Patents

Literature

95results about How to "High water consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

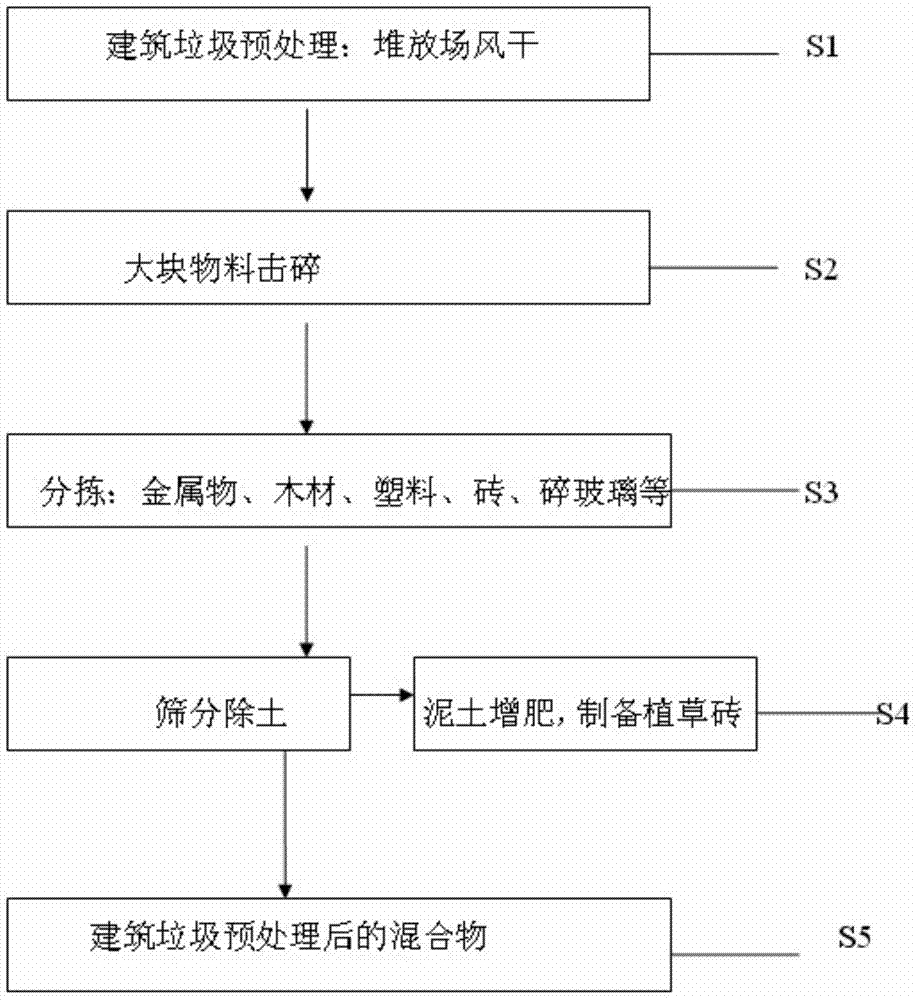

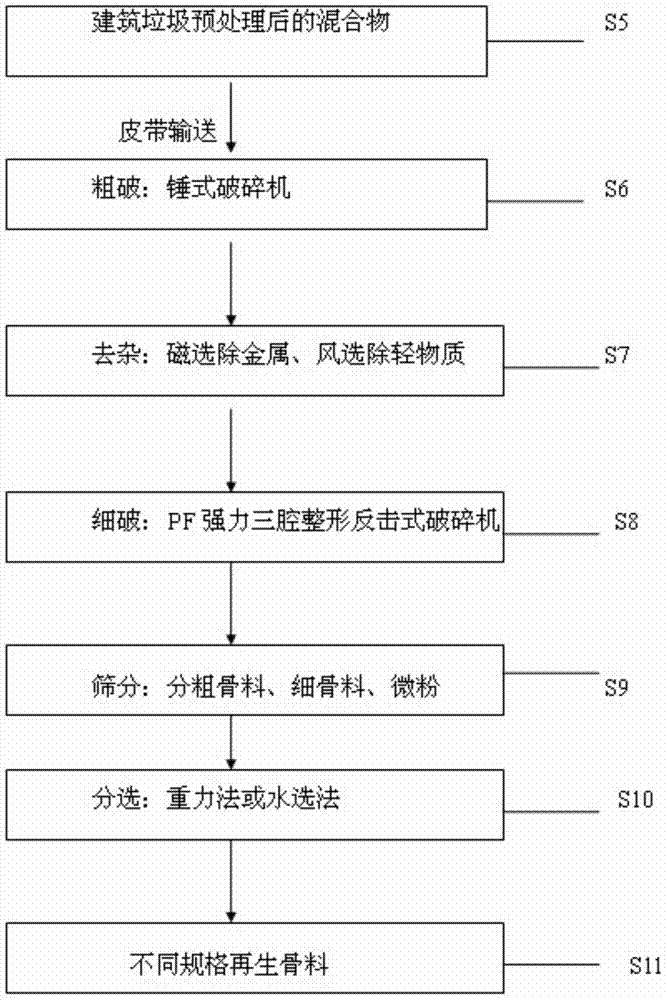

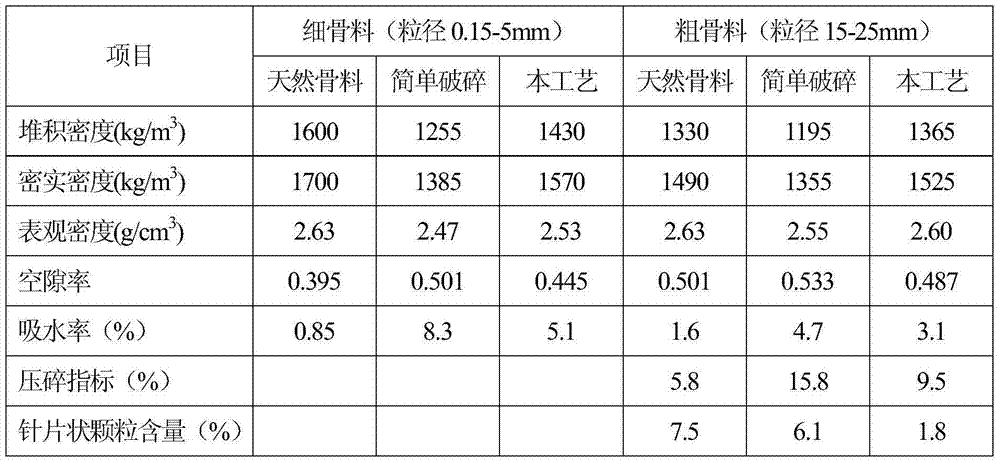

Ecological treatment technology for construction waste

The invention belongs to the field of recycling of construction waste, energy conservation and environment protection, and construction materials, and relates to an ecological treatment technology for construction waste, and particularly relates to the ecological treatment technology for construction waste and a preparation method for regenerated novel construction materials, which can efficiently use the construction waste and does not generate secondary pollution. The ecological treatment technology comprises the following steps of pretreating in a construction waste dump, namely, air drying the construction waste, crushing big blocks, sorting and removing soil through vibrating, adding a fertilizer in the soil to be used for filling grass planting bricks; preparing recycled aggregate, namely, crushing roughly, removing impurities, precisely crushing and simultaneously reinforcing and shaping the recycled aggregate, screening out the recycled aggregate with particle size less than 0.15mm as well as 0.15-5mm, 5-15mm and 15-25mm and micro powder for the secondary time, finally, separating the brick from concrete by a gravitational method or a hydraulic mineral beneficiation method according to different densities of the brick and concrete in the mixed recycled aggregate. Recycling and high value-added utilization of the construction waste are realized, and the ecological treatment technology gets major breakthrough in recycling industry of construction waste.

