Method for predicting necessary net positive suction head of axial flow pump based on pump unit

A technology of NPSH and prediction method, which is applied in special data processing applications, instruments, electrical digital data processing, etc., and can solve the hidden dangers of safe and stable operation of axial flow pumping stations, the judgment of necessary NPSH, and the high cost of testing, etc. problems, to achieve huge economic benefits and social impact, to facilitate safe and stable operation, and to speed up the progress of the pumping station project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

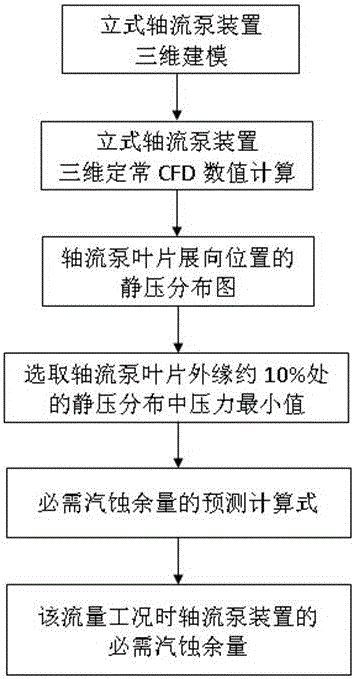

[0018] The present invention will be further elaborated below in conjunction with accompanying drawing and embodiment, the flow chart of the necessary NPSH prediction of a kind of axial flow pump device is as follows figure 1 shown.

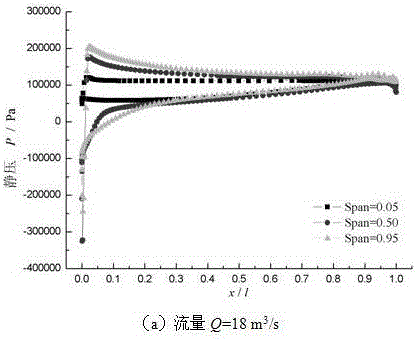

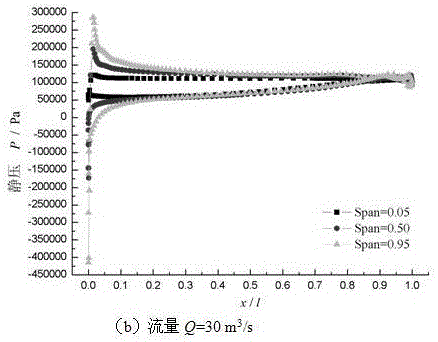

[0019] Taking the vertical axial flow pump device using the TJ04-ZL-23 hydraulic model as an example, the three-dimensional mathematical model of the vertical axial flow pump device was constructed using three-dimensional modeling software, and then the vertical axial flow pump device was constructed using CFD technology. Three flow conditions were carried out (Q=18m 3 / s, 30m 3 / s and 39m 3 / s) of the three-dimensional constant value calculation, the calculation of the three flow conditions all meet the residual convergence accuracy of each physical quantity is lower than 1.0×10 -5 requirements, and the head change tends to be stable. The static pressure distribution curves of the vane pressure along the chord direction are given when the ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com