Patents

Literature

42results about How to "Low frost resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

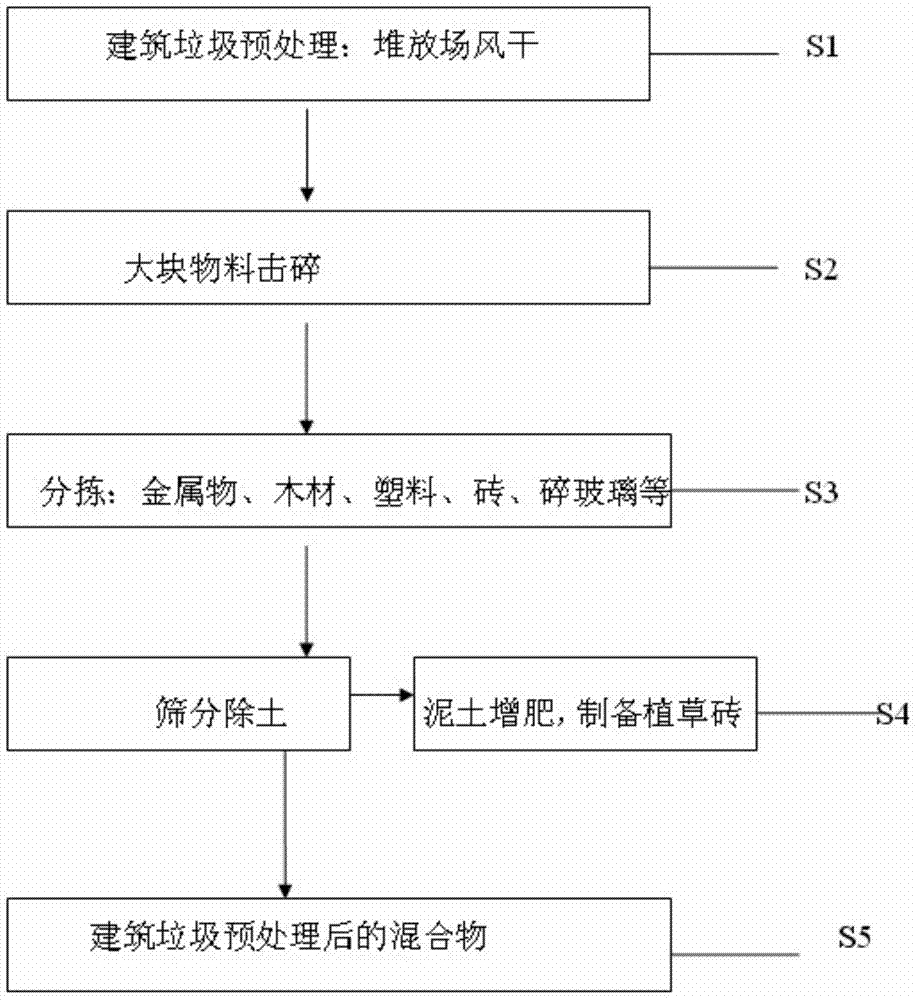

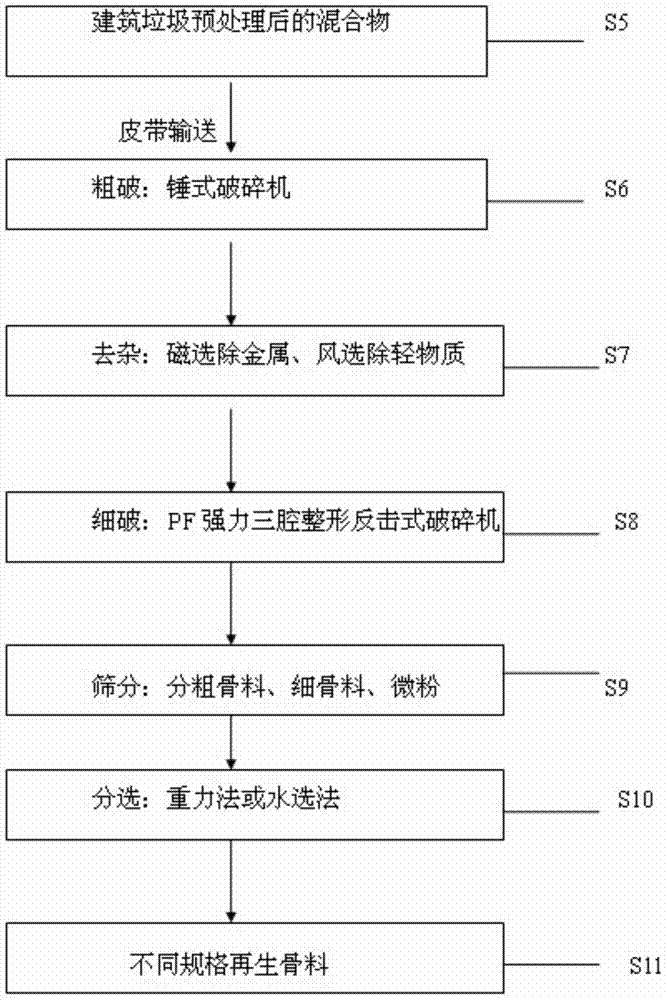

Ecological treatment technology for construction waste

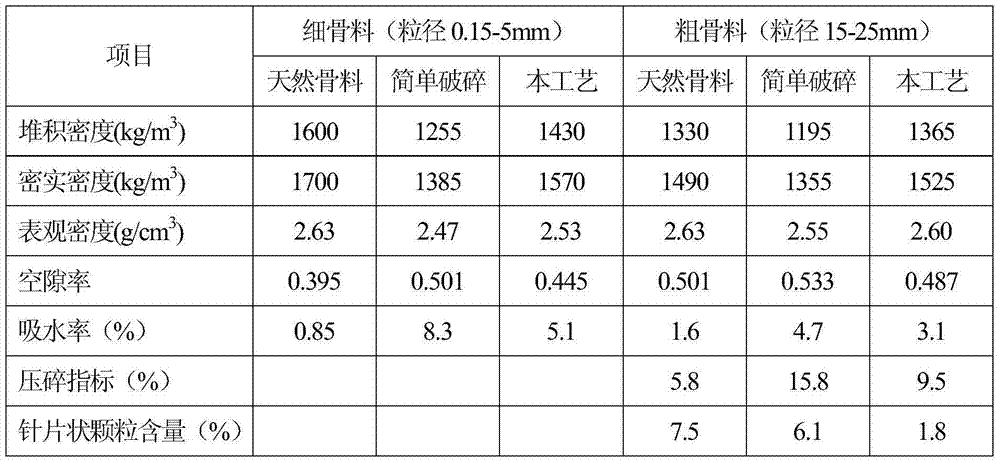

The invention belongs to the field of recycling of construction waste, energy conservation and environment protection, and construction materials, and relates to an ecological treatment technology for construction waste, and particularly relates to the ecological treatment technology for construction waste and a preparation method for regenerated novel construction materials, which can efficiently use the construction waste and does not generate secondary pollution. The ecological treatment technology comprises the following steps of pretreating in a construction waste dump, namely, air drying the construction waste, crushing big blocks, sorting and removing soil through vibrating, adding a fertilizer in the soil to be used for filling grass planting bricks; preparing recycled aggregate, namely, crushing roughly, removing impurities, precisely crushing and simultaneously reinforcing and shaping the recycled aggregate, screening out the recycled aggregate with particle size less than 0.15mm as well as 0.15-5mm, 5-15mm and 15-25mm and micro powder for the secondary time, finally, separating the brick from concrete by a gravitational method or a hydraulic mineral beneficiation method according to different densities of the brick and concrete in the mixed recycled aggregate. Recycling and high value-added utilization of the construction waste are realized, and the ecological treatment technology gets major breakthrough in recycling industry of construction waste.

