Embedding damping pulp and method for preparing same

A damping slurry and potting technology, which is applied in chemical instruments and methods, and other chemical processes, can solve the problems of insufficient damping performance, high cost of potting materials, high specific gravity, etc., and achieve high damping, low cost, and wide application foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

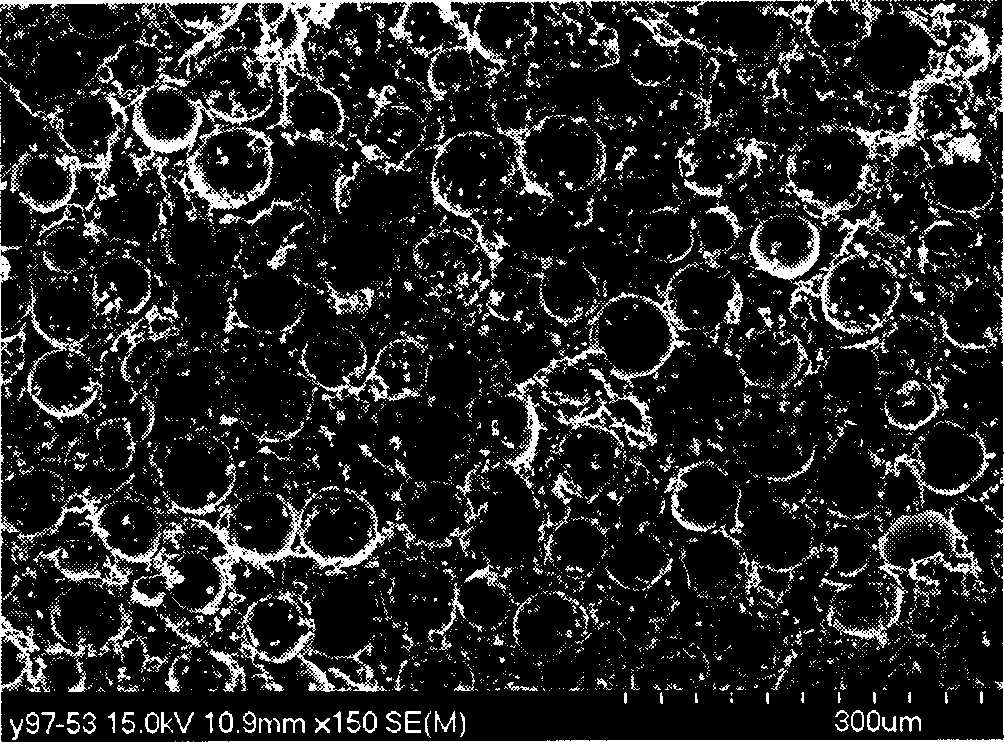

[0008] Embodiment 1: The mixed potting and damping slurry in this embodiment is an epoxy resin-polyurethane system mixed slurry containing 50-70 vol.% hollow microspheres.

[0009] In this embodiment, the epoxy resin is a glycidyl ether epoxy resin. The hollow microspheres are a kind of aluminosilicate hollow ceramic ball particles extracted from fly ash after coal combustion, and the average particle diameter is 60-140 μm.

specific Embodiment approach 2

[0010] Specific embodiment 2: In this embodiment, the mixed potting damping slurry is prepared according to the following method: (1) Wash the hollow microspheres with absolute ethanol to remove impurities on the surface, and then dry them at a high temperature of 110°C for later use; Microbeads are preheated at 100~120 ℃; (2) silane coupling agent is formulated into 10~20wt.% dehydrated alcohol solution, wherein the consumption of silane coupling agent is 6~10wt.% of hollow microbeads, will The above-mentioned hollow microspheres and absolute ethanol solution are mixed at a temperature of 40-60°C for 20-30 minutes, and then dried at a temperature of 100-120°C for 2-5 hours to obtain modified hollow microspheres; (3) in Add the above-mentioned modified hollow microspheres to the epoxy resin-polyurethane system, ultrasonically disperse them for 10-20 minutes, and dry them in vacuum to obtain an epoxy resin-polyurethane system mixed potting slurry containing 50-70vol.% hollow mic...

specific Embodiment approach 3

[0013] Embodiment 3: The hybrid potting and damping slurry of this embodiment is to add hollow microspheres to epoxy resin. The preparation process of the hollow microsphere / epoxy potting damping slurry is realized according to the following steps:

[0014] (1) Wash the hollow microspheres with an average particle size of 90 μm with absolute ethanol to remove impurities on the surface, and then dry them at a high temperature of 110° C. for later use;

[0015] (2) Preheat the hollow microspheres for use after drying at 110°C for 3 hours to a uniform temperature;

[0016] (3) Commercially available silane coupling agent KH-550 is formulated into 12wt.% dehydrated alcohol solution, wherein the consumption of silane coupling agent KH-550 is 8wt.% of the hollow microspheres, and the above-mentioned hollow beads with a mass of 40g Mix the microbeads with the solution at 50°C for 25 minutes, then dry in an oven at 110°C for 3 hours for use;

[0017] (4) Mix glycidyl ether epoxy res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com