Vibration isolation device for floating plate

A floating plate and vibration isolation technology, applied in the direction of vibration suppression adjustment, non-rotational vibration suppression, ballast layer, etc., can solve the problem of elasticity, damping characteristics are easily affected by ambient temperature, anti-pollution, poor acid corrosion ability, elasticity Degradation of damping characteristics and other problems, to achieve obvious vibration isolation effect, good vibration isolation effect, and suppression of resonance peak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

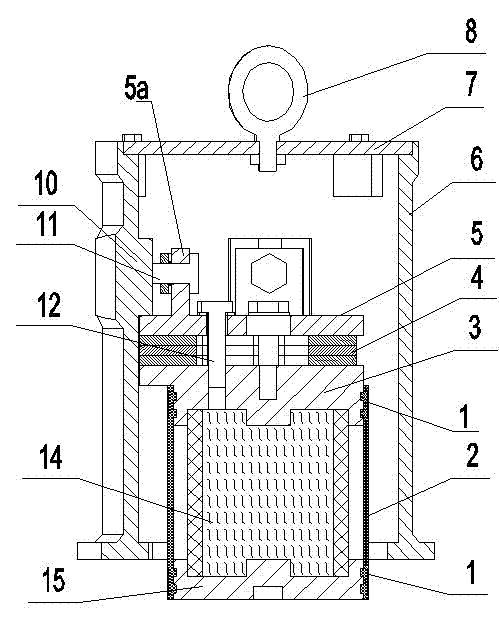

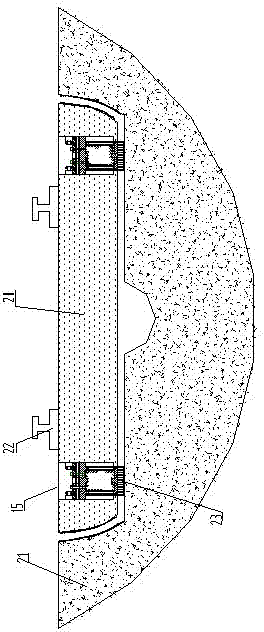

[0024] Example: as figure 1 , 3 , as shown in 4:

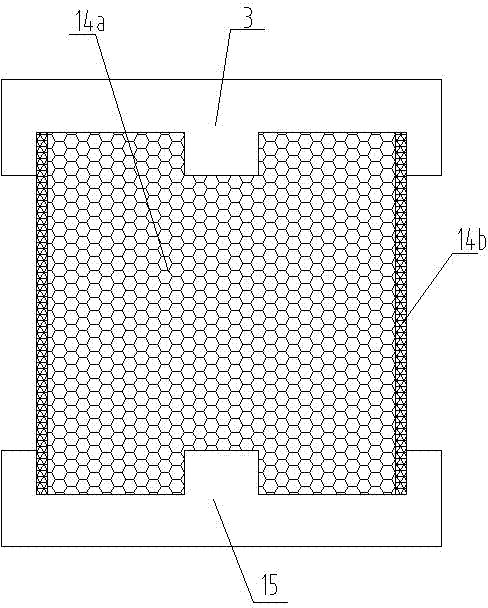

[0025] The vibration isolation device includes a sleeve 6, a locking backing plate 5, an upper support plate 3 and a base 15. The inner wall of the sleeve 6 has a limit stop shoulder 10, and the locking backing plate 5 is fixed on the place by a connecting plate 5a. On the limiting shoulder 10, wherein the locking backing plate 5 is matched with the lower surface of the limiting shoulder 10, and an adjusting backing plate 4 is arranged between the locking backing plate 5 and the upper support plate 3, The upper supporting plate 3 and the base 15 are connected by a sealing sleeve 2, and an elastic element 14 is arranged in the sealing sleeve 2, and the two ends of the elastic element 14 are connected with the lower surface of the upper supporting plate 3 and the bottom surface of the base 15 respectively. Compatible with the upper surface.

[0026] The locking backing plate 5 , the upper supporting plate 3 and the adjusting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com