Owner:DALIAN HONG YUAN GREEN BUILDING MATERIALS

Mortar special for light insulating brick construction and method of producing the same

InactiveCN101508543AAvoid quality problems such as cracking and water seepageImprove performanceSolid waste managementCelluloseWater leakage

The invention relates to mortar special for the masonry of light-weight insulating bricks, which comprises the following raw material compositions in portion by weight: 15 to 35 portions of fly ash, 20 to 40 portions of perlite, 1 to 7 portions of bentonite, 1 to 10 portions of hydrated lime, 1 portion of cellulose ether, 200 to 350 portions of sand, 50 to 100 portions of pottery sand, and 100 portions of cement. The preparation method thereof comprises the following steps that: 1) the fly ash, the sand, the pottery sand, the bentonite, the hydrated lime, the cellulose ether and the cement are evenly mixed through a machine according to the weight ratio respectively; 2) the perlite is added into the mixture according to the weight ratio, and the even mixing is performed through the machine again; and 3) mixed mortar is subjected to quota packaging. The mortar has the advantages of simple preparation technology, low drying shrinkage, high strength, low heat conductivity coefficient, good frost-resistant durability, and good thermal insulation effect, and solves the problems of cold and hot bridges, cracking and water leakage, poor thermal insulation performance, and the like existing on wall bodies which use common masonry mortar.

Owner:武汉城市建设集团有限公司

Aerated concrete block with composition of mica powder and fly ash and preparation method

InactiveCN103332916AImprove hydrophobicityHigh strengthCeramicwareTemperature resistanceSodium sulfate

Provided is an aerated concrete block with composition of mica powder and fly ash and a preparation method. The aerated concrete block is characterized by being prepared from, by weight, 12-15 parts of cement, 15-20 parts of quicklime, 12-16 parts of gypsum, 30-35 parts of fly ash, 0.2-0.4 parts of aluminium powder, 30-35 parts of mica powder, 12-16 parts of talcum powder, 2-3 parts of ferric nitrate, 2-3 parts of lard, 2-3 parts of sodium dodecyl benzene sulfonate, 1-2 parts of iron mine tailings, 2-3 parts of sodium persulfate, 3-4 parts of oil foot, 3-4 parts of polyisobutylene and 8-10 parts of alum. The aerated concrete block employs composition of mica powder and fly ash, and is advantaged by high temperature resistance acid and alkali resistance, corrosion resistance and high block strength.

Owner:梁莉

Diatomite-modified aerated concrete block and preparation method thereof

The invention relates to a diatomite-modified aerated concrete block and a preparation method thereof. The diatomite-modified aerated concrete block is prepared by the following raw materials by weight: 25-30 parts of cement, 18-22 parts of quicklime, 12-15 parts of gypsum, 50-55 parts of fly ash, 0.2-0.25 part of aluminum powder, 1-2 parts of isothiazolinone, 3-5 parts of chlorinated paraffin, 2-3 parts of gelatin, 20-25 parts of diatomite, 2-3 parts of methyl glucoside polyoxyethylene ether, 3-4 parts of sodium persulfate, 4-6 parts of oil residues and 10-12 parts of sodium carboxymethylcellulose. By adopting the diatomite to modify the aerated concrete block, binding power among the raw materials is enhanced; the strength of the block is increased; and at the same time, the block has a certain capacity for absorbing toxic elements.

Owner:TONGLING FENGZE BUILDING MATERIALS TECH

Edible fungus chaff aerated brick and preparation method therefor

The invention provides an edible fungus chaff aerated brick. The aerated brick is prepared from the raw materials comprising, by weight, 30-35 parts of edible fungus chaff, 24-28 parts of fly ash, 15-20 parts of cement, 12-16 parts of lime, 3-5 parts of bamboo charcoal powder, 3-5 parts of oil foot, 12-18 parts of gypsum, 1-2 parts of aluminium powder, 1-2 parts of nekal, 16-19 parts of bentonite, 3-4 parts of lignocellulose, 2-3 parts of chitosan, 3-5 parts of sodium metasilicate, 8-10 parts of argil, 2-3 parts of rapeseed meal, 1-2 parts of ammonium persulfate and moderate water. The method employs the rapeseed meal as a raw material and the hydrophobicity of the brick is raised and the seepage-proofing effect is improved. Edible fungus chaff is employed as a raw material and waste materials can be utilized.

Owner:唐海峰

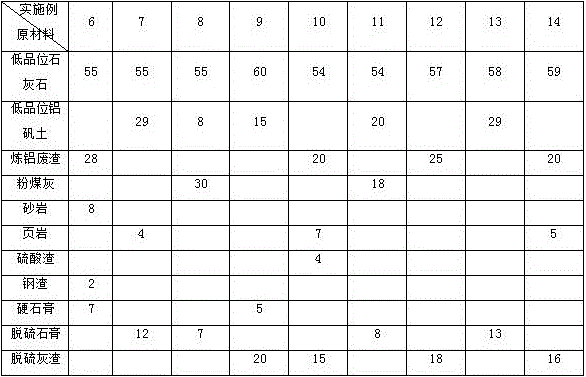

Cement clinker and preparation method thereof

The invention discloses a cement clinker and belongs to the technical field of cement clinker production. The clinker is prepared from the following raw materials in percentage by mass: 30 to 60 percent of calcareous materials, 0 to 25 percent of siliceous materials, 10 to 40 percent of aluminum materials, 0 to 10 percent of ferrous materials and 5 to 20 percent of gypsum materials; a mineral composition of the clinker is prepared from 10 to 40 percent of C4AS, 25 to 40 percent of C2S and 10 to 30 percent of C4AF. According to the clinker disclosed by the invention, the iron content of the cement clinker is low, and the seawater erosion resisting ability of the clinker is improved; the cement clinker is especially suitable for marine engineering.

