Hot investment casting method for electric heating element

An electric heating element and investment casting technology, which is used in the casting of shoulders and gates with multiple points and narrow gaps, can solve the problems of easy deformation of electric heating elements, achieve localization, save procurement costs, and reduce manufacturing. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

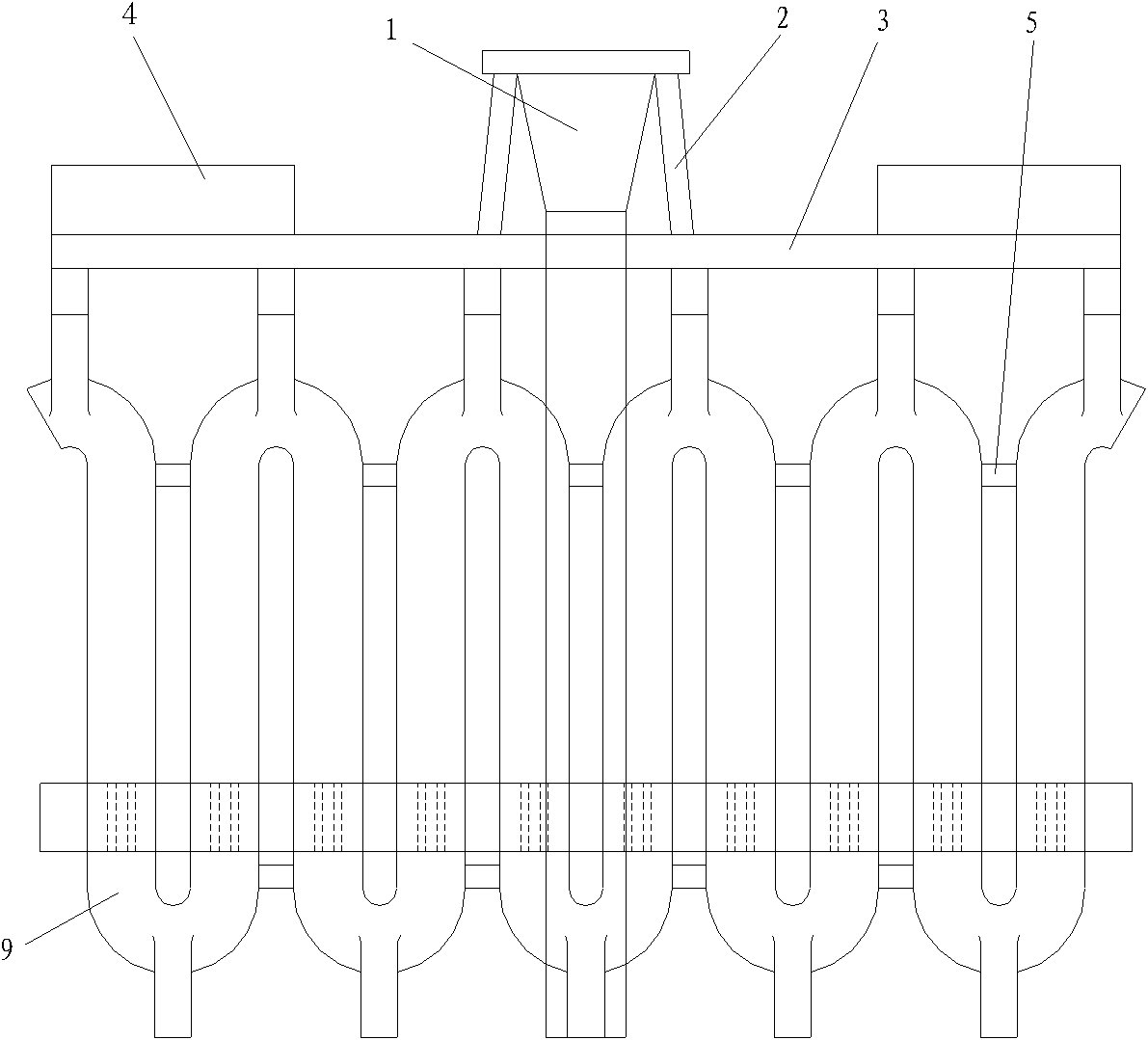

[0022] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

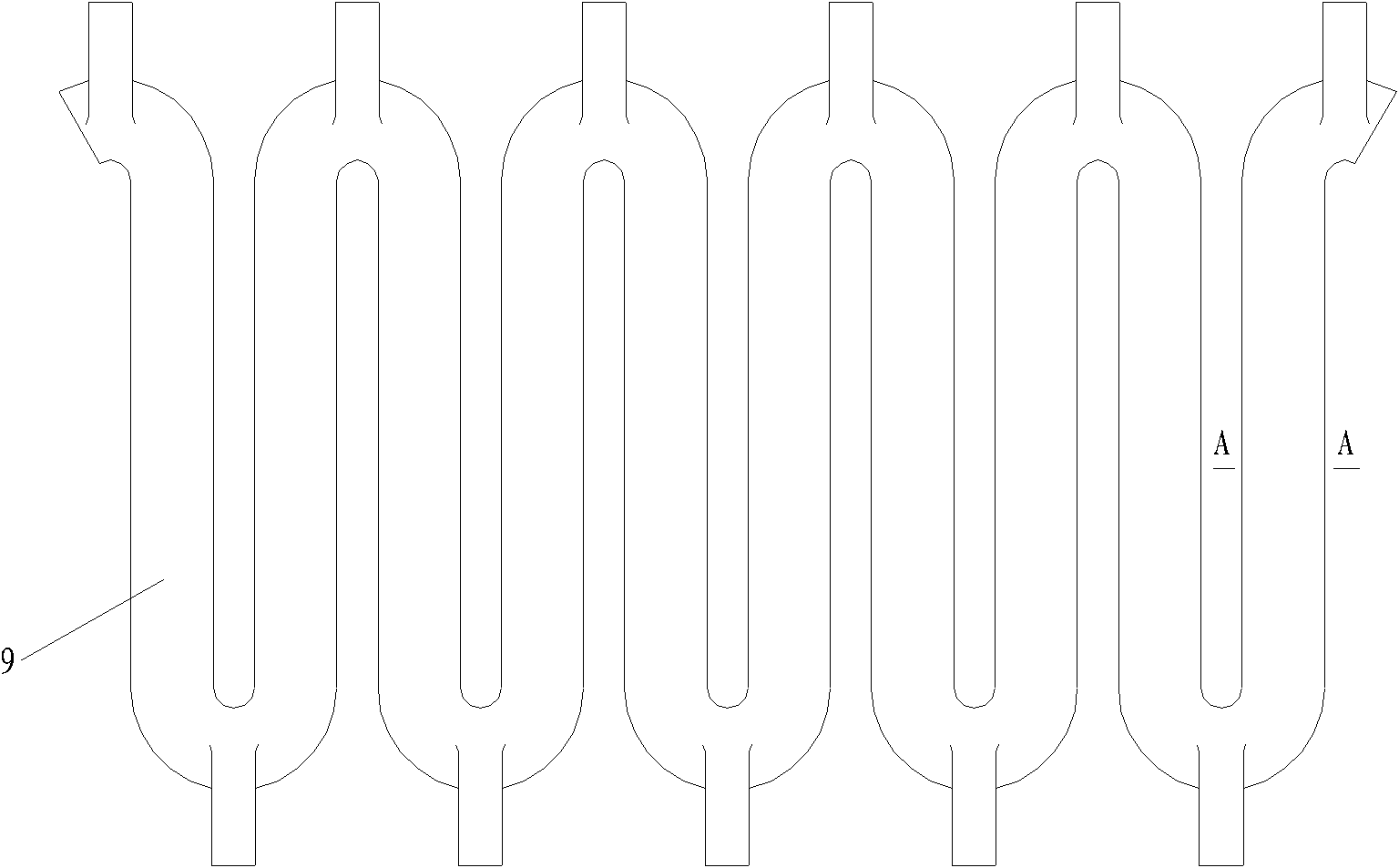

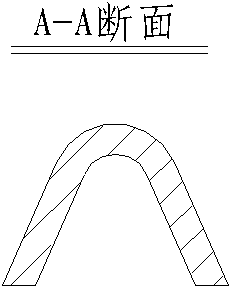

[0023] The electric heating element investment casting method is generally carried out according to the procedures of welding wax molds, making water glass shells, dewaxing, roasting and pouring. The welding wax molds include sprue cups 1, sprues 6, The runner 7 , the ingate 8 to the electric heating element 9 , and the exhaust channel 3 is connected with the sprue cup 1 through the exhaust rod 2 . The invention provides an investment casting method for an electric heating element in order to solve the problem that the electric heating element is easily deformed during the casting process due to its thin wall thickness and is prone to form defects such as pores, slag inclusions, and lack of meat.

[0024] The first step is to press figure 1 The shown group of welding wax patterns, wherein the wall thickne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com