Method and device for determining feasibility of setting filters at inlet pipes of water pumps in nuclear power plants

A determination method and filter technology, applied in the field of data processing, to achieve the effect of convenient and easy determination and avoiding cavitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

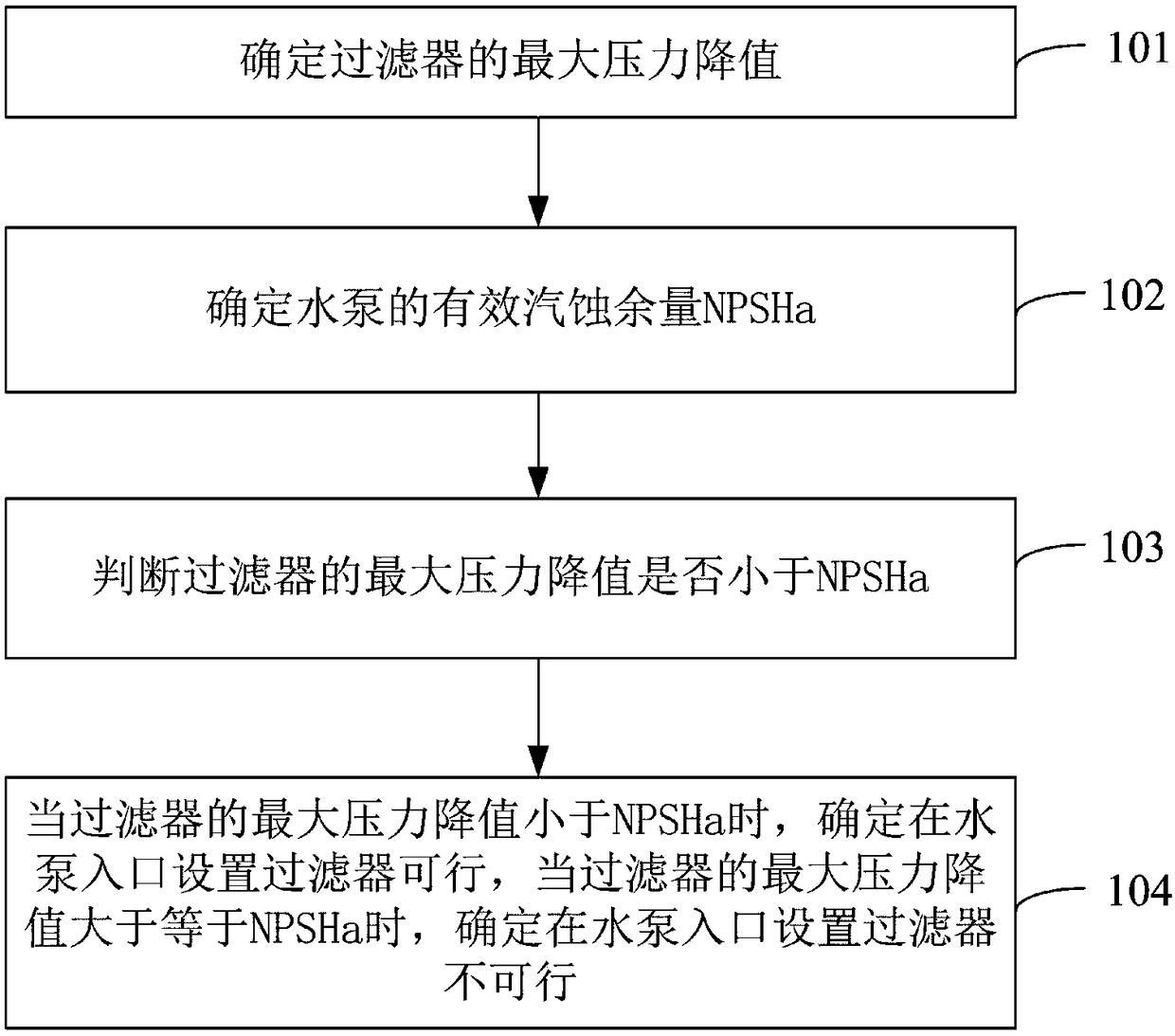

[0067] refer to figure 1 , shows a flow chart of the steps of a method for determining the feasibility of installing a filter in the inlet pipe of a nuclear power plant water pump according to the present invention, and the method may specifically include:

[0068] Step 101, determine the maximum pressure drop value ΔP of the filter max ;

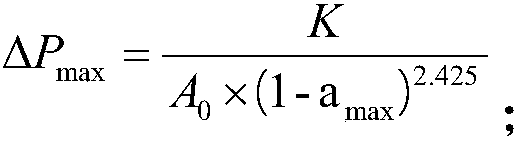

[0069] Specifically, ΔP max It can be determined by the following formula:

[0070]

[0071] Wherein, K is the coefficient of formula (1), is a definite constant value; A0 is the initial flow cross-sectional area of filter; a is the clogging coefficient of filter, and its value is from 0 to 100%, and amax is the filter's Maximum blockage factor.