Owner:JIAHUA SPECIAL CEMENT

Building waste/alkali waste-based autoclaved aerated concrete building block and preparation method thereof

PendingCN108424094APromote resource utilizationPromote environmental protectionSolid waste managementCeramicwareBiological activationSilicon

The invention discloses a preparation method for preparing an autoclaved aerated concrete building block from building waste and alkali waste. The autoclaved aerated concrete comprises the following components in percentage by mass: 43 to 63 percent of building waste, 15 to 25 percent of alkali waste, 5 to 15 percent of lime, 15 to 20 percent of cement, 1 to 3 percent of gypsum and 0.1 percent ofaluminum powder, wherein the ratio of water to materials is 0.55. The autoclaved aerated concrete building block is prepared by stirring the components uniformly, molding by casting and performing autoclave curing. The building waste contains a large amount of silicon aluminum; CSH gel can be formed in the autoclaving process through alkali waste activation; the prepared autoclaved aerated concrete building block has properties of high strength, light weight, heat insulation and freezing resistance; various property indexes meet the A7.5B07 requirement in GB11968-2006 'autoclaved aerated concrete building block standard'; and a new approach is provided for recycling the building waste and the alkali waste.

Owner:WUHAN UNIV OF SCI & TECH

High-iron sulfoaluminate cement clinker and preparation method of same

InactiveCN109020274ASmall shrinkageMake up for drying shrinkageCement productionCalcium in biologyPolymer science

The invention discloses a high-iron sulfoaluminate cement clinker and a preparation method of same. The high-iron sulfoaluminate cement clinker includes, by mass, 45-70% of a calcium material, 5-40% of an aluminum material, 5-30% of an iron material, and 5-15% of a gypsum material. The clinker has mineral composition of: 35-55% of C4A3S, 20-35% of C2S and 15-25% of C4AF. In the invention, the cement clinker is prepared from low-grade calcium material, gypsum material and the like being raw materials, so that the product is higher than ordinary Portland cement in both early strength and later strength; due to the specific mineral composition, the cement clinker is low in overall hydration heat and has a good volume stability.

Owner:JIAHUA SPECIAL CEMENT

Seepage-proofing aerated concrete building block and preparation method thereof

A seepage-proofing aerated concrete building block and a preparation method thereof are disclosed. The building block is composed of following raw materials in parts by weight: 20 to 25 parts of cement, 15 to 20 parts of quicklime, 10 to 15 parts of gypsum, 40 to 45 parts of fly ash, 0.1 to 0.2 part of aluminum powder, 1 to 2 parts of sulfonated lignin, 20 to 25 parts of slag, 10 to 15 parts of cotton straw powder, 10 to 15 parts of grapevine powder, 2 to 3 parts of waste engine oil, 1 to 2 parts of sodium persulfate, 2 to 3 parts of sweet rice flour, and a right amount of water. The aerated concrete building block adopts oil foot and waster engine oil components, which have been modified by initiator, to increase water-resistance ability of the building block, and the seepage-proofing ability of the building block is also largely improved. The seepage-proofing aerated concrete building block has been used in an outer wall body of a community for more than 3 years, and no seepage phenomenon has been found. But adopting conventional aerated concrete building blocks, every spring resident houses have seepage phenomenon. Sweet rice flour is used to prepare pulp, which can fill the cracks in the building block to reduce the possibility of seepage.

Owner:TONGLING FENGZE BUILDING MATERIALS TECH

Multilayer thin film sealing technology of organic light emitting display

ActiveCN101577317AHigh strengthImprove corrosion resistanceSolid-state devicesSemiconductor/solid-state device manufacturingOrganic filmOptoelectronics

The invention relates to the water-oxygen isolation sealing of an organic light emitting display, in particular to a multilayer thin film sealing technology of the organic light emitting display. The technology is characterized in that two layers of metal oxide films and one layer of high molecular organic film are adopted for sealing the organic light emitting display. The metal oxide film can isolate water and oxygen impurities that are greatly harmful to the organic light emitting display and simultaneously prevent the oxidation of metal layer, thereby improving the corrosion resistance, obviously reducing the degeneration rate of the device, and improving the service life of the organic light emitting display.

Owner:YUNNAN NORTH OLIGHTEK OPTO ELECTRONICS TECH

Porous aerated concrete building block and preparation method thereof

A porous aerated concrete building block is characterized by comprising following raw materials in parts by weight: 16 to 20 parts of cement, 20 to 25 parts of quicklime, 12 to 16 parts of gypsum, 0.45 to 0.65 part of aluminum powder, 1 to 2 parts of sodium dodecyl benzene sulfonate, 12 to 15 parts of kaolin earth, 5 to 8 parts of barite powder, 40 to 50 parts of river sands, 3 to 5 parts of dibutyl phthalate, 3 to 5 parts of polyethylene glycol, 2 to 3 parts of sodium persulfate, 4 to 7 parts of oil foot, 2 to 4 parts of chlorinated paraffin, 2 to 3 parts of phenyltriethoxysilane, and 5 to 10 parts of sodium metasilicate. In the preparation method, the aluminum powder and the surfactant commonly foam, therefore the numbers and sizes of air-holes are increased, the weight of building blocks is reduced, and the sound insulation and heat insulation effects are prominently improved.

Owner:TONGLING FENGZE BUILDING MATERIALS TECH

Aerated concrete block with good anticorrosion property, and preparation method thereof

ActiveCN103332951AImprove hydrophobicityNo water seepage was foundCeramicwareSodium bicarbonateHexamethylenetetramine

The invention relates to an aerated concrete block with a good anticorrosion property, and a preparation method thereof. The aerated concrete block with the good anticorrosion property is prepared by the following raw materials by weight: 18-22 parts of cement, 16-18 parts of quicklime, 8-15 parts of gypsum, 0.3-0.4 part of aluminum powder, 8-12 parts of propylene glycol, 40-50 parts of quartz sand, 10-14 parts of block slag, 3-4 parts of urotropine, 2-3 parts of sodium benzoate, 3-5 parts of sodium persulfate, 3-5 parts of oil residues, 3-5 parts of epoxidized soybean oil, 5-7 parts of sodium bicarbonate and 15-20 parts of rice bran. The raw materials of the urotropine, sodium benzoate and the like are used, so that the aerated concrete block has relatively good anticorrosion effect, and the service life of the block in an acid and big alkaline environment can be prolonged.

