Automatic testing system and method for water pump net positive suction head

An automatic test system and NPSH technology, which is applied in pump test, machine/engine, liquid variable capacity machinery, etc., can solve the problems of large test error, high labor intensity, low efficiency, etc., to reduce labor intensity, Effects of improving working environment, improving test efficiency and test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

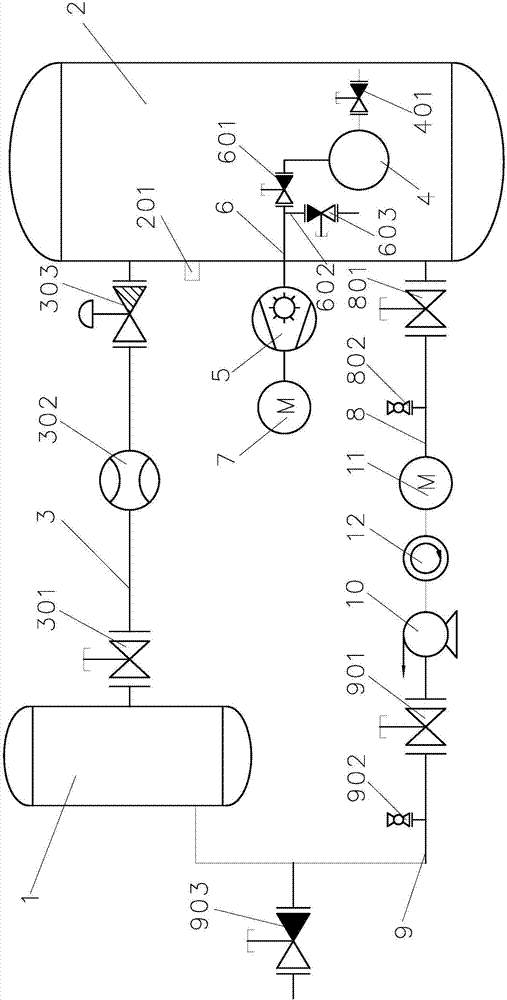

[0036] like figure 1 As shown, a water pump NPSH automatic testing system, which includes the following components:

[0037] (1) The discharge tank 1, the water storage tank 2, and the flow regulation pipeline 3 connecting the discharge tank 1 and the water storage tank 2. The flow regulation pipeline 3 is sequentially installed with an electric gate valve 301, a flow meter 302, and a pneumatic regulation valve 303 . The main function of the electric gate valve 301 is to cut off the water flow in the flow regulating pipeline 3 when the pipeline or instrument needs to be repaired. The flow meter 302 is used to measure the flow rate of the water pump 10 under test. The pneumatic regulating valve 303 is used to regulate the water flow in the flow regulating pipeline 3 . A temperature transmitter 201 is also installed on the water storage tank 2 to measure the liquid temperature in real time.

[0038] (2) The air extraction tank 4 installed on the water storage tank 2, the air...