Owner:DALIAN HONG YUAN GREEN BUILDING MATERIALS

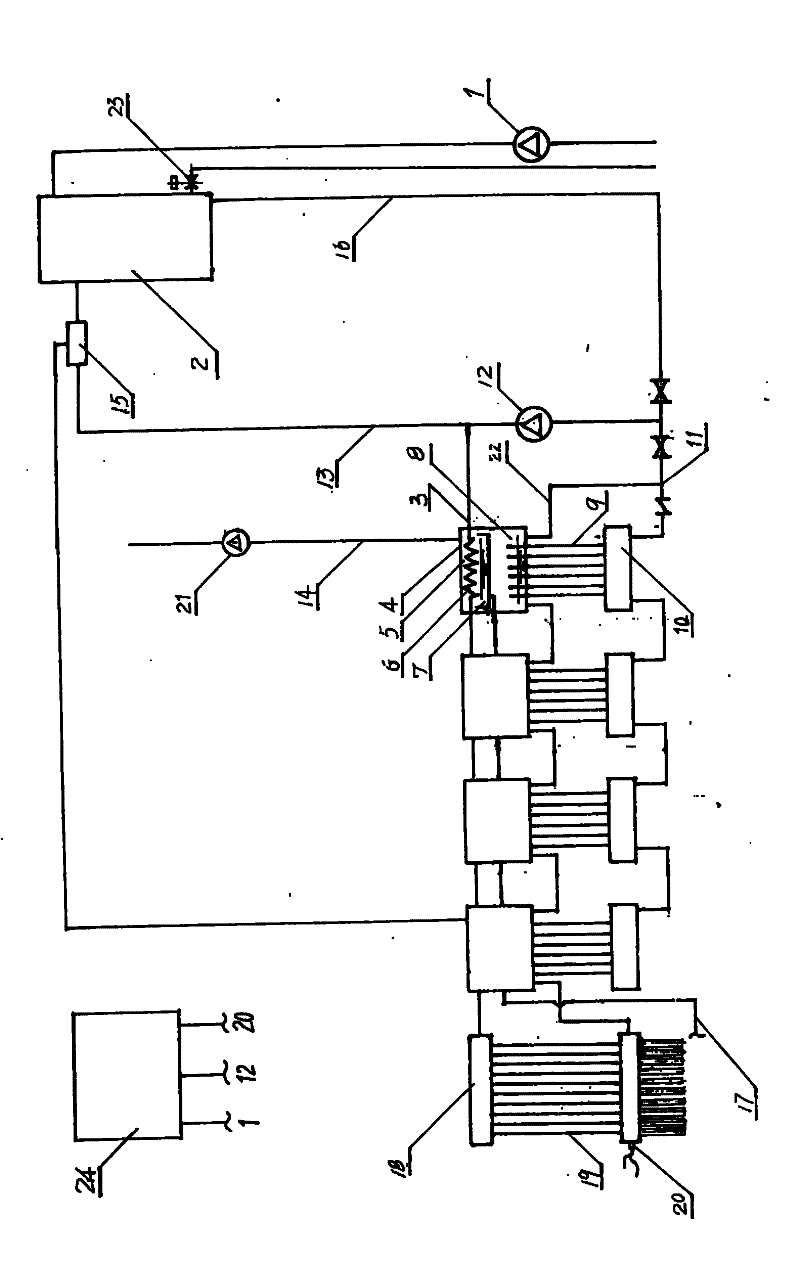

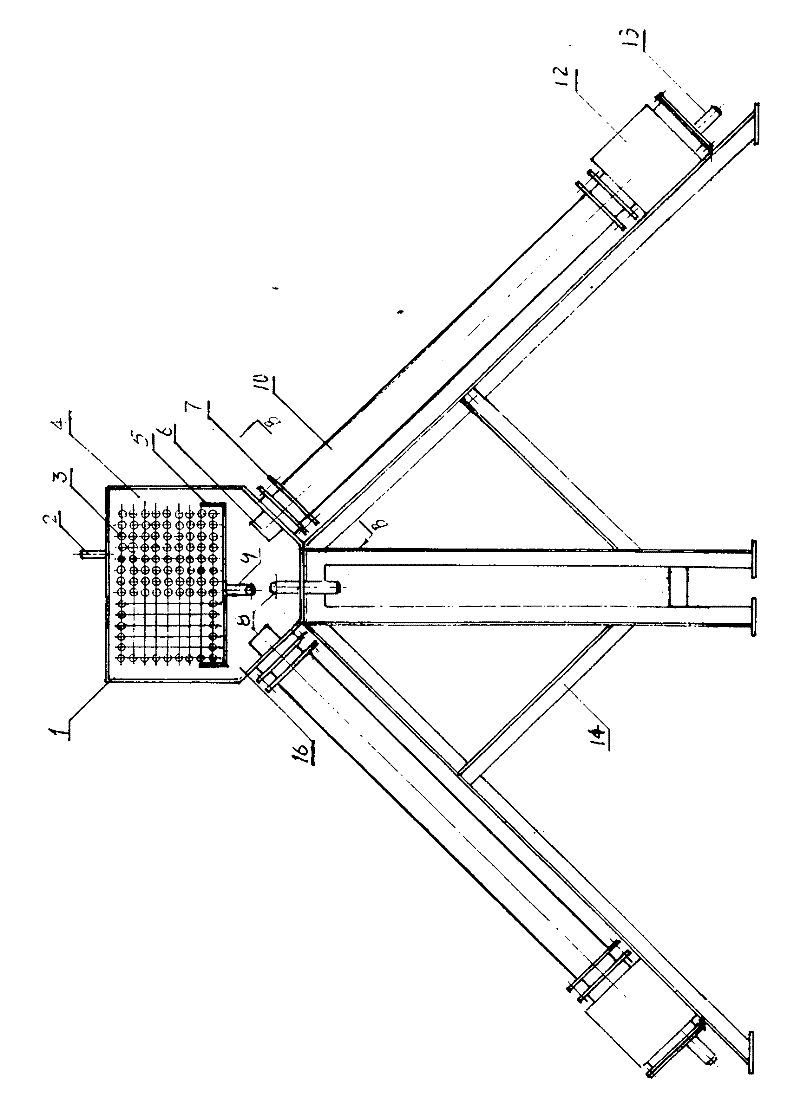

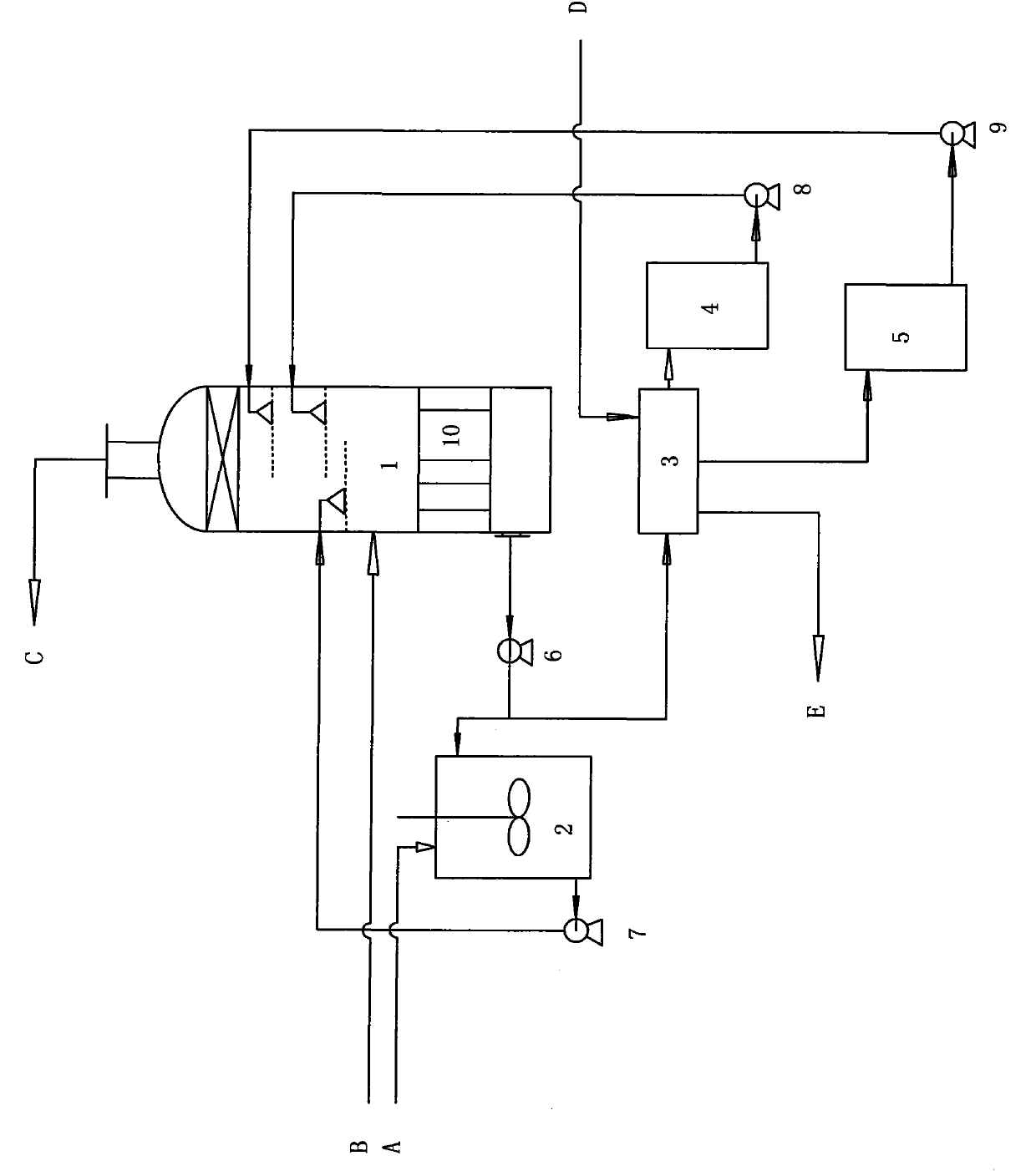

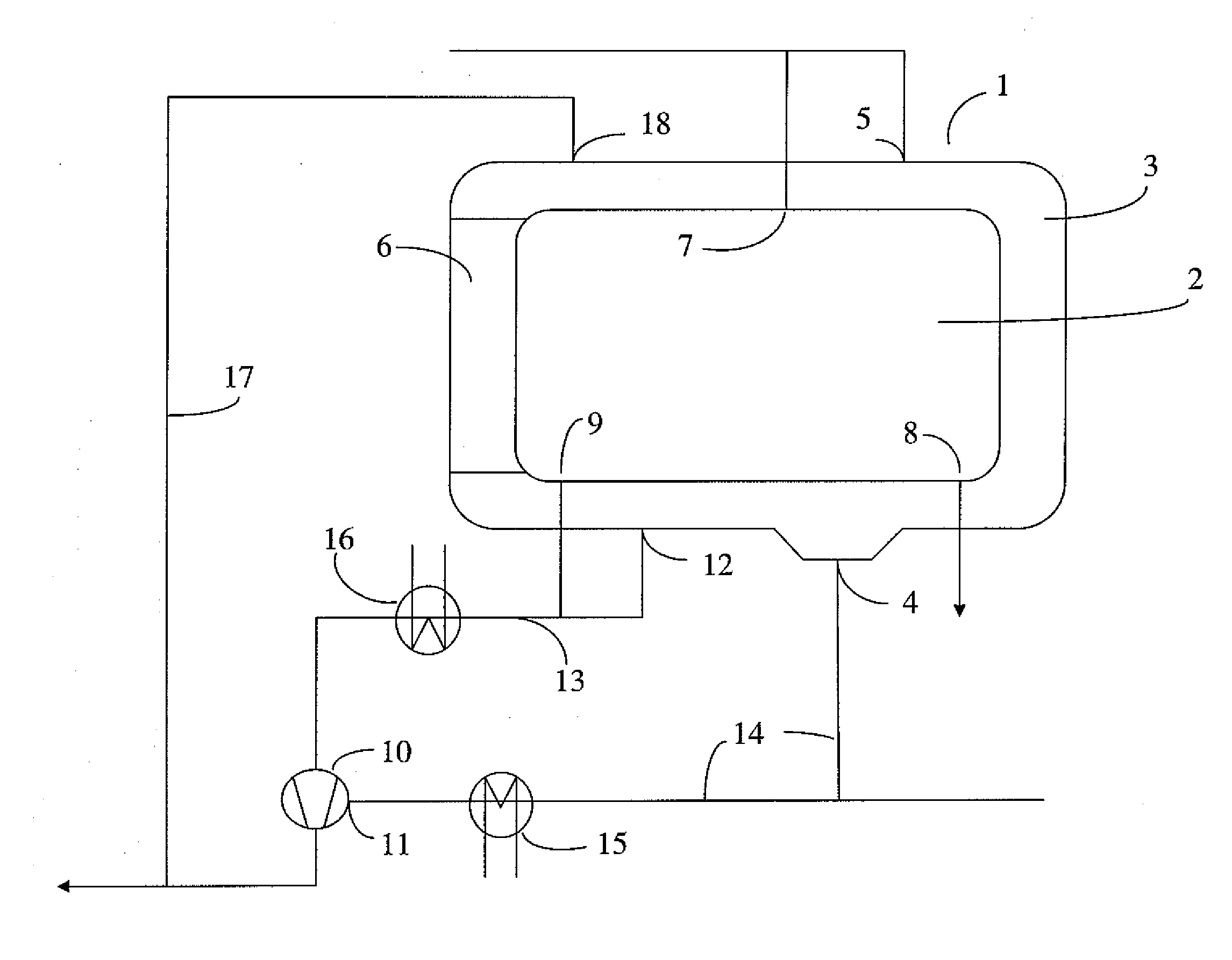

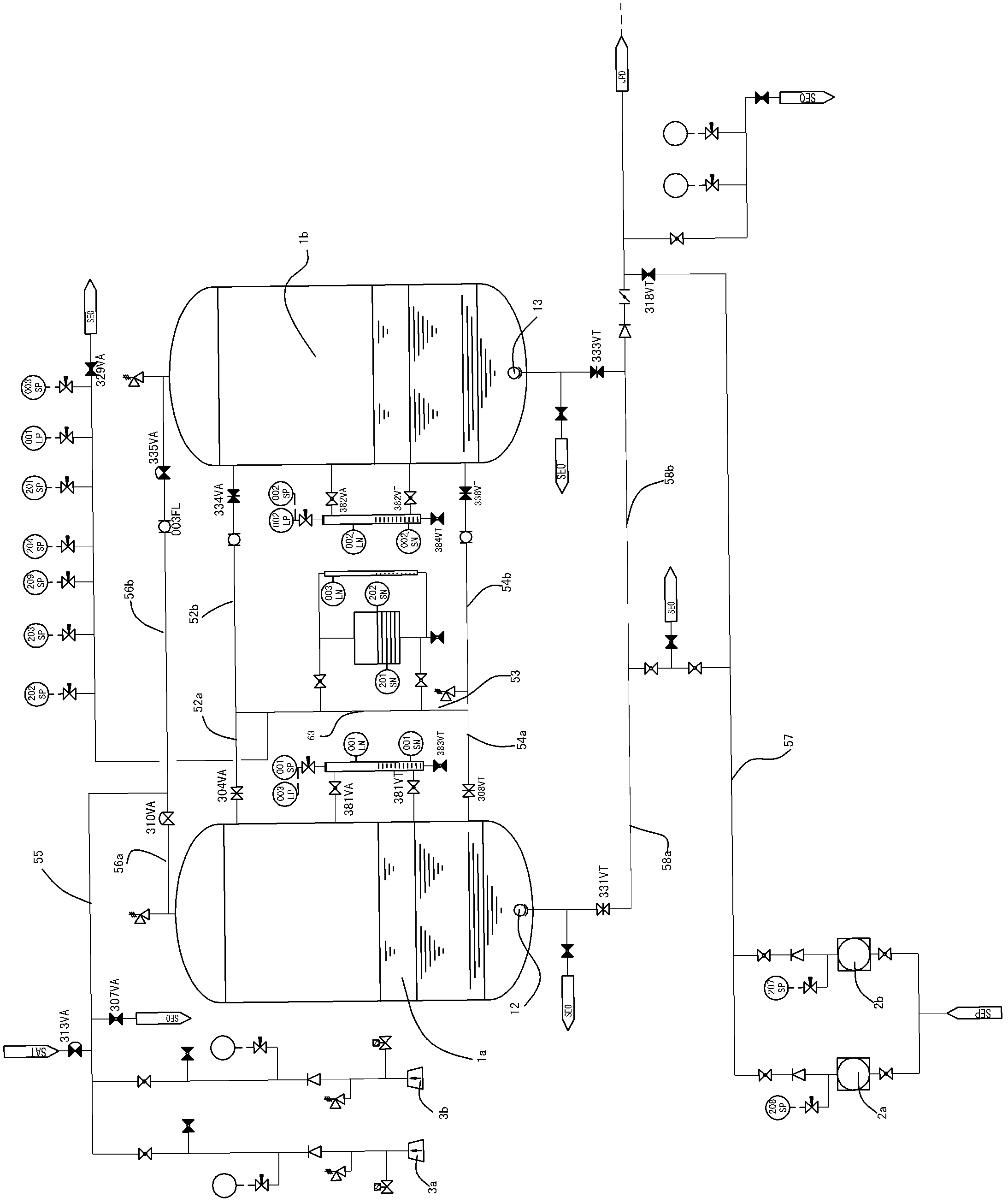

Multistage double effect distillation seawater desalination technology with heating seawater by solar energy

InactiveCN102190340AIncrease productionRelieve pressureGeneral water supply conservationSeawater treatmentDistillationEngineering

The invention relates to a multistage double effect distillation seawater desalination technology with heating seawater by solar energy. The technology comprises the following steps: seawater is delivered to a high cistern by a seawater pump; the seawater in the high cistern is delivered to a system for water supply through a water supply tube and a condenser inlet tube; the seawater is heated to a certain temperature by adsorbing latent heat of steam in an evaporator through all condensers of the system, and enters the evaporator after being heated to a designed temperature by a rapid heater with solar energy; the seawater enters the evaporator, becomes superheated water and is gasified rapidly and partially because a pressure in the evaporator is controlled to be lower than a saturation vapor pressure corresponding to a temperature of hot seawater; and a part of ungasified hot seawater enters a next stage evaporator and a part enters heat-collecting tubes at two sides of the evaporator. The heat-collecting tubes are provided with annular imbibition films, and the hot seawater flows from top to bottom after entering the heat-collecting tubes. In a flow process, the hot seawater is delivered to upper half parts of inner cavities of the heat-collecting tubes because of capillary imbibition actions of the imbibition films. The hot seawater is evaporated to steam because the heat-collecting tubes have a high temperature under the sunlight, the steam rises along the inner cavities of the heat-collecting tubes and enters the condenser to obtain fresh water which flows into a fresh water tank and then is output by a fresh water tube. Unevaporated concentrated seawater enters a concentrated water tank and is ouput by an inlet / outlet tube.

Owner:孙元新

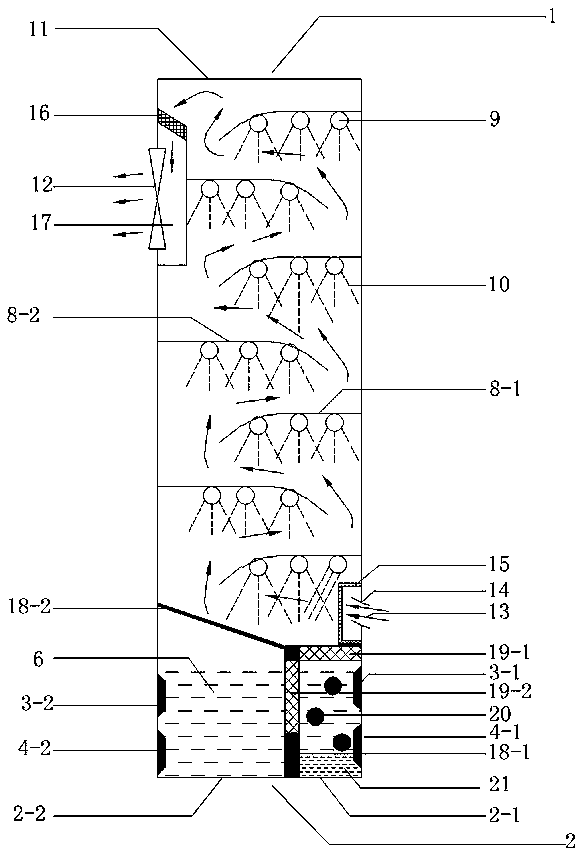

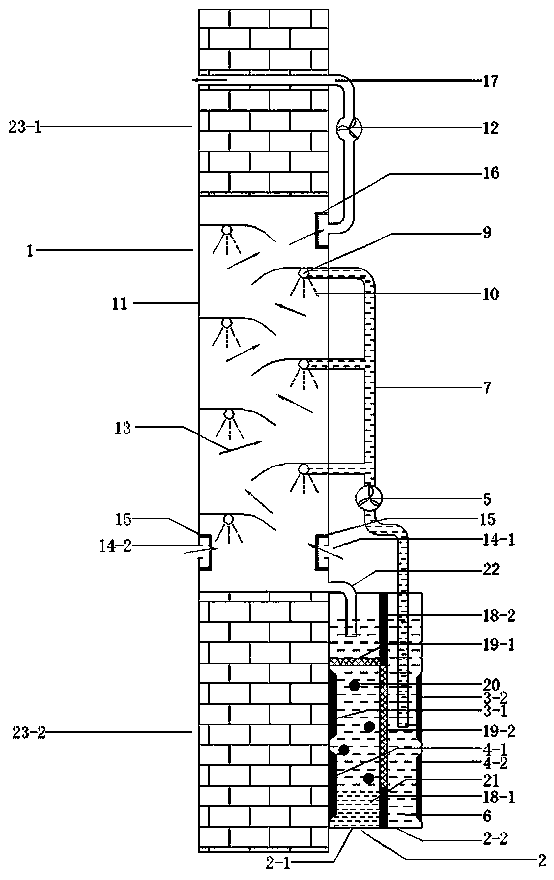

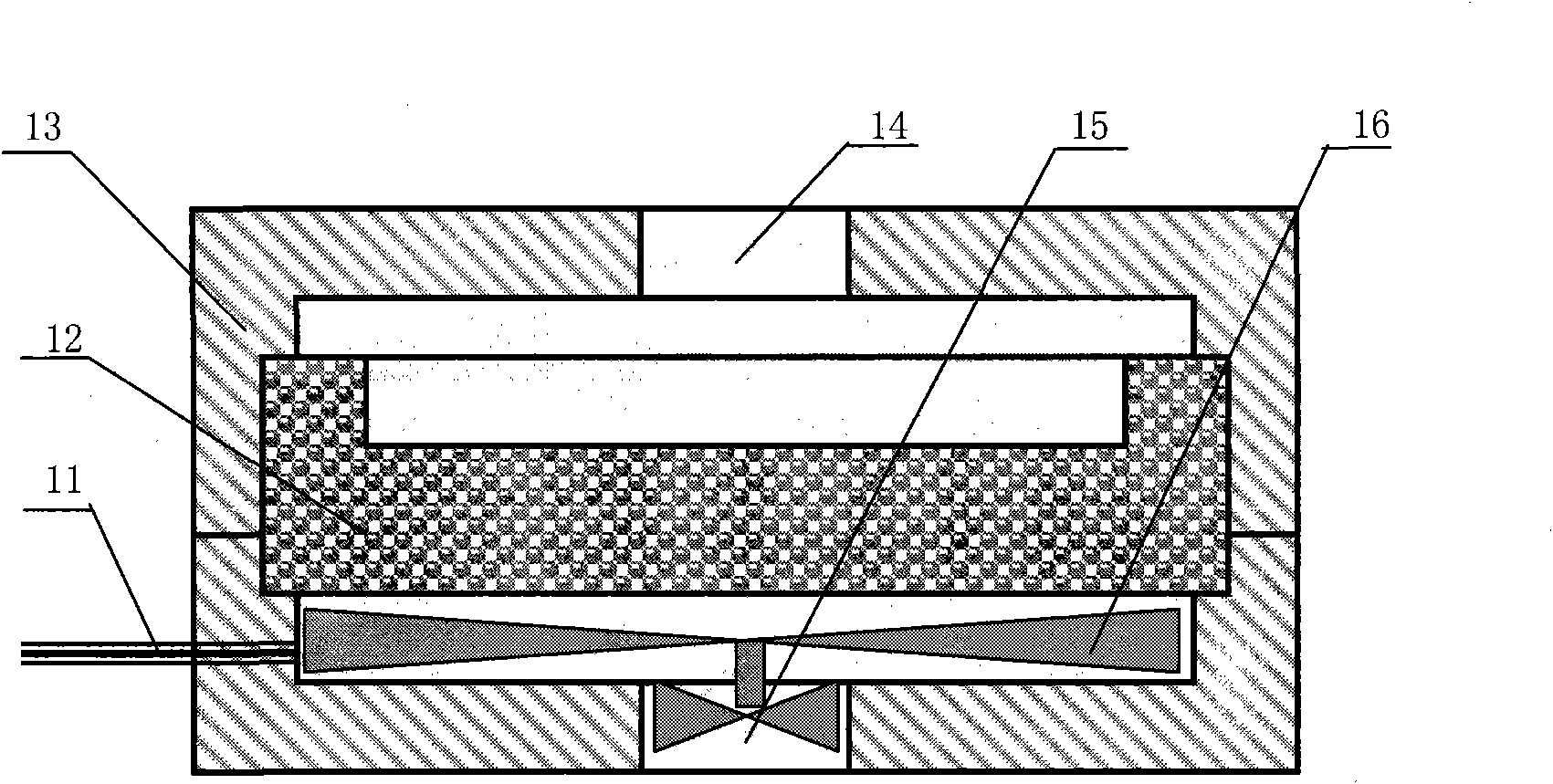

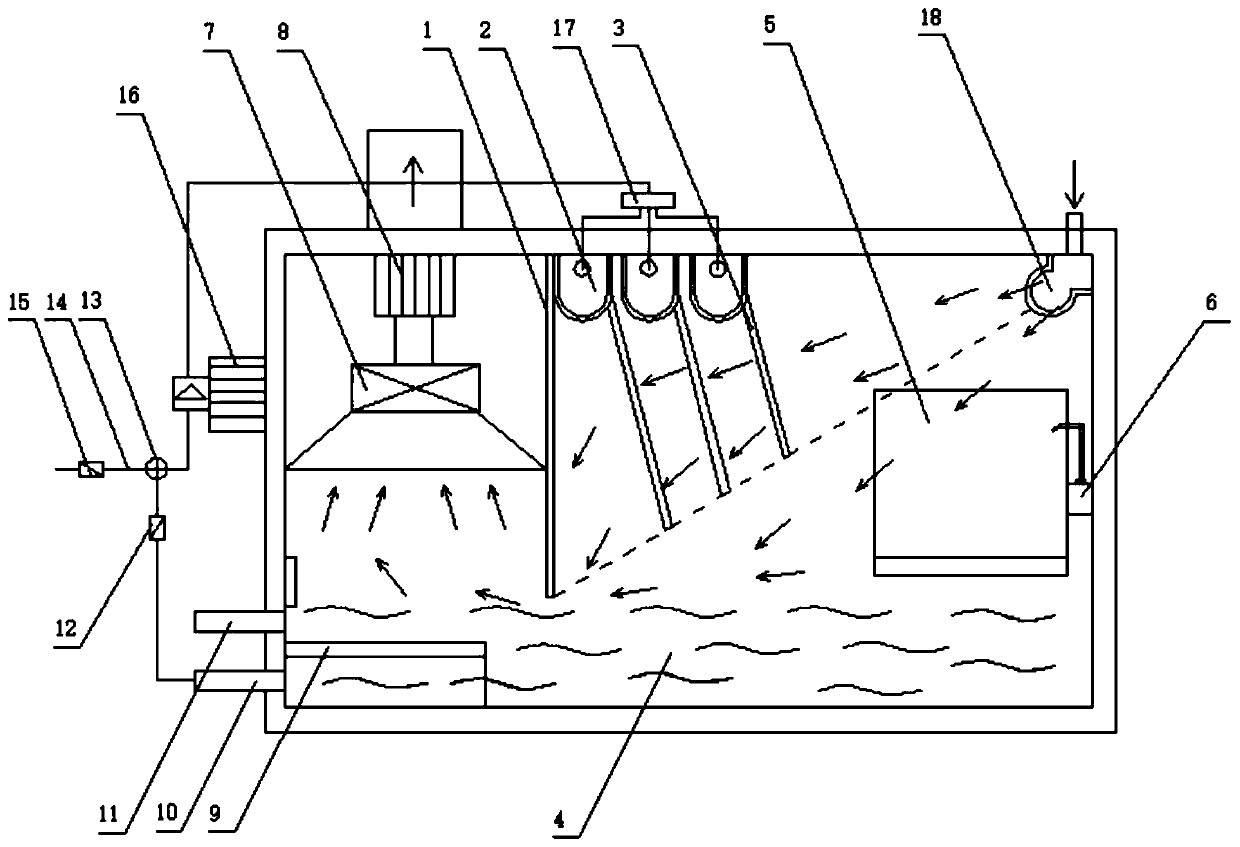

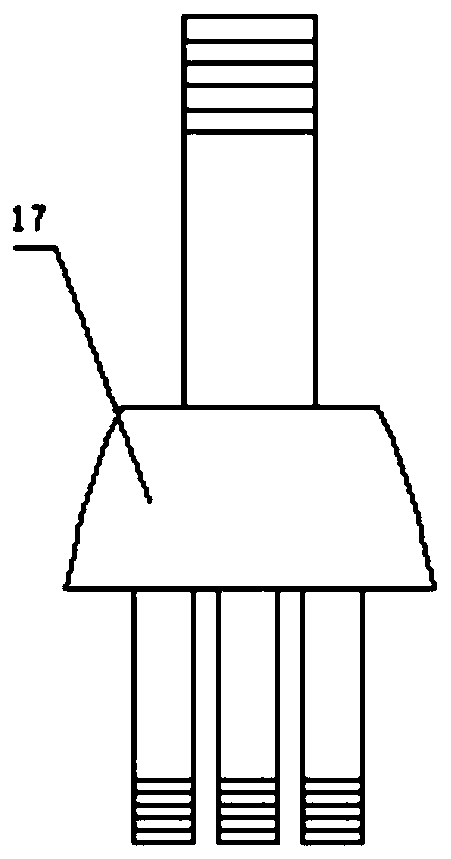

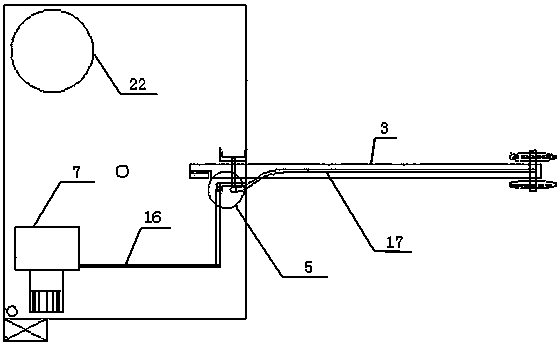

Cold-hot type rinsing air purification device using multilayer staggered spray method

InactiveCN104174248ASave spaceStrong functional scalabilityCombination devicesMultistage water/sewage treatmentIndustrial wasteWater pipe

The invention relates to a rinsing air purification technology and in particular relates to a cold-hot type rinsing air purification device using a multilayer staggered spray mode. The cold-hot type rinsing air purification device using the multilayer staggered spray method comprises a water storage tank, a spray tank, a water supply pipe, a water pump and an exhaust fan, wherein the water storage tank comprises a wastewater storage tank, a clear water storage tank, an electronic refrigerator, an electronic heater, an isolation plate and a wastewater filtration screen; the spray tank comprises a spray tank shell, a spray plate, a spray pipe, an air inlet, an air outlet and an air filtration screen; the spray plate, the spray pipe, the air inlet, the air outlet and the air filtration screen are arranged in a tank body; due to the adoption of the multilayer staggered spray method and a curve air flowing path, an equipment resource can be used to the greatest extent; air is fully sprayed and washed, so that the best purification effect can be achieved; the temperature of the air in a room can be adjusted according to the requirement during purifying of the air; the device can be used as an indoor moving air purifier, can be mounted on the wall to be used as an air purification window, and can be applied to spray purification towers for purifying industrial waste gas generated during waste incineration; the defects that a filter element is blocked and parts are frequently replaced can be avoided.

Owner:霍橡楠

Application of chemical foam finishing in weave dyeing and finishing technique

InactiveCN101168924AHigh water consumptionReduce water consumptionFibre treatmentEngineeringSewage treatment

The invention discloses an application of chemical foam finishing in textile dyeing and finishing process, and relates to an application of a functional chemical being made into foam state and then applied in the textile dyeing and finishing process. Any treatment process of the prior dyeing and finishing process takes water as a carrier. Thus a great amount of water is required, and the sewage treatment of the textile industry is also a most important issue, thereby reducing the drainage concentration, a great amount of water is added into for dilution, and thus the waste of water is caused. The invention adopts a treating liquid operating various functional treatments to the textile, such as: softening, waterproofing and fire preventing, etc., and is smashed into petty foams through the conventional lashing method such as egg breaking, so as to be uniformly and semi fluidly coated on a specified surface or a specified position of the textile by controlling. The invention is used on the site having the requirements of energy conservation, water conservation, raw material conservation and work efficiency improvement in the process, more particularly used for the requirement of excellently completing the single side coating and finishing.