Owner:JIANGSU GOLDEN CUBE ENVIRONMENTAL TECH CO LTD

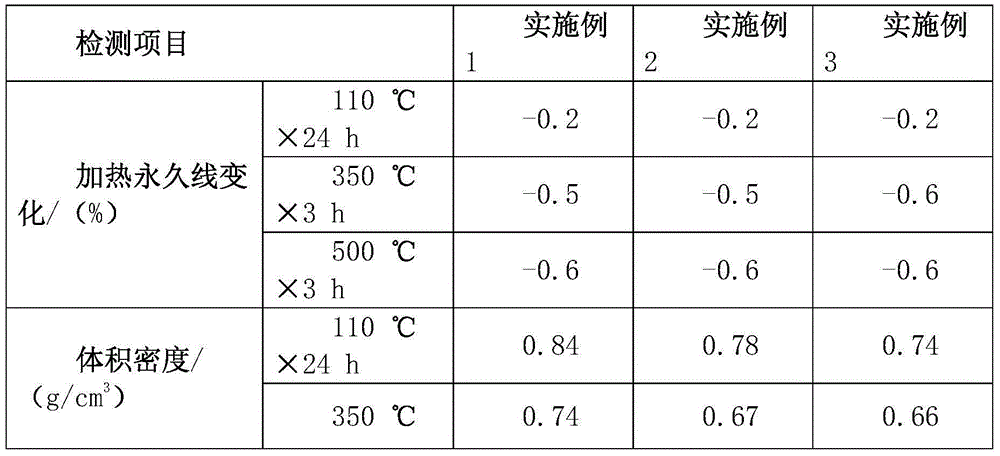

Lightweight, heat-insulation and fire-proof castable composition, and application and preparation method thereof

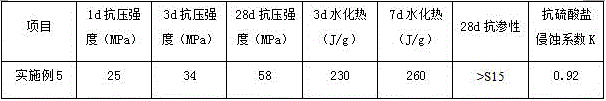

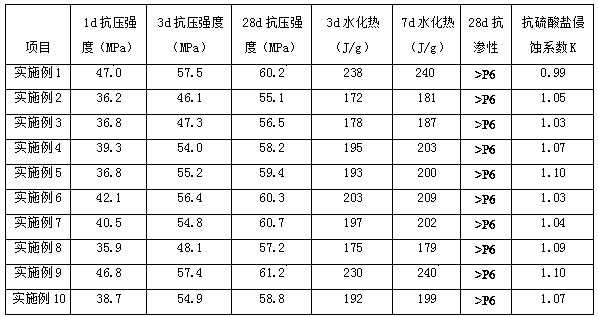

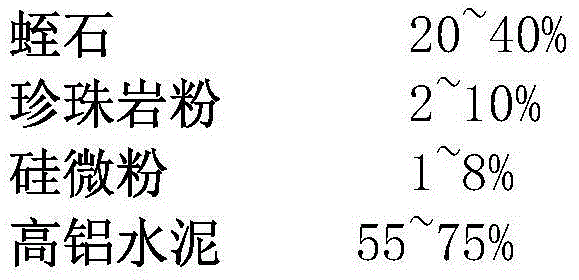

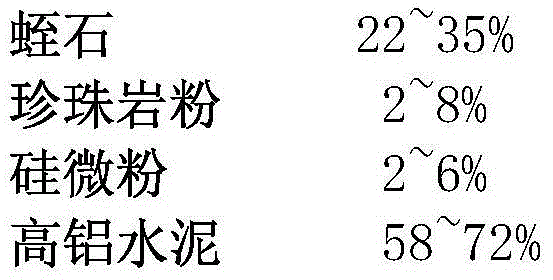

The invention discloses a lightweight, heat-insulation and fire-proof castable composition, and an application thereof in a nitrogen purification device and a preparation method thereof; the castable composition includes vermiculite, a perlite powder, a silica micro-powder and high-alumina cement. The castable composition has the characteristics of low thermal conductivity, low volume density, good thermal shock resistance, high use temperature and the like; at the same time, the castable composition also has good fluidity and easy and convenient construction; after being applied to the nitrogen purification device, the castable composition can effectively reduce heat loss of the nitrogen purification device, improves the thermal efficiency, reduces energy consumption, saves energy and reduces emissions. In addition, raw materials adopted by a lightweight, heat-insulation and fire-proof castable are non-toxic and non-corrosive, so the lightweight, heat-insulation and fire-proof castable has the characteristics of energy saving and environmental protection, and plays an important role in improving and protecting the environment. At the same time, all kinds of used raw materials can be purchased from markets, and the production costs of the lightweight heat-insulation and fire-proof castable are reduced.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

