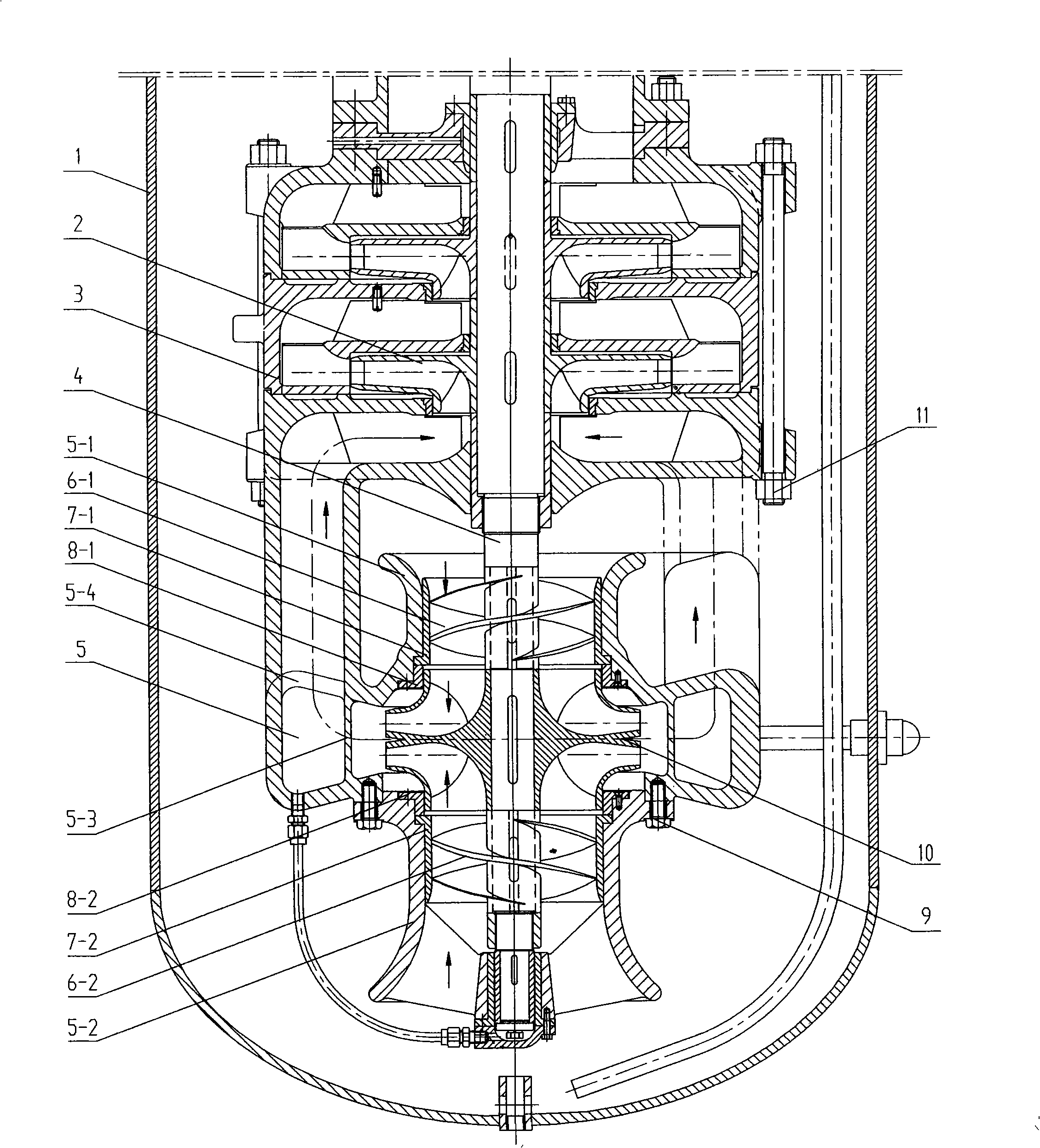

Vertical type multilevel barrel bag pump

A barrel pump, vertical technology, applied in the field of vertical multi-stage barrel pumps, can solve problems affecting pump efficiency, poor performance, large fluid energy loss, etc., to improve efficiency and operational reliability, and shorten the height of barrel bags and volume, easy installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