Owner:张志军

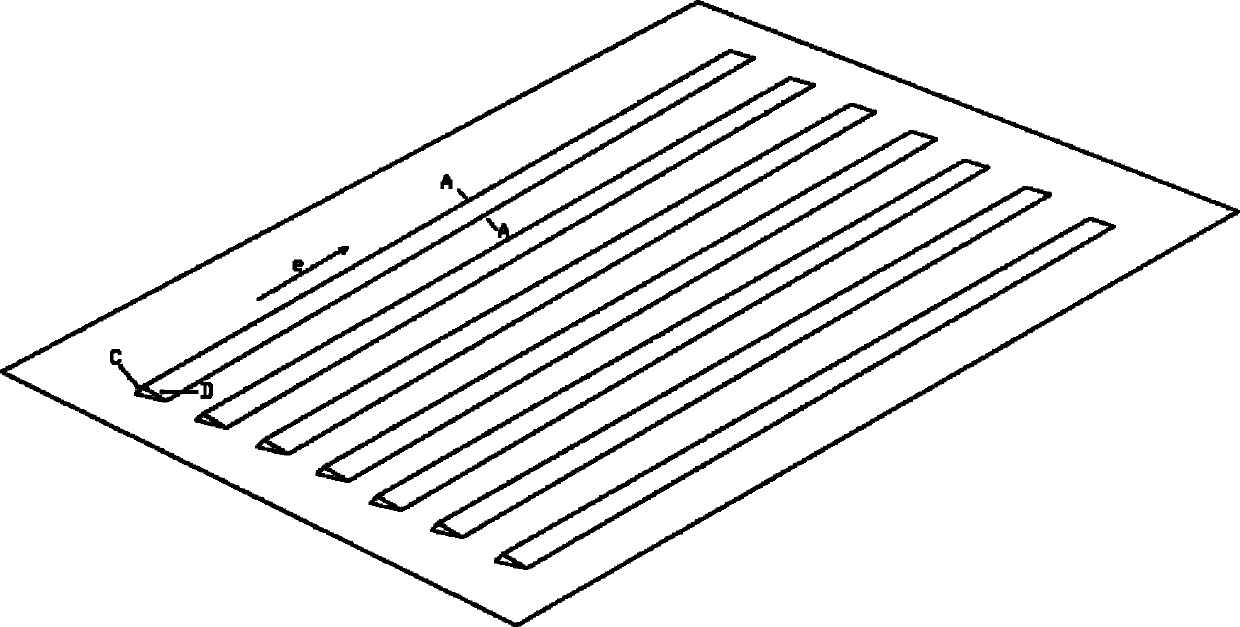

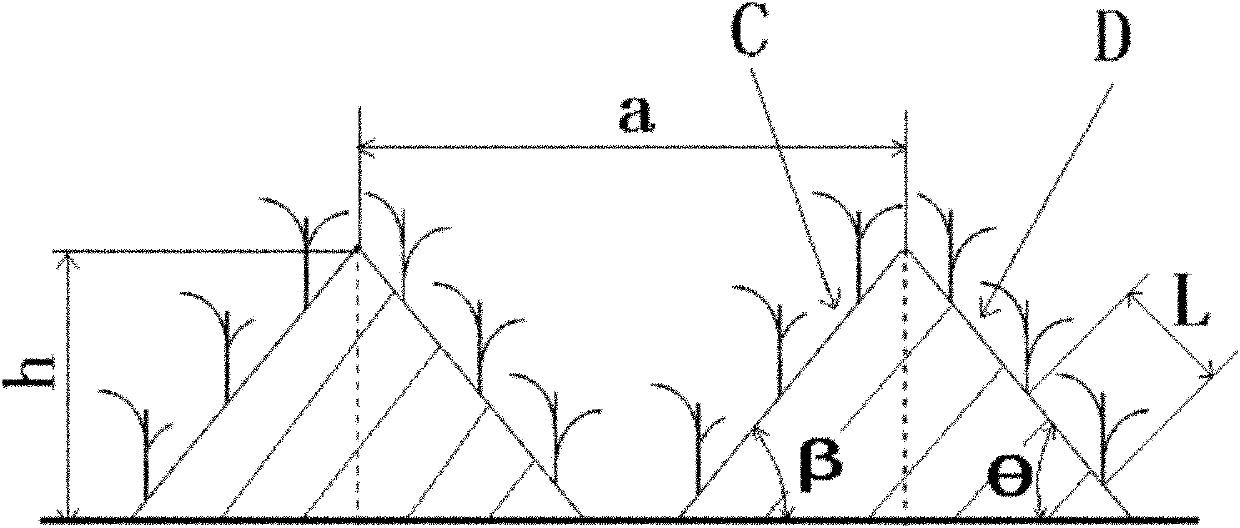

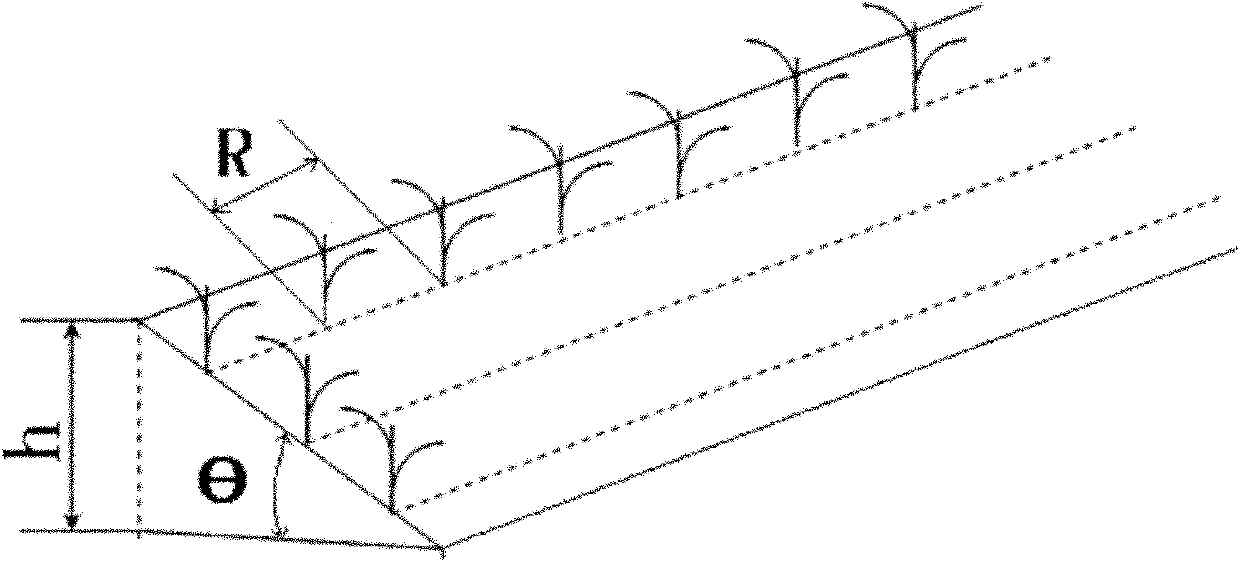

Chicken and duck mixed ecological culturing technical method under rice ladder-type cultivation

ActiveCN101946624AIncrease the utilization areaExpand the total light receiving areaFertilising methodsHorticultureDitchPaddy field

The invention discloses a chicken and duck mixed ecological culturing technical method under rice ladder-type cultivation, and belongs to a culturing method. The method comprises the following steps of: forming ridges in a rice field with enough base fertilizer; after the rice is cultivated for 3 to 7 days, putting 15 to 20 young ducks of 20 to 40 days into the rice field; keeping a water layer of over 5 centimeters for a long term in a ditch between two ridges; at the tillering final stage of the rice or at the differentiation initial stage of young ears, putting 15 to 20 chickens of 35 to 45 days into the rice field; and from the growth stage to the grain filling stage of the rice, taking back the chickens and the ducks in time from the field. The method has the advantages that: the land area is fully utilized, and the light area is increased; the chickens are fed movably on the ridges, the ducks are fed movably in the ridge ditches, and the rice is grown on the ridges; chicken manure and dust manure are directly returned to the field, and the application amount of inorganic fertilizer is reduced; the residue amount of the pesticide in the rice and the soil is reduced; the water is saved; and the added value of the rice is increased, and the income of peasants is improved.

Owner:HUNAN AGRICULTURAL UNIV

Plastering mortar using high-volume slag and preparation method thereof

The invention relates to a plastering mortar using high-volume slag and a preparation method thereof. Every cubic meter of plastering mortar using the high-volume slag comprises the following components in percentage by mass: 16 to 30 percent of ordinary Portland cement, 5 to 10 percent of pulverized fuel ash, 30 to 70 percent of sand, 0 to 30 percent of slag and 1.2 to 3.0 percent of plastering mortar master batch. The preparation method comprises the following steps of: firstly, drying the slag and machine-made river sand respectively until the water content is less than 0.2 percent, sieving the dried slag and machine-made river sand through a 3-millimeter sieve to remove large particles of more than 3 millimeters and feeding the slag and the machine-made river sand into a sand cabin for later use; secondly, metering the selected plastering mortar master batch serving as a raw material according to a mass proportion, fully mixing the materials in a mixing machine for 4 to 6 minutes and feeding the mixture into an additive cabin for later use; and lastly, metering the plastering mortar components according to the mass proportion in a formula and mixing the components in the mixing machine for 3 to 5 minutes so as to obtain a finished product. The slag is used instead of a part of river sand and machine-made sand, so that cost is low, environmental pollution is reduced, and social and economic benefits are remarkable.

Owner:JIANGSU NIGAO SCI & TECH +1

Method for preparing edible vegetable oil with idesia polycarpa crude oil

InactiveCN102051263AHigh yieldQuality improvementFatty-oils/fats refiningEdible oils/fatsSaline waterVegetable oil

The invention discloses a method for preparing edible vegetable oil with idesia polycarpa crude oil, and belongs to the field of foodstuff. The method comprises the procedures of crude oil phosphoric acid degumming, alkali refining, water washing, salt water debitterizing, activated clay decoloring, vacuum deodorizing and the like. The method is characterized in that the edible vegetable oil is prepared with the idesia polycarpa crude oil through the procedures of degumming, alkali refining, water washing, debitterizing, decoloring and deodorizing. In the technology, bitter principle in the crude oil is removed by adopting hot salt water, so that the removal is thorough, the removing time and the water consumption are saved, and high-quality edible vegetable oil is obtained eventually; and meanwhile, the technological process is simple, the requirements for equipment is not high, and the cost is remarkably reduced. Therefore, the method can have a wide application prospect in the production of idesia polycarpa edible oil.

Owner:四川省毛叶山桐子科技股份有限公司

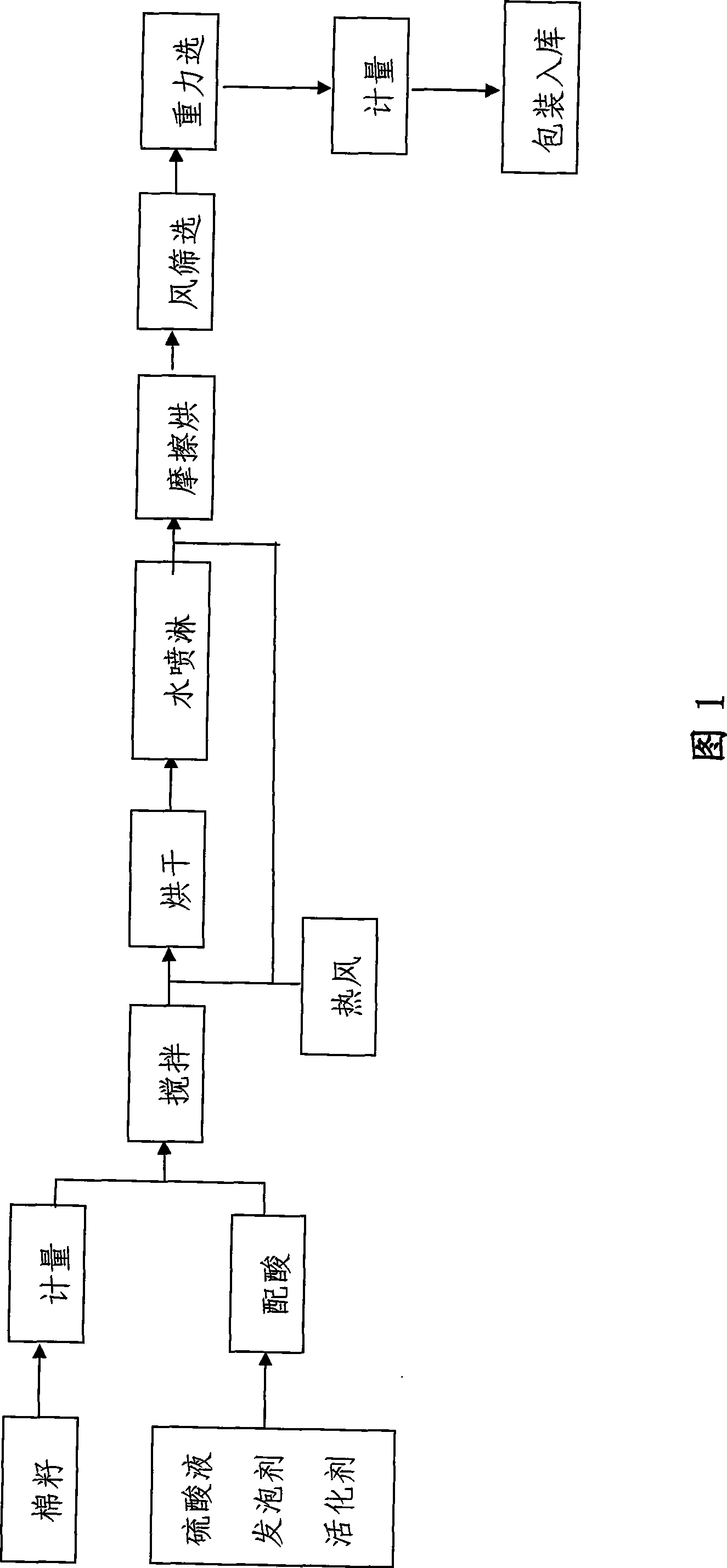

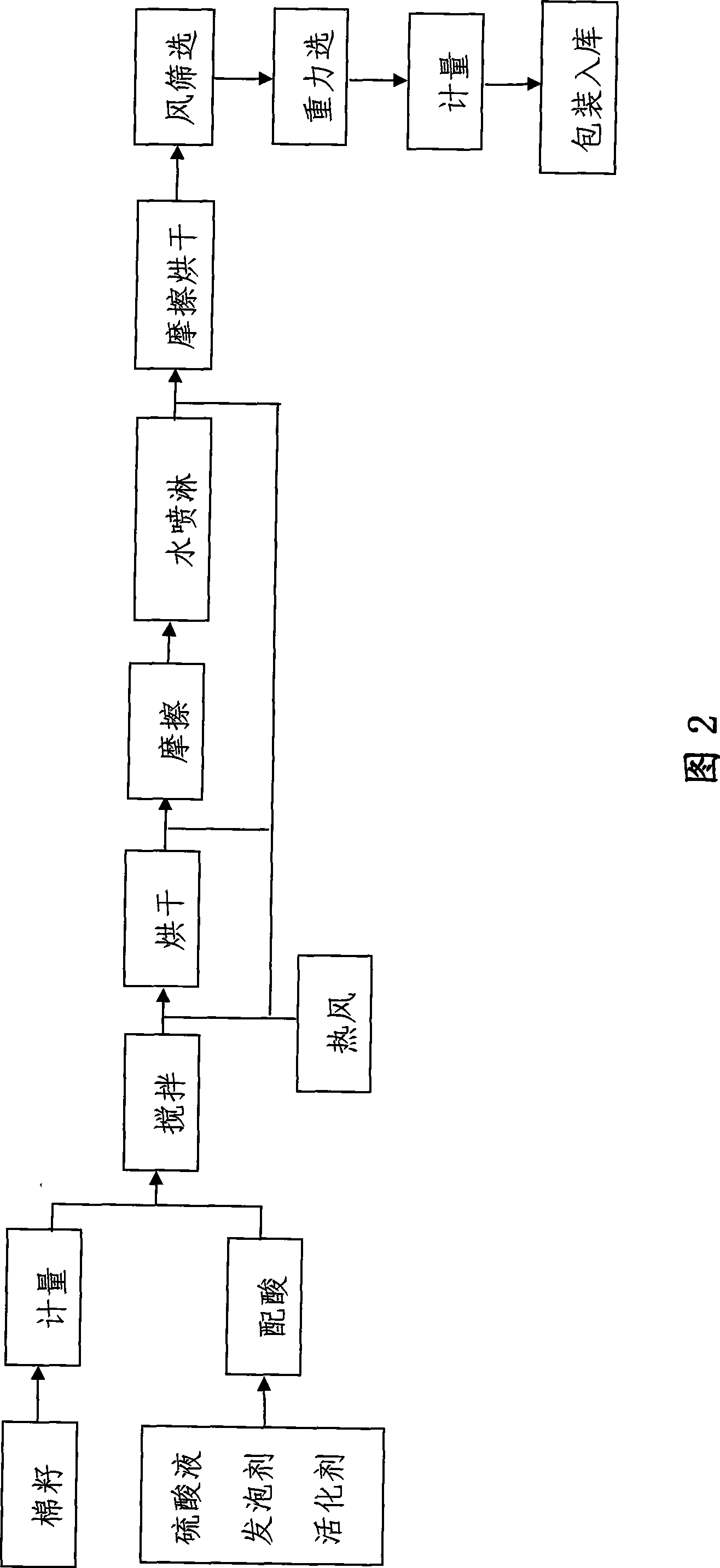

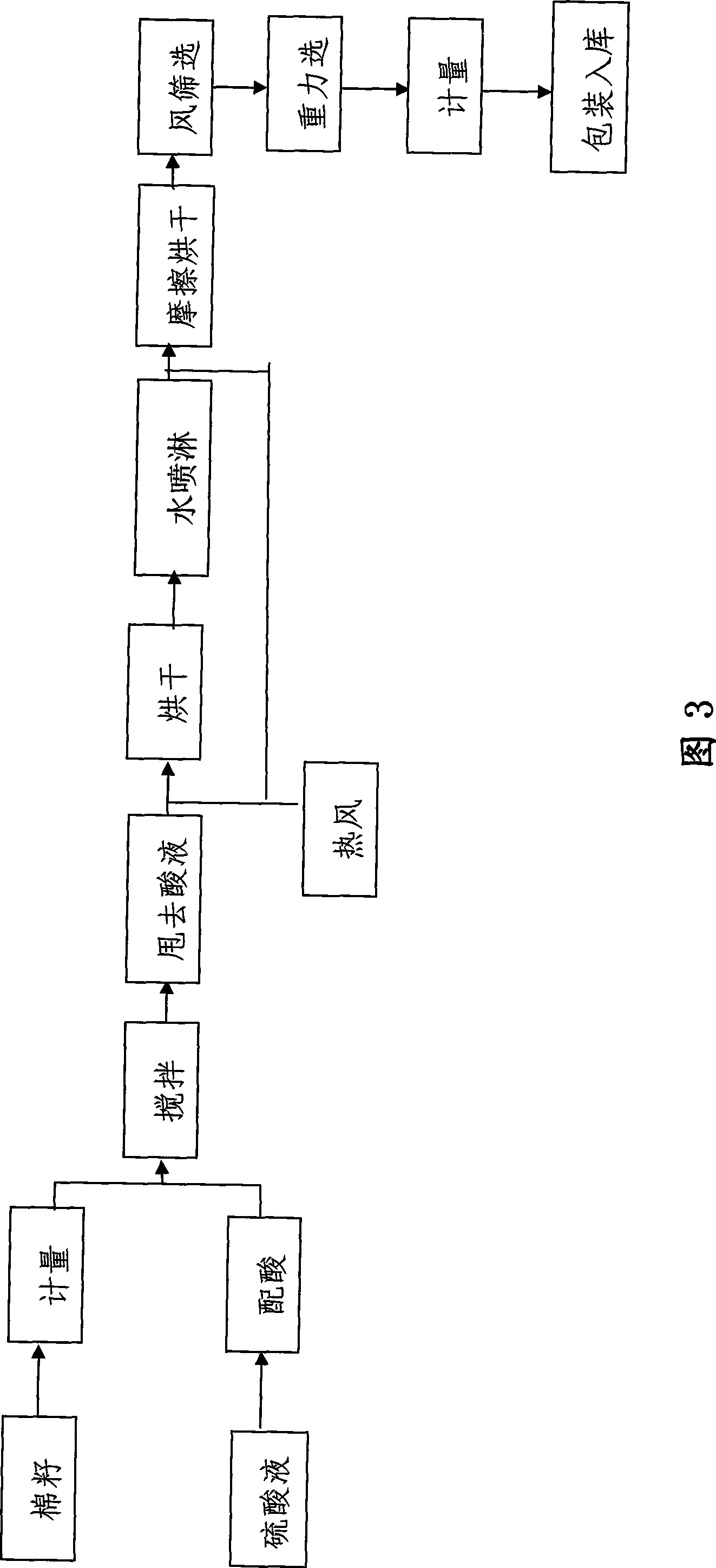

Cotton seeds processing technique

The invention discloses a processing technique for cotton seeds, pertaining to the technical filed of seed preparation before planting. Currently, an acid treatment technology is adopted to remove the residual velvet of the cotton seeds, and in order to protect the seeds against damage, strict control can be carried out on the concentration of the acid and the charing temperature of the residual velvet, as the sprouting rate and appearance of the cotton seeds can be affected due to any negligence. Therefore, the invention adds a water spray cleaning device and the working procedures thereof on the basis of the original processing technique. At the same time, the concentration of sulphuric acid in acid treatment solution is increased to 7.0-10.0 percent and the content of a foaming agent and an activating agent is reduced, wherein, the total content of the foaming agent and the activating agent is below 0.35 percent. The invention has the advantages of no residual acid, no residual velvet, lower cost, higher sprouting rate, less damage to the cotton seeds, higher safety and reliability, and glabrous appearance of the cotton seeds.