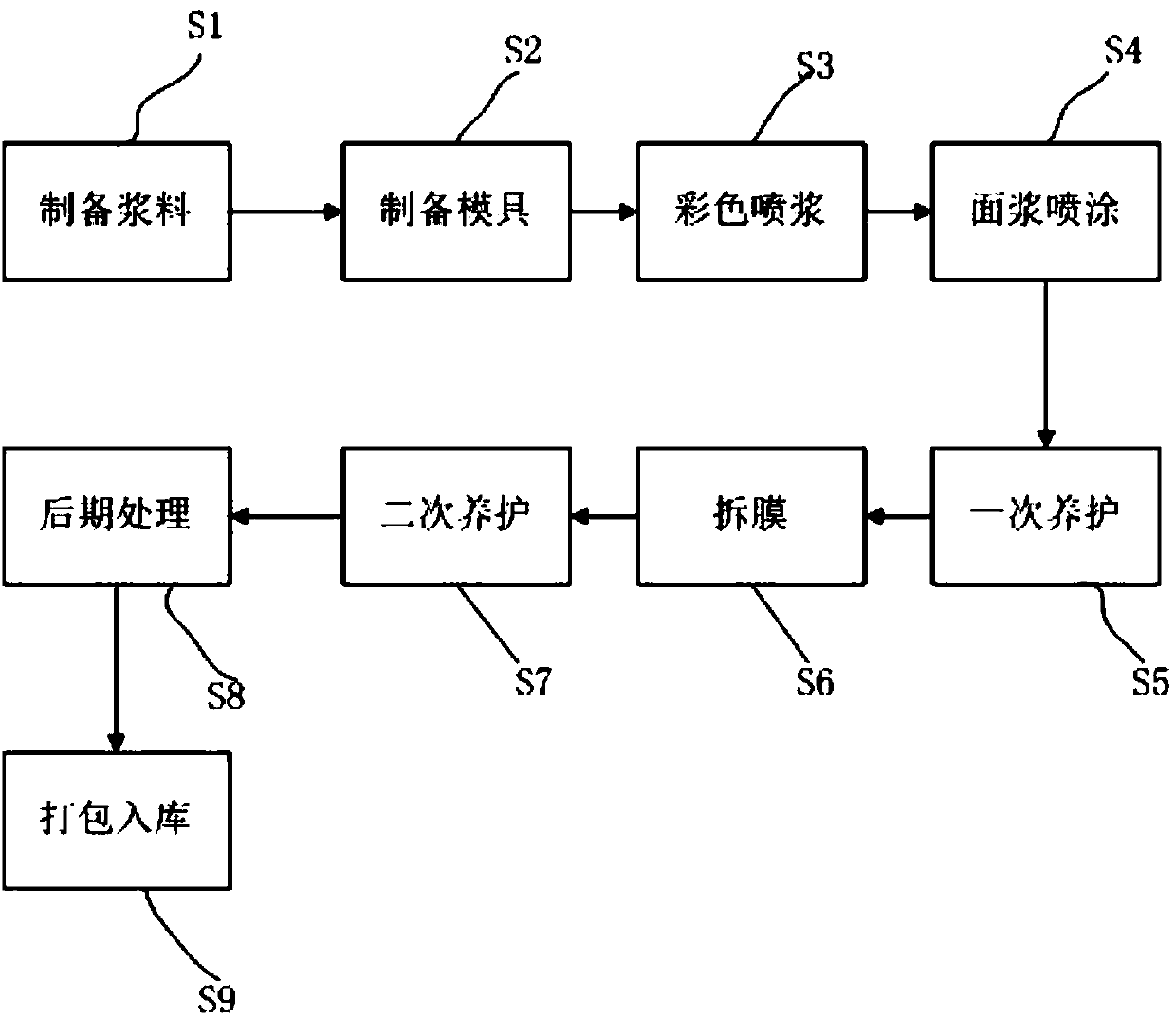

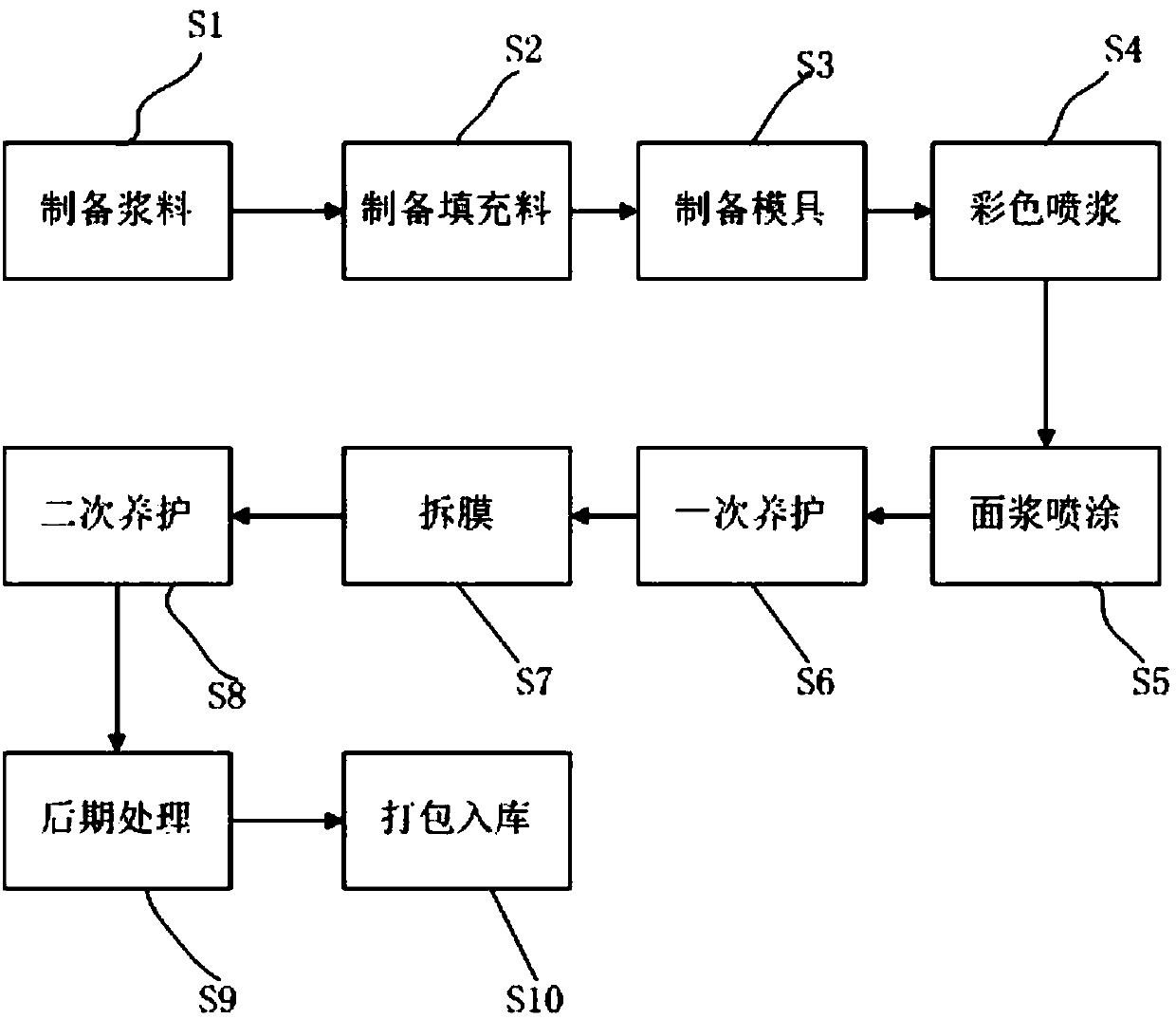

Technique for producing artificial culture stone

InactiveCN102837352AImprove surface densityHard surfaceFeeding arrangmentsEnvironmental resistanceCooking & baking

The invention discloses a stuffing material used for preparing an artificial culture stone and a technique for preparing the artificial culture stone by using the stuffing material. The technique comprises the following steps of: preparation of a mould, preparation of slurry, preparation of the stuffing material, mould coloring, slurry spraying or filling, filling of stuffing material, secondary sputtering or filling, vibrating and shaping, baking and product packaging. The stuffing material and the technique have the following beneficial effects that the artificial culture stone produced according to the technical scheme of the invention has the following characteristics of high surface compactness, low water absorption, good weather fastness, high surface strength, high ultraviolet resistance, high freezing resistance, high aging resistance as well as even and harmonious color; in particular, the artificial culture stone made of the stuffing material is hard in the surface and low in specific gravity of the middle part and can float on a water level; the bonding surface attached on the surface of a building is rough and is beneficial for bonding, so that the artificial culture stone can be bonded more firmly and is unlikely to release; and the artificial culture stone can insulate heat and can replace a heat-insulation layer, in this way, the building cost is reduced, and the requirements of national environmental friendliness and energy saving are met.

Owner:SICHUAN FUMEILAI NEW BUILDING MATERIALS CO LTD

High-strength aerated concrete block and preparation method thereof

InactiveCN103332949BImprove hydrophobicityHigh compressive strengthCeramicwarePolyvinyl alcoholCarboxylic acid

The invention relates to a high-strength aerated concrete block and a preparation method thereof. The high-strength aerated concrete block is prepared by the following raw materials by weight: 25-30 parts of cement, 10-15 parts of quicklime, 12-15 parts of gypsum, 0.15-0.2 part of aluminum powder, 10-15 parts of propylene glycol, 3-5 parts of a polycarboxylate water reducing agent, 12-15 parts of saw dust,5-8 parts of oil residues, 3-5 parts of branch powder, 5-8 parts of clay, 3-5 parts of sodium persulfate, 30-35 parts of gravels and 4-6 parts of 3-aminopropyl trimethoxysilane. Cement consumption in the high-strength aerated concrete block is relatively large, and the polycarboxylate water reducing agent and the gravels are added, so that compressive strength of the block is obviously enhanced, thereby meeting actual production requirements.

