Welded impeller of canned motor pump used for central air conditioner

A technology for shielding electric pumps and central air conditioners. It is applied to the components, pumps, and pump components of the pumping device for elastic fluids. It can solve the problems of increasing the outlet width of the impeller, low efficiency, and narrow outlet width. Pump efficiency, high efficiency and good anti-cavitation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

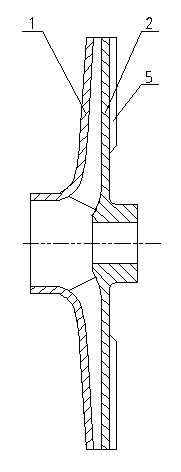

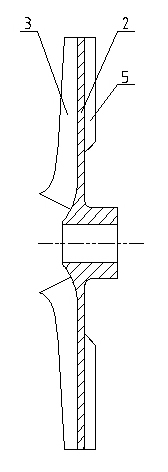

[0019] see figure 1 , the welded impeller of the canned electric pump for central air conditioning includes a front cover plate 1 and a rear cover plate 2 correspondingly matched. The front cover 1 and the back cover 2 are flange-shaped, the front cover middle part is provided with a suction port, the back cover middle part does not have a shaft hole, and the suction port of the front cover is coaxial with the shaft hole of the back cover.

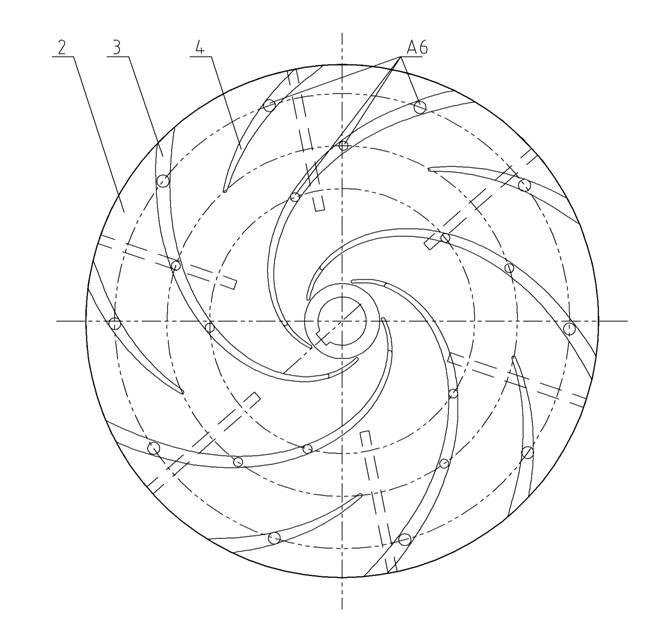

[0020] see image 3 , the inner surface of the back cover 2 is evenly equipped with five long blades 3 and short blades 4 in a spiral radial shape; one end of each long blade 3 is located at the shaft hole, and the other end is located at the edge of the rear cover; each short blade 4 It is located between two adjacent long blades 3, and one end is located at the radial middle of the rear cover, and the other end is located at the edge of the rear cover. see figure 2 and Figure 4 , the outer surface of the rear cover 2 is evenly dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com