Method for closed-loop magnetic fluid power generation by making use of latent heat of vaporization and cyclic power generation system

A technology of magnetic fluid power generation and latent heat of vaporization, which is applied to electrical components, electromechanical devices, etc., to achieve the effects of simple devices, fast start and stop, and improved thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] specific implementation plan

[0026] The specific implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. The following examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

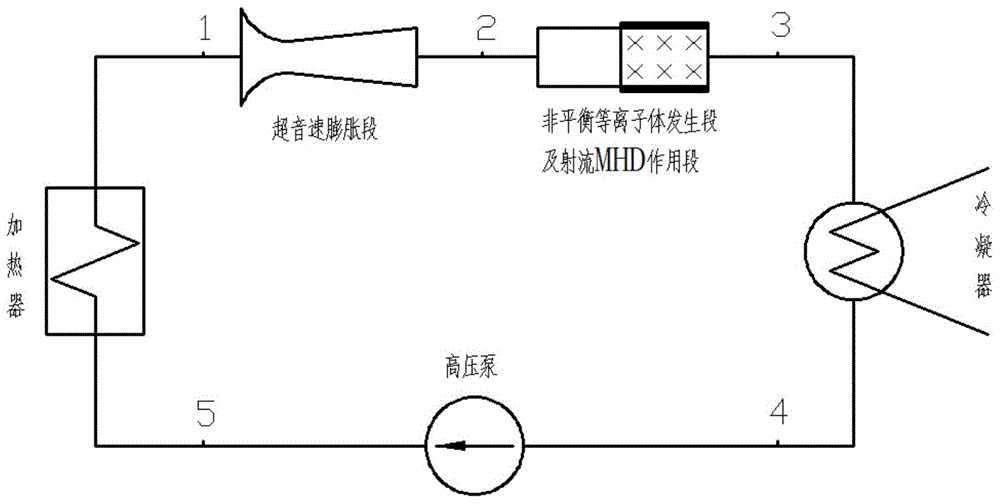

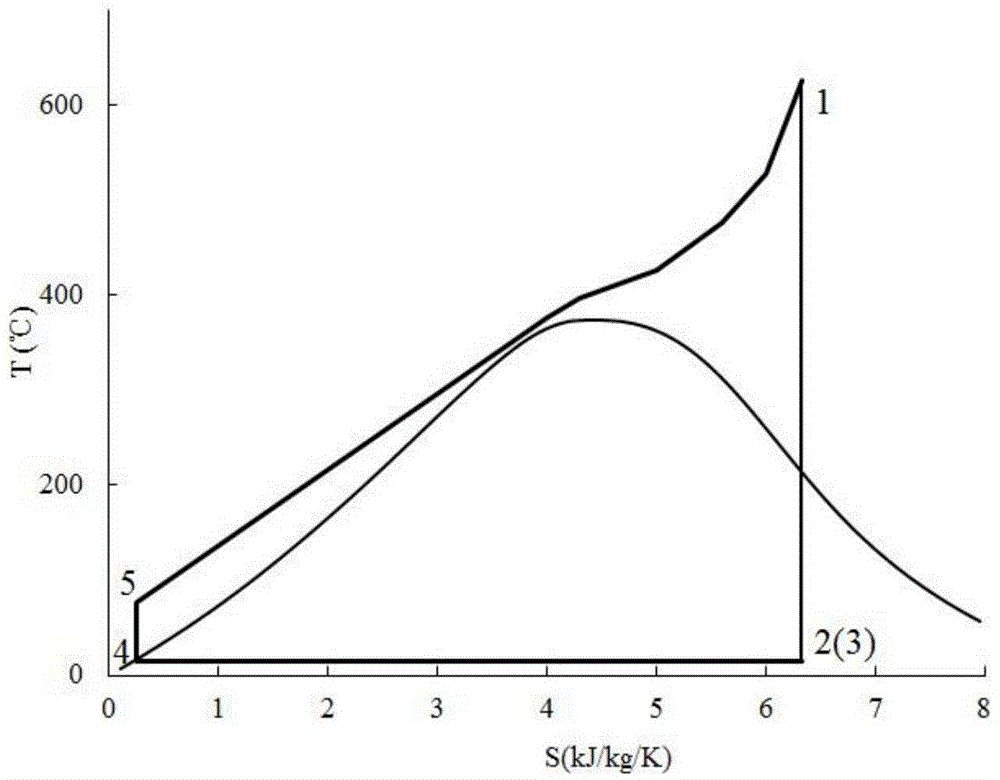

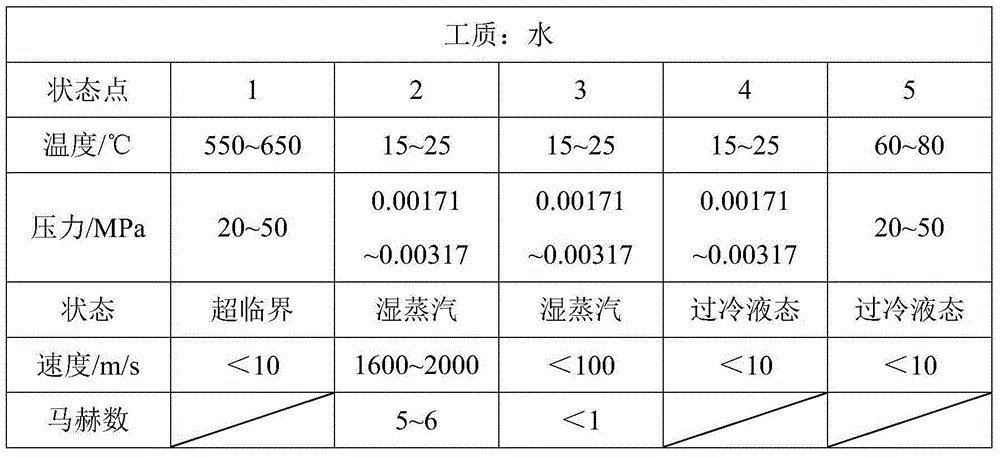

[0027] like figure 1 , a closed-loop magnetic fluid cycle power generation system that can utilize the latent heat of vaporization of the present invention includes six components: a supersonic expansion section, a non-equilibrium plasma generation section, a jet MHD action section, a condenser, a high-pressure pump and a heater.

[0028] The supersonic expansion section is the supersonic expansion coagulation channel. The supersonic expansion channel is a flow channel whose cross-sectional area shrinks first and then expands. The most common one is the Laval nozzle, and its purpose is to obtain high-speed fluid. During the flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com