Centrifugal type fluid machine blade wheel

A fluid machinery, centrifugal technology, applied in mechanical equipment, liquid fuel engines, components of pumping devices for elastic fluids, etc. Achieve high anti-cavitation performance, improve impeller efficiency, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

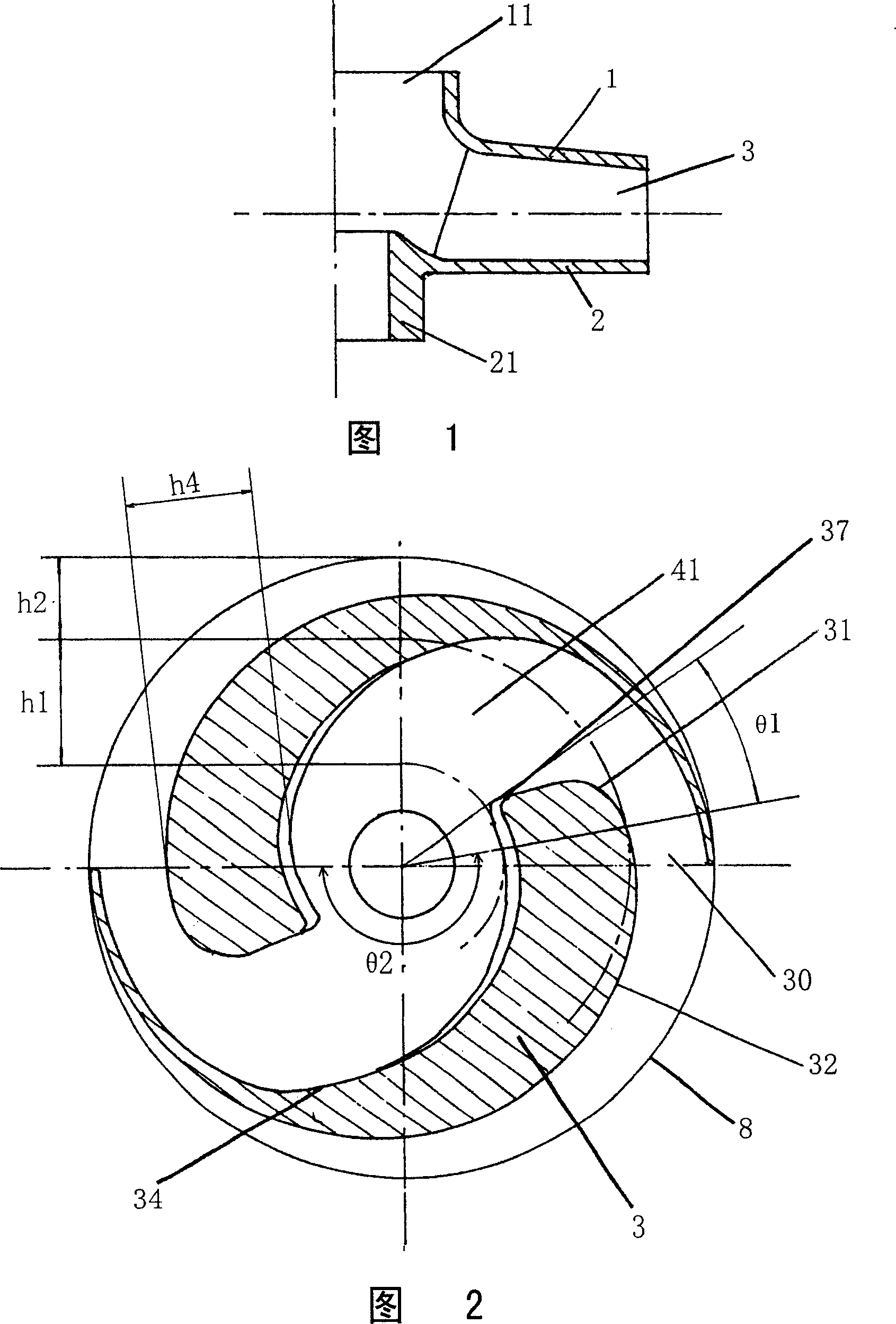

[0026] Figure 1 shows a first embodiment of the invention in which the impeller comprises two blades. As shown in FIG. 1 , the impeller according to the first embodiment of the present invention includes a front shroud 1 and a rear shroud 2 . Between the front cover plate 1 and the rear cover plate 2 there are two blades 3 distributed along the circumference, and the blades 3 are solid. The front cover 1 is integrated with the inlet 11 of the impeller, while the rear cover 2 is integrated with the hub 21 .

[0027] Fig. 2 is a top sectional view of Fig. 1 after cutting the front cover plate and part of the connected blades along the middle plane of the outlet between the two cover plates. As shown in FIG. 2 , the wrap angle of the front front section 31 of the blade 3 is θ1, and the radial extension is h1; the wrap angle of the front rear section 32 of the blade 3 is θ2, and the radial extension is h2.