Owner:张卫东

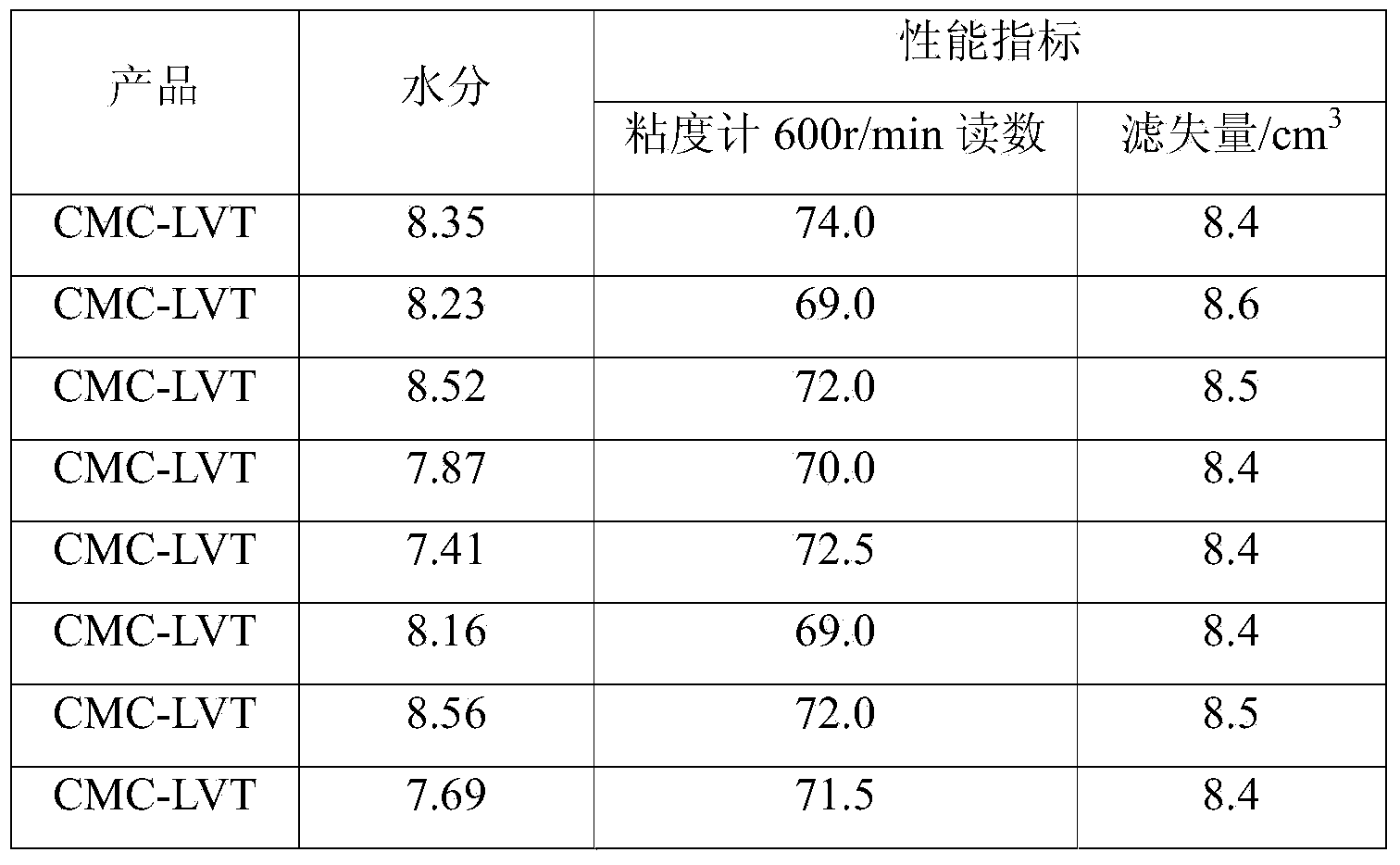

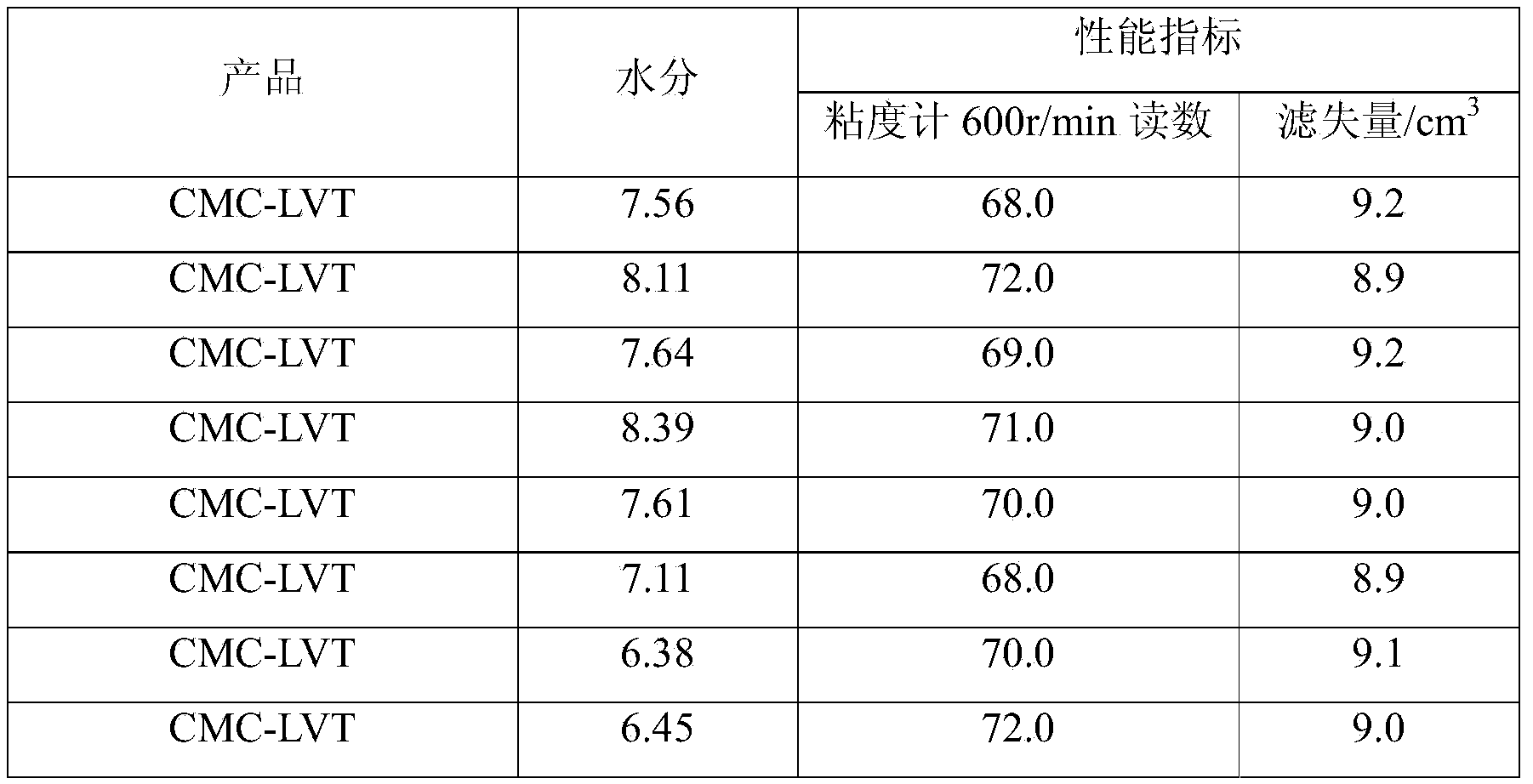

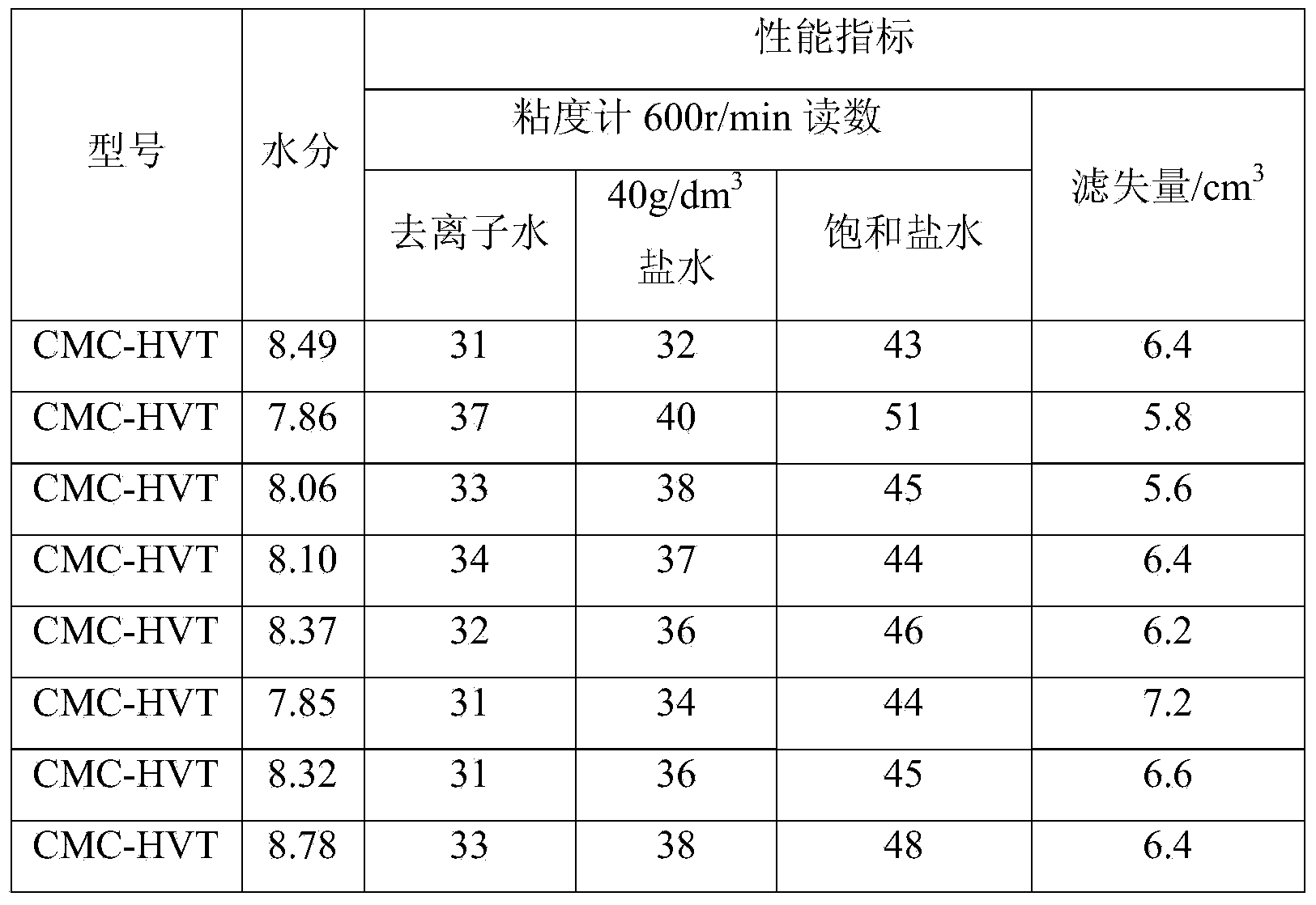

Production method of technical-grade sodium carboxymethylcellulose

The invention belongs to the field of production of sodium carboxymethylcellulose, and specifically relates to a production method of technical-grade sodium carboxymethylcellulose, wherein the method is low in production cost and can be carried out on a solvent method production line. The method comprises the following steps: a, preparation of liquor; b, alkalization reaction; c, acidification and etherification. The purpose of production on the original solvent method production line is realized by adopting a method of increasing the water content of a reaction system and reducing the use level of alcohol of the reaction system by means of adjusting and controlling parameters of the reaction system; the cost of producing technical-grade sodium carboxymethylcellulose [CMC-LVT (Carboxymethylcellulose-Low Viscosity Technical) and CMC-HVT (Carboxymethylcellulose-How Viscosity Technical)] by the original solvent method is lowered.

Owner:泸州北方纤维素有限公司

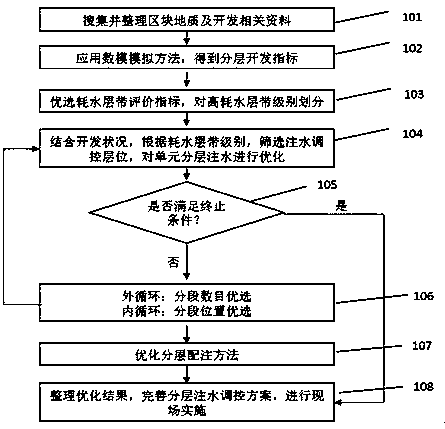

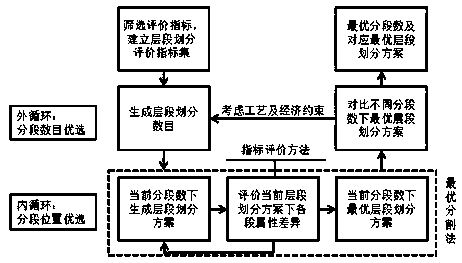

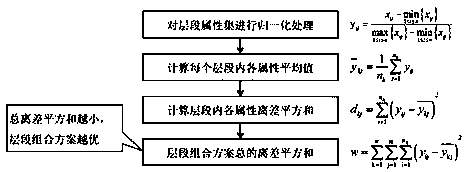

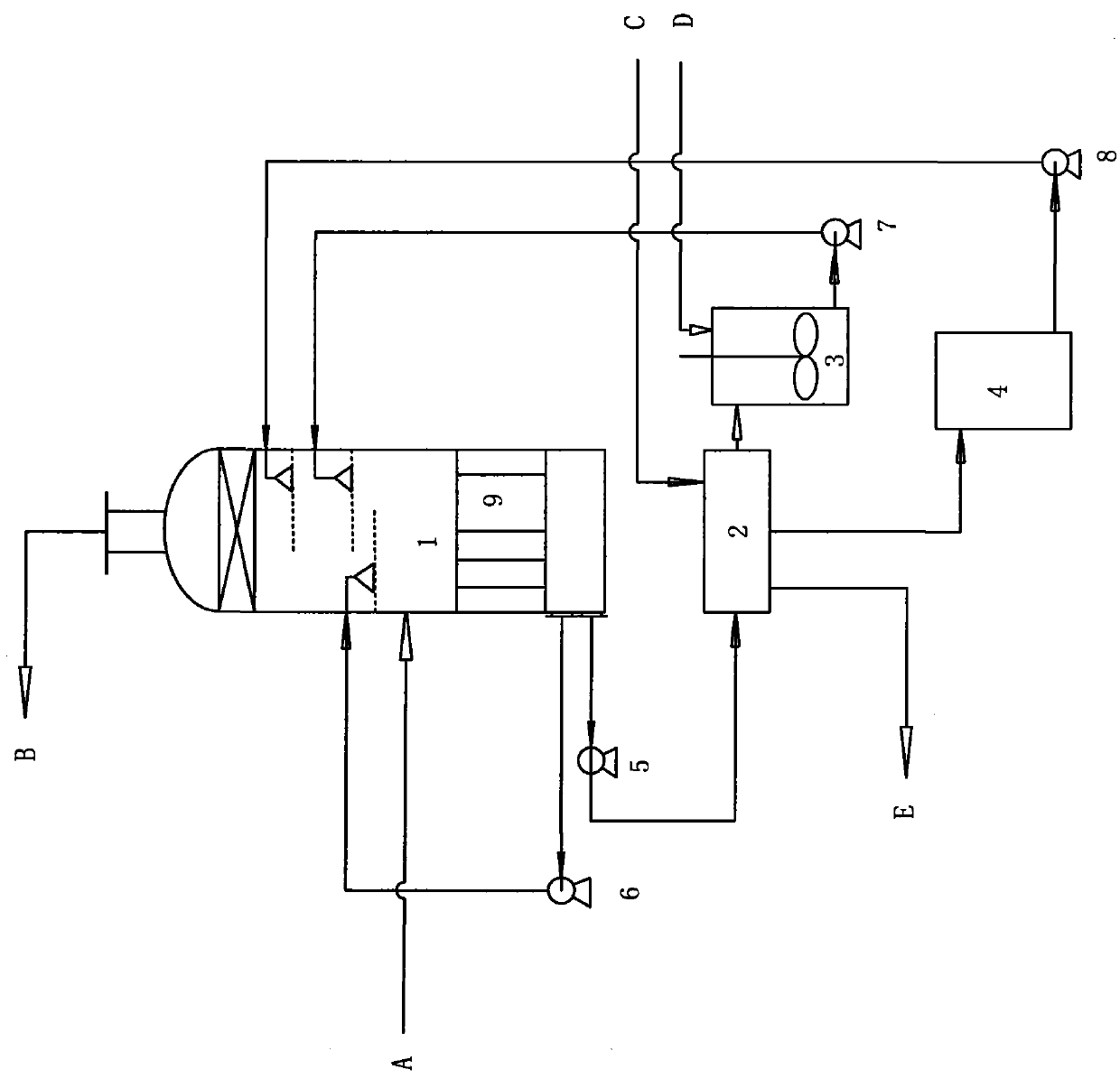

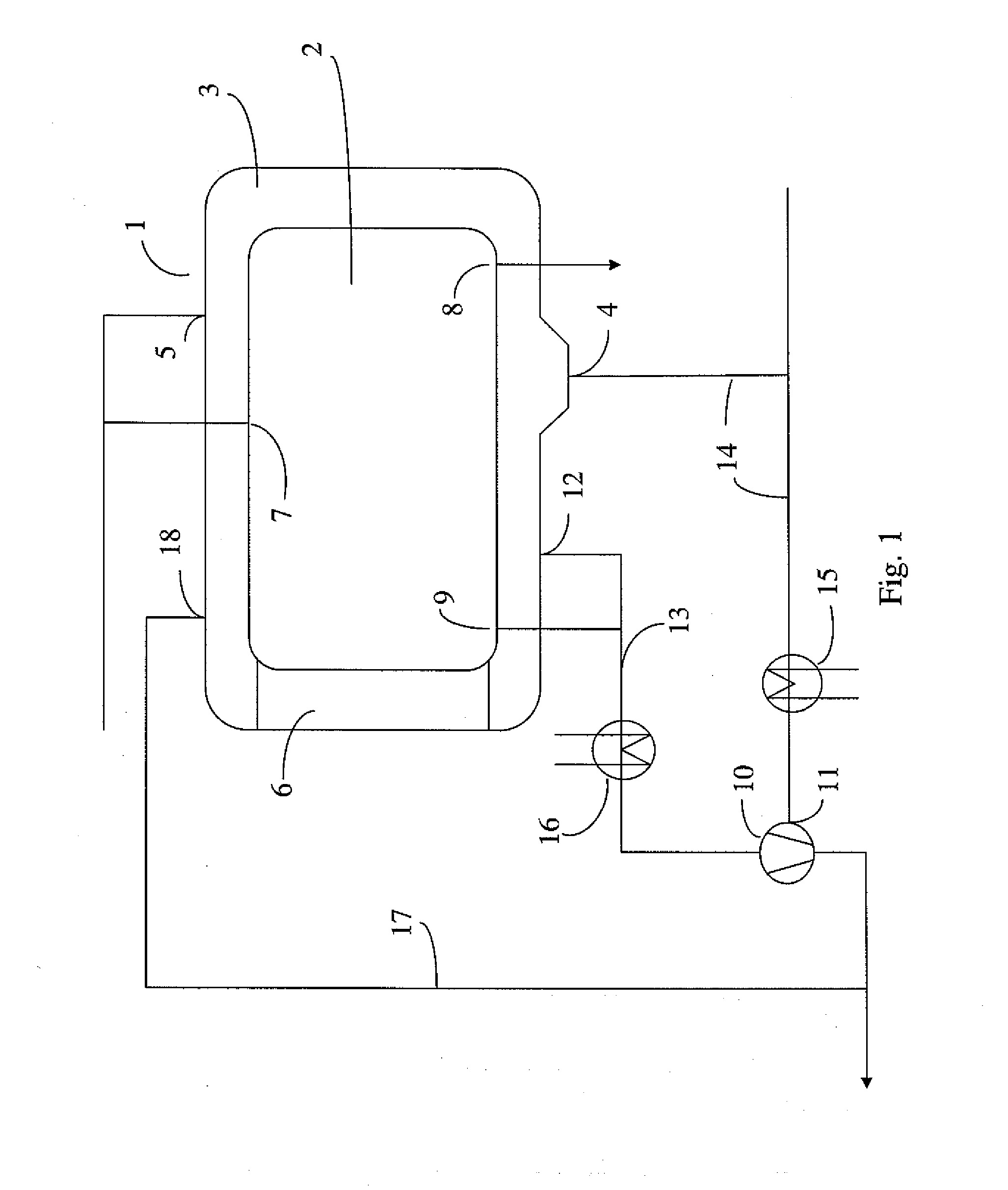

High water-consuming layer belt development oil reservoir layered water injection adjusting and controlling method

The invention relates to the field of oil-gas field development, in particular to a high water-consuming layer belt development oil reservoir layered water injection adjusting and controlling method which comprises the following steps: S1, collecting and tidying block geology and related development data; S2, applying the mathematical modeling analogy method to obtain a layered development index;S3, carrying out optimization on the water-consuming layer belt evaluation index to divide the level of the high water-consuming layer belt; S4, by combining with the development situation, screeningthe water injection adjusting and controlling horizon according to the level of the water-consuming layer belt to optimize the unit layered water injection; and S5, tidying the optimizing result to perfect the layered water injection adjusting and controlling scheme so as to carry out site implementation. According to the high water-consuming layer belt development oil reservoir layered water injection adjusting and controlling method, the level of the high water-consuming layer belt is distinguished and divided through the classifying coefficient of the high water-consuming layer belt; for different levels of the high water-consuming layer belt, the water flooding development index calculating method of the oil reservoir engineering theoretically established is combined with the optimal segmentation method theory, so that water consumption is reduced, and the economic life period of an oilfield is prolonged to finally realize the purpose of improving the oil reservoir recovery efficiency.

