BJL multi-channel modified line special air conditioner energy-saving centrifugal pump

A technology for centrifugal pumps and air conditioners, which is applied to non-variable volume pumps, components of pumping devices for elastic fluids, pumps, etc. It can improve the anti-cavitation performance, improve the comprehensive performance, and reduce the cavitation allowance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

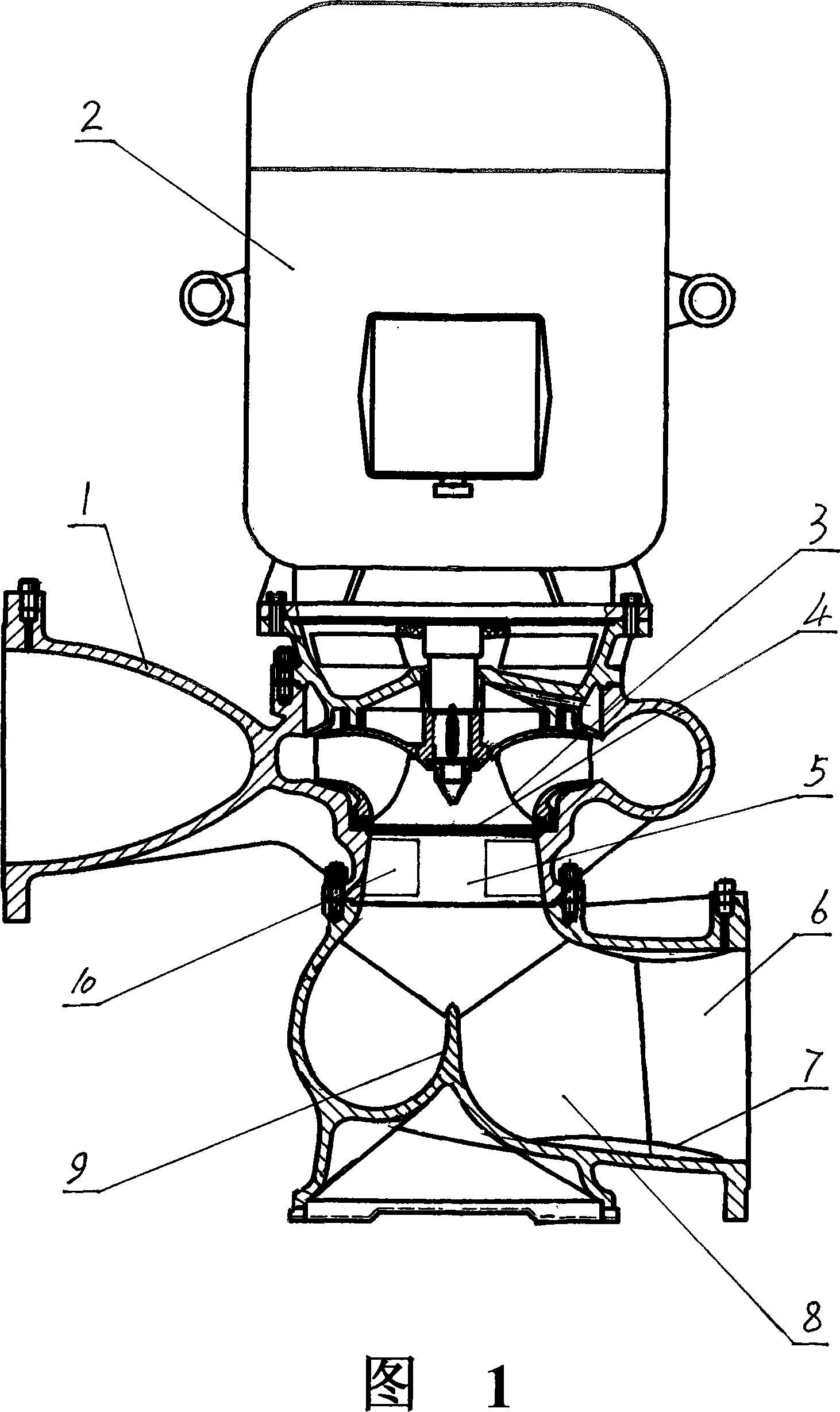

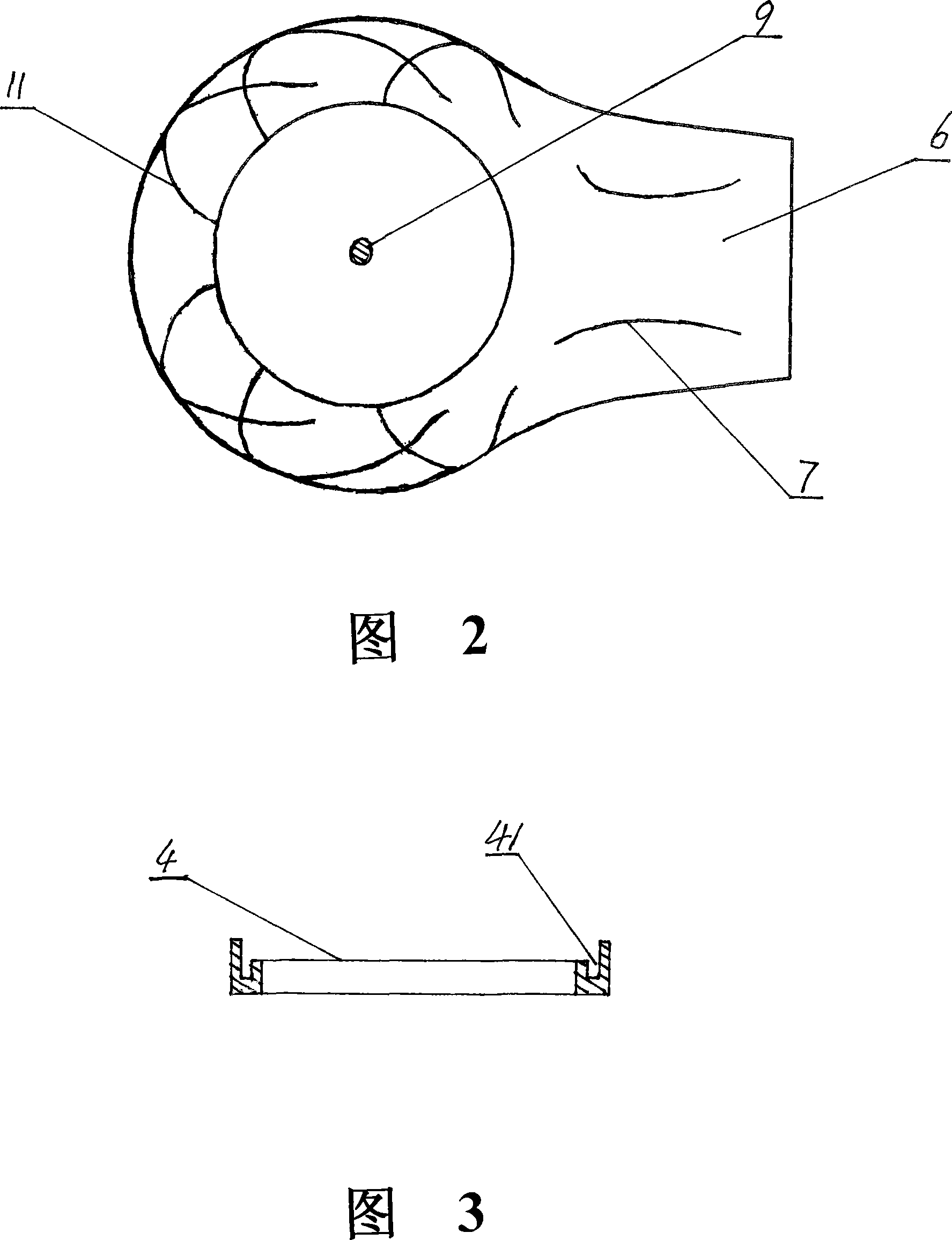

[0011] The BJL multi-channel air-conditioning energy-saving centrifugal pump for changing lines provided by the present invention includes a motor 2, an impeller 3 and a water outlet chamber 1, and the front water inlet section 6 of the suction water chamber is a front and rear semicircle increasing spiral elbow different diameter suction water chamber flow. The entrance of the flow channel is low, and the flow channel of the rear water chamber is high, forming a slope of 3°~8°, which is conducive to the balanced acceleration of the liquid fluid in the flow channel of the water absorption chamber, thereby reducing the cavitation of the pump and improving the efficiency of the pump; At the rear of the suction water chamber, there is a straight tapered pipe flow channel 5 at the inlet of the impeller 3, which is used to increase the relative flow velocity of the liquid before the impeller inlet, and eliminate the pressure drop here, thereby improving the performance of the vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com