Combined ventilation method for relieving cavitation of large water-level amplitude high-lift ship lock valve

A water level variable amplitude, high water head technology, applied in ship locks, ship lifting devices, water conservancy projects, etc., can solve the problems of increasing the embedding depth of the valve section, increasing the engineering quantity and construction difficulty, and being unable to adapt to large water level amplitude, etc., to achieve Improve engineering safety, good ventilation effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

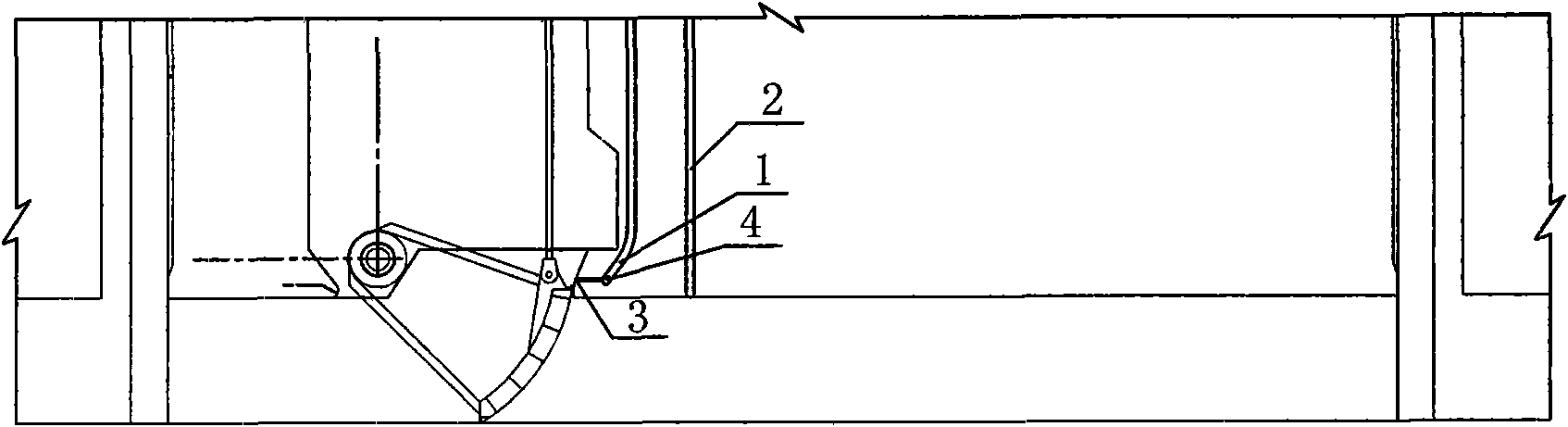

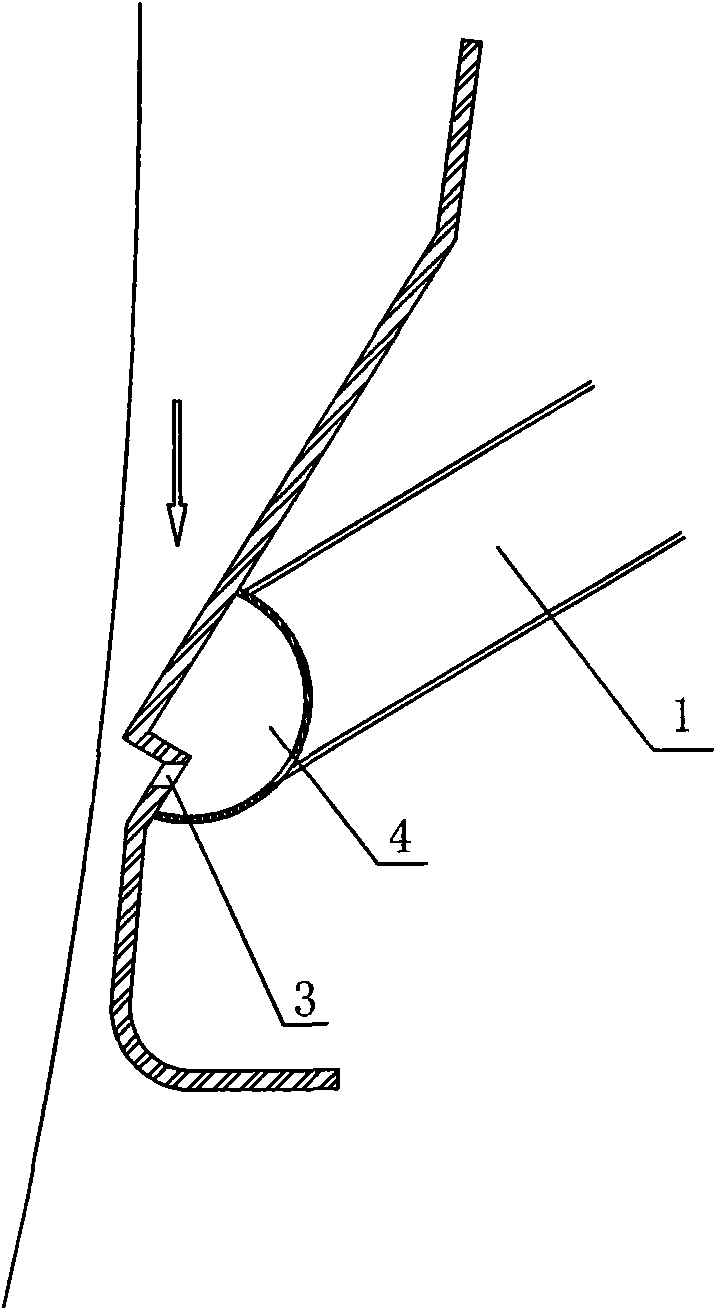

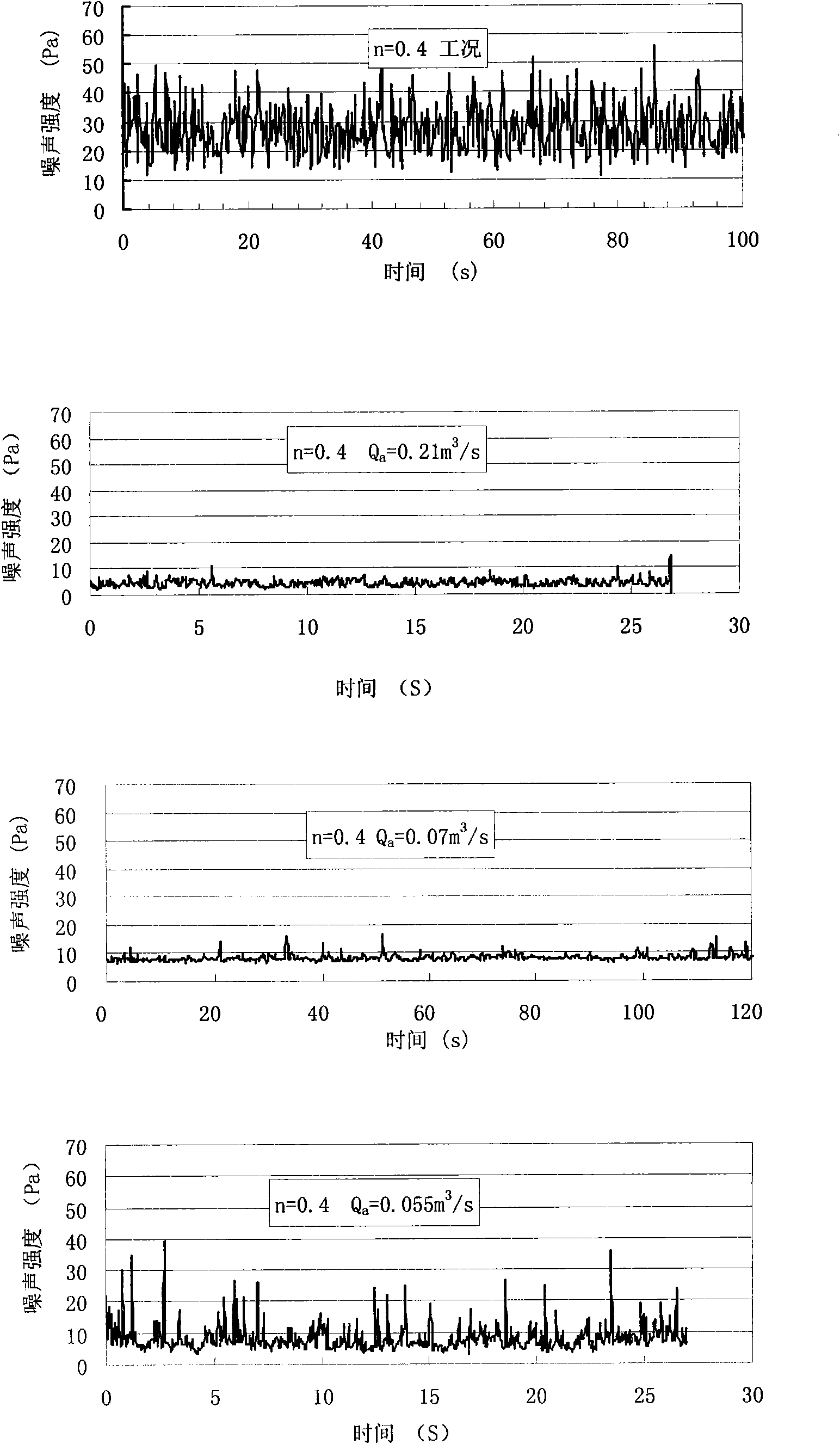

[0025] The combined ventilation method of reducing or exempting the cavitation of ship lock valves with large water level, variable amplitude and high water head adopts the combined ventilation method of "flat-roofed corridor shape + small submerged water depth + natural ventilation of lintel + natural ventilation at the top of the corridor". The shape of the valve section corridor is as follows: figure 1 As shown, the valve section corridor adopts the simplest equal-section flat-top type, and adopts a relatively shallow valve section corridor embedding depth of 5.0m to ensure that there is a relatively large negative pressure on the corridor top when the ship lock operates at high water head. Natural ventilation is taken as a basic measure, that is, a ventilation branch hole 3 is provided at the lintel, and the ventilation branch hole is connected with the ventilation horizontal pipe 4 in the gate wall downstream of the lintel. Natural ventilation is used as a supplementary me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com