Owner:CHINA PETROLEUM & CHEM CORP +1

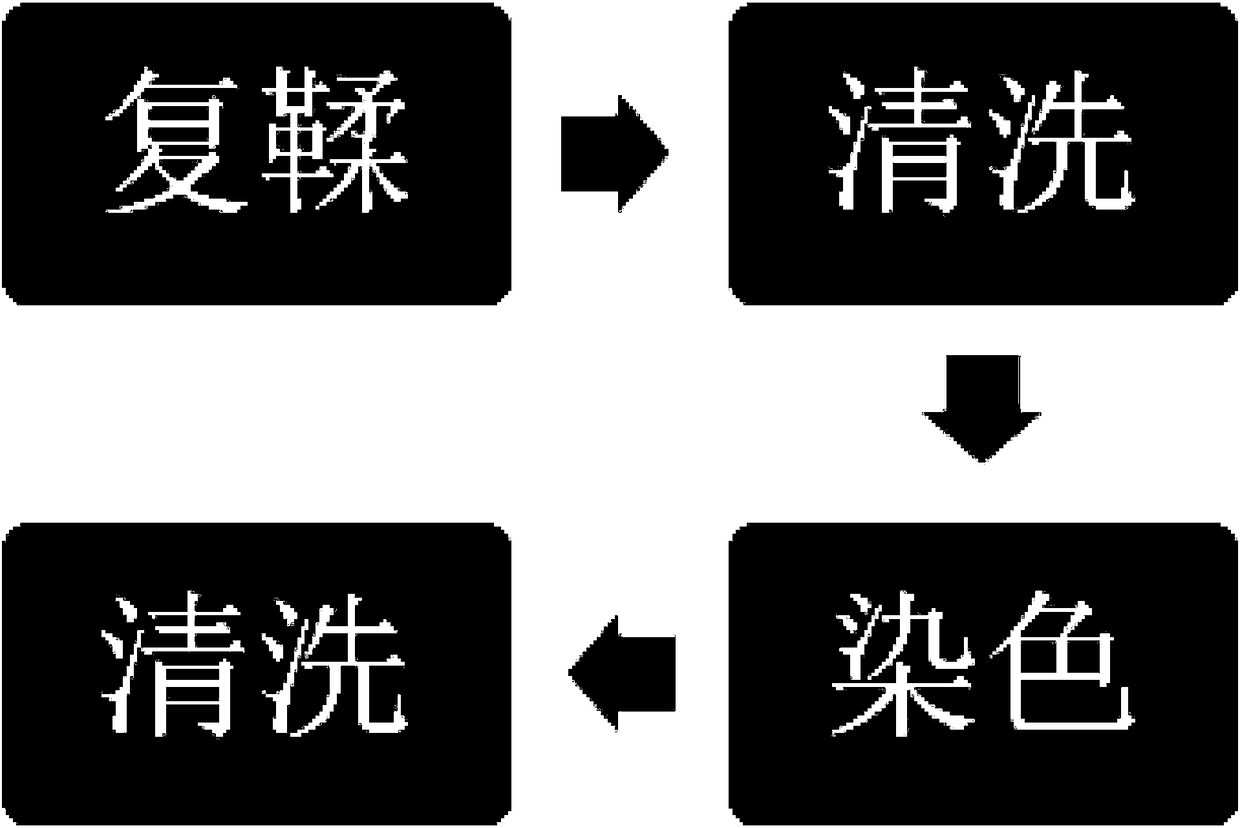

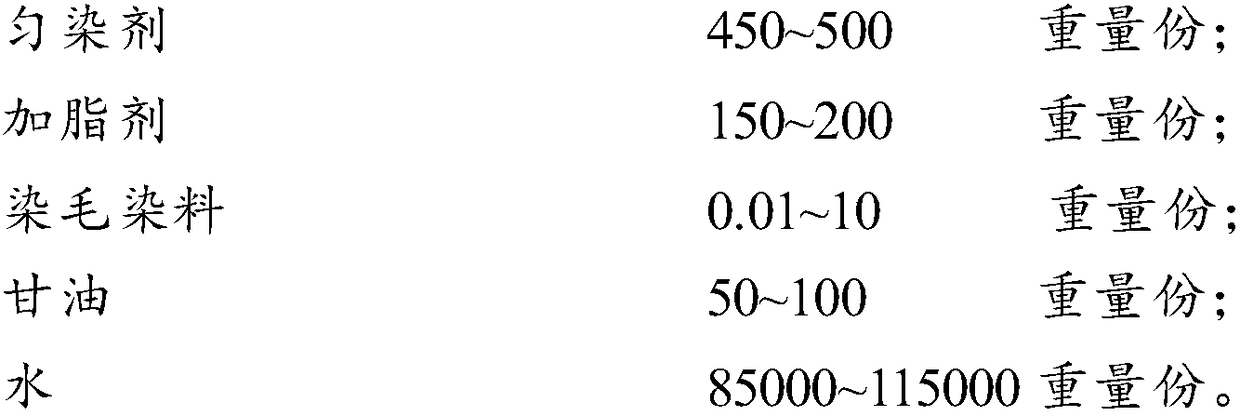

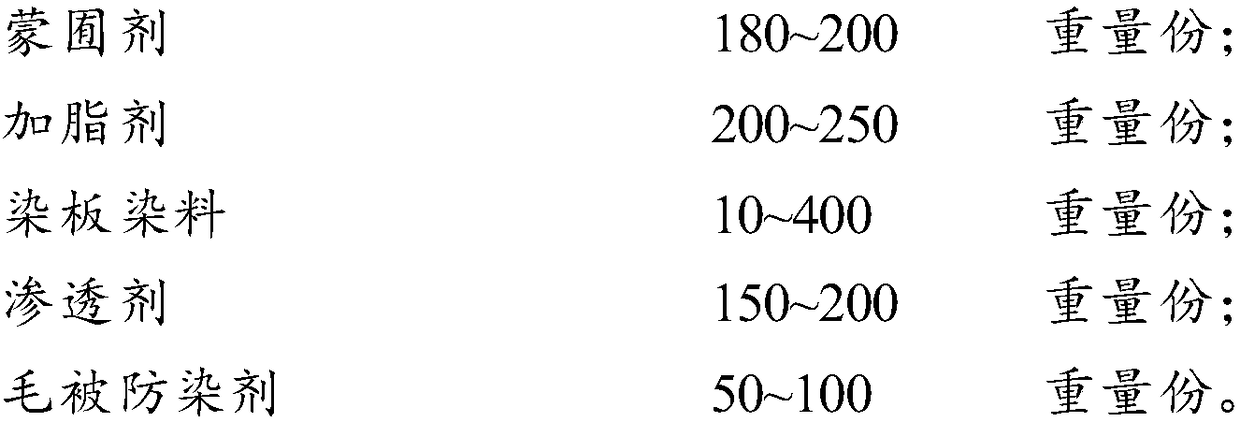

Coloring agent and dyeing process for double-faced leather

The invention provides a coloring agent for double-faced leather. A hair dyeing agent is prepared from the following components in parts by weight: 180 to 200 parts of a dye leveler, 150 to 200 partsof a fatting agent, 0.01 to 10 parts of hair dye, 50 to 100 parts of glycerin and 85000 to 115000 parts of water. The invention also provides a panel dyeing agent and a dyeing process for the double-faced leather. The coloring agent comprises the hair dyeing agent and the panel dyeing agent; the components and the proportions of the hair dyeing agent and the panel dyeing agent are adjusted, particularly the glycerin is added in the hair dyeing agent, and the temperature and a pH value of the dyeing process are controlled, therefore, the aims of synchronously adding a hair dye and a panel dye and dyeing in the same bath are achieved and the dyeing time is greatly shortened; in addition, the dyed hair panel has good color control degree and the quality of a finished product is improved.

Owner:隆丰革乐美时尚有限公司

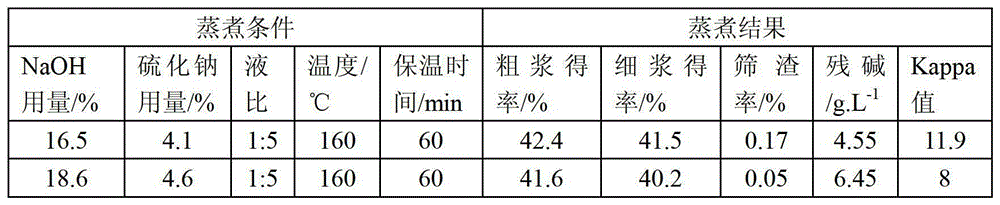

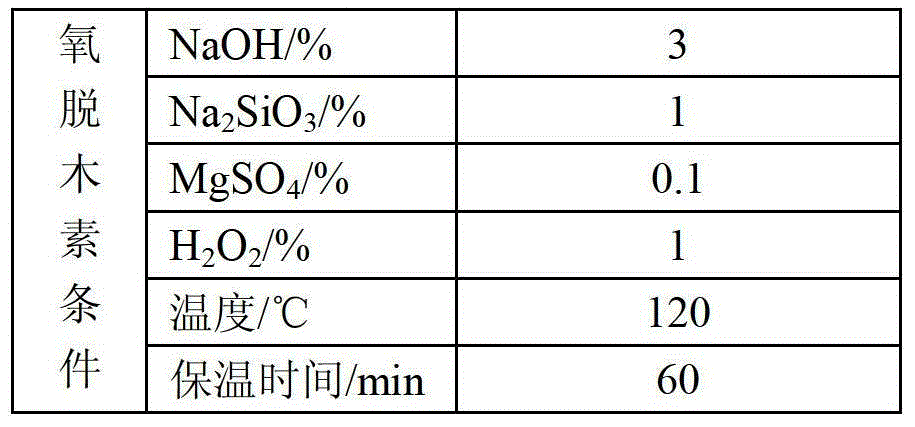

Preparation method of pollution-free high-whiteness palm silk paper pulp and application of paper pulp in paper product

InactiveCN103334335ARich reservesAddress resource shortagesWashing/displacing pulp-treating liquorsDigestersCardboardHypochlorite

The invention relates to a preparation method of pollution-free high-whiteness palm silk paper pulp and an application of the paper pulp in a paper product. The preparation method mainly comprises the steps that a palm silk raw material is cooked and bleached, and the obtained paper pulp is used for making the paper product. Cooking adopts a sulfate method, and paper pulp bleaching adopts a pollution-free (Total Chlorine Free-TCF) section procedure bleaching technology. Each section in an OPAP1P2 bleaching procedure adopts a medium-concentrated bleaching technique (a concentration of each section of paper pulp is 10-15%), so that the bleaching reaction efficiency can be improved, energy sources can be saved (heating the paper pulp), and the water consumption can be reduced. The bleaching does not require any chlorine (chlorine, pypocholoride or chlorine dioxide), so that bleaching waste water can be used for preparation of a cooking liquid and washing of unbleached pulp, and then enters an alkali recovery system, and the preparation method can save water and energy, reduce environmental pollution and allow resources to be fully used. With the adoption of the bleaching technology, the pollution-free high-whiteness (82-85% of ISO (Isobutanol)) paper pulp can be prepared, can substitute bleaching hardwood pulp, and is matched with bleaching sulfate softwood pulp for making advanced cultural paper as well as paper and cardboards with high hygienic index requirements.

Owner:马志强 +1

Process for simultaneously desulfurizing and denitrifying to coproduce calcium sulfate whisker

ActiveCN103908882ASimple filterReduce energy consumptionPolycrystalline material growthDispersed particle separationElectrolysisSulfate radicals

The invention discloses a process for simultaneously desulfurizing and denitrifying to coproduce a calcium sulfate whisker. The method comprises the following steps: absorbing SO2 and NOx in smoke by using a formula absorbent in an absorption tower, and then electrolyzing absorption liquid, so that N2 and sulfate radical are generated by NOx and SO2 respectively to be removed and the calcium sulfate whisker is coproduced. The process has the beneficial effects that (1) desulfurizing and denitrifying are integrated, the process is small in equipment investment, less in power consumption and low in operation cost, ammonia is not consumed in the denitrifying process, and a catalyst is not used; (2) an oxidation air blower is not arranged, so that energy consumption is greatly reduced, and the moisture content of a by-product can be up to no more than 3%; (3) the draw ratio of the by-product calcium sulfate whisker is greater than or equal to 50, and the calcium sulfate whisker has high product value; (4) the process is less in moisture consumption, the slurry prepared from lime is good in suspension property, and entrainment is reduced; (5) the absorbent is improved, so that the desulfurization rate is greater than or equal to 95%, the denitration rate is greater than or equal to 90%, and the prepared whisker is long in draw ratio; (6) the process is less in direct current consumed by electrolysis, the flue gas treatment process is a production process, and a value creation process is realized.

