Anti-cavitation cantilever centrifugal pump and manufacturing method thereof

A centrifugal pump and anti-cavitation technology, which is applied in the direction of pumps, pump components, non-variable pumps, etc., can solve the problems that the performance parameters of centrifugal pumps cannot meet the device requirements, the pump curve is prone to humps, and standard water pumps have cavitation. , to achieve superior cavitation resistance, easy control of dimensional tolerances, and stable product manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

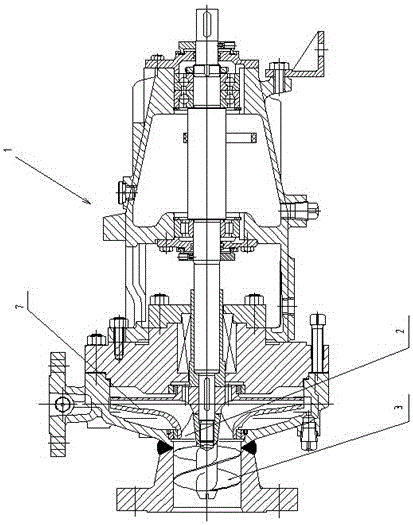

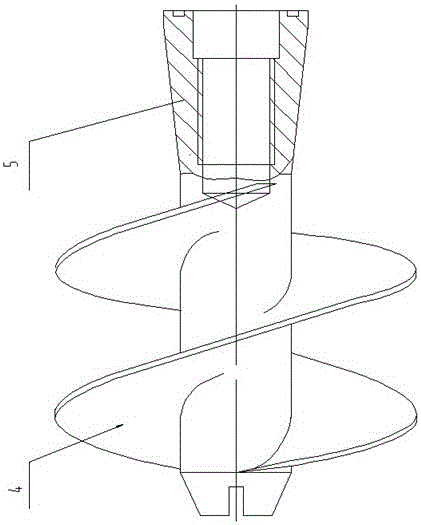

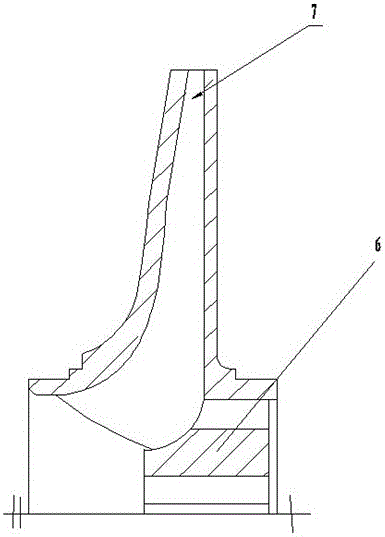

[0017] see Figure 1~3 In the single-stage cantilever pump 1, the impeller inlet 2 at the front of the impeller 7 is provided with an inducer 3, the inducer is a welded inducer, and the blade 4 of the inducer is made of steel sheet, and the thickness of the blade can be reduced to 2mm, can be reduced to thinner according to needs, the blade of the inducer is welded on the hub 5 of the inducer; the width of the impeller outlet 7 of the single-stage cantilever pump is smaller than the height of the impeller base 6 .

[0018] Its preparation method comprises the following steps:

[0019] 1) Prepare the components of the centrifugal pump (except the front cover of the impeller) and the inducer according to the standard. The hub of the inducer is turned from a bar, and the hub of the inducer is shuttle-shaped; the blades of the inducer are sheet metal The piece is processed by a sheet metal fitter, and its shape is a radian on the Z axis in the space coordinate system, and the pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com