Fine vacuum diaphragm pump

A diaphragm pump and high vacuum technology, applied in the field of diaphragm metering pumps and large hydraulic diaphragm pumps, can solve the problems of pump cavitation performance degradation, inlet pressure cavitation, exhaust pressure and flow instability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

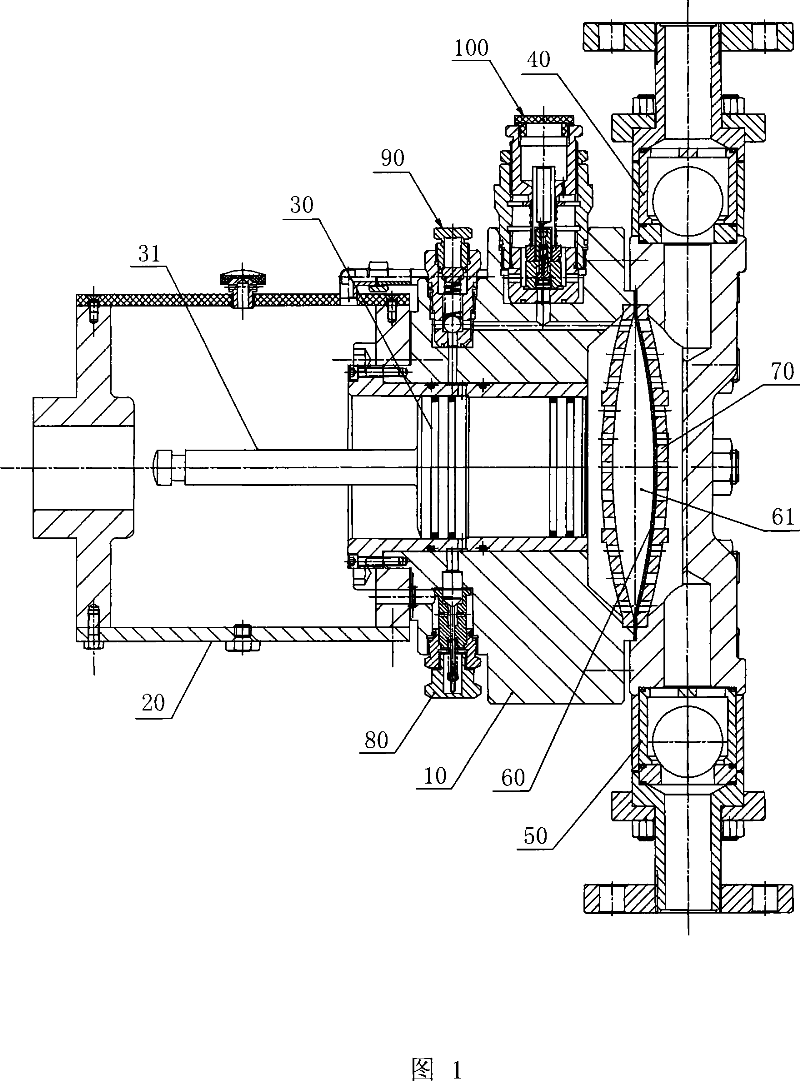

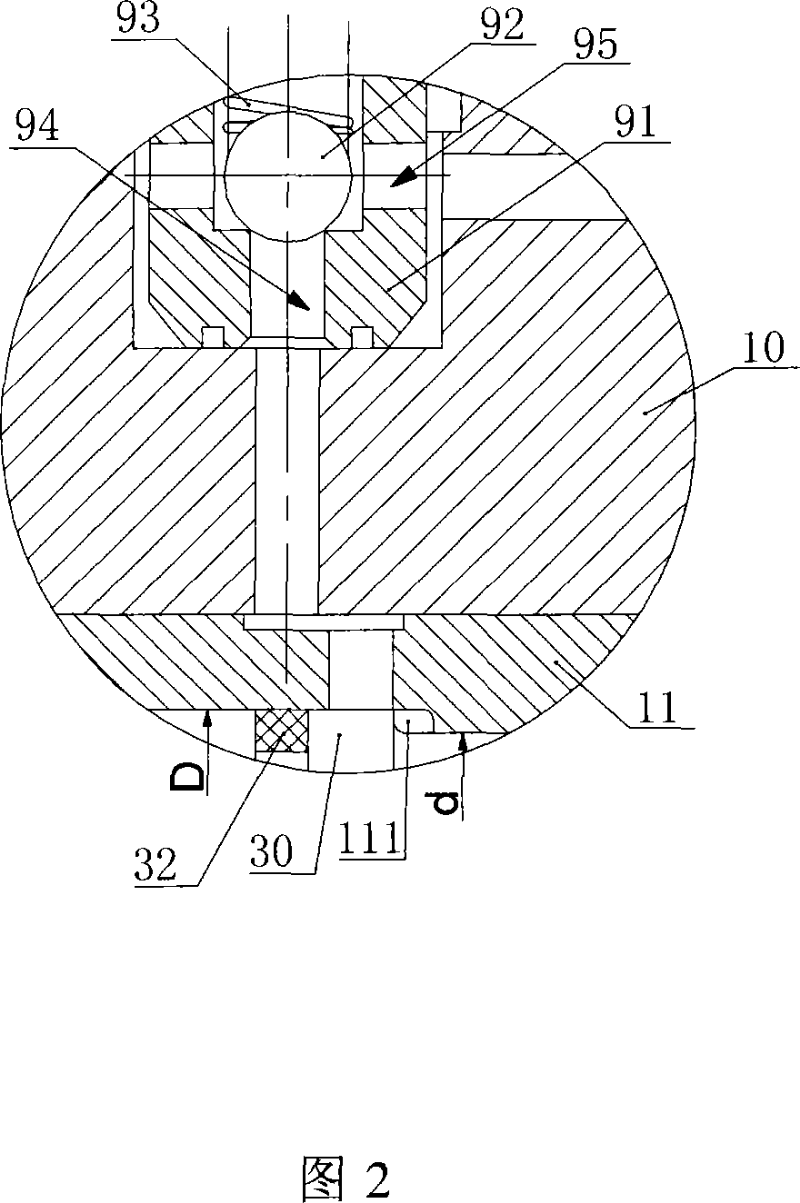

[0011] As shown in FIG. 1 , the high vacuum diaphragm pump disclosed in the present invention includes a cylinder block 10 and an oil pool cylinder 20. A piston 30 is located in the cylinder block 10, and a piston rod 31 of the piston 30 is located in the oil pool cylinder 20 and is submerged by the process fluid. , the cylinder 10 on the side of the piston 30 is provided with a pressure fluid inlet valve 40 and a liquid outlet valve 50, between which a diaphragm 60 and its fixing bracket 70 are arranged, the piston 30 is stepped, and the cylinder 10 has a The piston cavity of the piston 30 is matched with a piston ring on each diameter section of the piston 30 to cooperate with the piston cavity of the corresponding section, and the cylinder body 10 is also provided with a compensation valve 80 and an oil pressure control valve. Valve 90, the oil pool cylinder 20 is in one-way communication with the cavity between the piston 30 and the piston cavity through the compensation va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com