Design method of axial flow type low-lift prepositioned inducer

A design method and technology of inducer, which are applied to the components of pumping device for elastic fluid, mechanical equipment, non-variable-capacity pump, etc. Problems such as low suction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

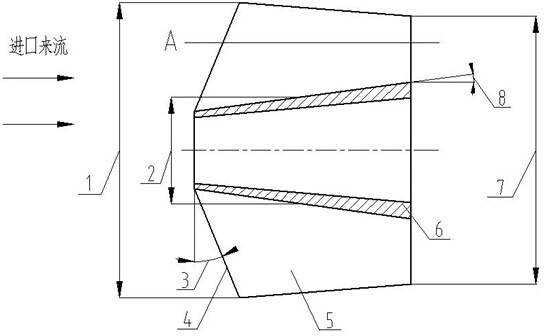

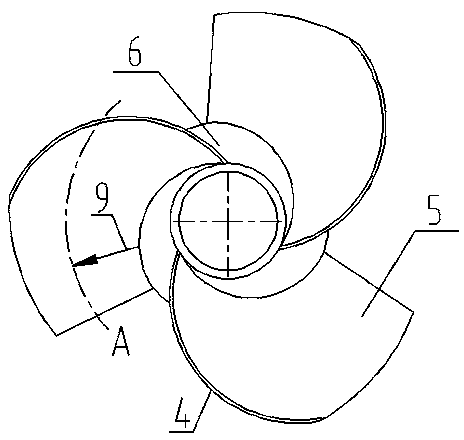

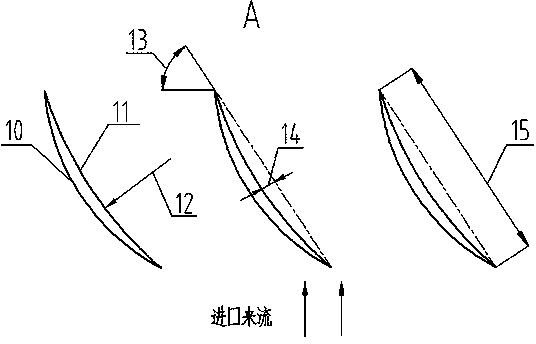

[0073] Figure 1 to Figure 3 The geometric shape and size parameters of this embodiment of the inducer are jointly determined. This is an axial flow type low-lift centrifugal pump with a front inducer. In the design of the axial surface, the inlet edge (4) of the inducer blade is inclined to the direction of the inducer outlet, and the inducer hub (6) is tapered The diameter (7) of the outer edge of the exit edge of the inducer is slightly smaller than the diameter (1) of the outer edge of the inducer. This structure makes the change of the axial flow passage of the inducer more uniform, which is beneficial to reduce the degree of cavitation on the outer edge of the inlet and the bubble in the flow passage. Intrusive. The shape of the inducer blade (5) is mainly determined by the airfoil parameters of the flow surface A. The airfoil working surface (11) and the back side (10) of the flow surface A adopt a circular arc structure, and the airfoil chord length (15) ) Is designed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com