Layered strip mining method for gently inclined ore body

A mining method and gently inclined technology, which are applied in the field of layered strip mining of gently inclined ore bodies, can solve the problems of restricting mine production capacity, low ore column recovery rate, unstable working face, etc. Reduce the workload of workers, the effect of small workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

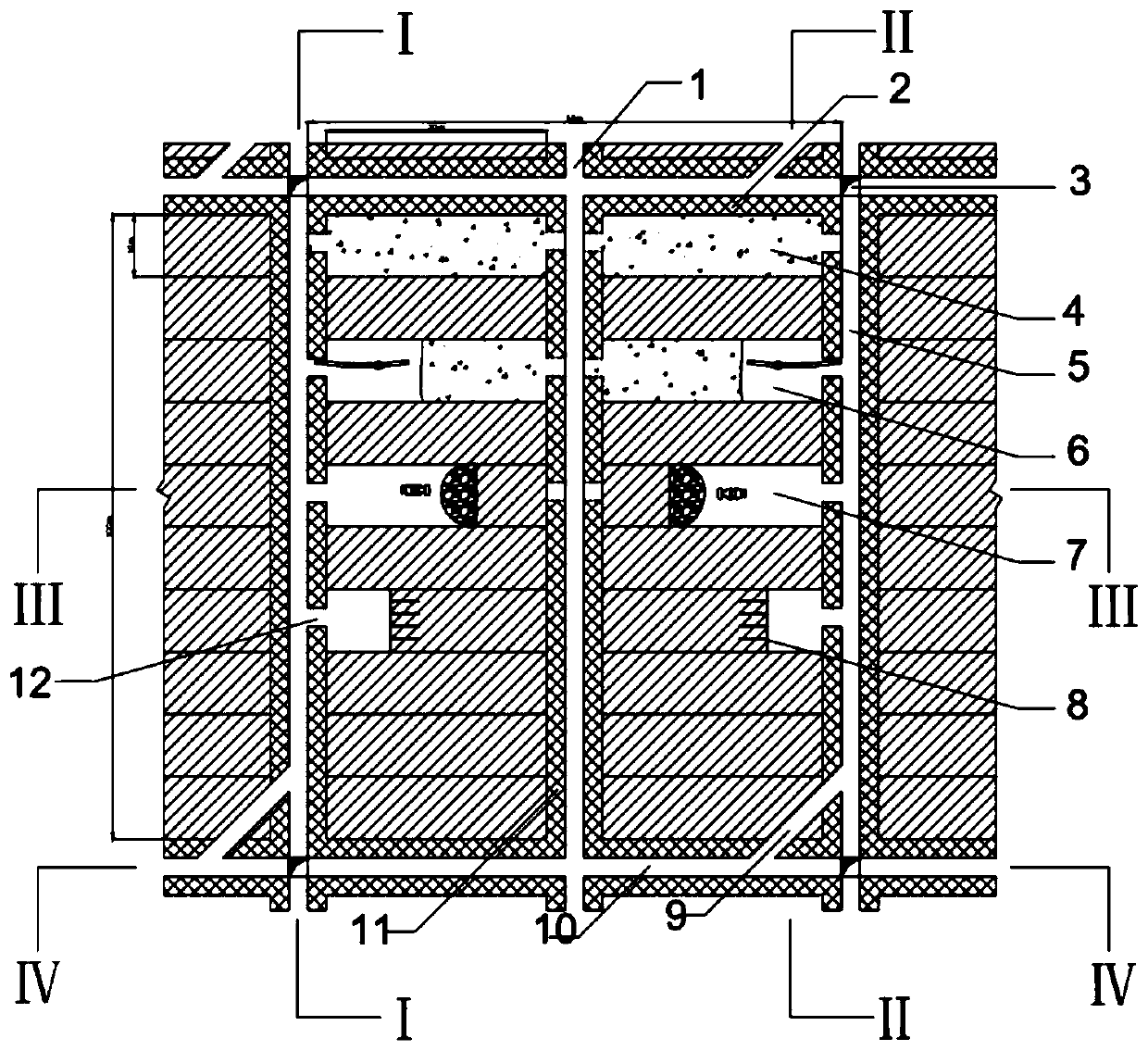

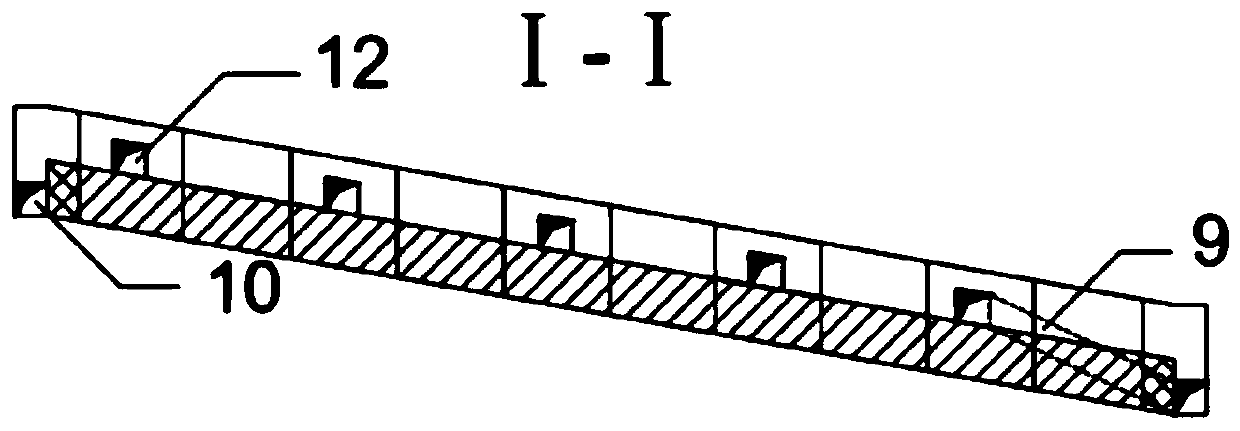

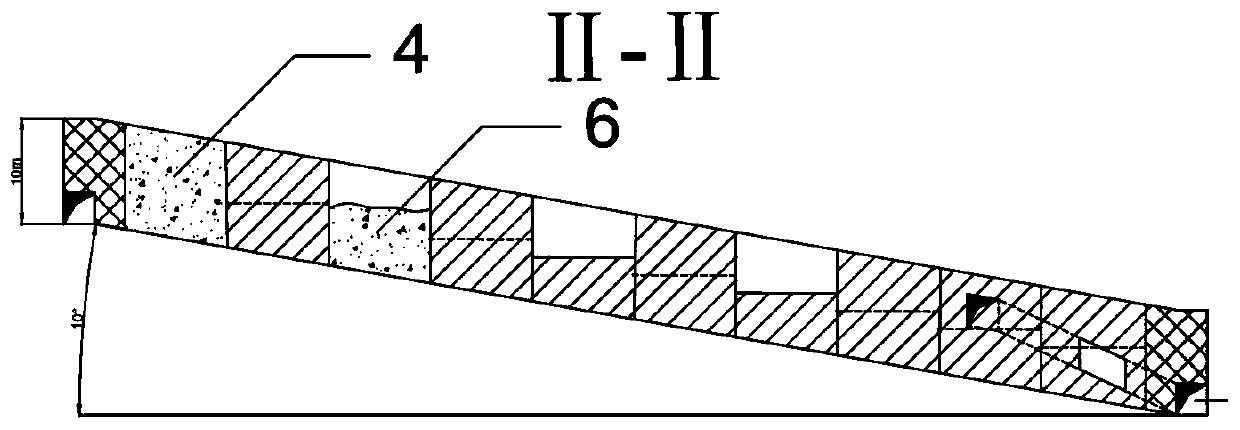

[0038] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0039] A layered strip mining method of a gently inclined thin-medium thick ore body according to an embodiment of the present invention. The ore bodies of this deposit are layered or nearly layered in parallel, with a dip angle of 10 degrees. The length of the ore body along the strike is generally 200-400 meters, and the thickness of the ore layer is generally 4-8 meters. The ore rocks of this deposit have good stability, and the engineering geological conditions of the mining area are of simple-medium type.

[0040] The concrete steps of this ore deposit filling mining method are:

[0041] 1) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com