Iron-based amorphous powder and preparation method and application thereof

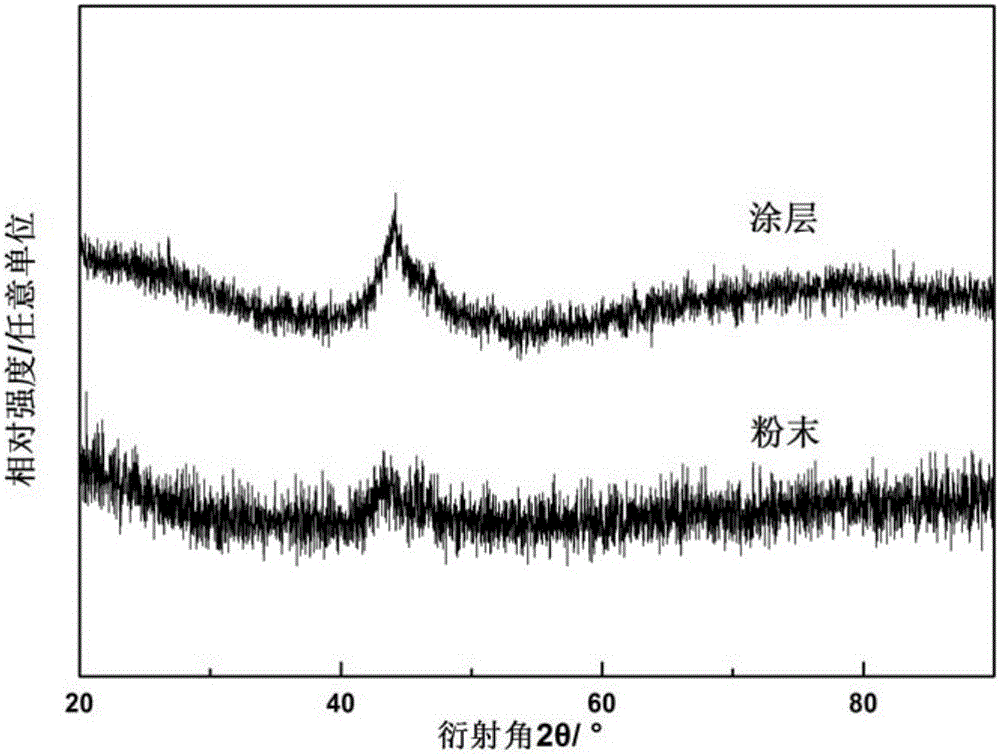

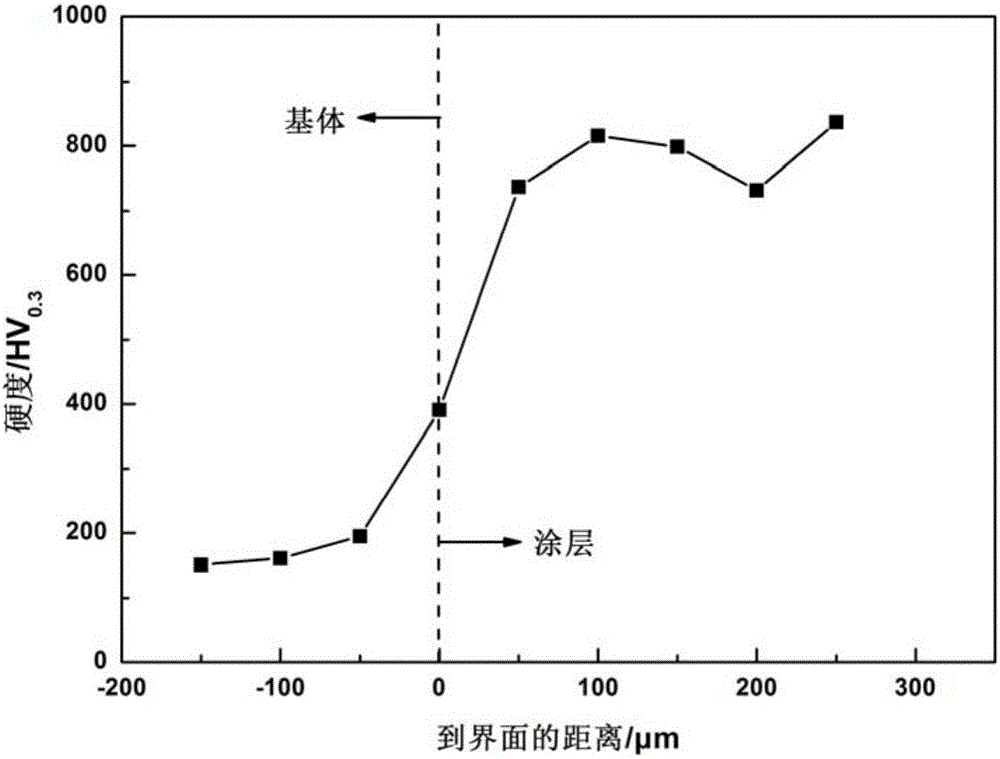

An iron-based amorphous and powder technology, which is applied in metal material coating process, melt spraying, coating and other directions, can solve the problems of amorphous coating polycrystalline phase and unreasonable powder composition design, and achieve thermal stability. High performance, excellent cavitation resistance, and the effect of improving the ability of amorphous formation and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] An iron-based amorphous powder, the powder is composed of the following elements, the weight percentage of each element is as follows: 20wt% Cr, 4.5wt% B, 0.625wt% C, 1.875wt% Si, 2.5wt% Cu, 5wt% Ni, 15wt% Mo, 3wt% Co, the balance being Fe.