Owner:淮南市明月环保科技有限责任公司

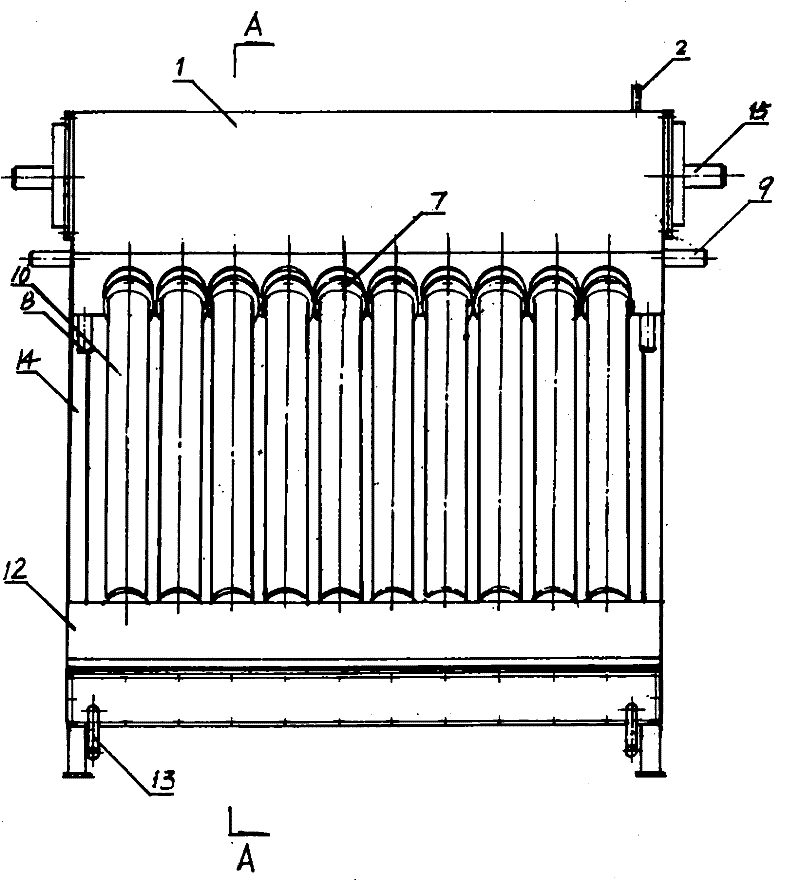

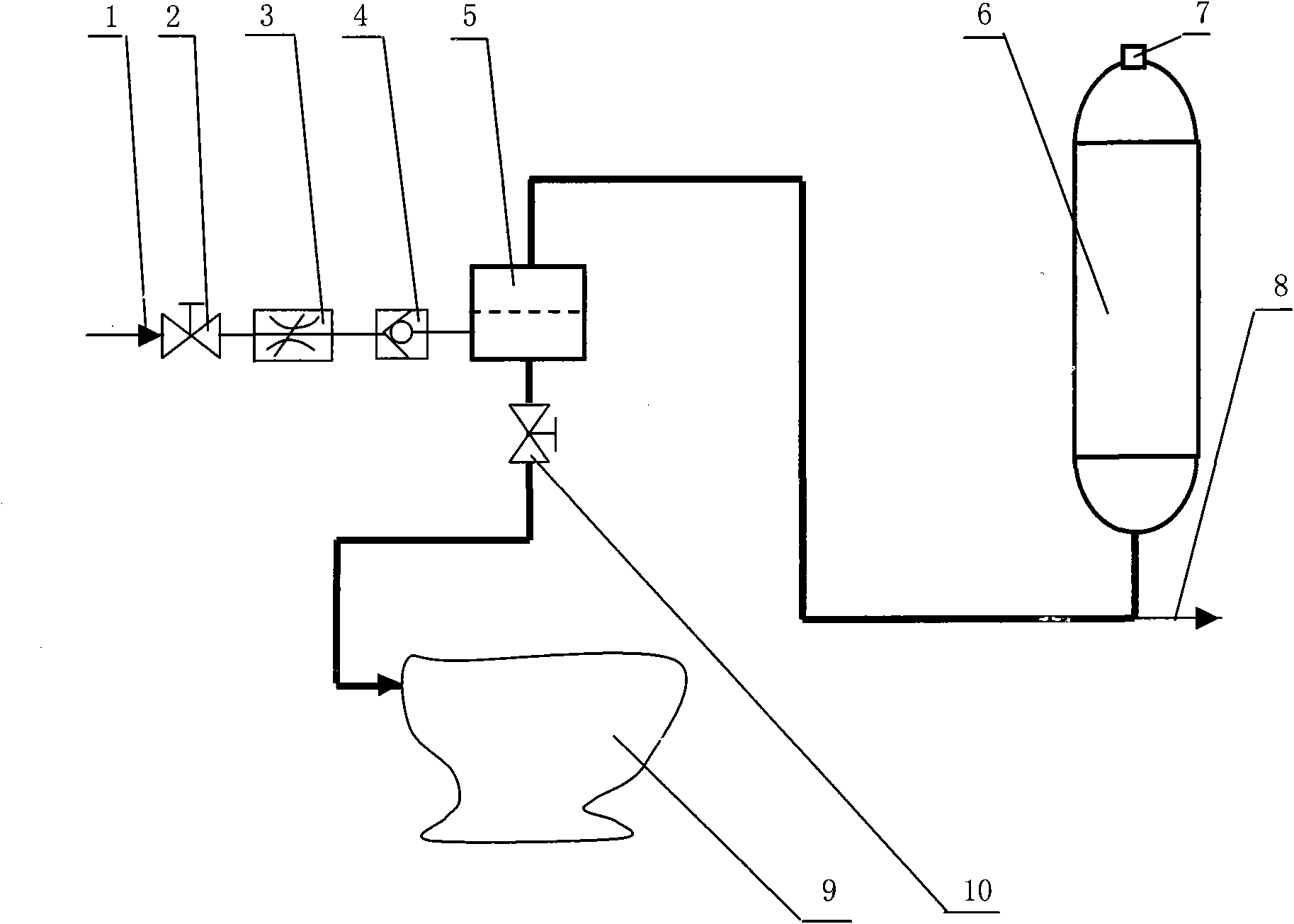

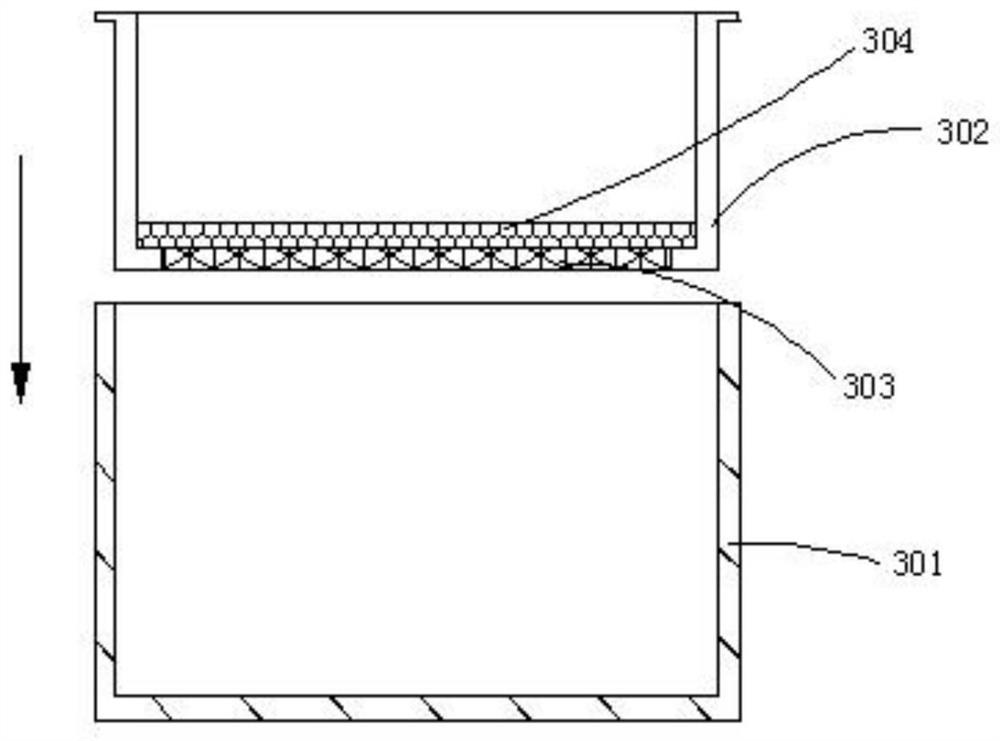

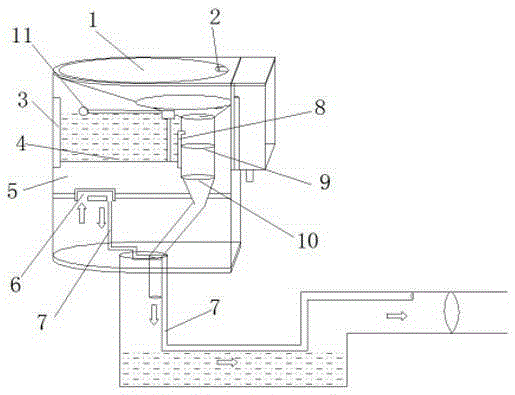

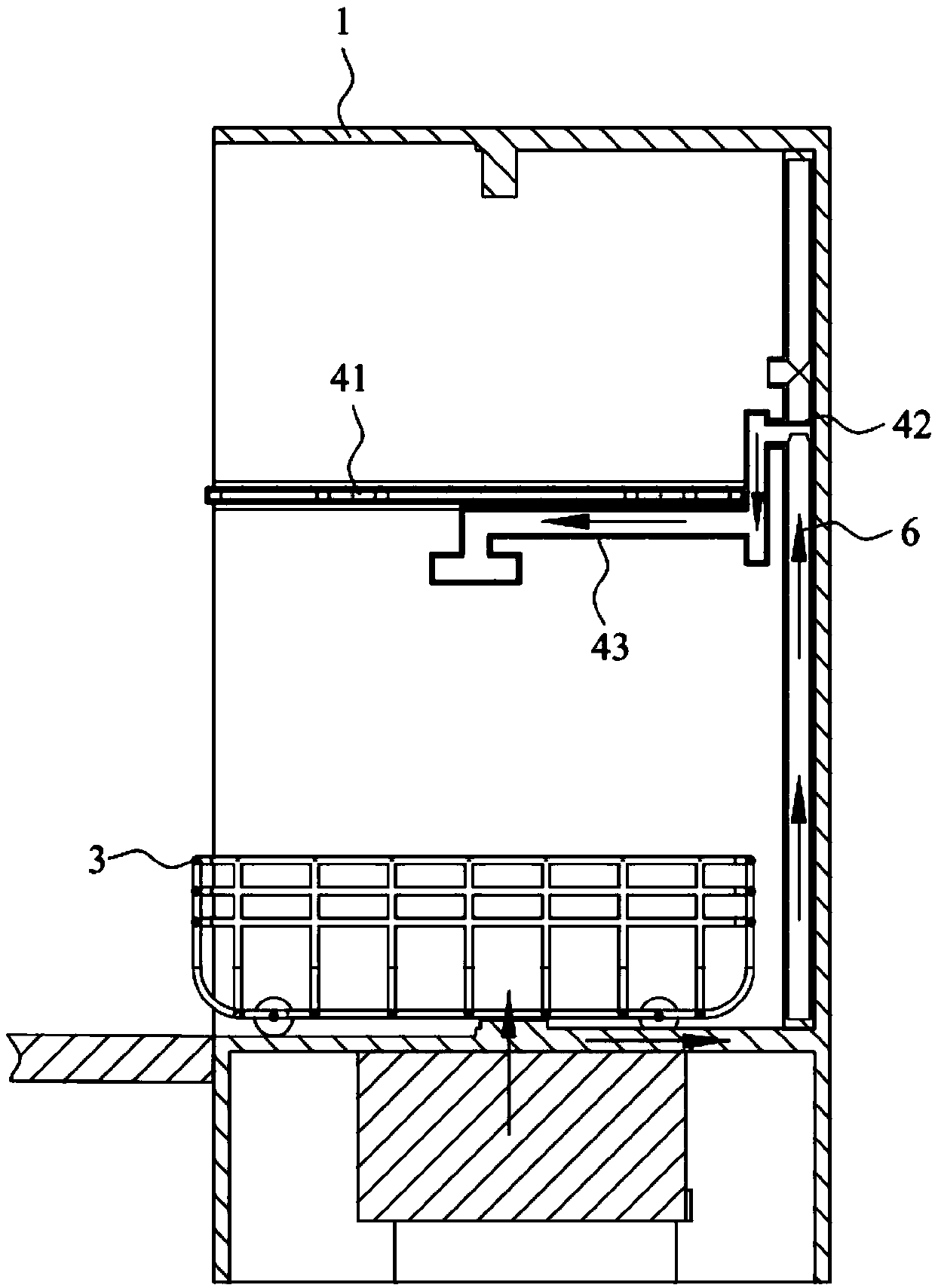

Filtration self-cleaning type clean water sump

InactiveCN101629426ALarge water storage capacityHigh water consumptionDomestic plumbingWater/sewage treatmentCheck valveEngineering

The invention discloses a filtration self-cleaning type clean water sump. The main application is that: the clean water sump is a facility which filters household tap water into clean water and can reserve the clean water with the same pressure as the tap water, and a filtration device thereof can self-clean and does not need power. A main structure thereof is that: the clean water sump is connected to a main tap water valve, and is connected to a back-flush type three-interface filter through a check valve and a throttle valve; the filtered clean water enters a container which can reserve water and pressure for reservation; at the same time, the clean water sump is connected to a household water consumption pipeline; the sewage of the back-flush cleaning filter is connected to a flushing toiler through a cutoff valve; the self-cleaning of the filter can be finished when the flushing toiler is flushed; and the check valve at the front end of equipment can ensure that the clean water with the pressure can be reserved for families to use when the tap water is cut off, thereby ensuring that the tap water is more convenient and sanitary when people uses the tap water.

Owner:马先伟

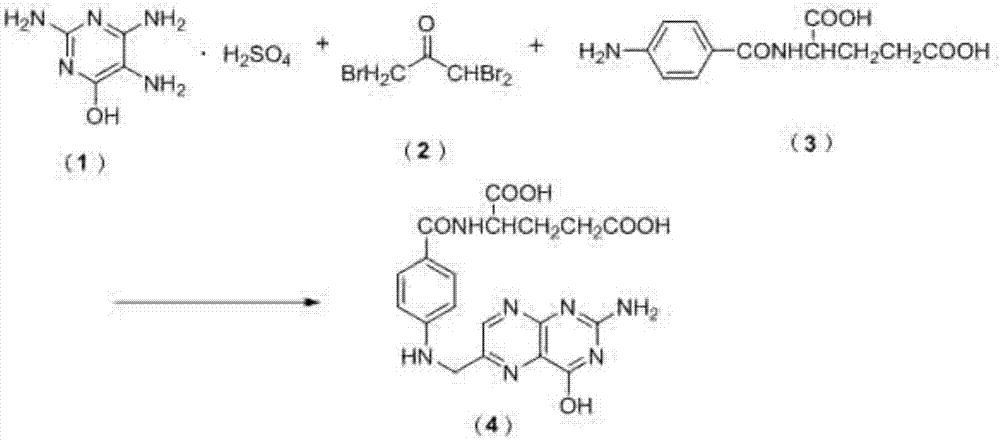

Preparation method of folic acid

The invention belongs to the technical field of medicine and particularly relates to a preparation method of folic acid, comprising the steps of (1) adding 1,1,3-tribromoacetone into ethanol solution, and stirring under heating; (2) dissolving the 1,1,3-tribromoacetone completely, continuing to add p-aminobenzoyl-L-glutamic acid, and stirring until full dissolution to obtain first reaction liquid; (3) dissolving 2,4,5-triamino-6-hydroxypyrimidine sulfate in water, and adjusting pH with saturated sodium carbonate until the 2,4,5-triamino-6-hydroxypyrimidine sulfate is fully dissolved to obtain second reaction liquid; (4) adding the second reaction liquid to the first reaction liquid, and allowing reacting under held temperature; (5) after reacting, performing suction filtering to obtain crude folic acid; (6) acid-dissolving the crude folic acid, alkali-dissolving, and refining to obtain finished folic acid. The preparation method of folic acid has the advantages that the defect that the prior art has high water consumption is changed from the purpose of saving resources and the integrated water saving is up to 40% and above.

Owner:NANJING JINHAO MEDICAL TECH CO LTD

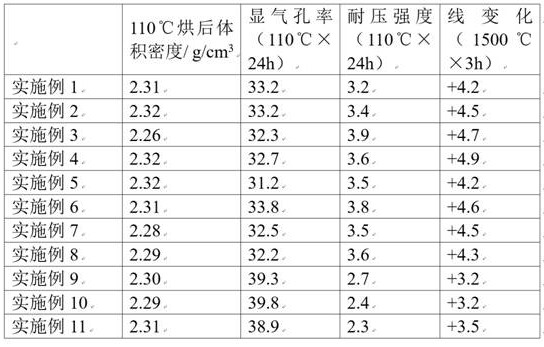

Anti-seepage steel environment-friendly tundish fire clay, preparation method and construction method

InactiveCN112374874AAvoid Chromium ContaminationSolve the problem of seeping steelMelt-holding vesselsFire clayTundish

The invention provides anti-seepage steel environment-friendly tundish fire clay, a preparation method and a construction method, and the anti-seepage steel environment-friendly tundish fire clay comprises the following preparation raw materials in parts by mass: 5-40 parts of white corundum, 35-80 parts of high bauxite, 5-35 parts of kyanite, 0.5-5 part of silica powder, 0.1-5 part of clay, 0.1-4part of zirconium oxide powder and 0.1-1 part of a water reducing agent. The tundish fire clay does not contain chromium, so that chromium pollution can be avoided; the viscosity of the fire clay isreduced through proper raw material particle size distribution, and field construction is facilitated; by adding zirconium oxide and utilizing the phase transformation toughening principle at the hightemperature, the high-temperature breaking strength of the fire clay is greatly improved, and the fire clay can resist to high-temperature molten steel scouring in the using process; and by adding kyanite and Al2O3-containing raw materials and using phase transformation at the high temperature of kyanite and expansion generated by secondary mullite, shrinkage, caused by liquid adding, of the fireclay is made up, gaps between the fire clay and the tundish nozzle are avoided, and the problem of steel seepage is solved.

Owner:北京利尔高温材料股份有限公司

Method for preparing reducing leather based on collagen fiber grey fabric by combining with spunlacing technology

The invention discloses a method for preparing reducing leather based on collagen fiber grey fabric by combining with a spunlacing technology. The method comprises the following steps of treating of the collagen fiber grey fabric by the spunlacing technology, and preparing by a non-solvent film forming technology. The method has the advantages that according to the characteristics of the collagen fiber grey fabric, the reducing leather is prepared by the spunlacing technology and the non-solvent film forming technology, so that the obtained reducing leather has the sense and effect of true leather (two-layer leather), simple structure, high content of collagen (greater than 80%), and excellent mechanical property; the grey fabric treated by the spunlacing technology is treated by the non-solvent film forming technology to prepare a resin layer at the surface of the grey fabric, the elasticity and the hand feel of the reducing leather are improved, and the high-quality leather product is obtained; the utilization rate of the leather raw material is greatly improved, and the environment-friendly level of the leather industry is effectively improved.

Owner:徐琦

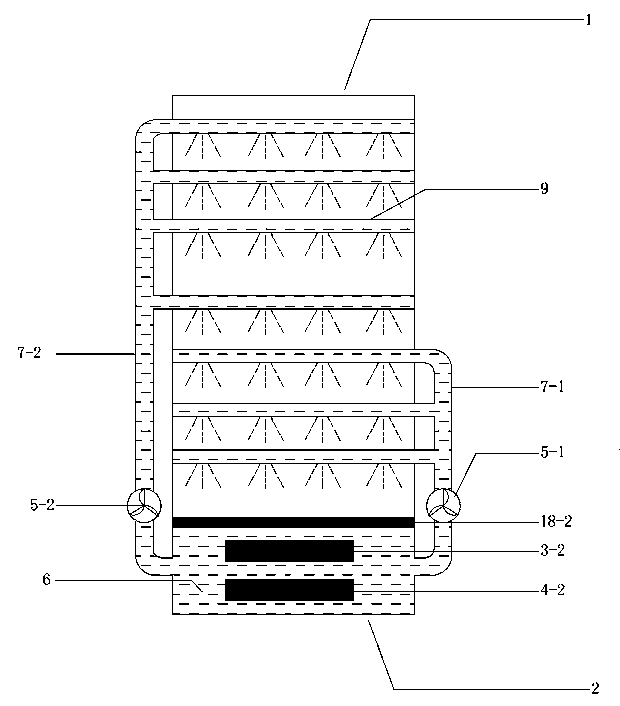

Water curtain spray booth

The invention discloses a water curtain type paint spraying room. The water curtain type paint spraying room is characterized that the paint spraying room is divided into a spraying chamber and a gas-liquid recycling chamber through a vertical partition plate, three overflow grooves are formed on the top of the paint spraying room, inclined water curtain plates are arranged at a overflow opening of each overflow groove, three water curtain plates are parallel to one another, the bottom of the paint spraying room is provided with a water containing tank, a gas and liquid circulating channel isreserved between the lower end of the vertical partition plate and a bottom plate of the water containing tank, a spraying workbench and a paint spraying gun are arranged in the spraying chamber, a gas-water separator and an exhaust fan are arranged in the gas-liquid recycling chamber, the spraying chamber is provided with an air inlet, and air flow sent by the air inlet sequentially passes through three water curtains and then passes through the gas and liquid circulating channel at the lower end of the vertical partition plate and sent into the gas-liquid recycling chamber, and then is discharged outwards through the exhaust fan after being separated by the gas-water separator. The water curtain type paint spraying room has the advantages that paint mist diffused in air can be fully fused with water, and the paint mist purification efficiency is improved.

Owner:扬州琼花涂装工程技术有限公司

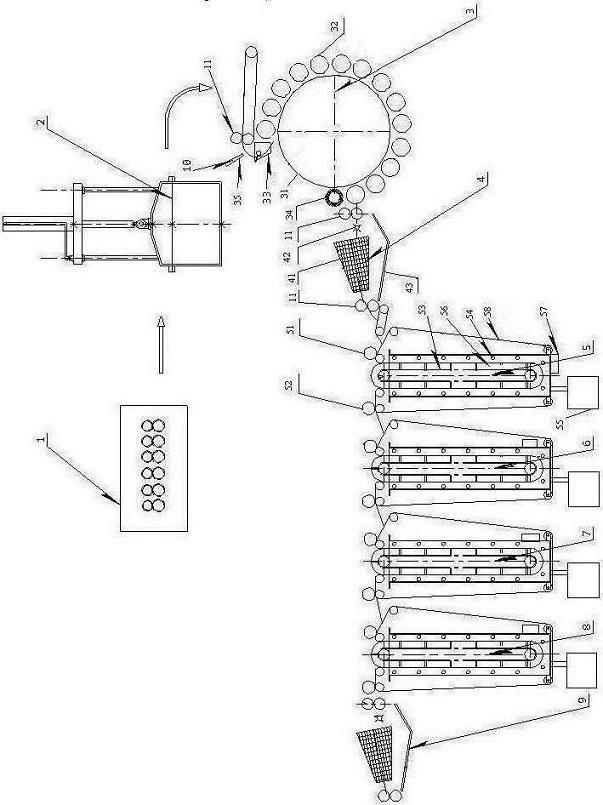

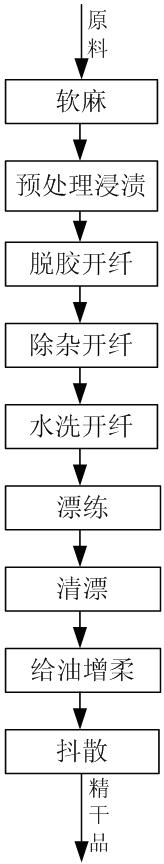

Automatic production process for preparing fibers by combining ramie finishing

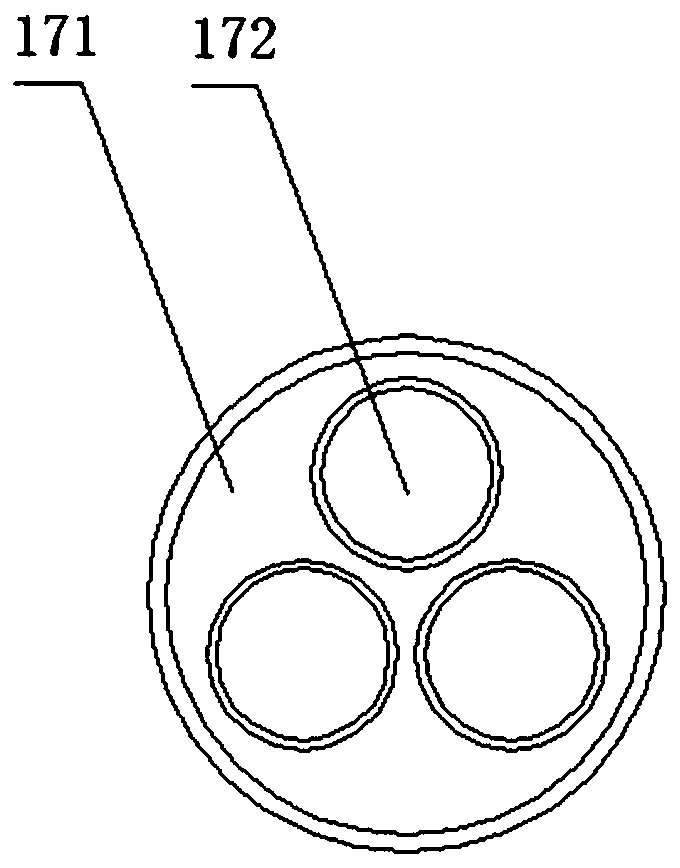

ActiveCN102251294AImprove fiber qualityOvercome discontinuityMechanical fibre separationVegetal fibresProcess engineeringAutonomation

The invention discloses an automatic production process for preparing fibers by combining ramie finishing. The process comprises the following steps of: (a) feeding a ramie raw material into a softening machine, removing partial impurities by mechanical kneading, and then coiling the strip-like ramie raw material into a dipping barrel; (b) pushing the dipping barrel into a bast fiber pretreatment machine, performing vacuum pretreatment, pushing out the ramie raw material and storing the ramie raw material for 2 to 3 hours to finish dipping treatment of the ramie raw material; and (c) and sequentially performing degumming and fiber opening, impurity removal and fiber opening, washing and fiber opening, bleaching, rinsing, oil supply softening and trembling on the dipped ramie raw material by using a degumming and fiber opening machine, an impurity removal and fiber opening machine, a washing and fiber opening machine, a bleaching machine, a rinsing machine, an oil supply softening machine and a trembling machine respectively. By the process, continuous mechanical production of the whole degumming process can be realized, and the purposes of saving energy, reducing emission, reducing consumption and improving the quality of the fibers are fulfilled.

Owner:SICHUAN RES INST OF SILK SCI

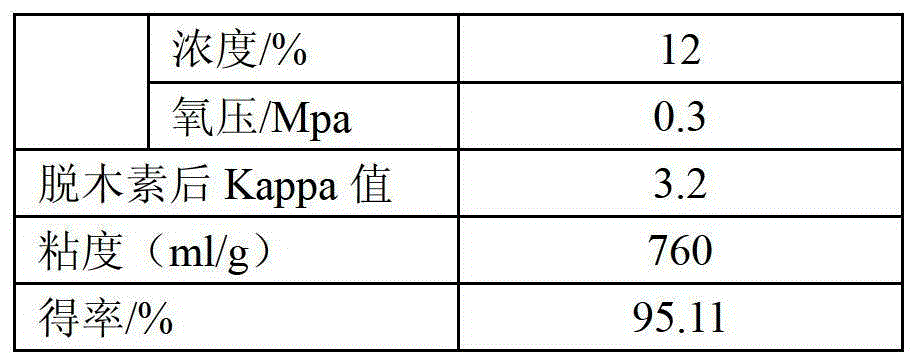

Traditional Chinese medicine (TCM) biological agent cold pulping method

ActiveCN105274891AShort softening timeHigh water consumptionPretreatment with alkaline reacting compoundsFibrous raw materialsFiberSlag

The invention provides a traditional Chinese medicine (TCM) biological agent cold pulping method comprising the following steps: (1) material preparing and soaking; (2) grinding and dividing: dividing and fibrillating softened pulping raw material into tobacco shred-like fibers; (3) residual water recycling: conveying pulp ground out by pulping equipment through a single-helix conveyor, and extracting residual chemical water through a double-helix press washer; (4) screening and slag removing: adding water to dilute the pulp in a transition pool and pumping the pulp to screening equipment, and pumping the pulp after screening to slag removing equipment to remove sand impurities; (5) washing and concentrating: inputting the pulp to dehydration equipment for dehydration, and then, adding bleaching agent and removal agent and entering a delignification and bleaching link; and (6) concentrating the pulp into finished pulp: further dehydrating and concentrating the pulp for using or selling. The method is non-toxic, bubble-free, odor-free and emission-free, and causes no pollution to the air and the environment. The pulp can be stored without changing color; the whiter the pulp is, the longer the pulp is stored; and the pulp does not go bad. Moreover, the method is simple in operation, can save electricity, water, equipment and manpower, and is low in cost.

