Method for preventing urea pump from cavitation corrosion in post-treatment system

A urea dosing pump and post-processing technology, which is applied to the electronic control of the exhaust treatment device, the diagnosis device of the exhaust treatment device, and the exhaust treatment, etc., can solve the problems of damage to the urea pump and cavitation of the urea pump.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

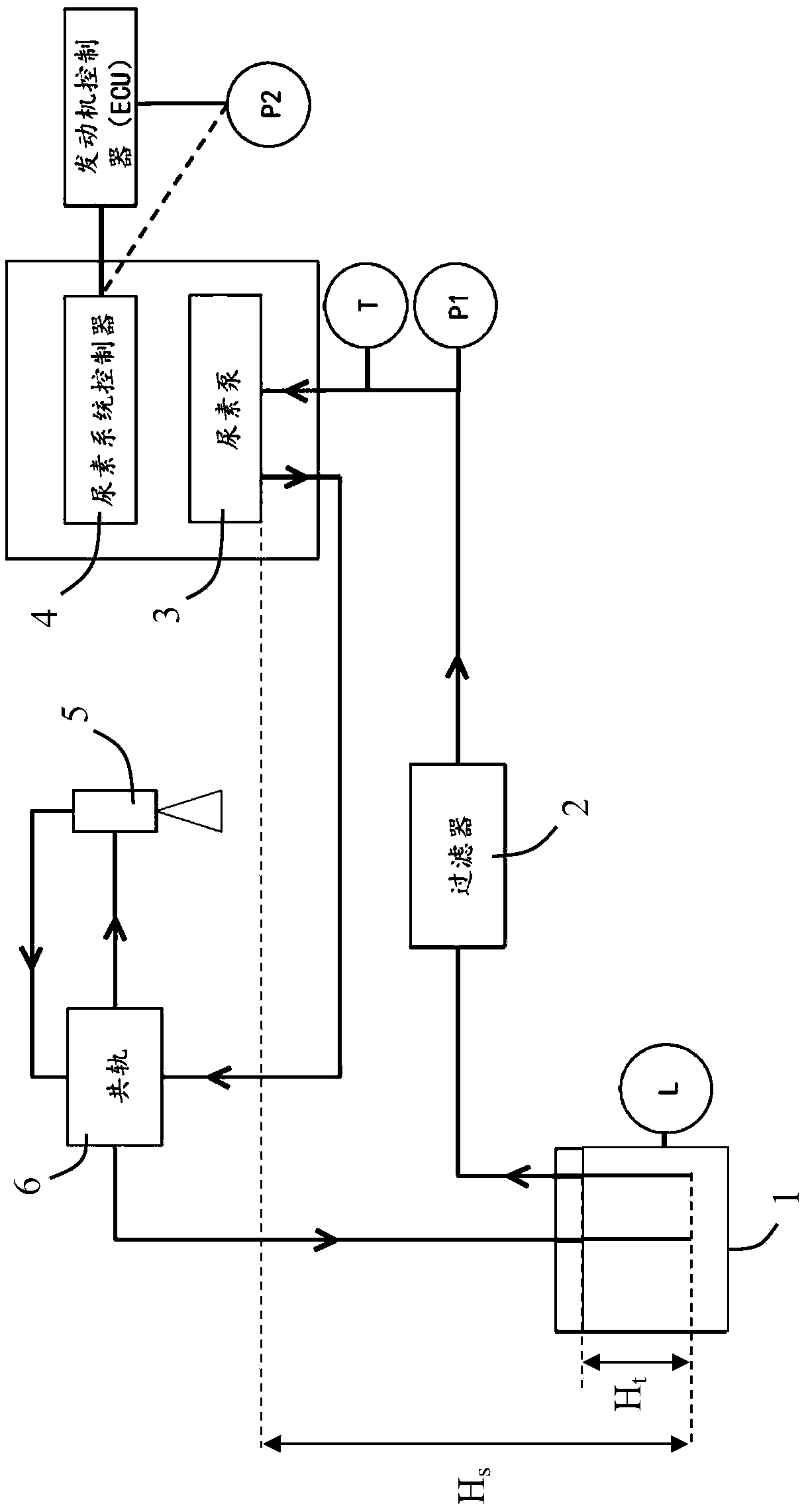

[0045] Please refer to figure 1 As shown, the present invention discloses an aftertreatment system for treating exhaust gas from a diesel engine. The post-treatment system includes a urea tank 1, a filter 2 connected to the urea tank 1, a urea pump 3 for sucking urea solution from the urea tank 1, and a common pump 3 in fluid communication with the urea tank 1. rail 4, the urea nozzle 5 communicating with the common rail 4, the temperature sensor T connected in the flow path of the aftertreatment system, the vacuum pressure sensor P1 connected upstream of the inlet of the urea pump 3, and the The aftertreatment system is controlled by a urea system controller 6 . The urea nozzle 5 is used to spray urea droplets into the exhaust of the engine, and the excess urea solution flows back to the common rail 4 and finally returns to the urea tank 1 . The urea system controller 6 communicates with the engine controller (ECU). The urea droplets are broken down in the engine's exhaust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com