[0028] Since the main function of the front front section 31 of the bla...

Embodiment 2

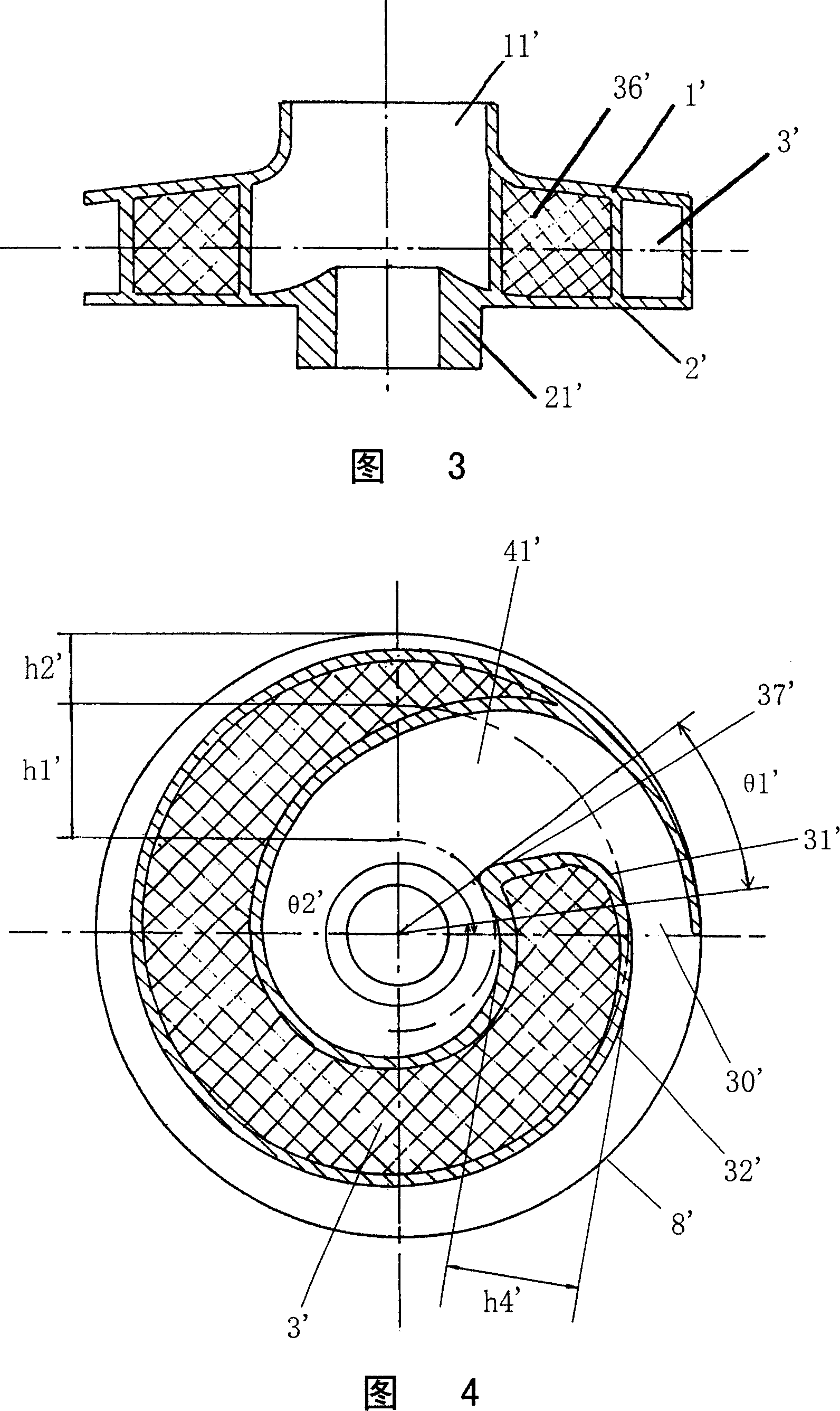

[0038] Figure 3 shows a second embodiment of the invention in which the impeller contains only one blade.

[0039] In the case of small flow rate, the impeller of the present invention can only have one blade, and the structure of this impeller has the following two differences from the structure of the impeller in the first embodiment of the present invention:

[0040] 1. The impeller with only one blade in the second embodiment of the present invention forms the inter-blade flow channel through the front and back of the blade itself.

[0041] 2. The impeller with only one blade in the second embodiment of the present invention needs to use conventional balancing techniques to solve the problem of unbalance of the impeller itself.

[0042] Since the rest of the structural features are the same as those of the impeller in the first embodiment of the present invention, they will not be repeated here.

[0043]As shown in Fig. 3, the impeller of the second embodiment of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com