High-damping and high-performance alloy cylinder sleeve and preparation technology thereof

A preparation process and technology of cylinder liner, applied in the direction of cylinder, cylinder head, mechanical equipment, etc., can solve the problems of vibration and noise, affecting the engine, wet cylinder liner early grinding, cavitation, etc., to reduce vibration and noise, run-in period The effect of short, good corrosion resistance and anti-cavitation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

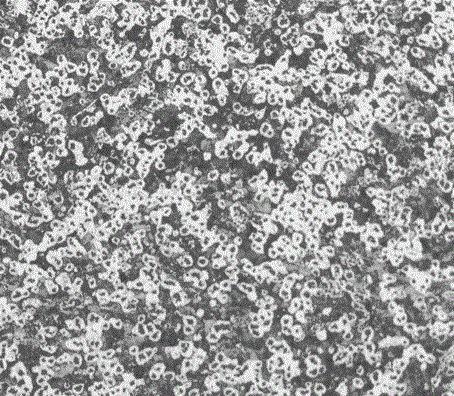

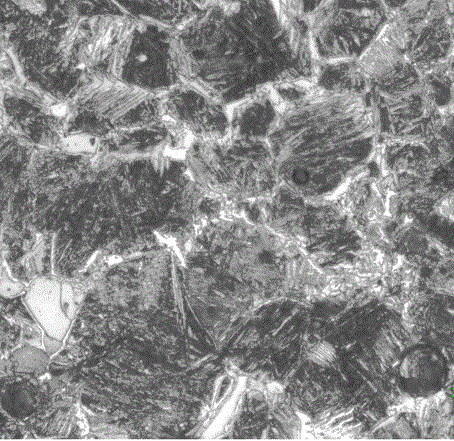

[0018] A high-damping high-performance alloy cast iron cylinder liner, including a cylinder liner body and a zinc-aluminum high-damping alloy coating sprayed on the outer wall of the cylinder liner body, the thickness of the zinc-aluminum alloy layer is 0.3-1mm, and the zinc content in the zinc-aluminum alloy is 60- 70wt%, aluminum content 30-40wt%; the chemical composition of the cylinder liner body material is as follows in weight percentage (%): C: 3.45, Si: 3.15, P: 0.018, S: 0.008, Cu: 3.2, Mn: 1.51, Ni: 0.49, Mg: 0.07, Ce: 0.035, and the balance is iron.

[0019] The preparation process of the above-mentioned high-damping high-performance alloy cast iron cylinder liner comprises the following steps:

[0020] Step 1. Dosing ingredients according to the weight percentage of the above-mentioned high-damping high-performance alloy cylinder liner, adopting the water-cooled metal mold centrifugal casting method to produce the cylinder liner blank, the melting temperature is 14...

Embodiment 2

[0025]A high-damping high-performance alloy cast iron cylinder liner, including a cylinder liner body and a zinc-aluminum high-damping alloy coating sprayed on the outer wall of the cylinder liner body, the thickness of the zinc-aluminum alloy layer is 0.3-1mm, and the zinc content in the zinc-aluminum alloy is 60- 70wt%, aluminum content 30-40wt%; the chemical composition of the cylinder liner body material is calculated in the following weight percentage (%):

[0026] C: 3.29, Si: 2.96, P: 0.016, S: 0.007, Cu: 3.5, Mn: 1.61, Ni: 0.55, Mg: 0.079, Ce: 0.03, and the balance is iron.

[0027] The preparation process of the above-mentioned high-damping high-performance alloy cast iron cylinder liner comprises the following steps:

[0028] Step 1. Ingredients are prepared according to the weight percentages of the above ingredients, and the cylinder liner blank is produced by the water-cooled metal mold centrifugal casting method. The melting temperature is 1450-1500°C. The smelte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com