Electromagnet composite electrolysis type polishing device for inner wall of non-magnetic-conductive metal pipe and process

A polishing device, electrolytic polishing technology, applied in metal processing equipment, machine tools suitable for grinding the edges of workpieces, electrolytic processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below, but the implementation scope of the present invention is not limited to the following embodiments.

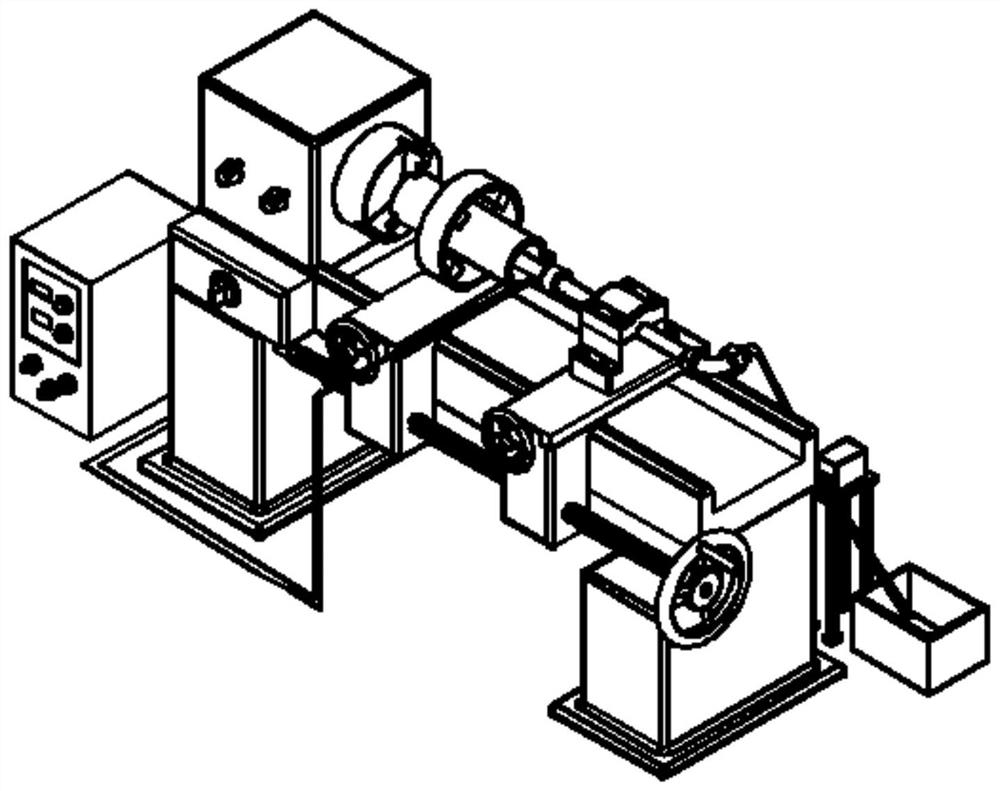

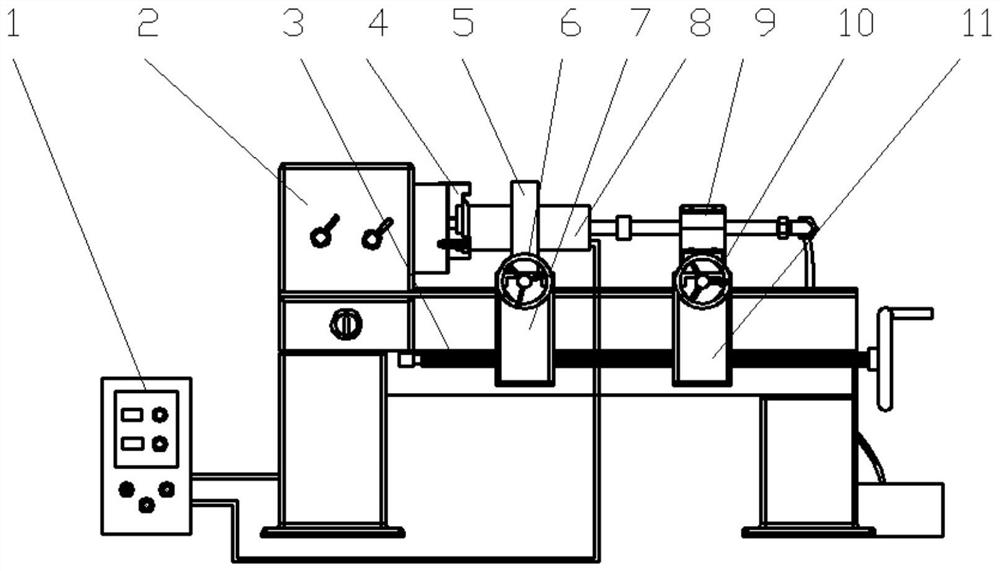

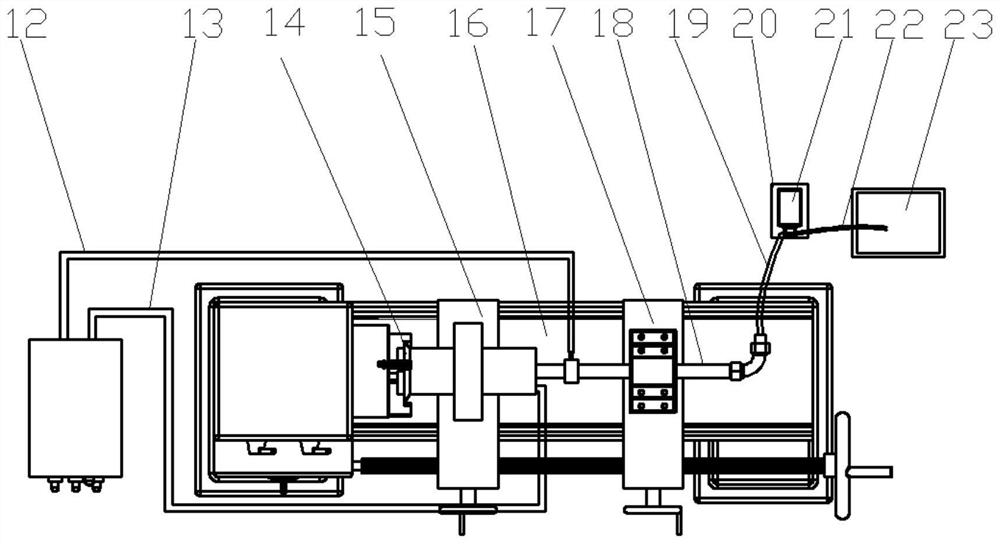

[0028] Such as Figure 1-Figure 6 As shown, an electromagnet composite electrolysis polishing device for the inner wall of a non-magnetic metal pipe includes a machine tool 2, an electromagnet grinding device, and an electrolytic polishing device. The electromagnet 25 on the electromagnet grinding device is set outside the workpiece 8 , and can be driven by the first sliding table 15 on the machine tool 2 to move axially along the workpiece 8, the electrolyte in the electrolytic polishing device is sent into the interior of the workpiece 8 through the hollow copper tube 18, and the hollow copper tube 18 can pass through the machine tool The second sliding table 17 on the 2 is driven to move axially along the workpiece 8.

[0029] The machine tool 2 is equipped with an electromagnet grinding device and an electroly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com