Method for measuring torsion shaft rolling characteristic parameter by using laser displacement sensor

A technology of laser displacement and characteristic parameters, applied in measurement devices, optical devices, instruments, etc., can solve problems such as being unsuitable for the measurement requirements of torsion shaft rotating workpieces, improve measurement efficiency and measurement accuracy, and have a simple and easy structure. The effect of automation and intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

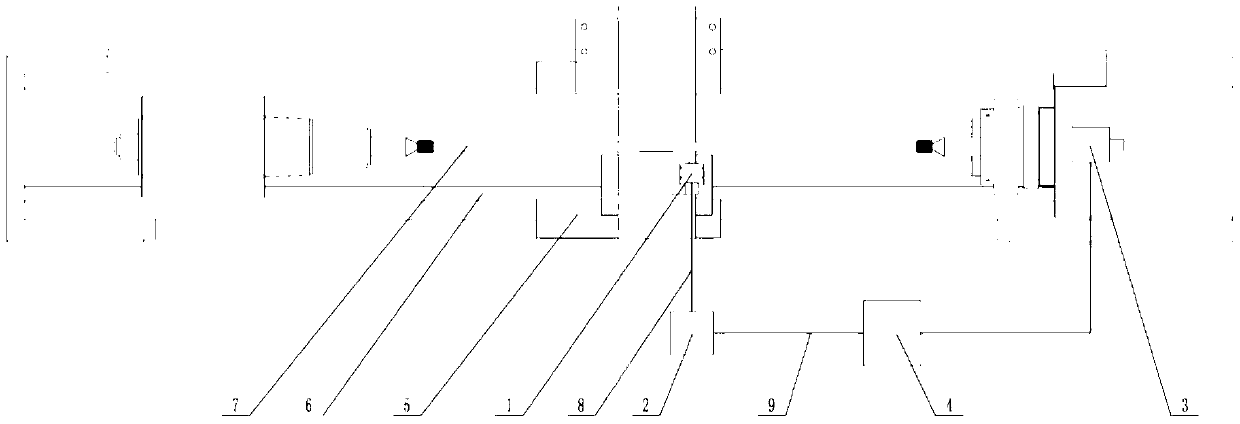

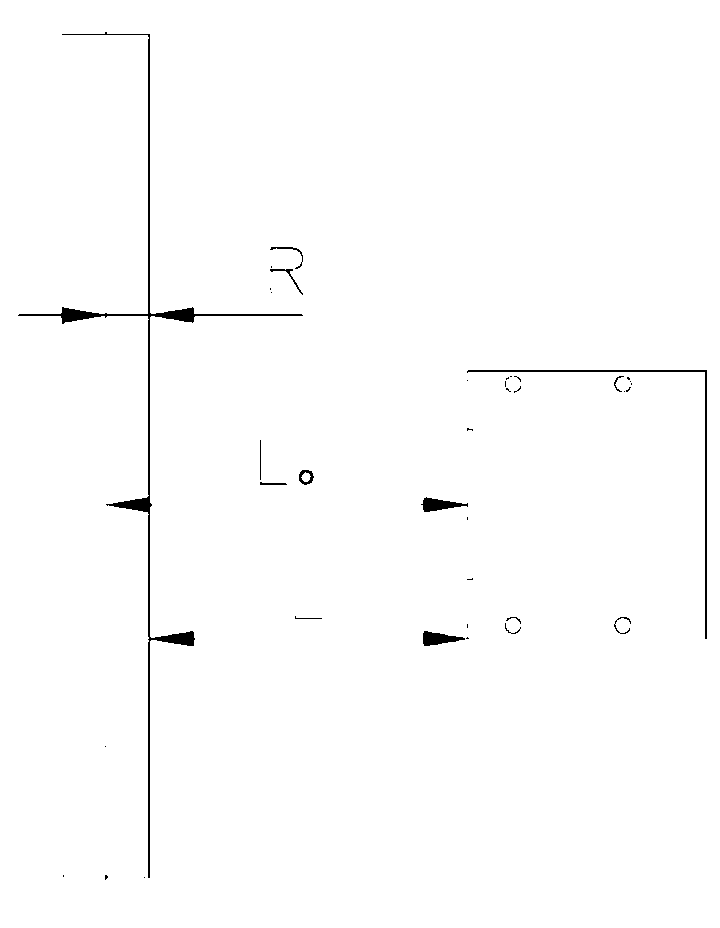

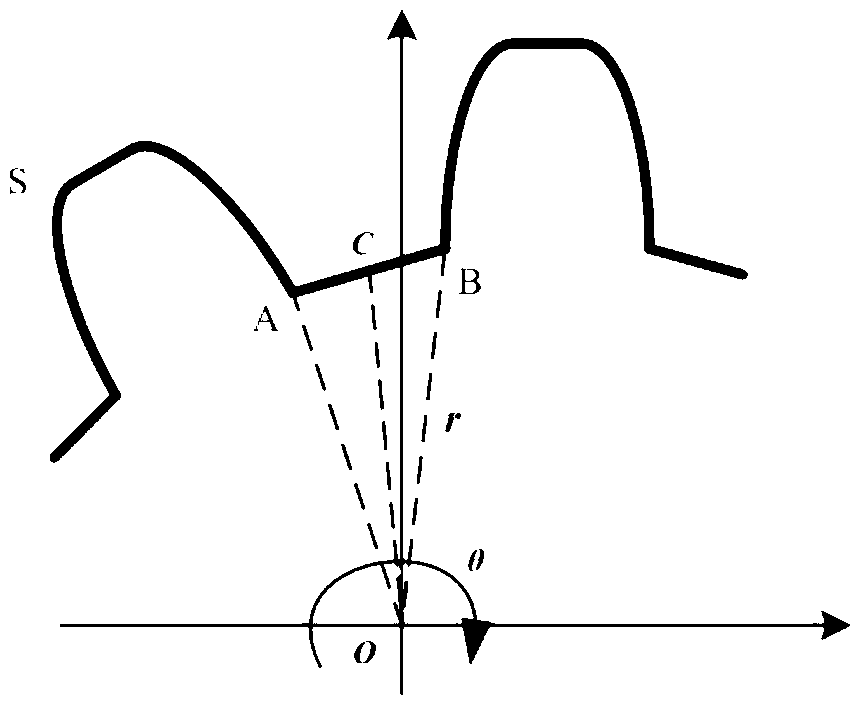

[0020] The present invention is implemented according to the method steps specified in the technical solution, wherein, in the measuring device established in the first step, the laser displacement sensor adopts the LK-H050 laser displacement sensor of Keyence Corporation of Japan, and the data acquisition card adopts its supporting products , The encoder is an EMICON encoder, the model is NOC-SP10000-2MD-500, and the industrial computer is Advantech's industrial computer IPC610H. The laser displacement sensor is fixed on the machine tool pallet through the installation device, and can reciprocate along the direction of the machine tool guide rail. The laser displacement sensor is connected to the data acquisition card through the first data transmission line, and the data acquisition card is connected to the industrial computer through the second data transmission line to measure data. The laser displacement sensor is transmitted to the data acquisition card, and then transmit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com