Owner:湖北汇绿纸业有限公司

Instant electric water heater with syncretic volume and the heating method

InactiveCN101105331AEasy to useReduce electricity consumption costsWater heatersWater sourceEngineering

The invention discloses a quick-heating and positive displacement integrated electric water heater and its heating method. The electric water heater comprises a cabinet, wherein a water inlet port and a water outlet port are provided on the cabinet. The invention is characterized in that a group of chambers for storing water is provided in the cabinet, and a guide hole is provided between each chamber; an electric heating membrane heater is provided outside the cabinet, one end of the electric heating membrane heater is communicated with the water inlet port of the cabinet via a circulating pump; the other end of the electric heating membrane heater is connected with water source via an automatic switch; the water outlet port of the cabinet is connected with the water utilization pipe of the electric water heater via the electric heating membrane heater; and a temperature detector is provided in the cabinet and connected with a control device for coordinating the operation of the electric heating membrane heater, circulating pump and automatic switch. The invention can meet the requirement of randomly supplying hot water, and has the advantages of convenient and rapid usage, good energy-saving effect, long service life, easy arrangement, high hot water supplying rate, and high safety.

Owner:王斌

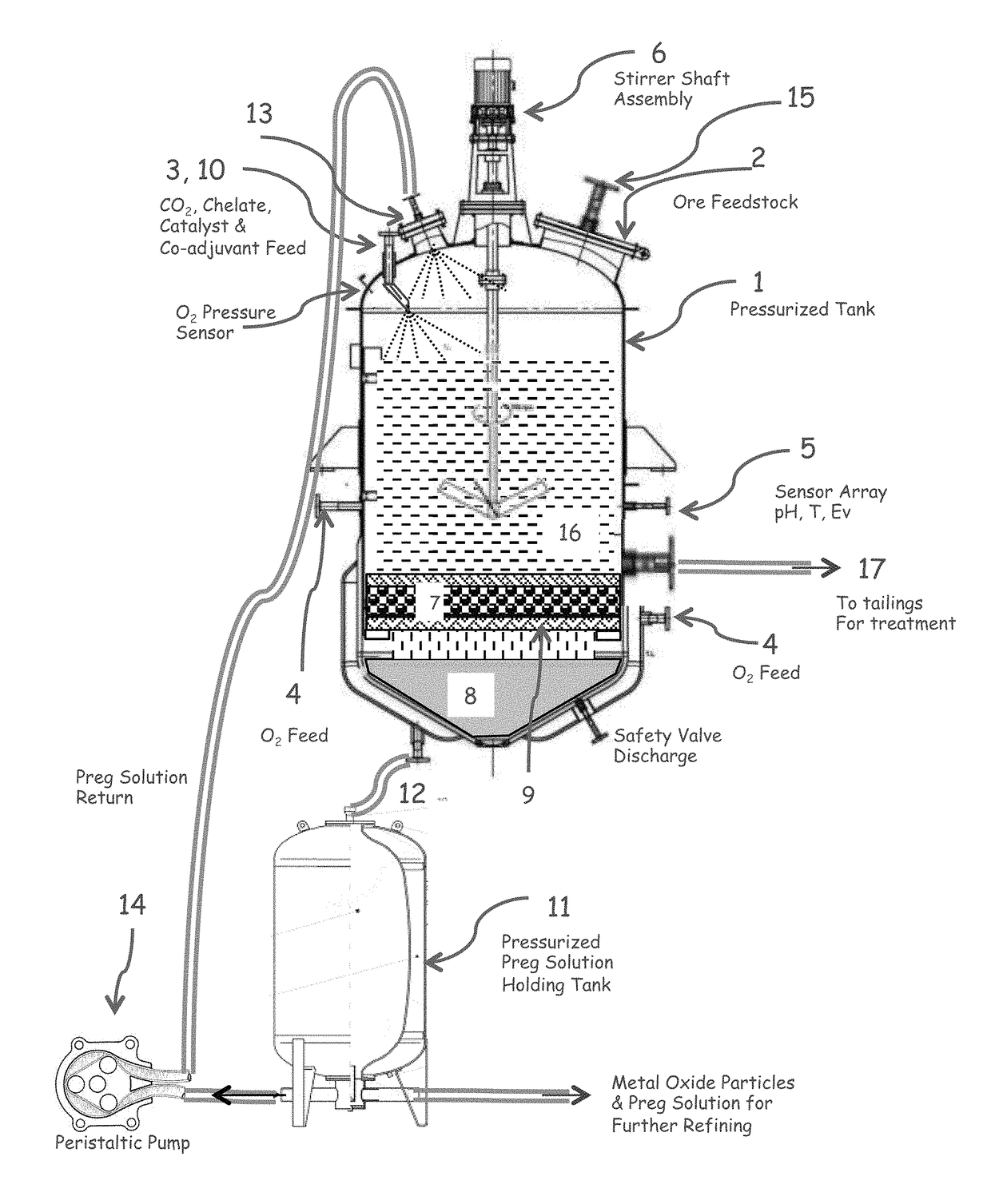

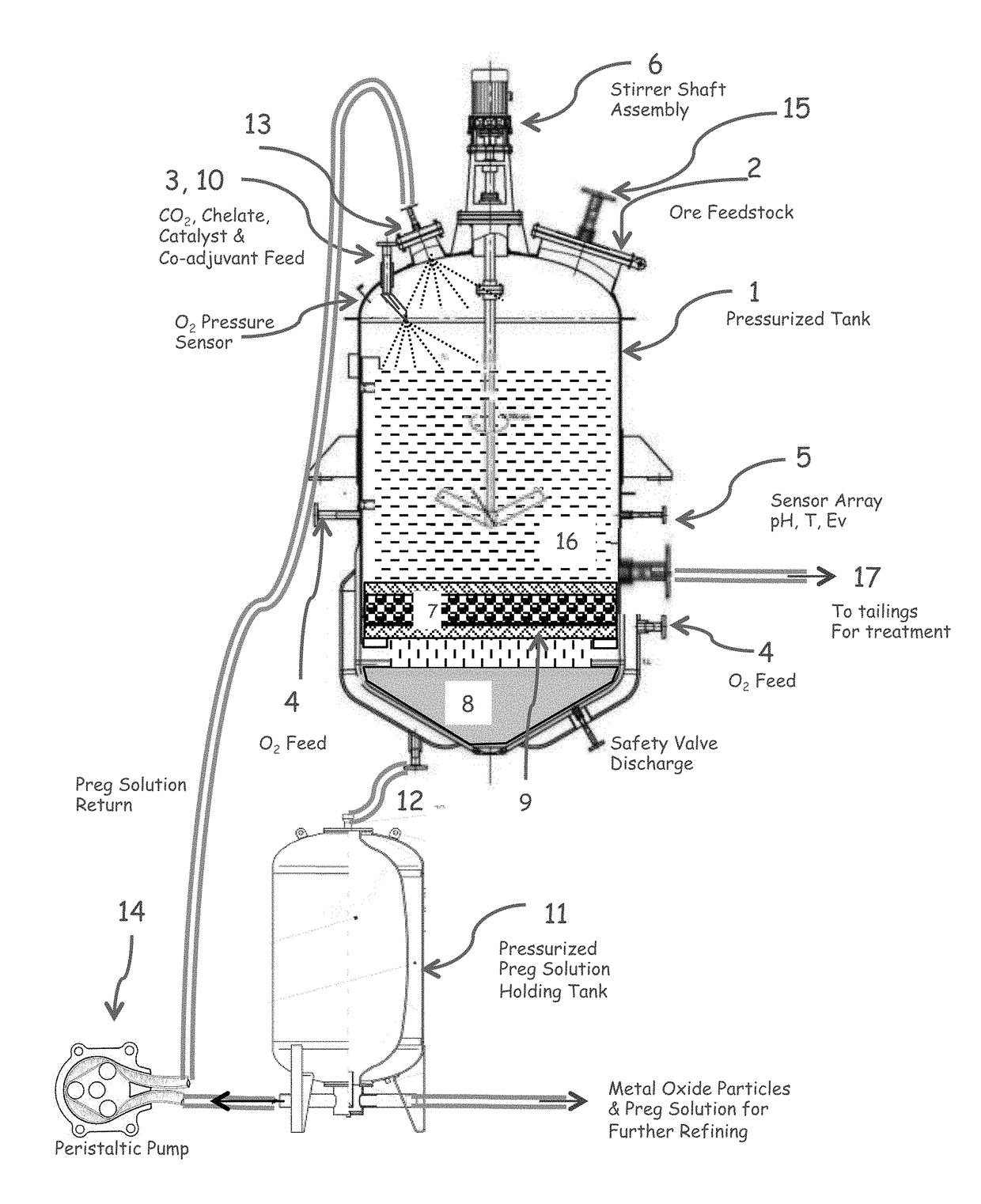

Enhanced metal recovery through oxidation in liquid and/or supercritical carbon dioxide

ActiveUS20170240434A1Huge savingsSignificant energy savingIron sulfatesProcess efficiency improvementMaceralOxidizing agent

Process for enhanced metal recovery from, for example, metal-containing feedstock using liquid and / or supercritical fluid carbon dioxide and a source of oxidation. The oxidation agent can be free of complexing agent. The metal-containing feedstock can be a mineral such as a refractory mineral. The mineral can be an ore with high sulfide content or an ore rich in carbonaceous material. Waste can also be used as the metal-containing feedstock. The metal-containing feedstock can be used which is not subjected to ultrafine grinding. Relatively low temperatures and pressures can be used. The metal-containing feedstock can be fed into the reactor at a temperature below the critical temperature of the carbon dioxide, and an exotherm from the oxidation reaction can provide the supercritical temperature. The oxidant can be added to the reactor at a rate to maintain isothermal conditions in the reactor. Minimal amounts of water can be used as an extractive medium.

Owner:KING ABDULLAH UNIV OF SCI & TECH

Recycling device for textile and garment broken cloth

The invention provides a recycling device for textile and garment broken cloth, and relates to the technical field of textile and garment processing. The recycling device comprises a main body box, a crushing mechanism and a water filtering mechanism, cutting blades are welded to the outer side of a rotating shaft, a supporting plate is fixedly connected to the left side wall of an inner cavity of the main body box and located on the left side of a crushing chamber, a draught fan is installed at the top of the supporting plate, a exhaust disc is vertically connected to the output end of the draught fan, and a pull net is fixedly connected to the left side wall of an inner cavity of the crushing chamber and covers the tail end of an air outlet. According to the device, airflow is provided for the crushing chamber through the designed draught fan, so that poured crushed clothes are easier to contact with a crushing blades, therefore, the overall crushing effect is improved, clear water is injected into the crushing chamber through a spray head, the crushed clothes are mixed in water flow, discharging is easier, residues are avoided, the clear water can be reused through a water pump after passing through the water filtering mechanism, and therefore excessive water consumption is avoided, and the overall cost is controlled.

Owner:安徽职业技术学院

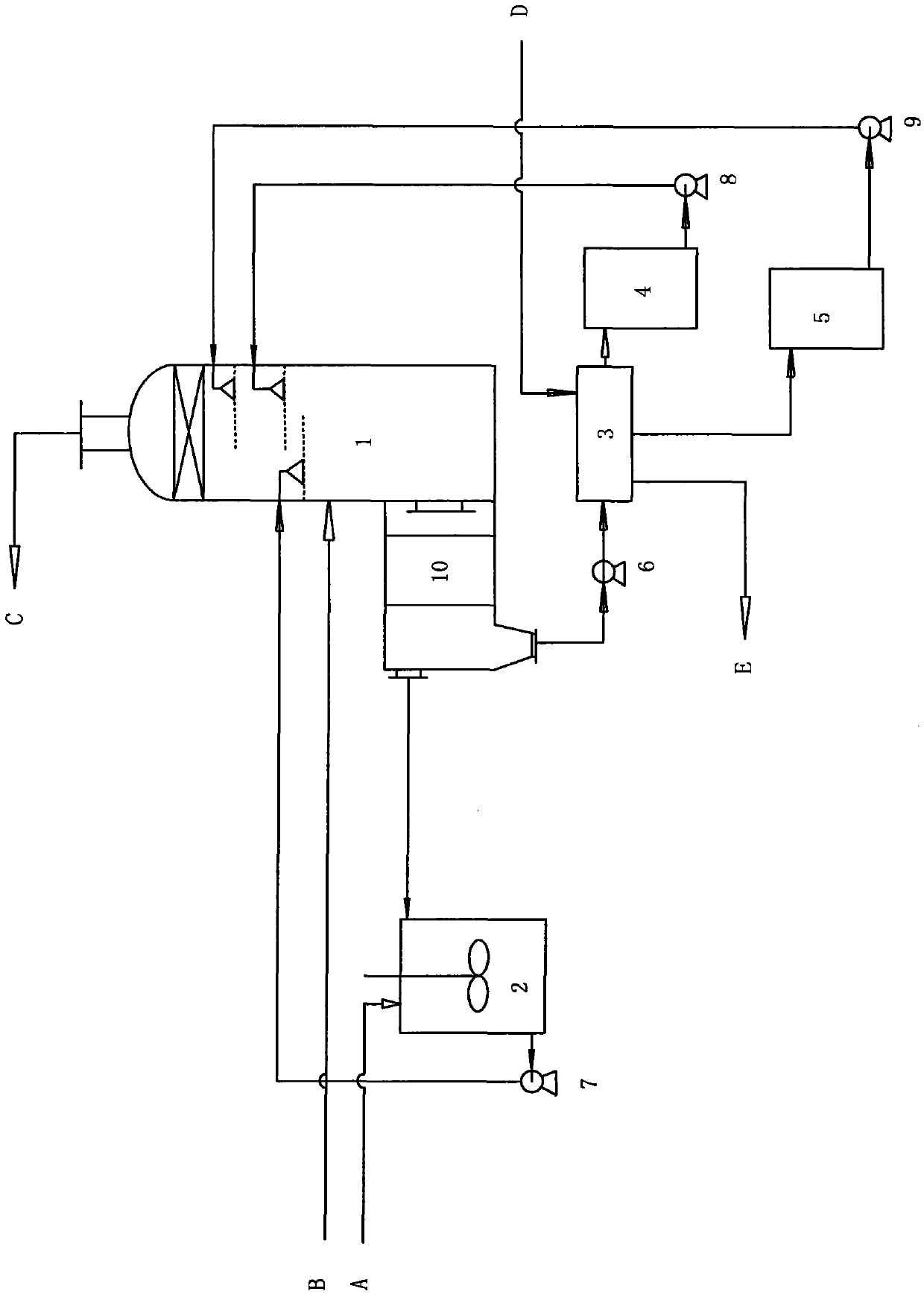

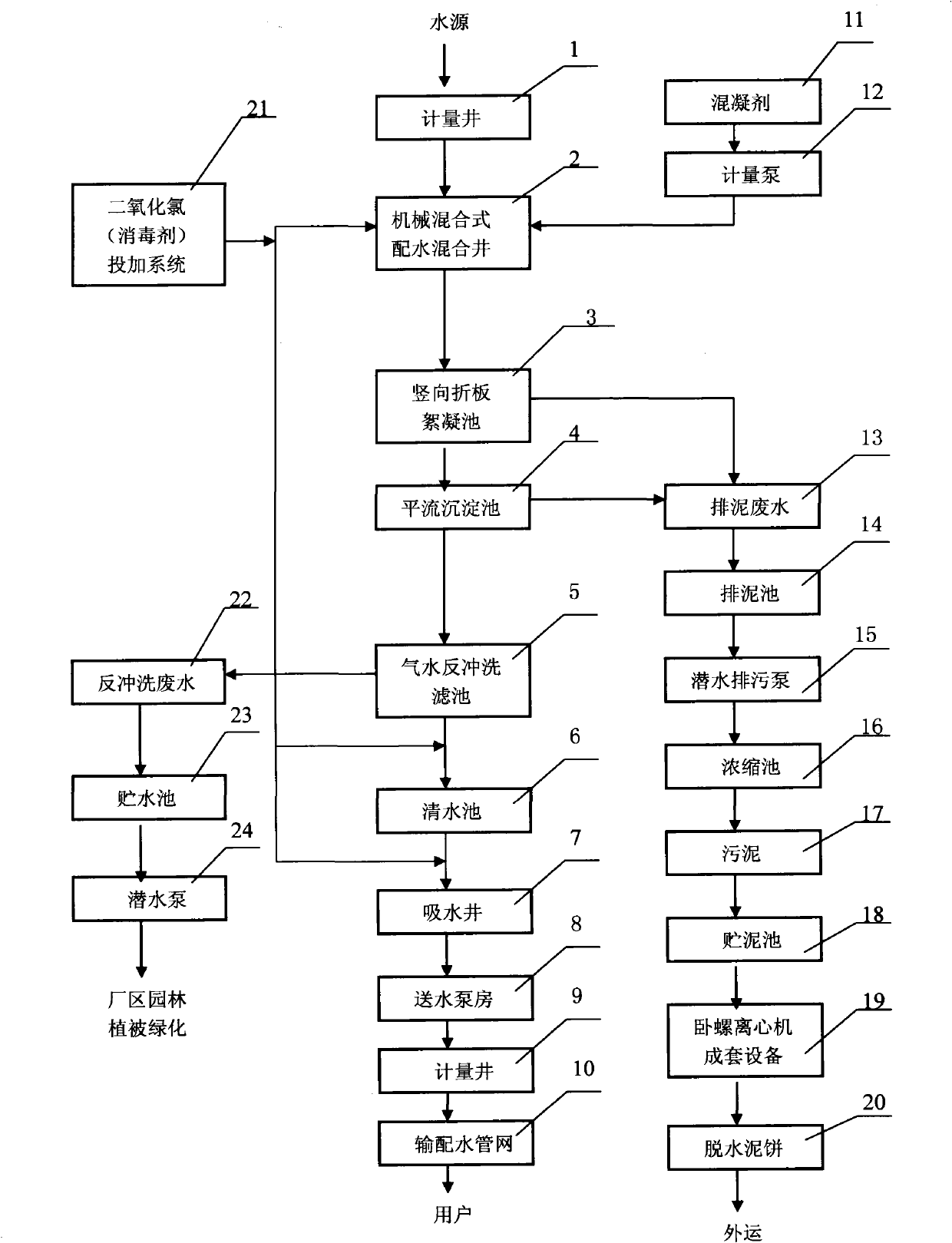

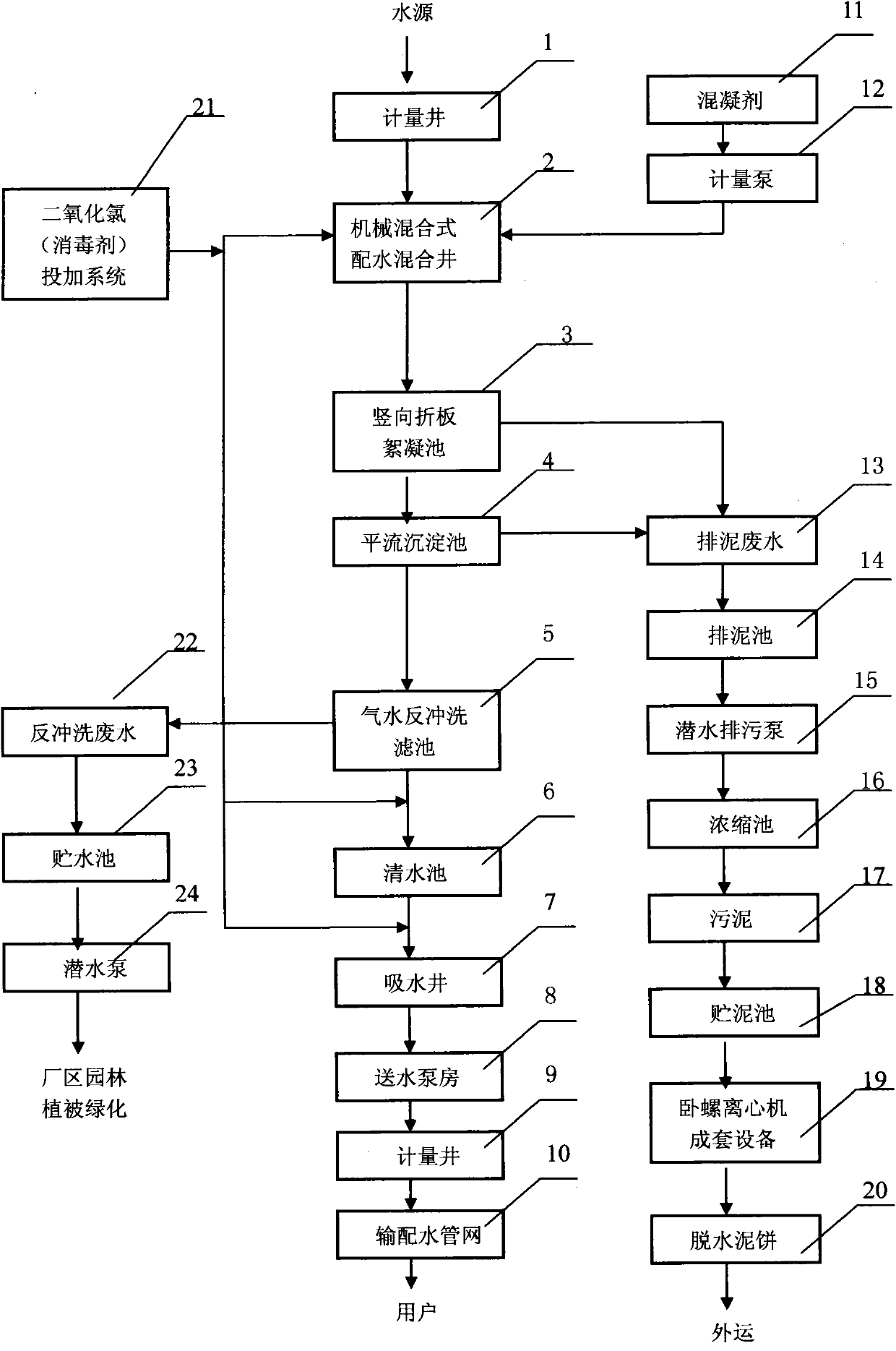

Low-carbon, environment-friendly, economical and reasonable water treatment process flow and method for water treatment plant

InactiveCN102167456AReduce volumeIncrease solid contentSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentWastewaterWater resources

The invention discloses a low-carbon, environment-friendly, economical and reasonable water treatment process flow and method for a water treatment plant, and belongs to the fields of water resource reasonable utilization technology and environmental protection. The water treatment process flow and method comprises the following steps of: adding a coagulant; adding a disinfectant; purifying water; and utilizing and treating wastewater. The invention has the advantages that: problems of the conventional process are solved; and the water treatment process and method for the water treatment plant is low-carbon, environment-friendly, economical, reasonable, stable and reliable in operation and convenient to manage and maintain, ensures water treatment effect to reduce project investment and daily operating cost.

