Vertical pipeline desulfurization pump for ship

A technology for vertical pipelines and desulfurization pumps, which is applied to non-variable pumps, pumps, components of pumping devices for elastic fluids, etc., which can solve the problem of low medium flow capacity, unfavorable medium flow, and cooling effect Insufficient and other problems, to achieve the effect of solving the limitation of structural space position, good cooling effect, convenient disassembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The content of the present invention will be further described below in conjunction with the drawings and embodiments:

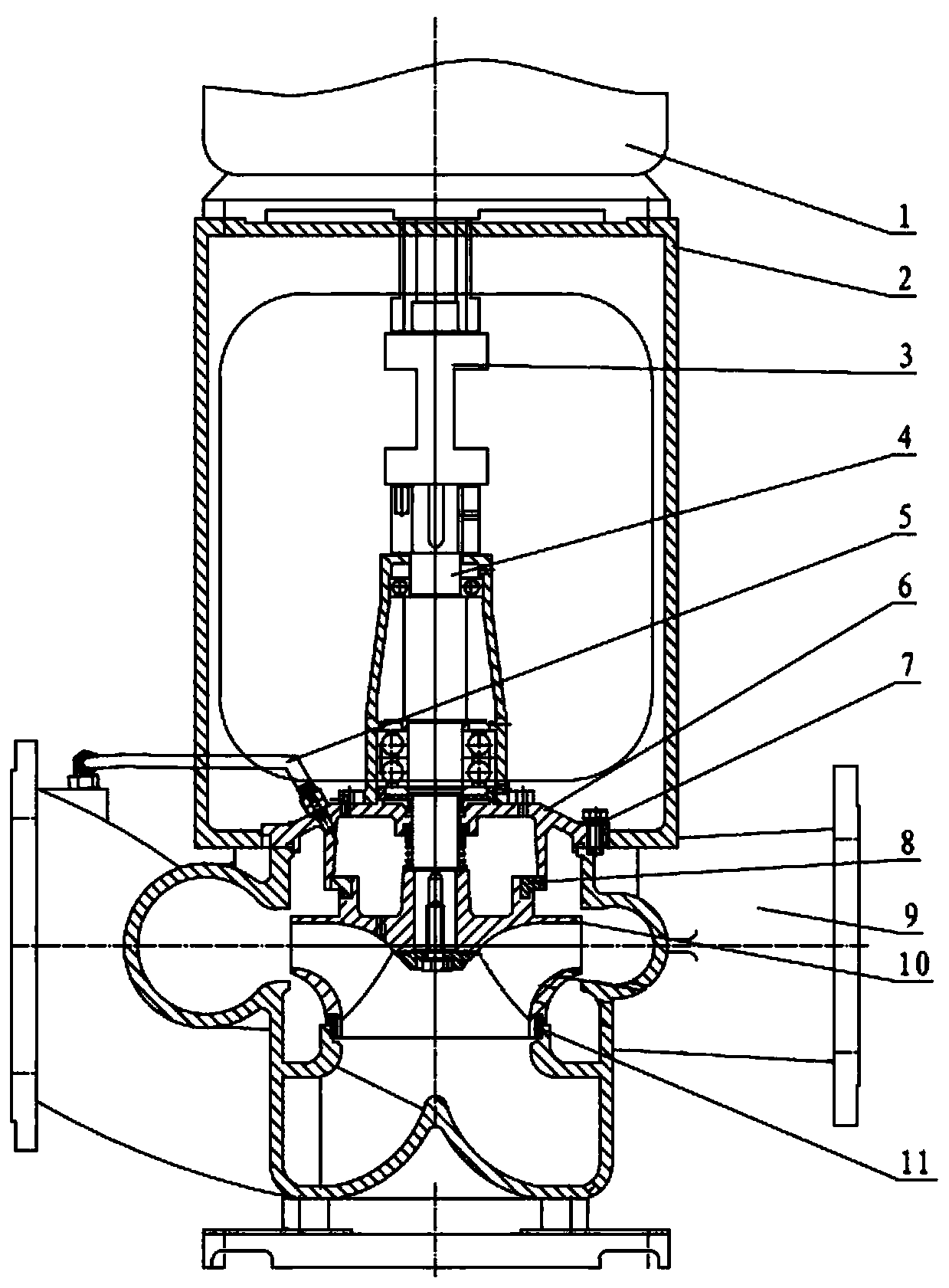

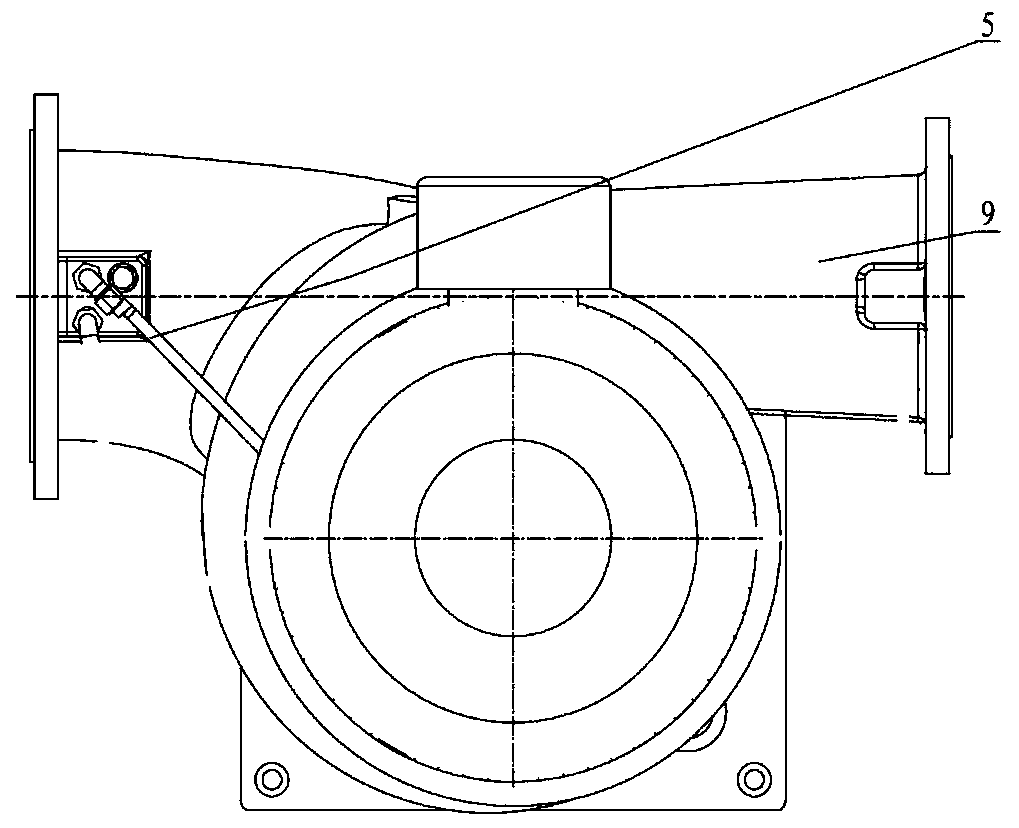

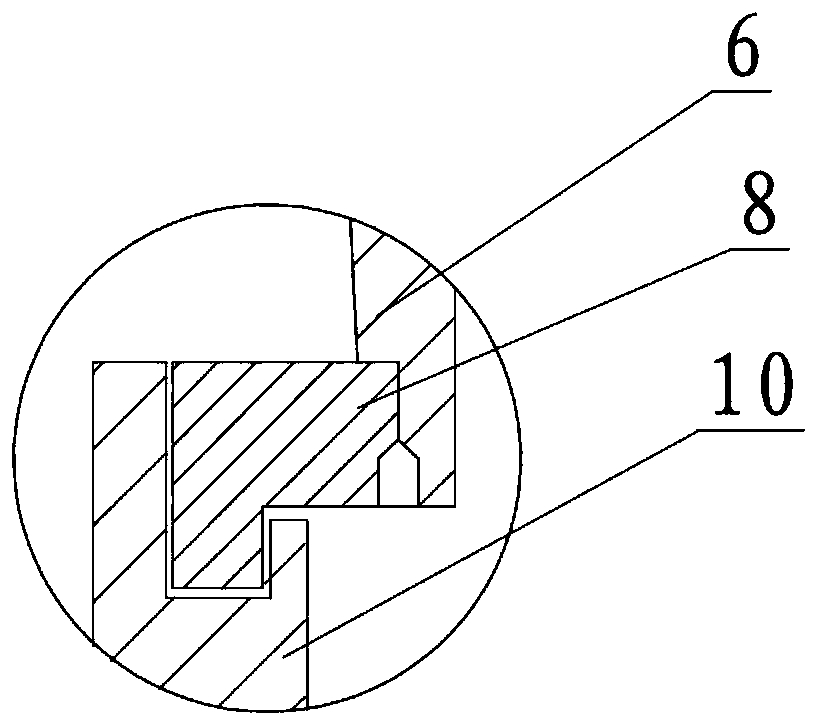

[0023] Such as figure 1 , 2 As shown, a marine vertical pipeline desulfurization pump includes a pump body 9, a pump cover 6 encapsulated on the upper end of the pump body 9, an impeller 10 arranged in the inner cavity of the pump body 9, and a front end and a fixed rear end of the impeller 10 The pump shaft 4 passing through the pump cover 6 and the motor bracket 2 and the motor 1 fixed above the pump body 9 are provided with a mechanical seal at the junction of the pump body 9 and the pump cover 6; the motor bracket 2 The fixed position between the bottom and the upper end of the pump body 9 leaves the packaging position of the pump cover 6, the motor bracket 2 has a disassembly window on the side, the motor 1 is fixed above the motor bracket 2, and the pump The upper end of the shaft 4 and the output shaft of the motor 1 are connected by a coupling 3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com