Horizontal multi-stage centrifugal pump

A centrifugal pump, horizontal technology, applied in the field of horizontal multi-stage centrifugal pumps, can solve the problems of different impellers at different levels, different flow losses, poor suction performance, etc., and achieve simple structure, extended service life, and easy manufacturing and maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

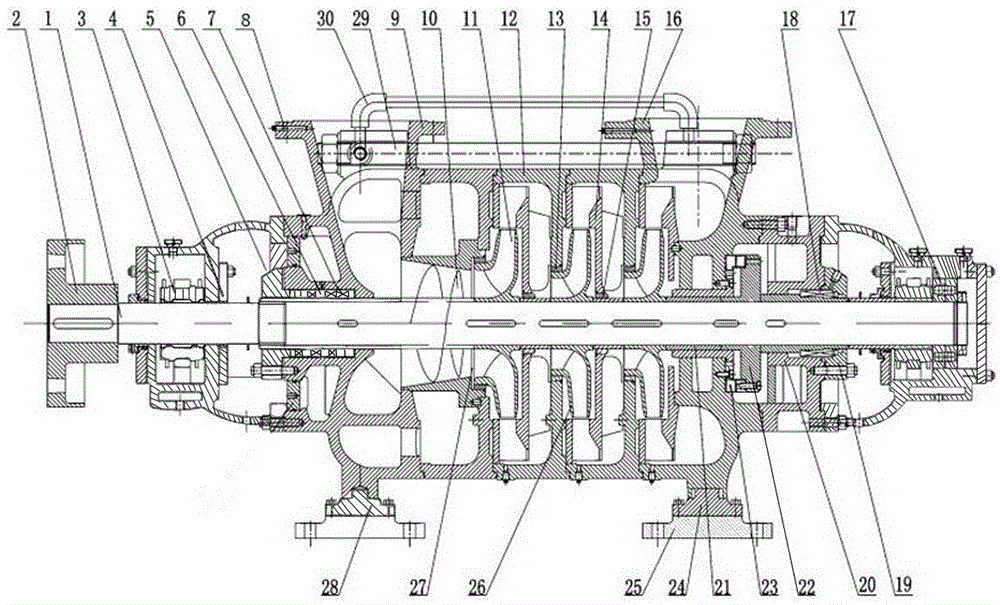

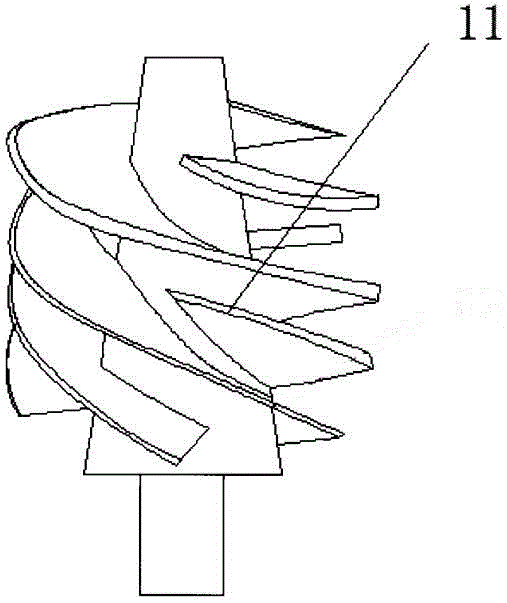

[0020] as attached Figure 1-2 As shown, a horizontal multi-stage centrifugal pump includes a pump body. A pump shaft 1 is installed in the pump body. The pump shaft 1 is connected to the prime mover through a coupling 2. The pump body includes a suction section 9 connected in sequence, a pumping Section 12 and pumping section 16, the pump shaft 1 is set in the suction section 9, pumping section 12 and pumping section 16, the suction section 9 is provided with a suction port, the pumping section 16 is provided with a discharge port, the suction port and the discharge port The outlets are all set up, and the pump shaft 1 in the pumping section 12 is equipped with an impeller, the impeller includes a first-stage impeller 11 installed on the pump shaft 1 close to the suction section 9, and several secondary impellers behind the first-stage impeller 11 26, the inducer 10 is installed on the pump shaft 1 close to the primary impeller 11 in the suction section 9, and the guide vane ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com