[0072] Since A0 is the initial cross-sectional area of the filter, when the filter is continuously blocked, its cross-sectional area becomes A0×(1-a), and its specific value depends on the size of the clogging coefficient a. When a reaches the maximum blocking coefficient, the cross-se...

Embodiment 2

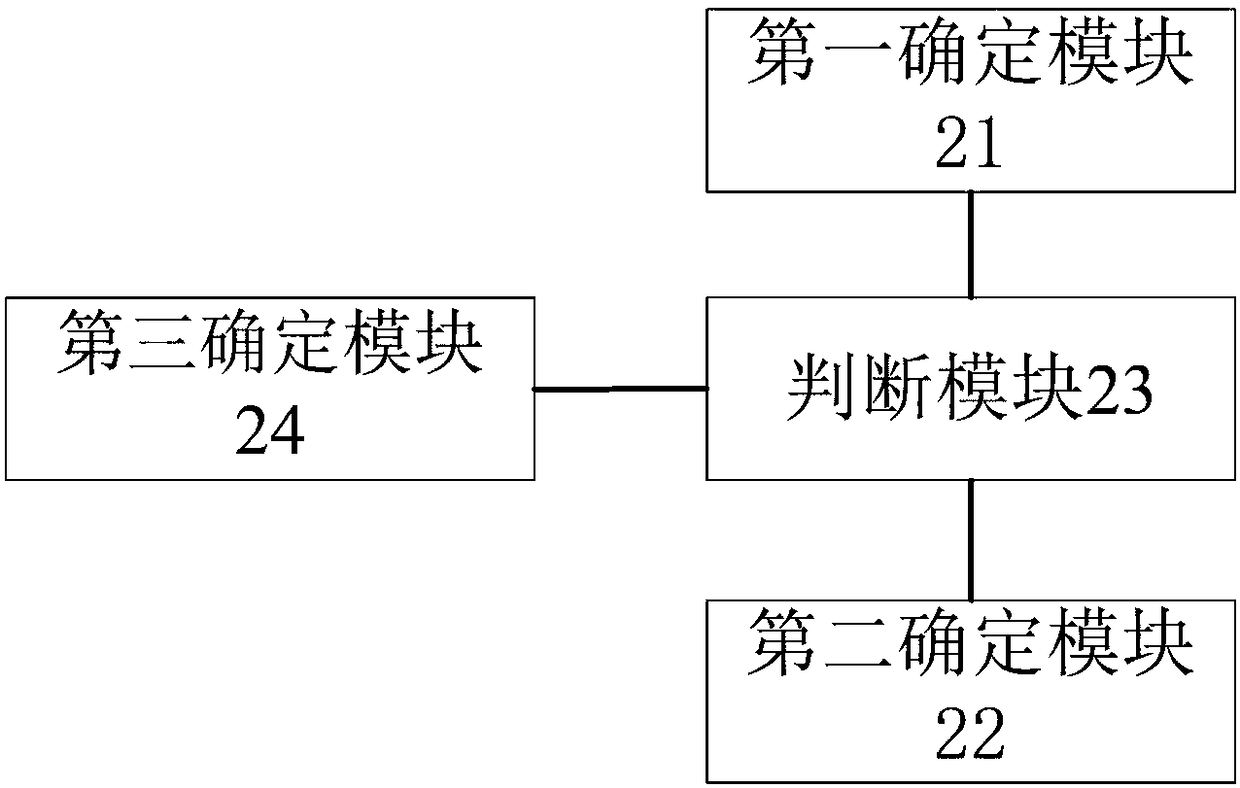

[0102] refer to figure 2 , shows a structural block diagram of an embodiment of a device for determining the feasibility of installing a filter in the inlet pipe of a nuclear power plant water pump according to the present invention, the device includes: a first determining module 21, a second determining module 22, a judging module 23 and a second determining module Determining module 24; wherein,

[0103] The first determination module 21 is used to determine the maximum pressure drop value ΔP of the filter max ;

[0104] The second determination module 22 is used to determine the effective NPSH NPSHa of the water pump;

[0105] Judgment module 23, for judging ΔP max Is it less than NPSHa;

[0106] The third determining module 24 is used for determining ΔP when the judging module 23 max When it is less than NPSHa, it is determined that it is feasible to install a filter at the water pump inlet; it is also used when the judgment module 23 judges ΔP max When it is great...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com