Owner:富强科技股份有限公司

Tea seed episperm powder aerated concrete block and preparation method thereof

The invention provides a tea seed episperm powder aerated concrete block and a preparation method thereof. The tea seed episperm powder aerated concrete block is prepared by the following raw materials by weight: 30-35 parts of broken block slag, 20-25 parts of fly ash, 15-18 parts of cement, 12-16 parts of lime, 2-3 parts of sodium benzoate, 15-20 parts of gypsum, 1-2 parts of aluminum powder, 20-25 parts of the tea seed episperm powder, 8-10 parts of vermiculite powder, 4-8 parts of polyvinyl alcohol, 2-3 parts of borax, 2-3 parts of waste oil, 2-3 parts of sodium persulfate, 3-5 parts of asphalt, 1-2 parts of a silane coupling agent KH570 and a proper amount of water. By adopting the tea seed episperm powder as a raw material, the weight of the aerated concrete block is lightened, and wastes can be utilized.

Owner:滨海县益彬新型建材有限公司

Fireproof and fire retardant aerated concrete block and preparation method thereof

ActiveCN103332921AImprove hydrophobicityNo water seepage was foundCeramicwareCelluloseSodium metasilicate

The invention relates to a fireproof and fire retardant aerated concrete block and a preparation method thereof. The fireproof and fire retardant aerated concrete block is prepared by the following raw materials by weight: 15-20 parts of cement, 10-15 parts of quicklime, 8-12 parts of gypsum, 20-25 parts of loess, 0.2-0.3 part of aluminum powder, 1-2 parts of cellulose ether, 20-25 parts of corn stalk powder,10-15 parts of chilli vine powder, 8-10 parts of oil residues, 3-5 parts of aluminium hydroxide, 3-5 parts of ammonium alum, 2-3 parts of ammonium persulfate and 10-15 parts of sodium metasilicate. The aerated concrete block produced by the method has increased hydrophobicity and greatly improved water permeability by adopting the oil residues and modifying by an initiator. No wall seepage phenomenon is found in over 3 years by using the block produced by the invention in external walls of small residential areas, while the seepage is found every spring in some residents whose walls are built by conventional aerated concrete blocks. Aluminium hydroxide and ammonium alum are used by the method, so that the aerated concrete block has relatively good fire retardance and can greatly reduce risks of fire.

Owner:TONGLING FENGZE BUILDING MATERIALS TECH

Construction method for heat-insulating layer of environment-friendly roof

InactiveCN103821285ALow shrinkageReliable qualityRoof covering insulationsCost (economic)High frequency

Owner:SICHUAN YAHAO REAL ESTATE DEV

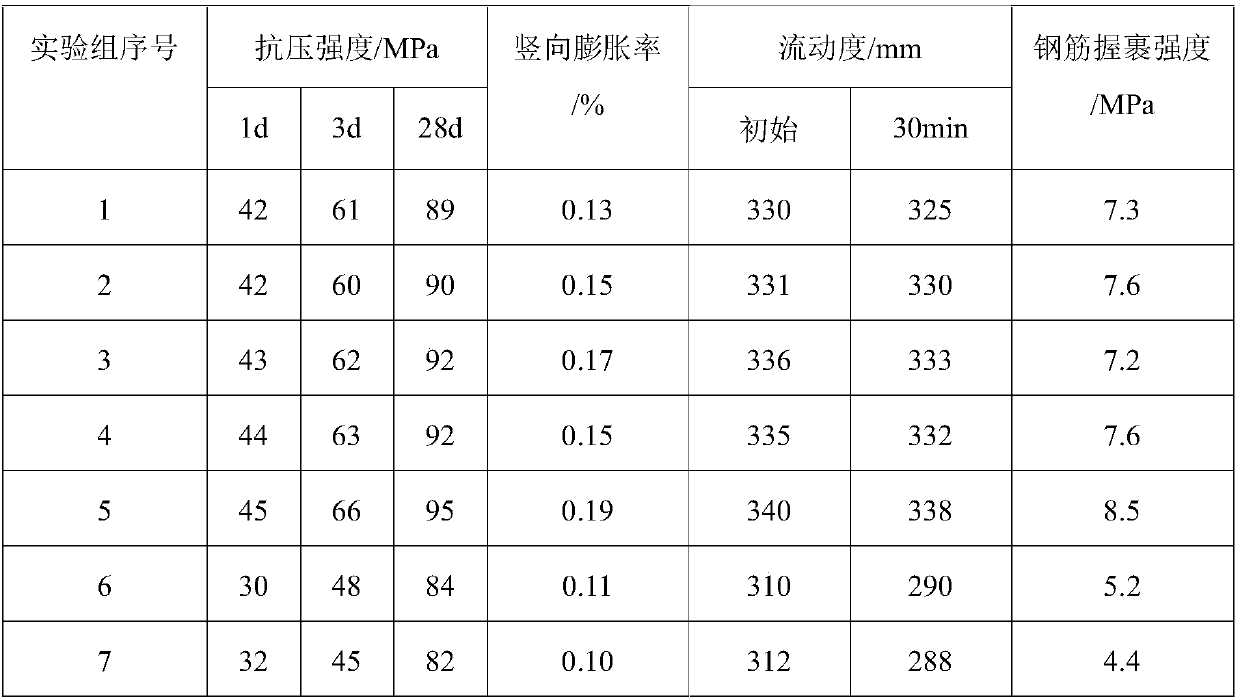

Grouting material for sound barrier backboard

InactiveCN107602006AHas fast hardeningGood adhesionNoise reduction constructionPre stressingHeat stability

The invention relates to the technical field of building materials and provides a grouting material for a sound barrier backboard. The grouting material comprises the following raw materials (by weight): 15-25 parts of Portland cement, 30-40 parts of fly ash, 50-70 parts of building rubbish, 10-15 parts of water and 0.61-1.08 parts of additives. The grouting material has advantages of wide sourcesof raw materials, high utilization rate of solid wastes, low cost, rapid hardening, early strength, slight expansion, strong bonding force, good heat stability and the like, and can be used as a binder for bonding or reinforcement of engineering equipment. The sound barrier backboard is provided with multiple reinforcing holes. after the backboard is maintained to design strength, the backboard is tensioned with pre-stress steel bars or steel strands, and then the grouting material is injected to glue the pre-stress steel bars or steel strands with the sound barrier backboard as a whole. Thus, the sound barrier backboard is safe and stable and durable.

