Machining equipment used for impeller with super-hydrophobic surface and impeller manufactured by machining equipment

A super-hydrophobic surface and processing equipment technology, applied in metal processing equipment, components of pumping devices for elastic fluids, mechanical equipment, etc., can solve the problems of impeller strength and life impact, and reduce fluid resistance and cost , good corrosion resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

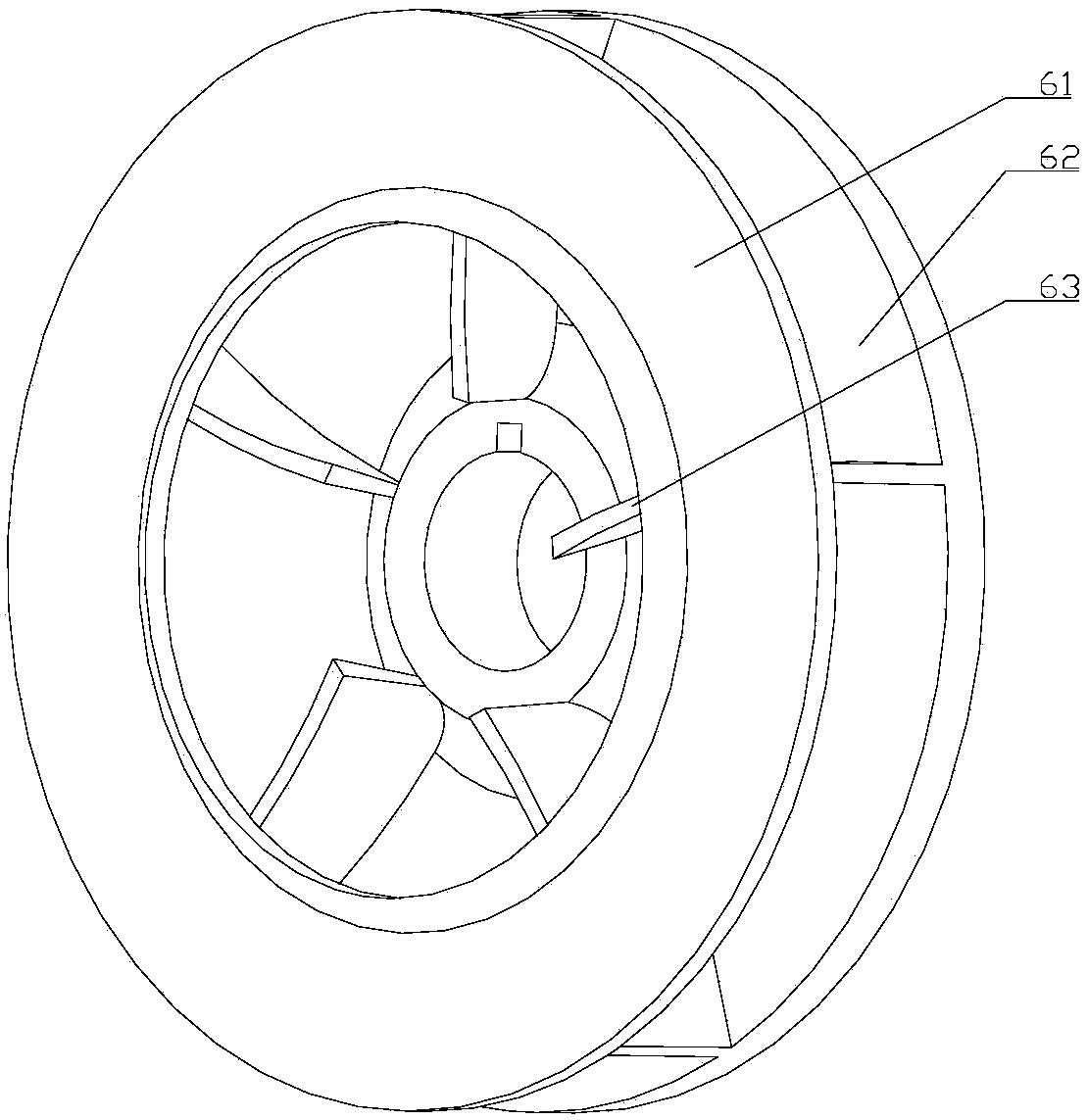

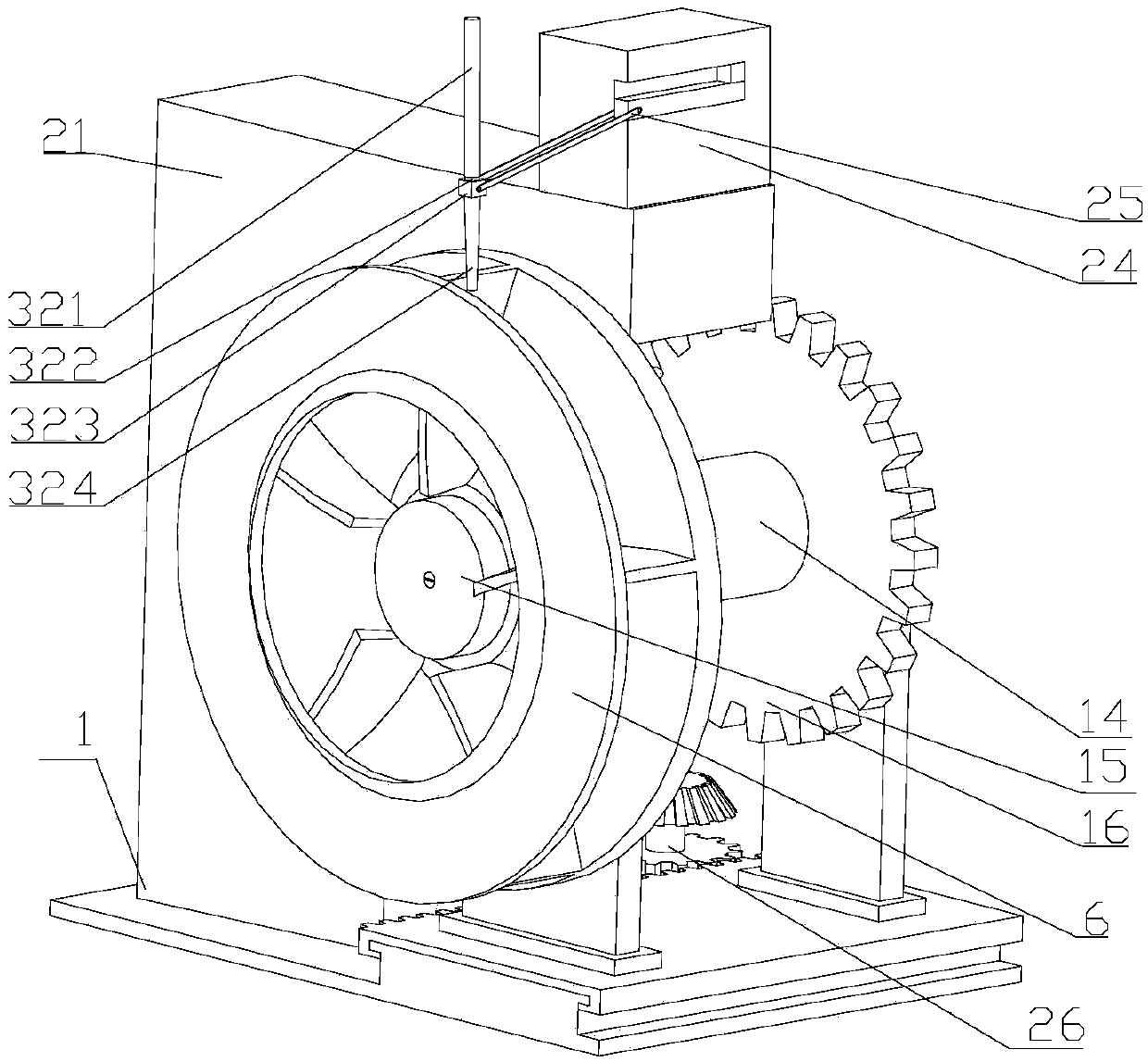

[0031] Embodiment 1 A kind of processing equipment for superhydrophobic surface impeller according to the present invention includes a fixed bracket 1 for clamping the impeller, a driving device 2 for driving the impeller to rotate, and is used for processing the superhydrophobic surface on the surface of the impeller The laser etching equipment 3, the dust suction device 4 for absorbing dust particles, and the controller 5 for controlling the entire processing process, the fixed bracket 1 is provided with a working area for installing the impeller, and the driving equipment 2 is installed On the fixed support 1, the laser etching device 3 is installed on the driving device 2, and the gun head of the laser etching device 3 is aimed at the surface of the impeller 6 to be processed; the dust suction device 4 is aligned with the working area of the fixed bracket 1; the control end of the drive device 2, the control end of the laser etching device 3 and the control end of the dus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com