Water curtain spray booth

A paint spray booth and water curtain technology, which can be applied to spray devices and other directions, can solve the problems of poor treatment effect of harmful substances and high waste water discharge, and achieve the effect of improving the purification efficiency of paint mist, reducing discharge and increasing airborne time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

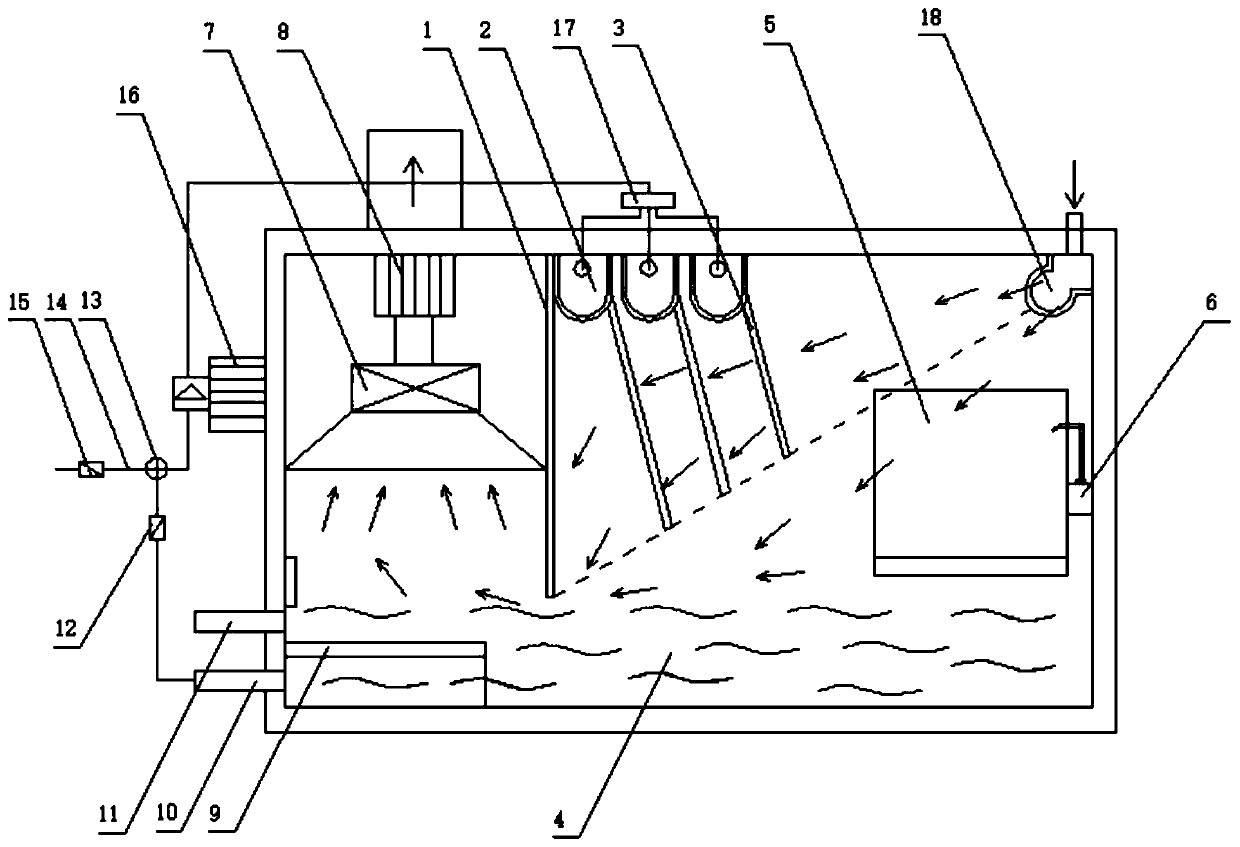

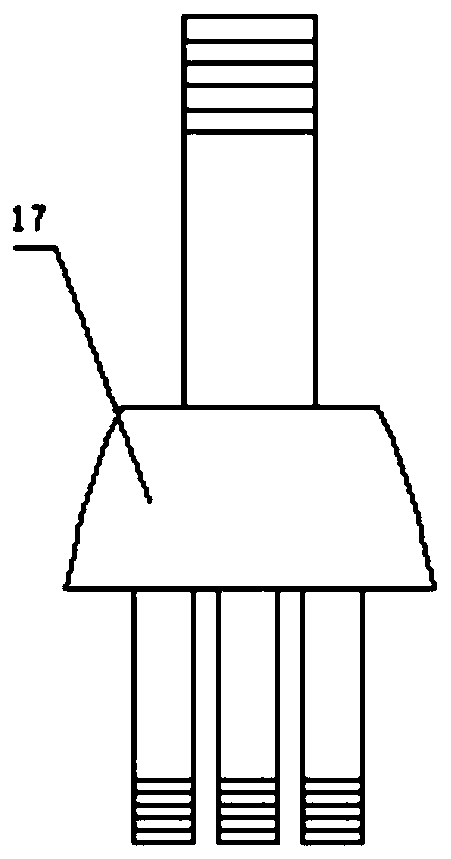

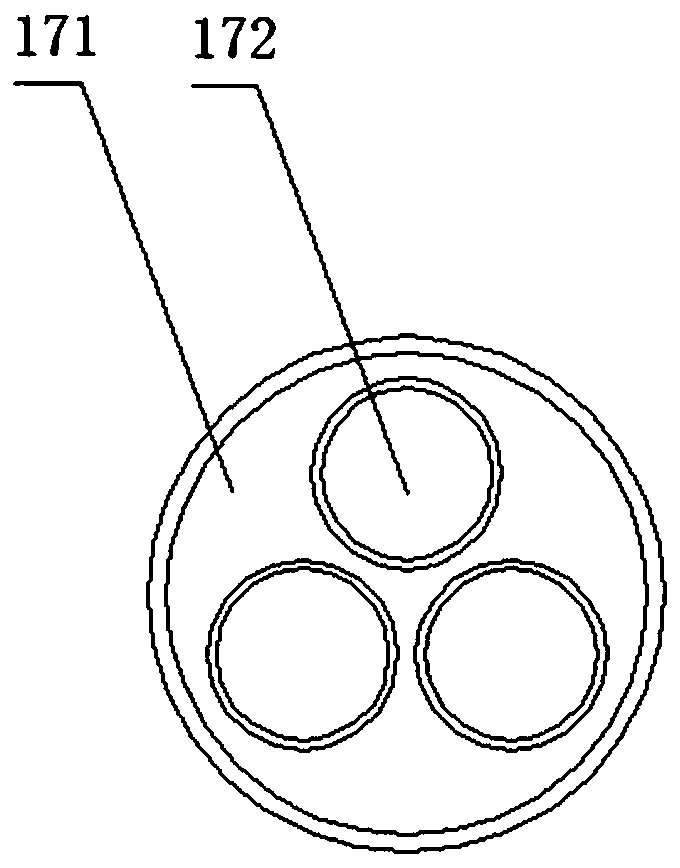

[0027] Such as figure 1 As shown, the present embodiment provides a water curtain spray booth, which is divided into a spray booth and a gas-liquid recovery room through a vertical partition 1, and three overflow tanks 2 are arranged on the top of the spray booth, each overflow The overflow of the water tank 2 is provided with an inclined water curtain plate 3, and the three water curtain plates 3 are parallel to each other. There is a certain gap between the bottom plates of 4 as the gas and liquid circulation channel between the spraying room and the gas-liquid recovery room. In the spraying room, a spraying workbench 5 and a paint spray gun 6 are arranged. In the gas-liquid recovery room, a There is a gas-water separator 7 and an exhaust fan 8, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com