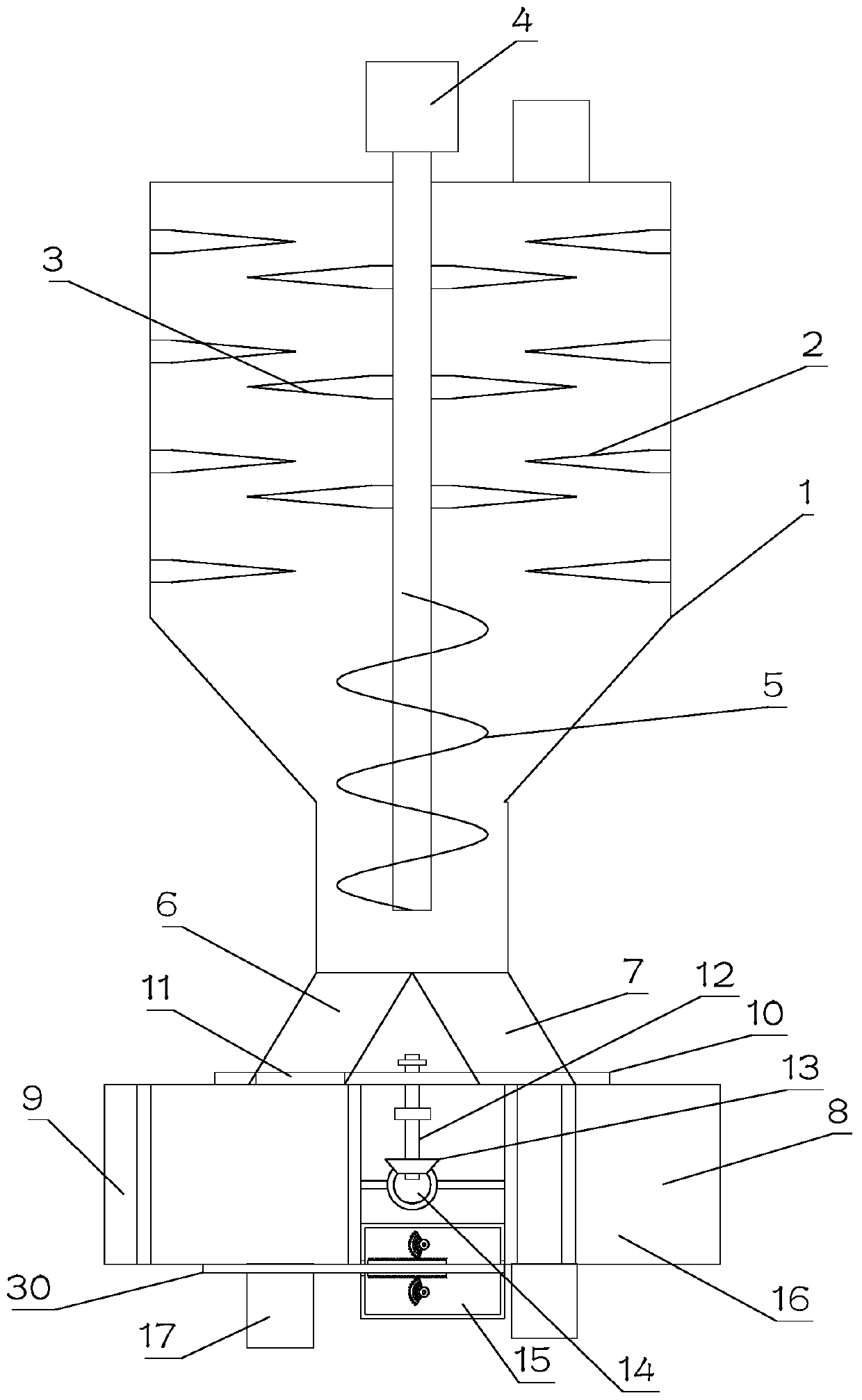

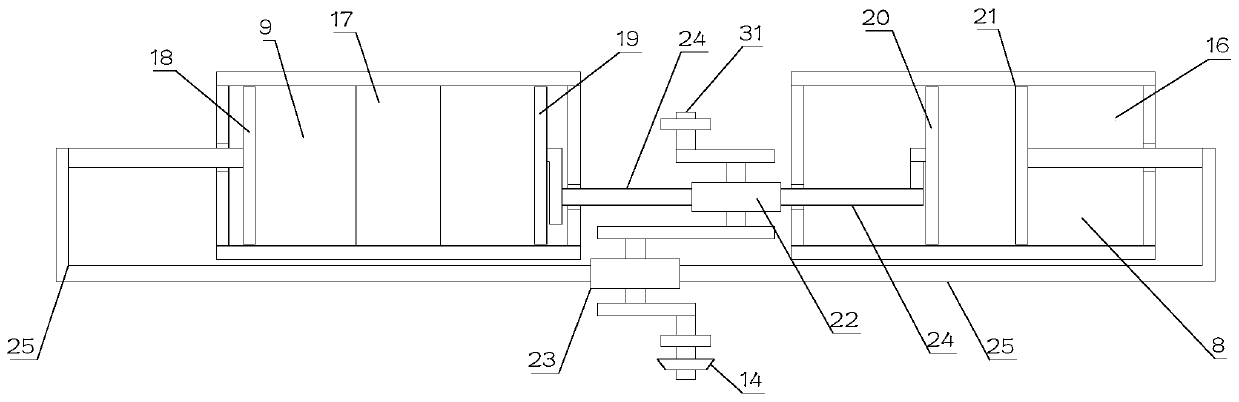

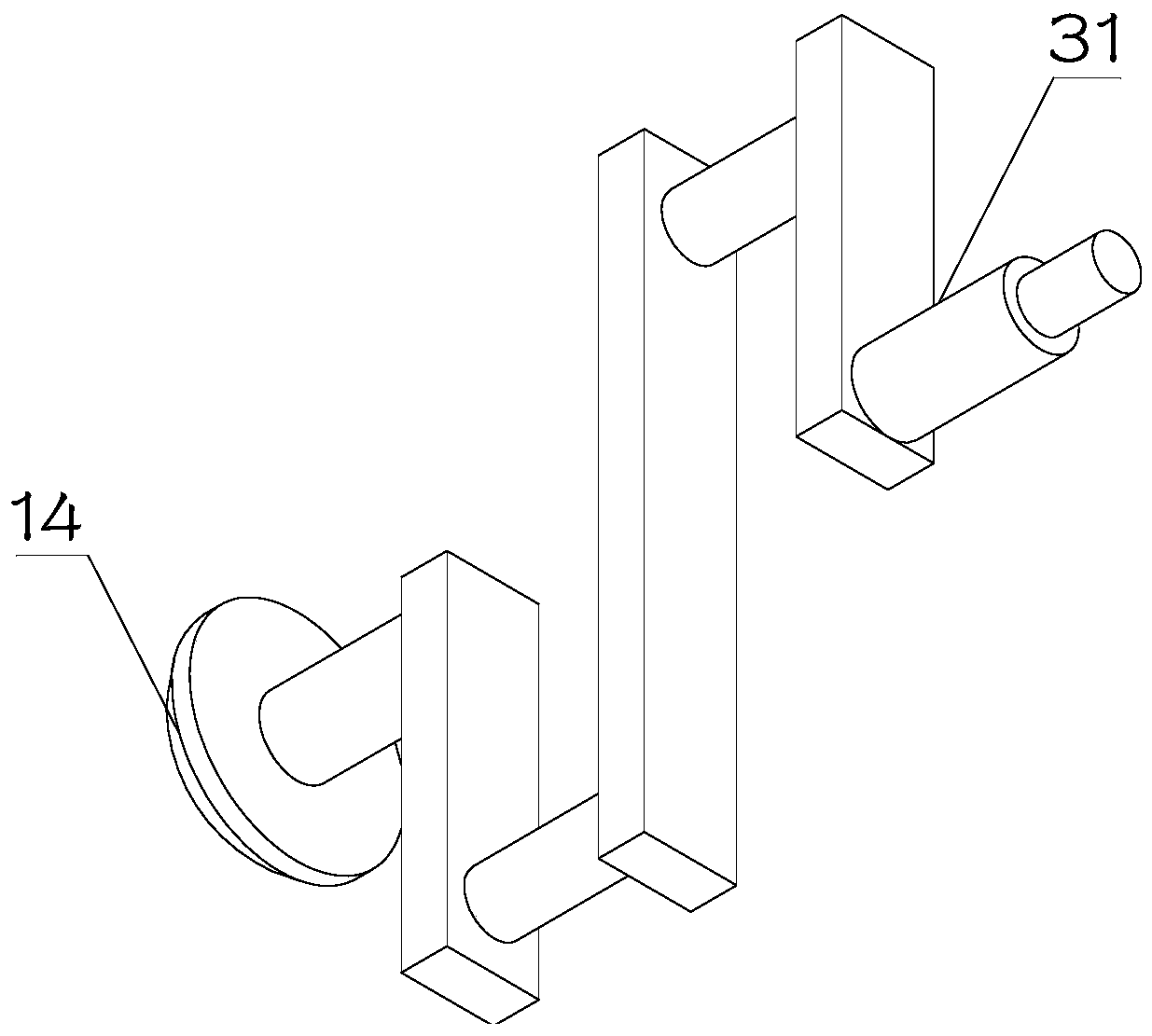

[0022] See Figure 1~3 , In the first embodiment of the present invention, a continuous garbage disposal device includes a crushing body 1, and the bottom outlet of the crushing body 1 is provided with an A conveying pipe 6 and a B conveying pipe 7 communicating with it. A ram plate 10 is arranged at the bottom of A feed pipe 6 and B feed pipe 7, and A ram plate 10 is provided with a through hole 11 for controlling the on and off of A feed pipe 6 and B feed pipe 7. The outlets of the A feed pipe 6 and the B feed pipe 7 are respectively communicated with the B compacting cavity 9 and the A compacting cavity 8 inside the compression assembly 16; the A gate plate 10 is rotatably mounted on the compression assembly 16; A compacting cavity 8 is provided with a C pressure plate 20 and a D pressure plate 21 that are matched with each other, and the B compacting cavity 9 is provided with a mutually matched A pressure plate 18 and a B pressure plate 19, and the crankshaft 31 is rotatably...

Embodiment 2

[0025] See Figure 1~5 The main difference between this embodiment 2 and embodiment 1 is that the crushing body 1 is provided with a B rotating shaft, the B rotating shaft is fixedly provided with B crushing teeth 3, and the inner wall of the crushing body 1 is provided with a B crushing tooth 3 Cooperate with broken A crushing teeth 2; the upper part of the B rotating shaft is fixedly installed at the output end of A motor 4; setting A crushing teeth 2 and B crushing teeth 3 is convenient for crushing garbage.

[0026] The crushing body 1 is provided with a feeding port.

[0027] A conveyor auger 5 is fixedly arranged at the bottom of the B rotating shaft, and the conveyor auger 5 is arranged to facilitate the squeezing of the garbage after the crushing, and ensure the continuous discharge of the garbage.

[0028] The A shaft 12 is fixedly installed in the middle position of the A gate 10, the A shaft 12 is rotatably mounted on the compression assembly 16, and the A bevel gear 13 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com