[0042] The preparation method of iron-based amorphous powder, comprises the steps:

[0043] (1) Put the block raw materials into the induction induction furnace according to the calculated ratio, put the high melting point on the lower part, and put the low melting point on the upper part, and heat to 2350 ℃ to melt all the materials;

[0044] (2) Water atomize the molten metal, the water atomization pressure is 9 MPa, and then dry the powder for 3 hours;

[0045] (3) Sieve the powder between 325 mesh and 800 mesh and vacuum seal it.

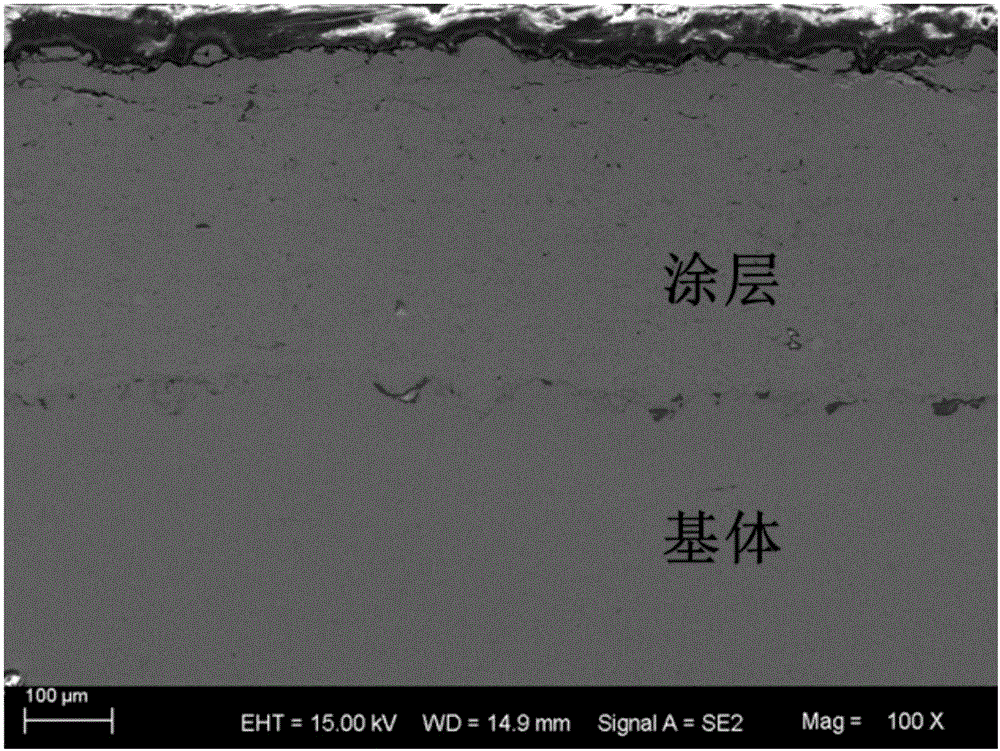

[0046] The application of the prepared iron-based amorphous powder in the preparation of the iron-based amorphous coating comprises the following steps:

[0047] (1) Pretreatment of the surface of...

Embodiment 2

[0051] An iron-based amorphous powder, the powder is composed of the following elements, the weight percentage of each element is as follows: 20wt% Cr, 3.6wt% B, 0.5wt% C, 1.5wt% Si, 2.5wt% Cu, 5wt% Ni, 15wt% Mo, 3wt% Co, the balance being Fe.

[0052] The preparation method of iron-based amorphous powder, comprises the steps:

[0053] (1) Put the block raw materials into the induction induction furnace according to the calculated ratio, put the high melting point on the lower part, and put the low melting point on the upper part, and heat to 2350 ℃ to melt all the materials;

[0054] (2) Water atomize the molten metal, the water atomization pressure is 10 MPa, and then dry the powder for 3 hours;

[0055] (3) Sieve the powder between 325 mesh and 800 mesh and vacuum seal it.

[0056] The application of the prepared iron-based amorphous powder in the preparation of the iron-based amorphous coating comprises the following steps:

[0057] (1) Pretreatment of the surface of th...

Embodiment 3

[0060] An iron-based amorphous powder, the powder is composed of the following elements, the weight percentage of each element is as follows: 20wt% Cr, 2.7wt% B, 0.375wt% C, 1.125wt% Si, 2.5wt% Cu, 5wt% Ni, 15wt% Mo, 3wt% Co, the balance being Fe.

[0061] The preparation method of iron-based amorphous powder, comprises the steps:

[0062] (1) Put the block raw materials into the induction induction furnace according to the calculated ratio, put the high melting point on the lower part, and put the low melting point on the upper part, and heat to 2350 ℃ to melt all the materials;

[0063] (2) Water atomize the molten metal, the water atomization pressure is 8 MPa, and then dry the powder for 3 hours;

[0064] (3) Sieve the powder between 325 mesh and 800 mesh and vacuum seal it.

[0065] The application of the prepared iron-based amorphous powder in the preparation of the iron-based amorphous coating comprises the following steps:

[0066] (1) Pretreatment of the surface of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| corrosion potential | aaaaa | aaaaa |

| corrosion current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com