Circulating mother liquor feeding device for producing aluminum oxide and feeding method

A technology of circulating mother liquor and feeding device, which is applied in the direction of alumina/aluminum hydroxide, can solve the problems of complicated preparation of the blending and mixing tank, increased flow of circulating mother liquor, and increased operating costs, so as to reduce the number of power equipment, The effect of simplifying the process and reducing the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

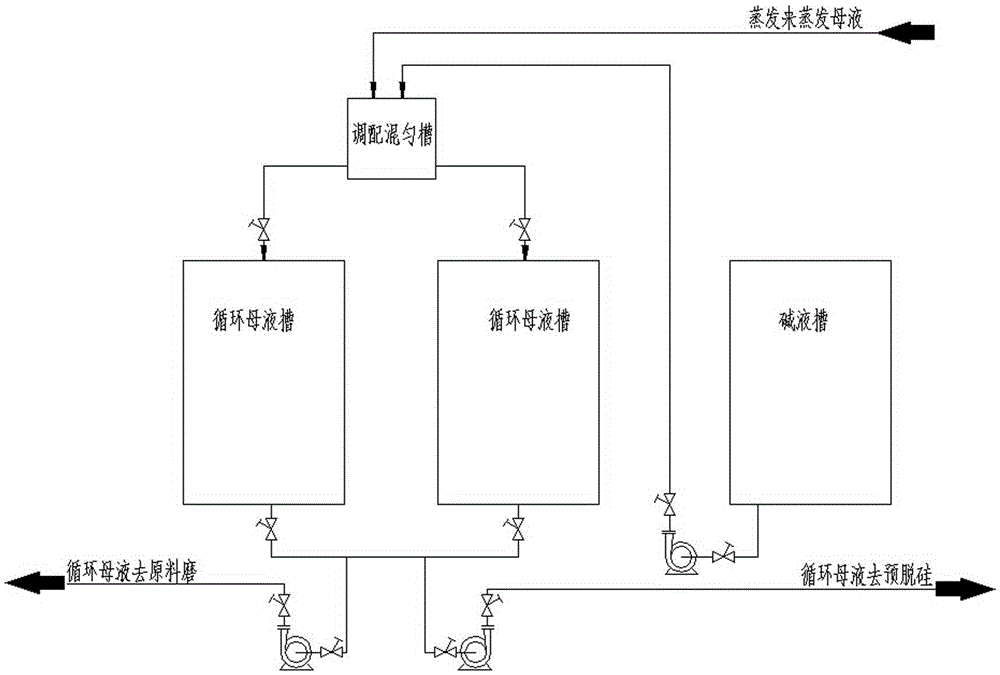

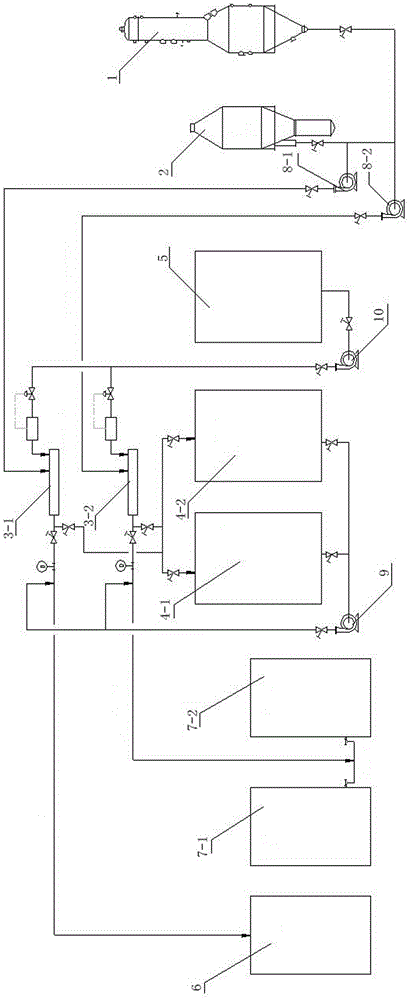

[0021] The alumina production circulating mother liquor feeding device of the present embodiment is as follows: figure 2 As shown, the specific example is an evaporation station with a V-effect evaporator, a IV-level self-evaporator, two circulating mother liquor tanks, and two desiliconization tanks.

[0022] The aluminum oxide production cycle mother liquor feeding device in this embodiment includes a V-effect evaporator 1, a IV-stage self-evaporator 2, a first static mixer 3-1, a second static mixer 3-2, and two circulating mother liquor tanks 4 -1 and 4-2, lye tank 5, mother liquor tank 6 and two desilication tanks 7-1 and 7-2;

[0023] Wherein the IV level self-evaporator 2 is connected with the V-effect evaporator 1 through a pipeline, and the first evaporation mother liquor pump 8-1 and the second evaporation mother liquor pump 8-2 are installed on the pipeline, and the first evaporation mother liquor pump 8- 1 is connected to the feed port of the first static mixer 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com