Owner:SICHUAN SHUANGTIE TECH CO LTD

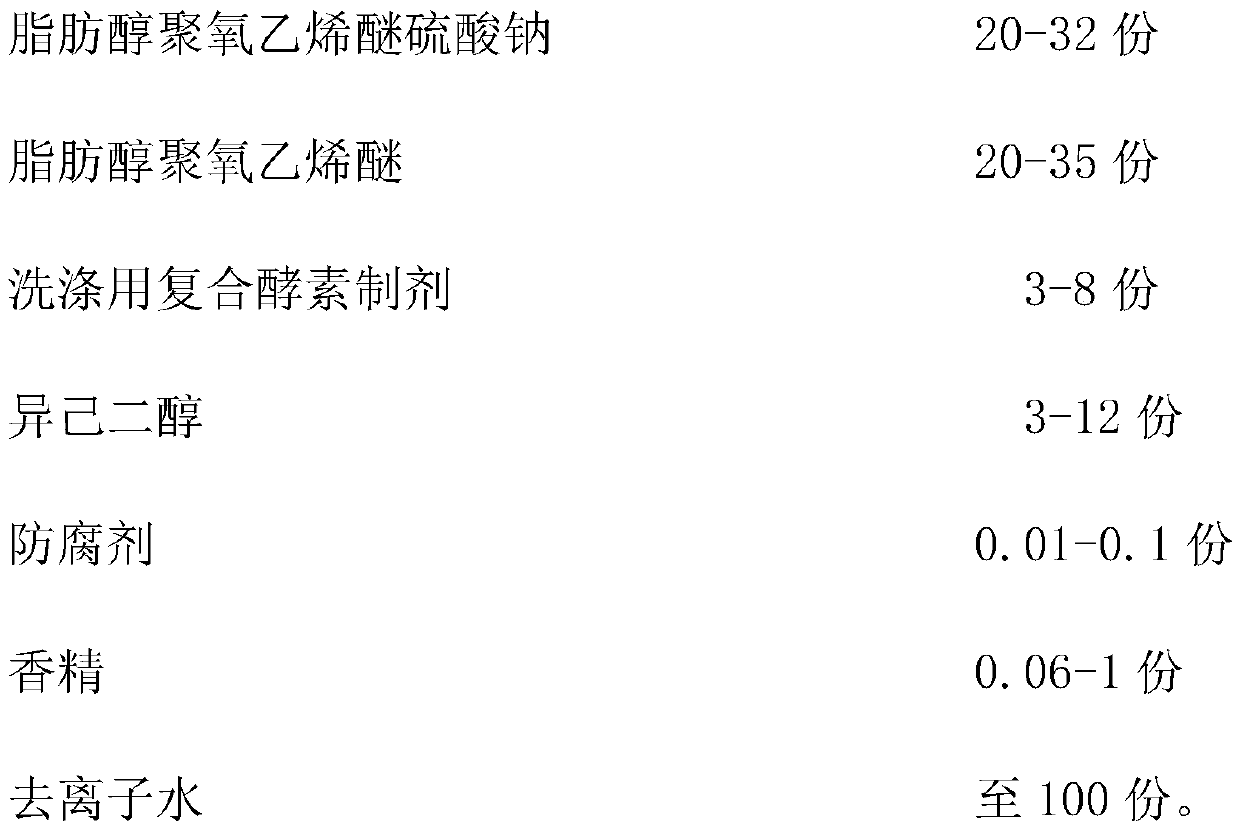

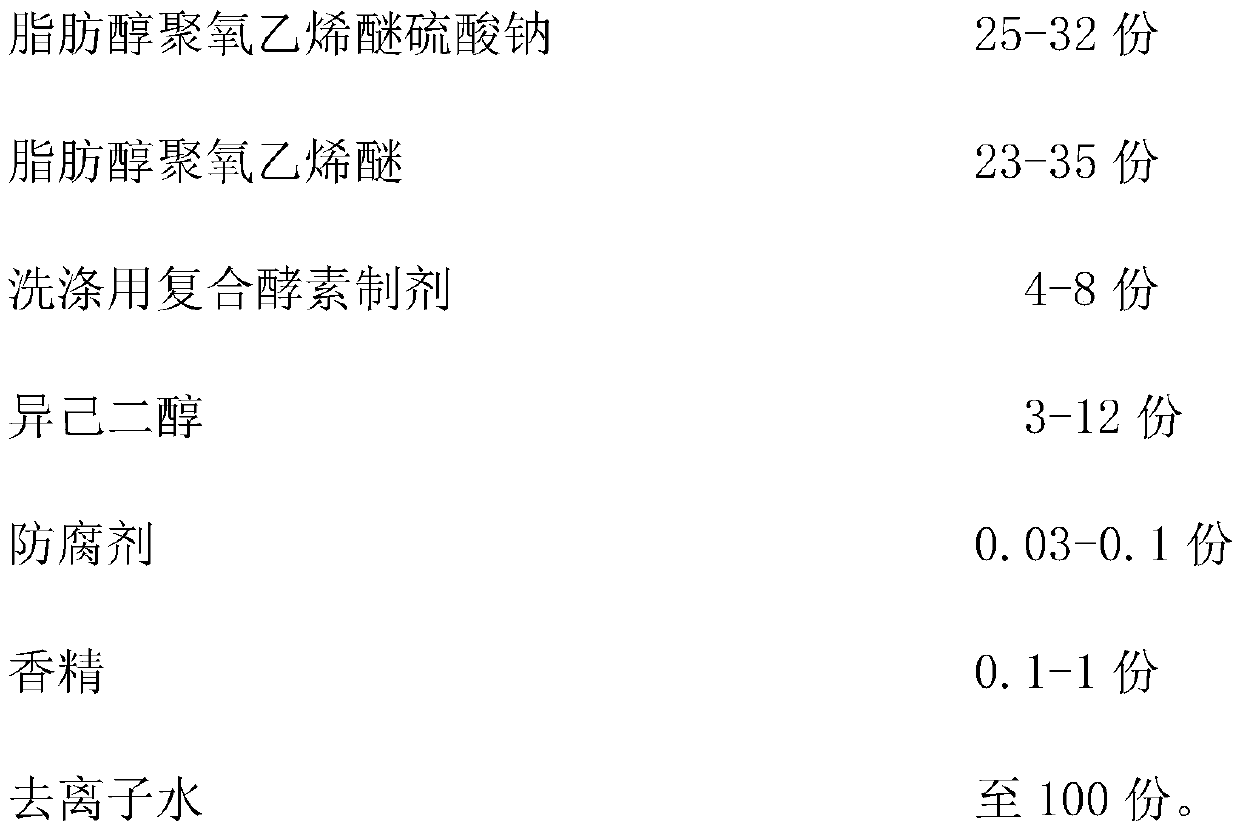

Enzyme highly concentrated laundry detergent

InactiveCN109797054AReduce usageThe amount of usage is greatly reduced, not only the reduction of packaging materialsNon-ionic surface-active compoundsDetergent compounding agentsHigh concentrationWater dispersible

