Composite structure vibration isolator with rubber and wire mesh combined

A technology of wire mesh and composite structure, which is applied in the direction of shock absorber, friction shock absorber, shock absorber, etc., to achieve the effect of compact structure, simple structure and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution will be described in further detail below in conjunction with the accompanying drawings.

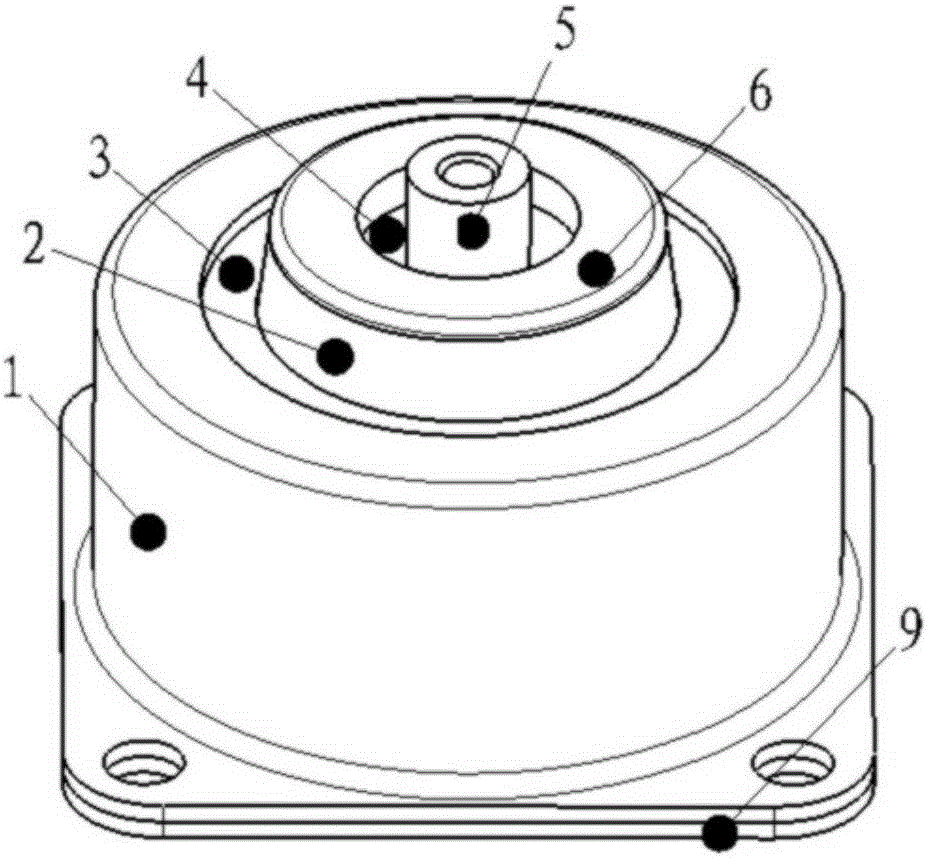

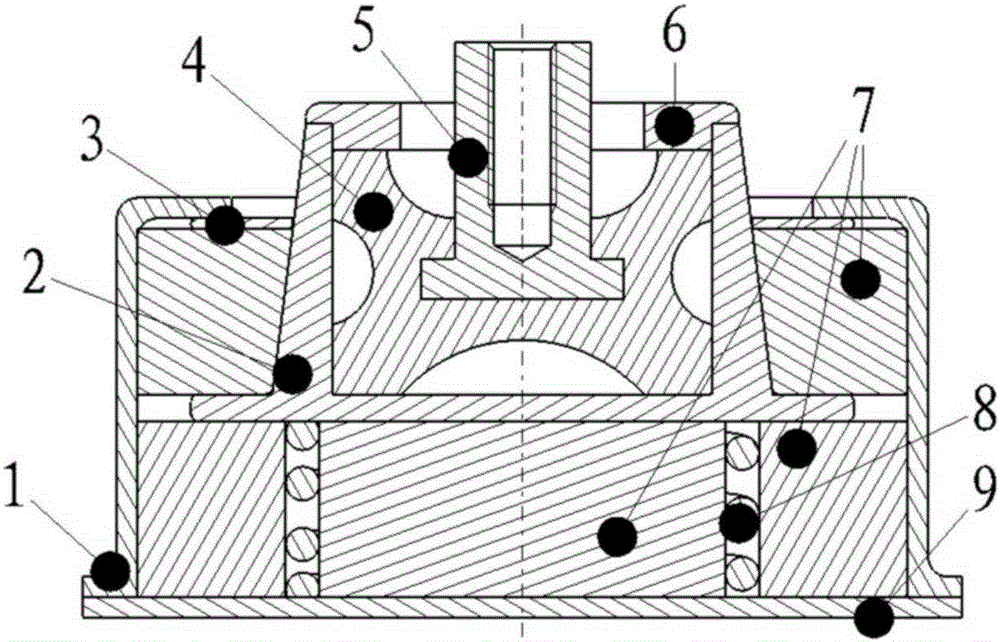

[0015] The vibration isolator includes a shell 1, a transition core 2, a block 3, a rubber block 4, a mounting core 5, a threaded cover 6, a wire mesh pad 7, a spring 8 and a bottom plate 9, and the spring 8 is located on the bottom plate 9 of the shell 1 Above, the interior of the spring 8 is filled with a wire mesh pad 7, the transition core 2 is placed on the spring 8, and the outside of the spring 8 below the transition core 2 is filled with a wire mesh pad 7;

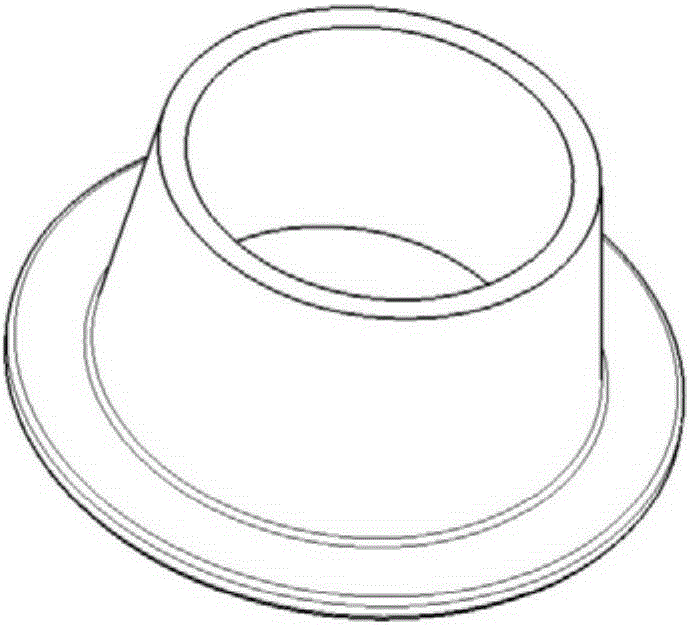

[0016] There is a cavity in the transition core 2, and a rubber block 4 is installed in the cavity. The upper end of the cavity has an internal thread, which is used to fix the rubber block 4 in cooperation with the external thread of the threaded cover 6. A mounting core 5 is fixed on the rubber block 4, and a wire mesh pad 7 is filled between the shell 1 and the transition core 2, and a baffle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com