Car lamp intelligent assembly production line and production process

A technology for assembling production lines and car lights, which is used in the direction of testing the alignment of automobile headlights, measuring devices, and testing optical performance, etc. Ensure the effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

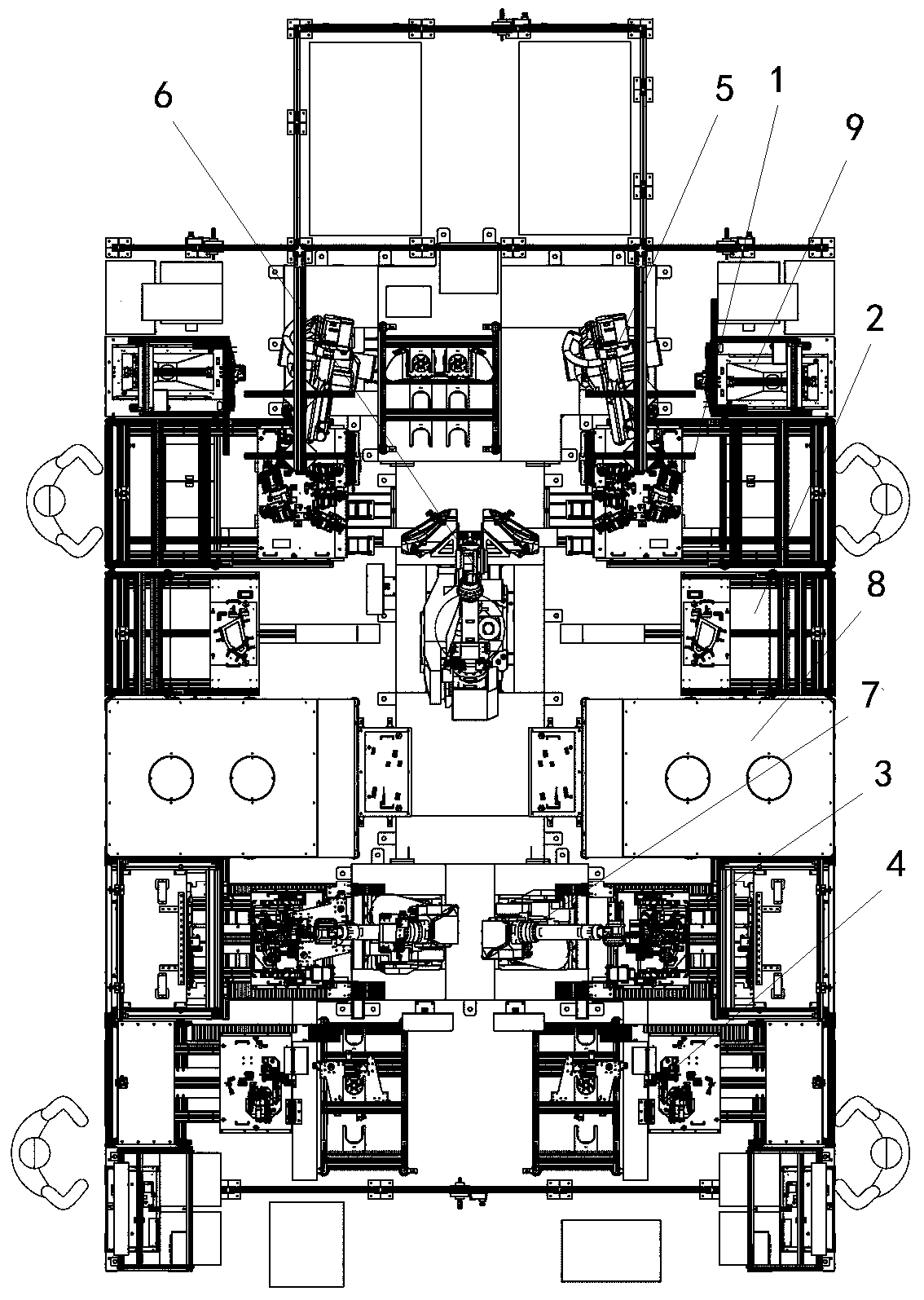

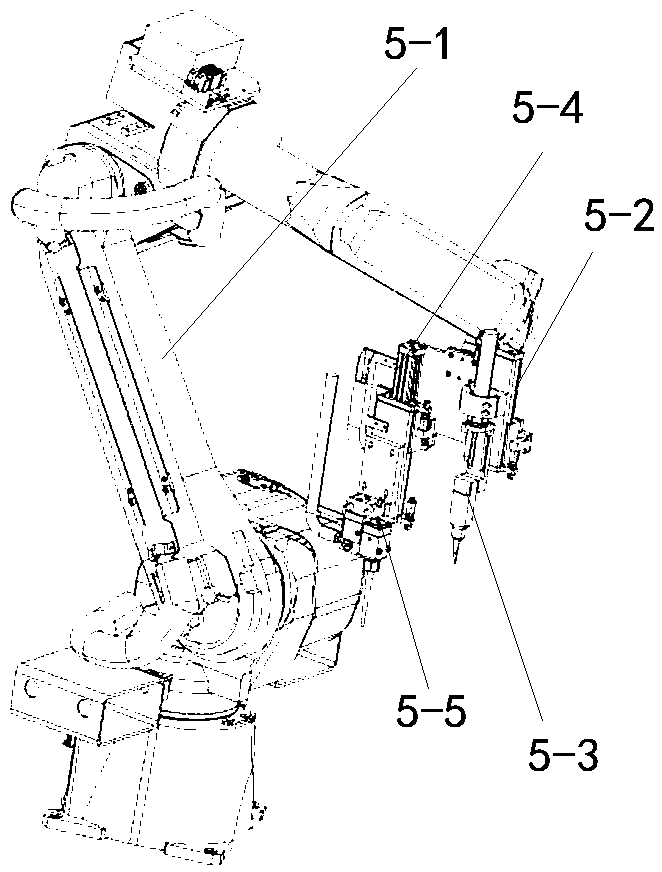

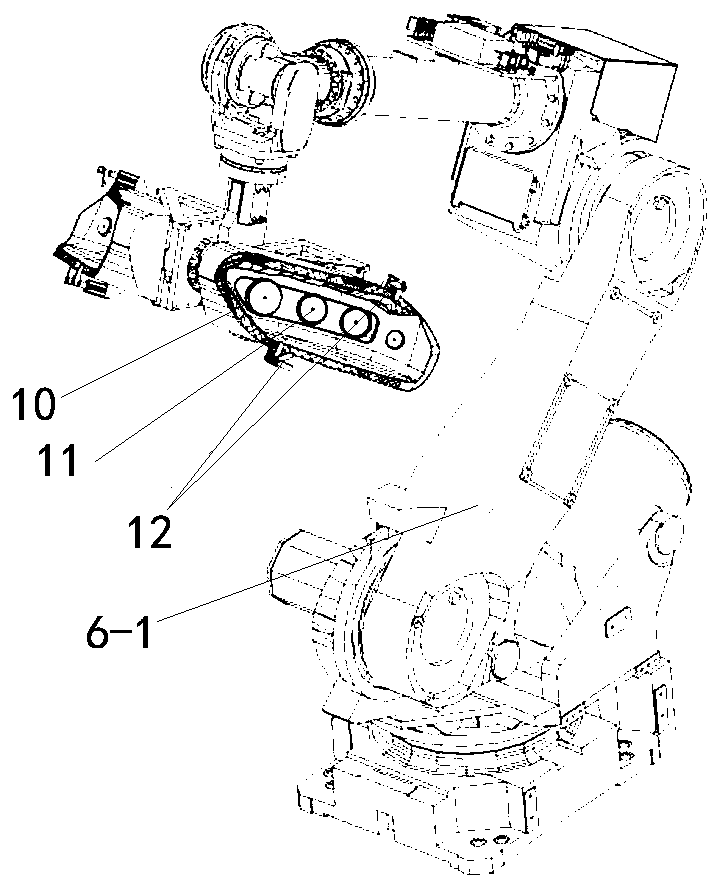

[0037] See Figure 1 to Figure 15 As shown, an intelligent assembly production line for automobile lamps, which includes a mask fastening station 1, a mask feeding station 2, a light pattern detection station 3, an air-tight detection station 4, a gluing robot mechanism 5, a first gripper Picking robot mechanism 6, second grasping robot mechanism 7, dust removal station 8 and glue drying station 9, in order to realize simultaneous assembly of left and right lights, mask fastening station 1, mask feeding station 2, light pattern detection Station 3, airtight detection station 4, gluing robot mechanism 5, second grasping robot mechanism 7, dust removal station 8 and glue airing station 9 are symmetrically arranged in two, and the first grasping robot mechanism 6 is used for The transfer of the mask between the mask feeding station 2 and the mask fastening station 1 is used for the transfer of the lamp between the mask fastening station 1 and the glue drying station 9, and the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com