Cavitation corrosion gradient reparation coating of water pump blade and producing method thereof

A technology of blades and water pumps, which is applied in coatings, chemical instruments and methods, metal material coating processes, etc., can solve the problems that cannot completely solve the problems of water pump flow parts, high weldability requirements of workpiece substrate materials, and large substrate deformation. , to achieve excellent cavitation resistance, good sealing effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

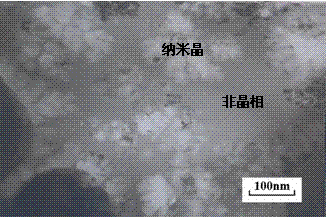

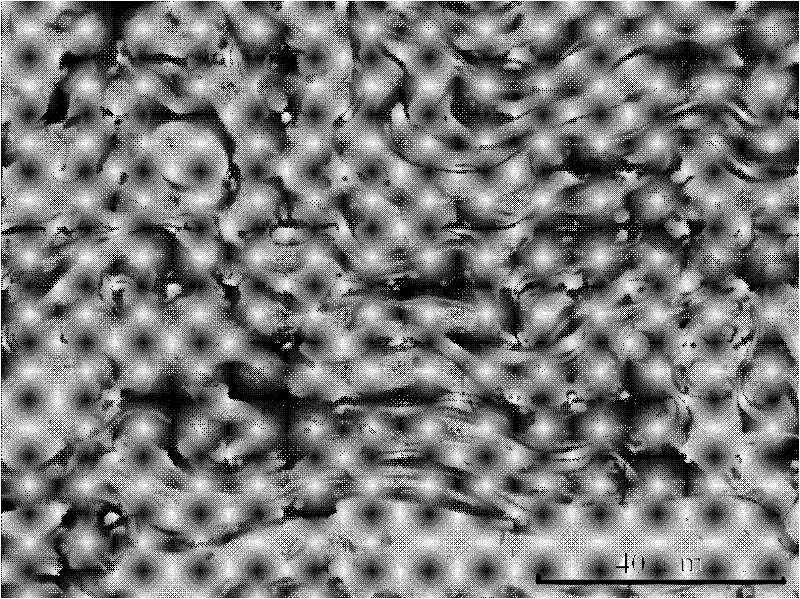

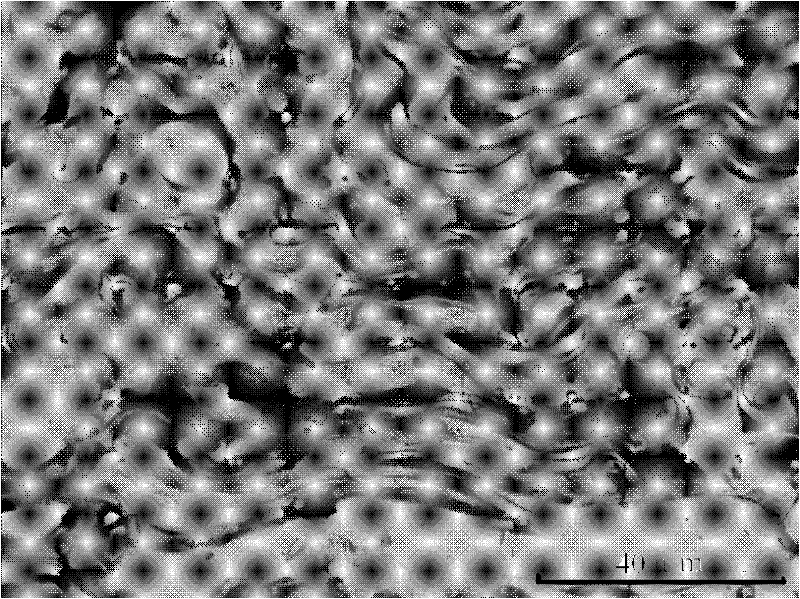

Embodiment 1

[0032] Sand blast ZG230-450 to obtain a rough surface. First, use high-energy arc spraying NiAl alloy as the bottom bonding layer with a thickness of 0.2mm, and then alternately use high-energy arc spraying to spray the working layer of Fe-based alloy and the composition is The bonding layer of NiAl alloy has a total thickness of 2 mm. Among them, the Fe-based alloy can be specifically coated with low-carbon steel alloy powder. The powder composition is 2.0% boron, 3.0% silicon, 10% chromium, and the rest is iron by weight percentage; finally, the Fe-based alloy is sprayed with high-energy arc. Working layer, total thickness 2.5mm. The working layer contains amorphous and nanocrystalline. Finally, seal the pores with organic silicon, which contains 3%wt nano-ceramic Al 2 o 3 . The bonding strength between the coating and the substrate is 45MPa, the hardness of the working layer is 640HV, and the cavitation resistance of the gradient composite coating is close to that of 1C...

Embodiment 2

[0034] Sand blast ZG230-450 to obtain a rough surface. First, high-energy arc spraying NiAl bonded base layer, thickness 0.15mm, and then alternating high-energy arc spraying Fe-based alloy (3.5% by weight boron, 2.5% silicon, 12% chromium, The rest is Fe) and NiAl alloy layer, with a total thickness of 5mm, and then high-energy arc spraying Fe-based working layer containing amorphous and nanocrystalline, with a total thickness of 6.6mm, and finally sealed with organic silicon, which contains 5% nano-Al 2 o 3 , The bonding strength is 40MPa, the hardness of the working layer is 750HV, and the cavitation resistance of the gradient composite coating is close to that of 1Cr18Ni9Ti.

example 3

[0036] Sand blast ZG230-450 to obtain a rough surface. First, high-energy arc spraying NiAl bonded base layer, thickness 0.15mm, and then alternating high-energy arc spraying Fe-based alloy (4.0% by weight boron, 3.0% silicon, 15% chromium, The rest is iron) and NiAl alloy layer, with a total thickness of 5mm, and then high-energy arc spraying Fe-based alloy, the working layer contains amorphous and nanocrystalline, with a total thickness of 8.0mm, and finally sealed with epoxy resin. Contains 5% nano Al 2 o 3 , The coating and bonding strength is 38MPa, the hardness of the working layer is 900HV, and the cavitation resistance of the gradient composite coating is close to 1Cr18Ni9Ti.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com