Embodiment 2

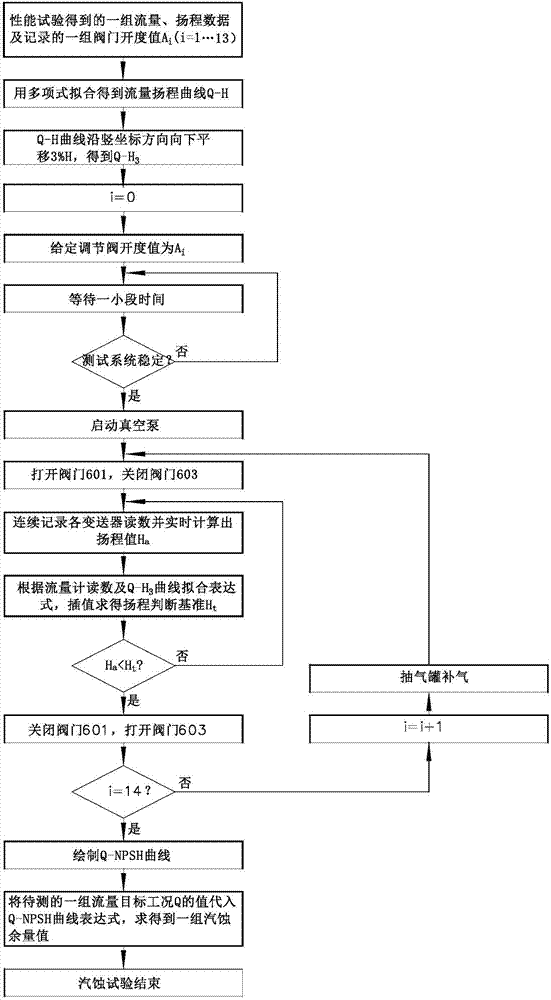

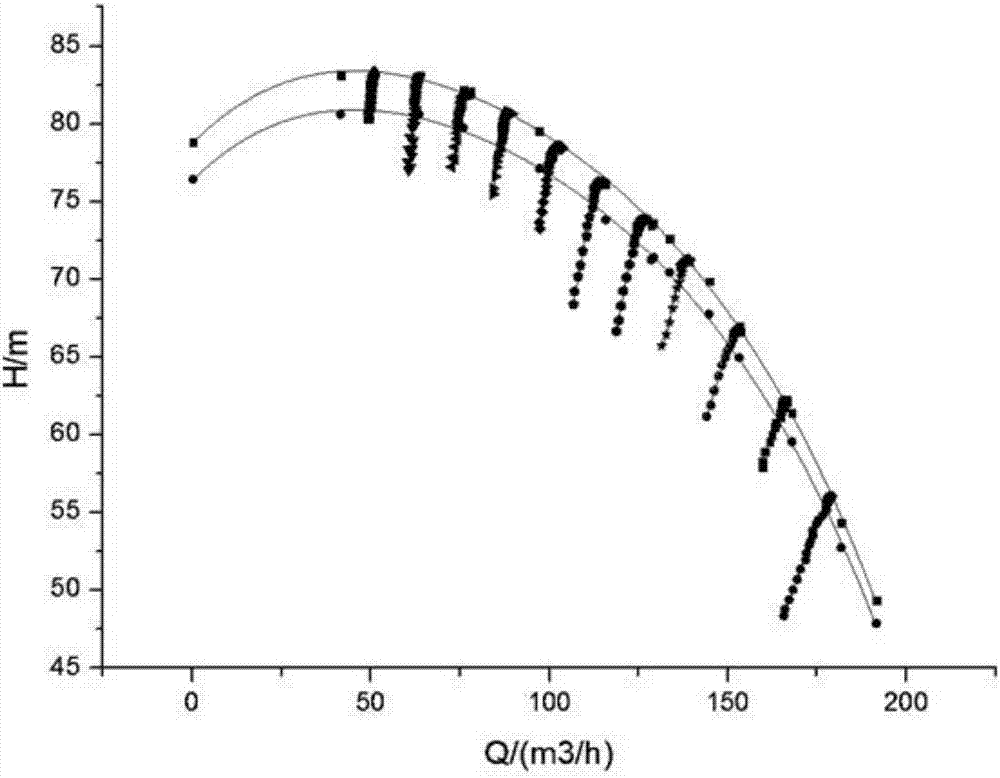

[0046] Embodiment 2 relates to a method for testing the NPSH of a water pump, that is, the method part of the present invention. Generally speaking, before the pump cavitation test, the pump performance test (referred to as performance test) has been carried out first, and a set of flow and head data can be obtained through the performance test. During the cavitation test, the flow and head data can be fitted into a flow-head curve Q-H by a polynomial, and the curve can be shifted down by 3% along the vertical coordinate (that is, each point on the curve corresponds to the coordinate system). The height value H drops by 3%), and the cavitation test judgment reference curve Q-H is obtained. 3. In addition, during the performance test, a set of flow and valve opening data will be obtained, that is, each target flow value corresponds to a valve opening value. These data are also useful for cavitation tests. In a word, the present invention makes full use of the performance test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com