Low-temperature deep-well pump

A deep well pump, low temperature technology, applied in the direction of pumps, pump components, non-variable pumps, etc., can solve the problems of high cost investment, high requirements for materials and manufacturing technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

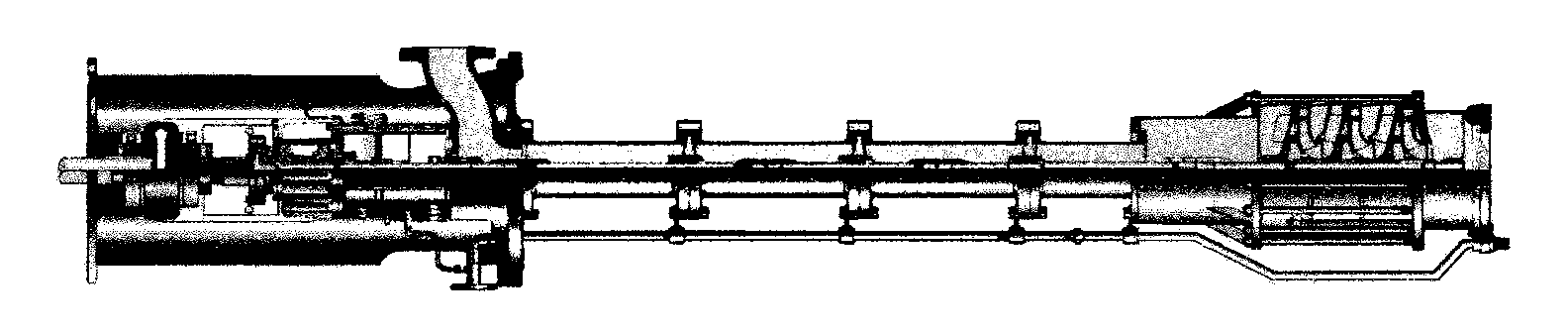

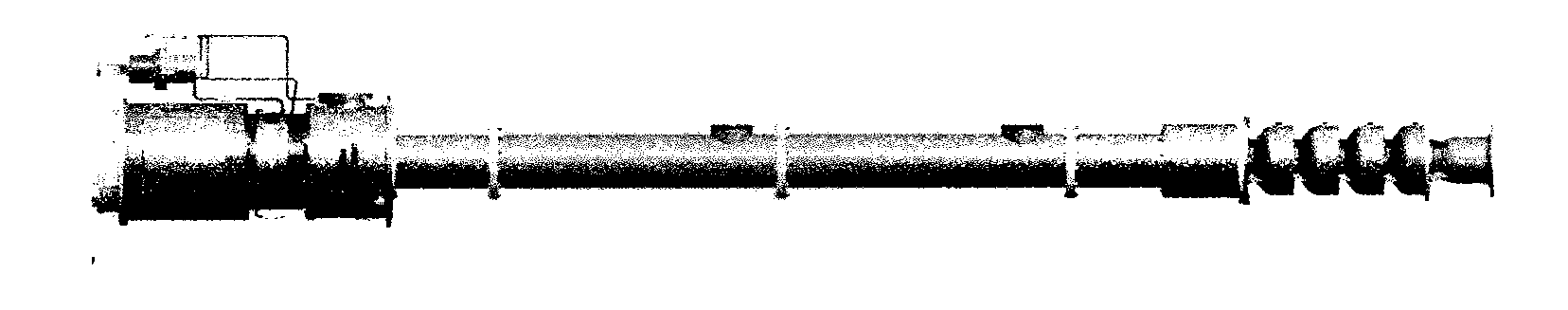

[0074] see Figure 3-6 ,

[0075] The guide vane and impeller assembly adopts a vertical single-casing space guide vane centrifugal pump with multiple sliding bearings. Higher efficiency, minimum radial force, large number of sliding bearings, long service life of sliding bearings, fixed axial thrust direction, small thermal shock deformation, small vibration, easy hoisting, see Figure 4 ;Cylinder assembly adopts a detachable single tube with sliding bearing bracket structure. Axisymmetric, consistent temperature influence, not suitable for deformation; single tube part in the cylinder part can be disassembled and installed separately, easy to maintain; grooved gasket is used, and the tubes are easy to center: the coupling adopts key connection, which is not easy to bite Dead: The sliding bearing is lubricated by pumping medium, which makes the operation easier, see Figure 5 ;The pump spit assembly is connected by a bearing supporting the motor bracket. The motor bracket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com