Double-jet refrigerating system

A refrigeration system and ejector technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of poor economy, low refrigeration coefficient, small space occupation, etc., and achieve the goal of increasing pressure, reducing moving parts, and saving electric energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

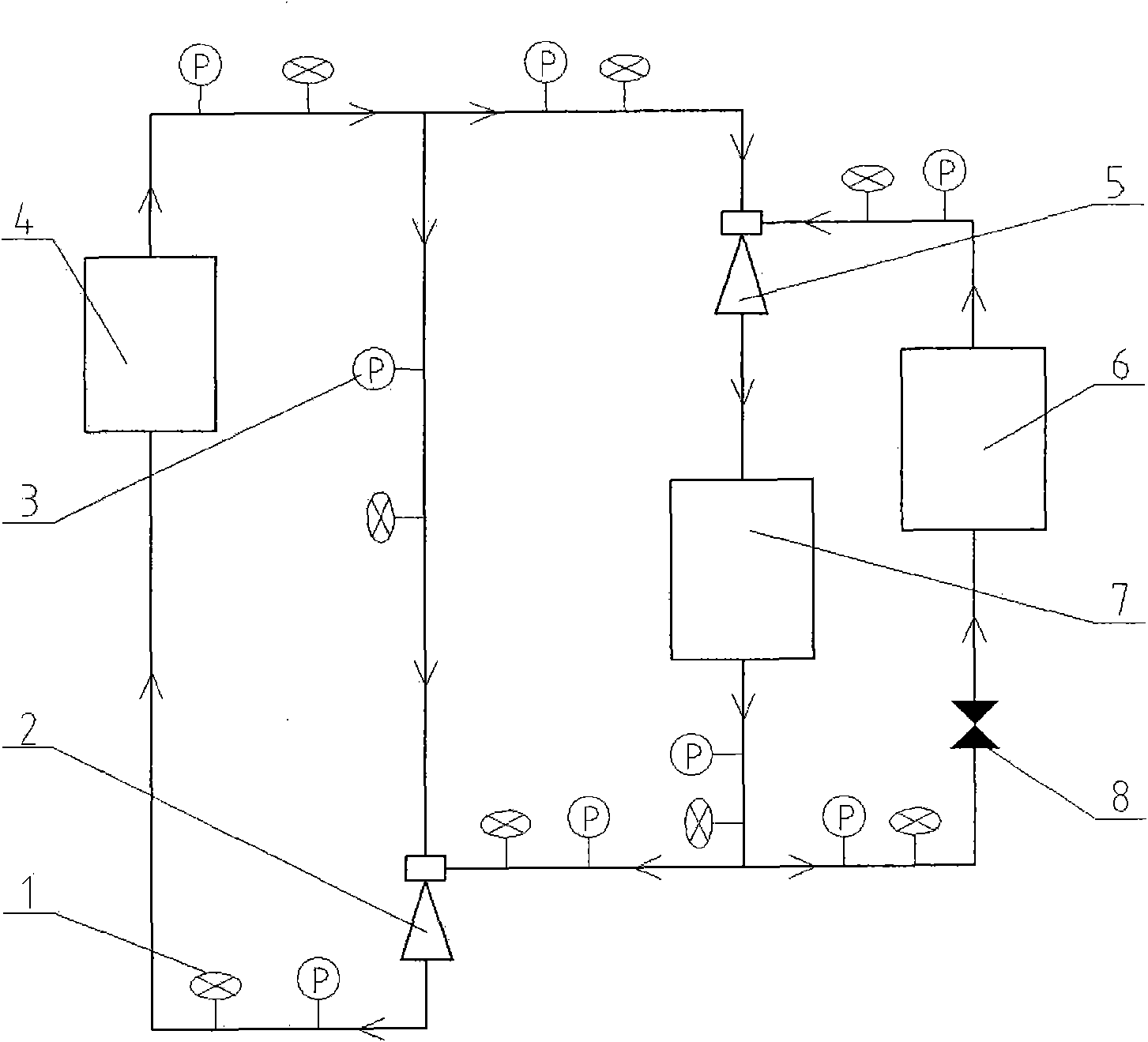

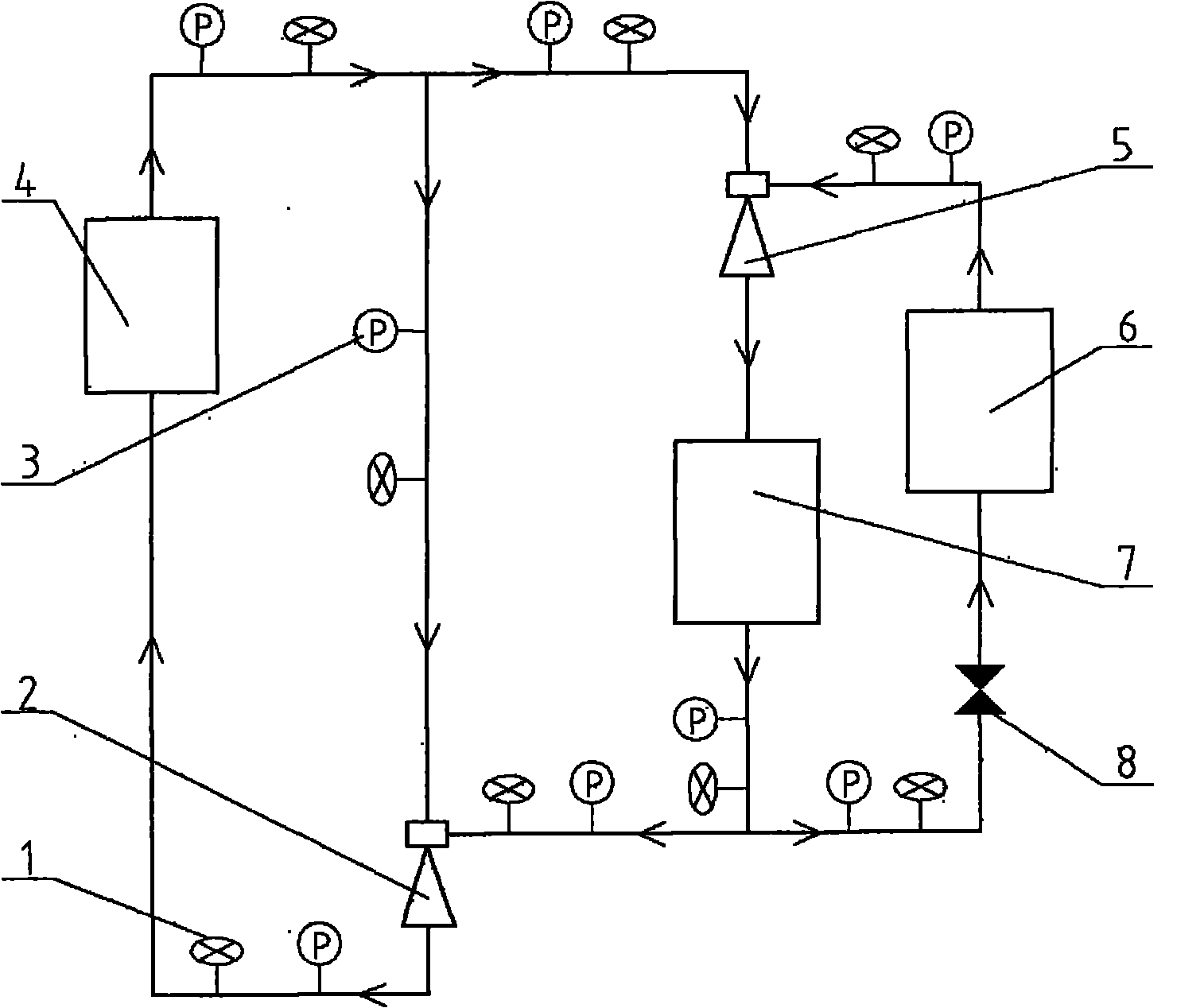

[0012] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

[0013] A steam-liquid ejector 2 is added to the traditional single-jet refrigeration system, and the working steam at the outlet of the generator 4 is divided into two paths, which are respectively connected to the working steam inlet port of the steam-vapor ejector 5 and the working steam of the vapor-liquid ejector 2. Steam inlet port connection. The outlet end of the condenser 7 is connected to the expansion valve 8 and the injection port of the vapor-liquid injector 2 in two ways. The outlet of the evaporator 6 is connected with the injection port of the steam-steam injector 5 through a pipeline. The outlet fluid of the vapor-liquid injector 2 flows back to the generator 4 through the pipeline.

[0014] The driving heat source of the present invention comes from the hot water produced by the hot water preparat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com