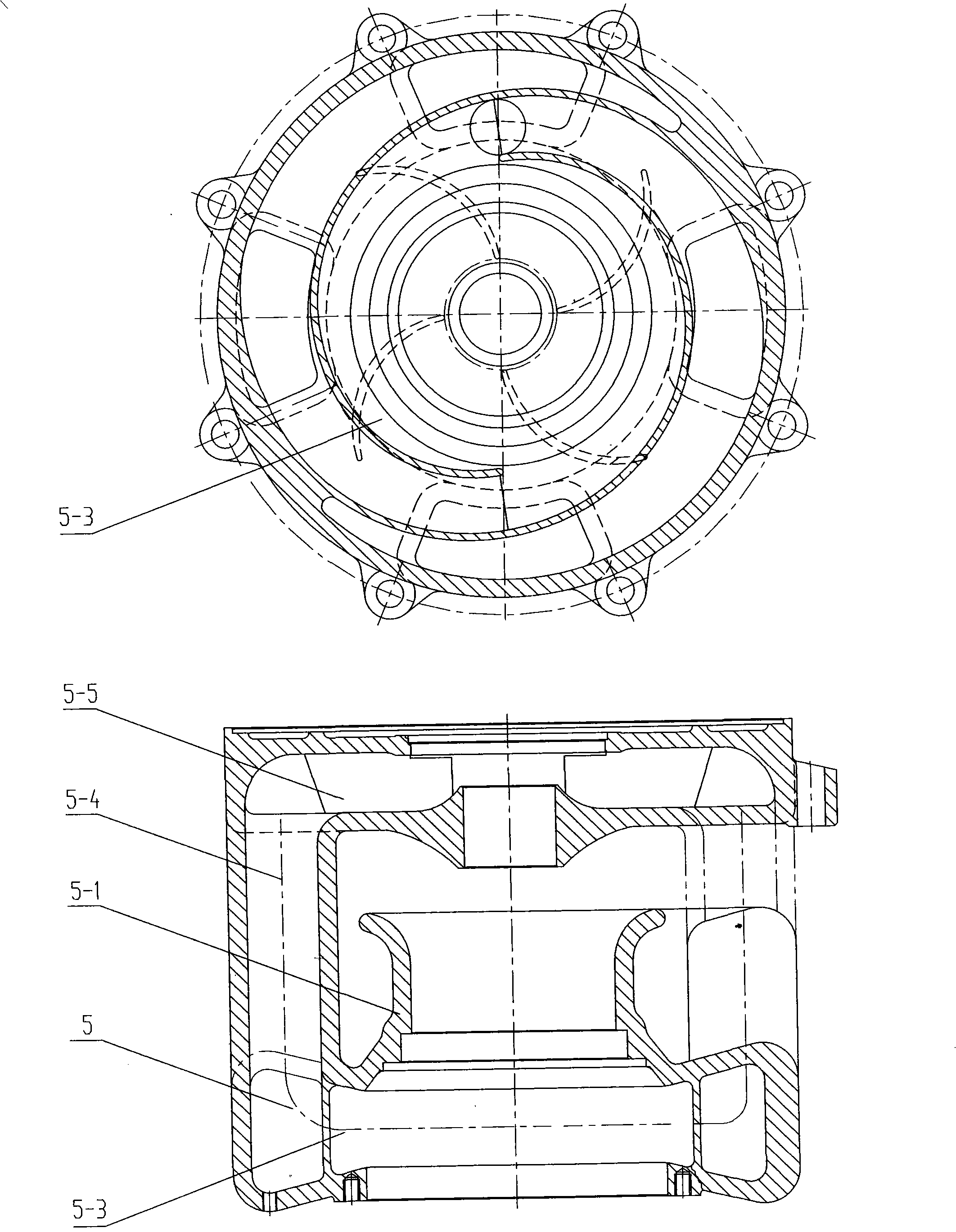

[0008] The structure of the upper half of the vertical multistage barrel pump according to the present invention is the same as that of the conventional vertical multistage barrel pump, so it will not be repeated here. refer to figure 1 As shown, the present invention includes basic components such as a rotating shaft 4, a rear-stage pump body 3, an impeller 2, and a barrel bag 1, and also includes a first-stage pump body 5 with a double-channel radial volute 5-3. On the shaft 4 at the center of the volute 5-3, a double-suction impeller 10 is housed, and on the shaft 4 above and below the double-suction impeller 10, a front inducer 6-1, 6-2 is respectively provided, and the inducer 6- 1 and 6-2 are placed in the matching suction conduits 5-1 and 5-2, and the suction conduits 5-1 and 5-2 are connected with the primary pump body 5. The above-mentioned double-suction impeller 10 is formed on the basis of the single-suction impeller, with the back surface of the single-suction im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com