Owner:姚家泰

Method of cooling a sterilizer

ActiveUS20110274592A1High water consumptionAvoid paddingLavatory sanitoryIndirect heat exchangersWater flowEvaporation

Cooling of a jacketed autoclave or steam sterilizer is carried out by allowing a film of water to flow down the inner wall of the sterilizer's jacket space. Condensate from the jacket space is drawn into the water ring pump provided for vacuum in the autoclave jacket. The condensate is conducted to the water side of the pump while the normal suction line is connected at the pump to the gas zone. Thus, the water ring pump draws condensate from the lowest point of the jacket to the water side, and gas from the jacket space to the normal suction inlet. During the process of sterilizer cooling, a stream of water and air from the water ring pump is conducted to the upper part of the jacket space of the steam sterilizer and is allowed to flow as a film down the inner wall of the jacket space. Evaporation takes place with cooling of the jacket inner wall. This evaporation is enhanced by the lowering of pressure in the jacket due to the action of the water ring pump. Thus, the autoclave is cooled by a film of water flowing across the jacket inner wall while evaporating.

Owner:STERIS EURO INC SUOMEN SIVULIIKE

Pedestal pan capable of generating air pressure by utilizing self-generated pressure of water supply

ActiveCN105275068AHigh water consumptionSmall footprintFlushing devicesLavatory sanitoryExhaust pipeHydraulic pressure

The invention relates to a pedestal pan capable of generating air pressure by utilizing self-generated pressure of water supply. The pedestal pan comprises a pedestal pan body; the lower part or side part of the pedestal pan body is provided with two chambers which are separated from each other, wherein one of the chambers is a water storage chamber, and the other chamber is a gas storage chamber; the water storage chamber is provided with the water inlet of a water level control valve and a water outgoing pipe connected with the water spraying head of the pedestal pan; a gas intake and exhaust pipeline which presses gas in the water storage chamber into the gas storage chamber is arranged between the water storage chamber and the gas storage chamber; a discharging opening at the lower end of the pedestal pan body is connected with a flushing pipeline device of which the closing is controlled by air pressure or hydraulic pressure; the gas storage chamber is provided with a gas discharging pipeline communicated with the flushing pipeline device; and the lower parts of the flushing pipeline device and the gas storage chamber are provided with a one-way bleed valve which can directly discharge stink to the outside of the outer water level of a sunk water pipe of an indoor sewer pipe. According to the pedestal pan of the invention, the defects of a traditional pedestal pan, such as water flushing, water seal deodorization and large size can be eliminated. With the pedestal pan of the invention adopted, average single water consumption is equal to or less than 1.99 liters, and floor space can be saved, and energy can be saved, and emission can be reduced.

Owner:明春刚

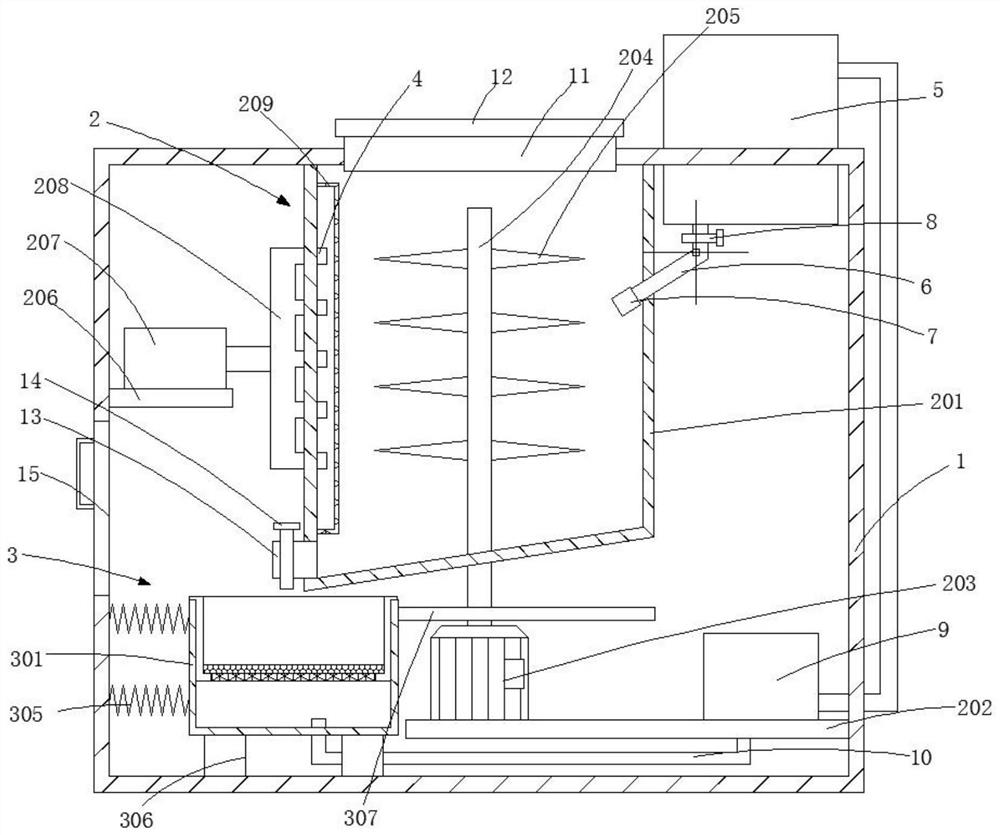

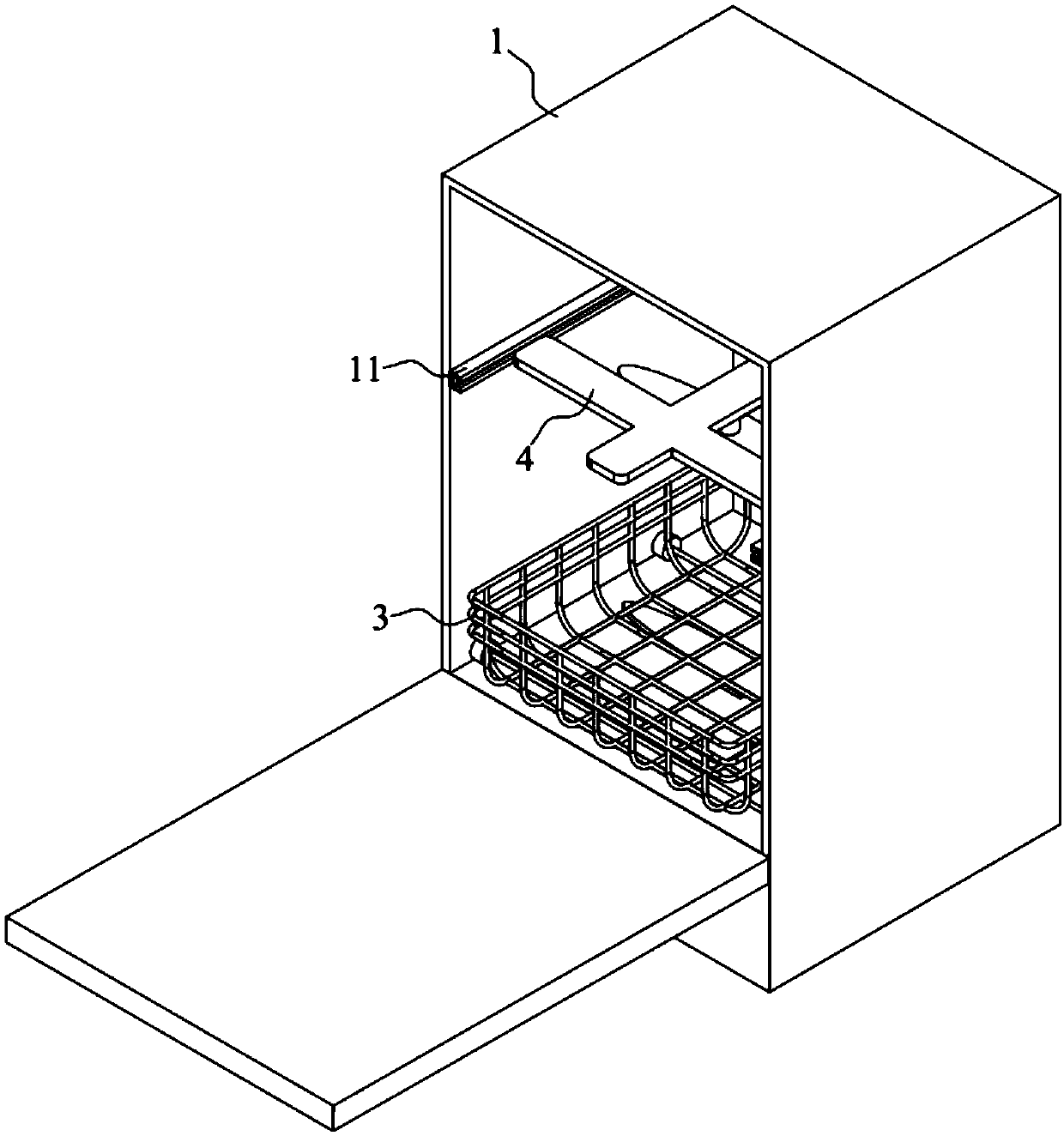

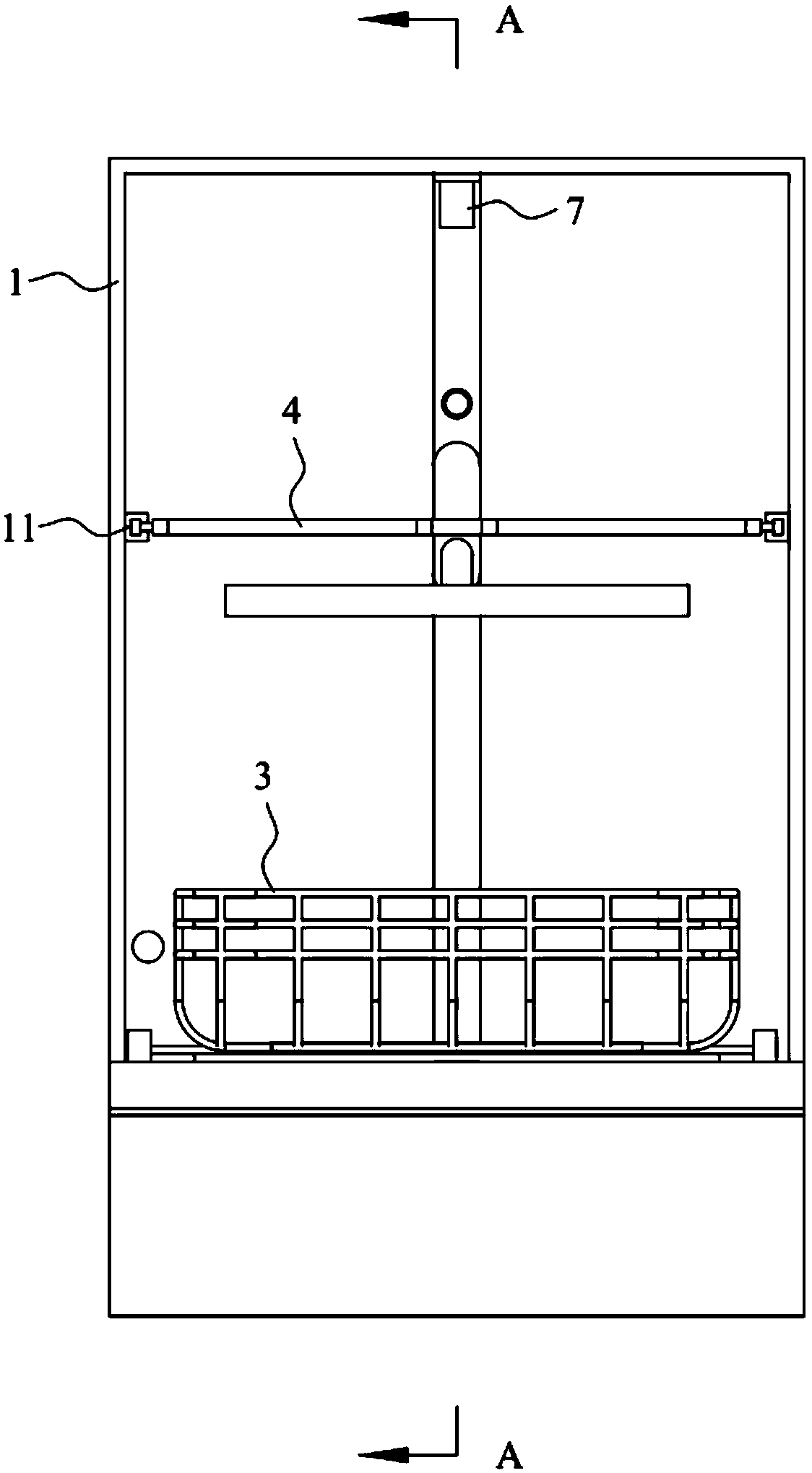

Regional cleaning mechanism and dish-washing machine

PendingCN111067451AFully cleanedIncrease water pressureTableware washing/rinsing machine detailsProcess engineeringMechanical engineering

The invention discloses a regional cleaning mechanism and a dish washing machine, and belongs to the technical field of utensil washing. The regional cleaning mechanism comprises a cleaning chamber, and an upper shelf and a lower shelf arranged in the cleaning chamber, and further comprises a partition plate, the upper shelf and the partition plate are selectively connected with the cleaning chamber, a lower spraying water path, a middle spraying water path and an upper spraying water path which are communicated from bottom to top are arranged in the cleaning chamber, and the partition plate can close the upper spraying water path and change the spraying direction of the middle spraying water path to achieve downward spraying. The dish washing machine comprises the regional cleaning mechanism. When more utensils need to be cleaned, all the spraying water paths are opened, so that the utensils on the upper shelf and the lower shelf are fully cleaned, when the number of appliances needing to be cleaned is small, only the appliances are placed on the lower shelf, the partition plate is connected with the cleaning chamber, the middle spraying water path and the lower spraying water path spray water to the lower shelf, so that the water pressure of the middle spraying water path and the lower spraying water path is increased, and the water amount and the electric quantity are saved.

Owner:QINGDAO HAIER DISHWASHER

Hakka rice wine and production technology thereof

InactiveCN109022204ASimple processEasy to control fermentationAlcoholic beverage preparationYeastSugar

The invention belongs to the field of wine production, and concretely relates to a Hakka rice wine and a production technology thereof. The production technology comprises the following steps: 1) cleaning, soaking and draining glutinous rice, and steaming the glutinous rice for 15-20 min; 2) cooling the steamed glutinous rice, adding glucoamylase accounting for 0.005-0.02% of the amount of the glutinous rice, Angel rice wine yeast accounting for 0.02-0.04% of the amount of the glutinous rice and rice milk accounting for 20-40% of the amount of the glutinous rice, and saccharifying the glutinous rice; 3) adding rice shochu accounting for 35-45% of the amount of the glutinous rice after the saccharification is carried out for 12 h, and carrying out post-fermentation; and 4) carrying out squeezing, clarification and sterilization after the post-fermentation is carried out for 35 d. Traditional rice wine has a high sugar content of 180 g / L or above, is not well received by people, and is not well consumed by consumers. The novel technology rice wine has a lower sugar content than the rice wine produced by traditional technologies, has a sugar content of about 70 g / L, is rich in nutrients, and is well received by consumers.

Owner:瑞金客佳红酿造股份有限公司

Stable air-pressure fire water supply system

ActiveCN102312467BShort startup timeReasonable useService pipe systemsWater mainsNuclear powerEngineering

The invention discloses a stable air-pressure fire water supply system. In the stable air-pressure fire water supply system, a non-diaphragm type air-pressure water pot with a bigger volume is adopted; a spare air-pressure water pot, a water replenishing pump and an air-pressure compressor are additionally arranged; the two air-pressure water pots are connected with each other through a connecting water tank; the operations of the water replenishing pump and the air-pressure compressor are controlled in the manner of changing the water level and the pressure of the connecting water tank; two water replenishing pumps or two air-pressure compressors can be simultaneously started or singly started according to a practical condition, thereby not only being capable of reasonably utilizing the resource but also being capable of ensuring the safety, reliability and stability of the stable air-pressure fire water supply system. The stable air-pressure fire water supply system not only can be applied in a thermal power fire water supply system but also can be applied to a nuclear power fire water supply system which is characterized by short fire pump starting time, large water consumption at initial fire stage, high water supply pressure and strict system safety demand.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

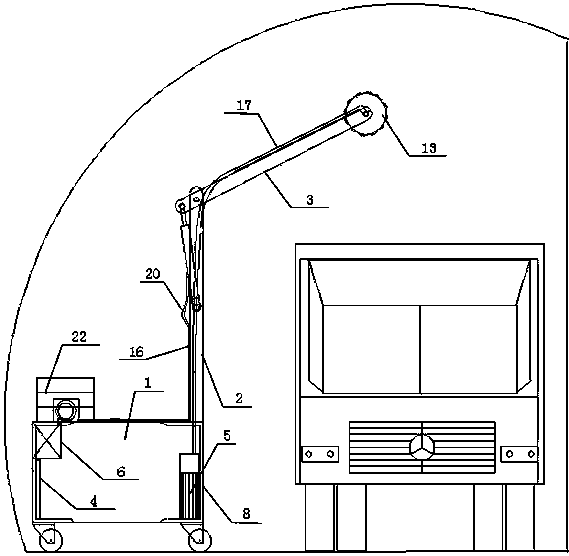

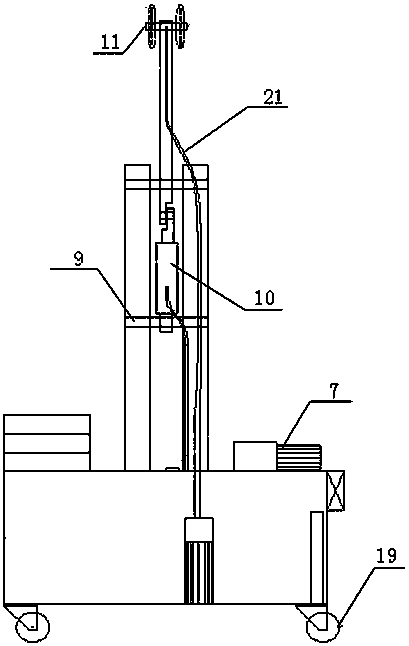

Movable folding arm type rotary water-spraying dust-removing device

InactiveCN108561173ASpray water evenlyImprove dust removal effectDust removalFire preventionElectric machineAgricultural engineering

The invention belongs to the field of tunnel construction, and can solve the problems of large water consumption, high cost, difficult movement and low water mist utilization rate of existing tunnel construction dust removing device. The movable folding arm type rotary water-spraying dust-removing device comprises a water tank, a main arm and a rotating arm, a water level sensor and a water pump are arranged in the water tank; the outside of the water tank is provided with a control box; the top end of the water tank is provided with an oil pump motor; the main arm is connected with the main beam of the water tank; the rotating arm is connected with the main arm; a hydraulic jack is fixed on the main arm; the telescopic arm of the hydraulic jack is connected with the rotating arm; the topend of the rotating arm is provided with a hollow turntable shaft, two ends of the turntable shaft are respectively provided with a water spraying rotary table, the water outlet of the turntable shaftis connected with the water inlet I of the water spraying rotary table, the water level sensor is connected with the control box, the oil pump motor is connected with the hydraulic jack through the oil return pipe, the water pump is connected with the water inlet II of the turntable shaft through a water supply pipe, and universal wheels are arranged at the bottom of the water tank. The movable folding arm type rotary water-spraying dust-removing device is suitable for different section tunnels and can cover the whole tunnel section.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com