The invention discloses an enzyme highly concentrated laundry detergent. The enzyme highly concentrated laundry detergent is prepared from, by weight, 20-32 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 20-35 parts of fatty alcohol-polyoxyethylene ether, 3-8 parts of a laundry compounded enzymatic preparation, 3-12 parts of 2-methyl-2,4-pentendiol, 0.01-0.1 part of a preservative, 0.06-1 part of an essence and 100 parts of deionized water. By the adoption of the formula, the enzyme highly concentrated laundry detergent solves all the technical difficult problems during high concentration of a conventional laundry detergent, such as gelling, flowability and layering, and meanwhile solves the problems that the conventional highly concentrated laundry detergent has poor dispersion in water and easily becomes flocculent or spherical during use. Due to high concentration, the use amount of the laundry detergent is greatly reduced, the material packaging and transporting costsand the like are obviously reduced, the adding quantity of non-functional components is also obviously reduced, and thus the production cost is obviously reduced.

Owner:党峰

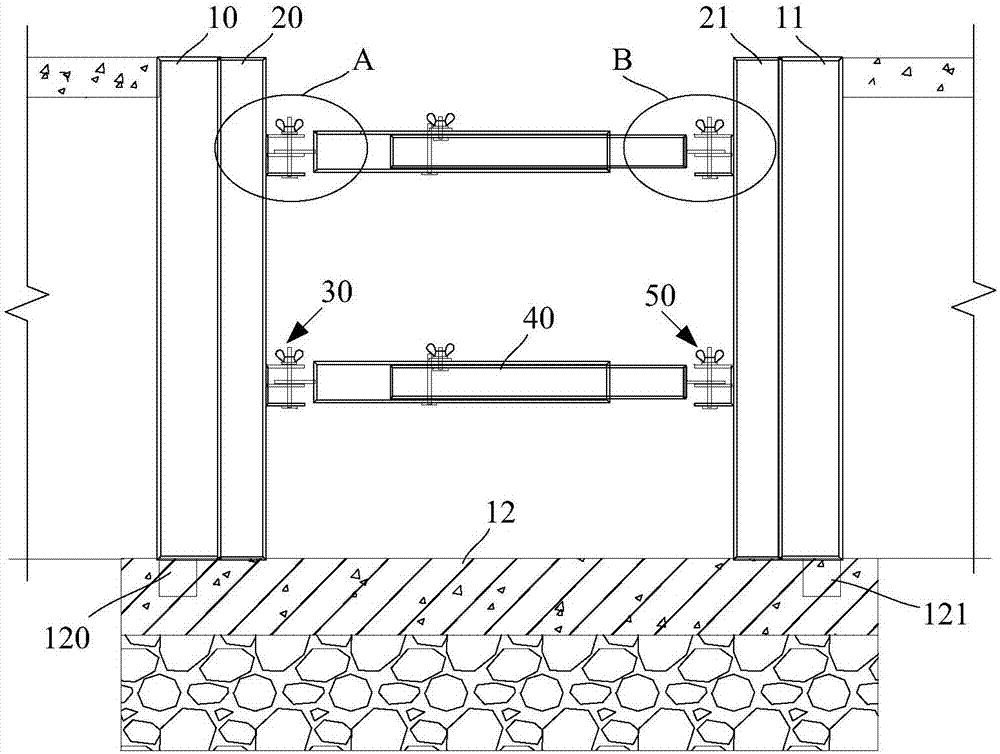

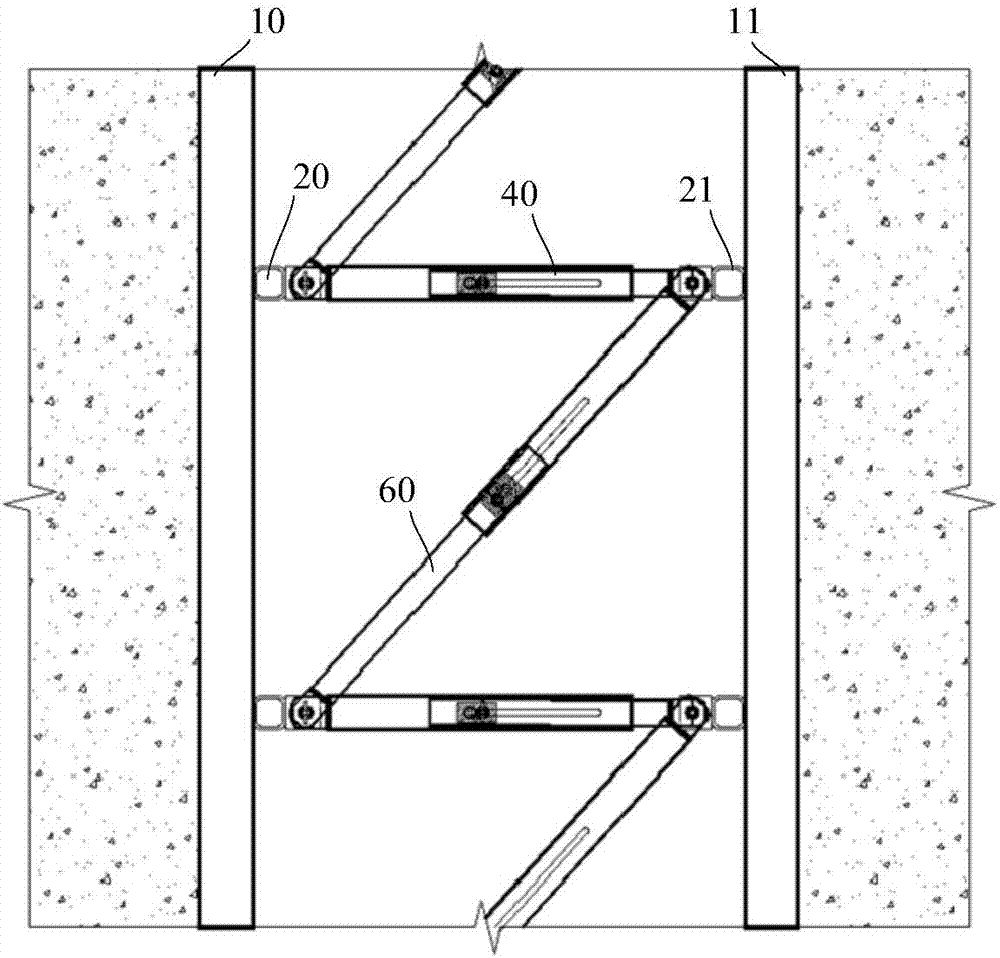

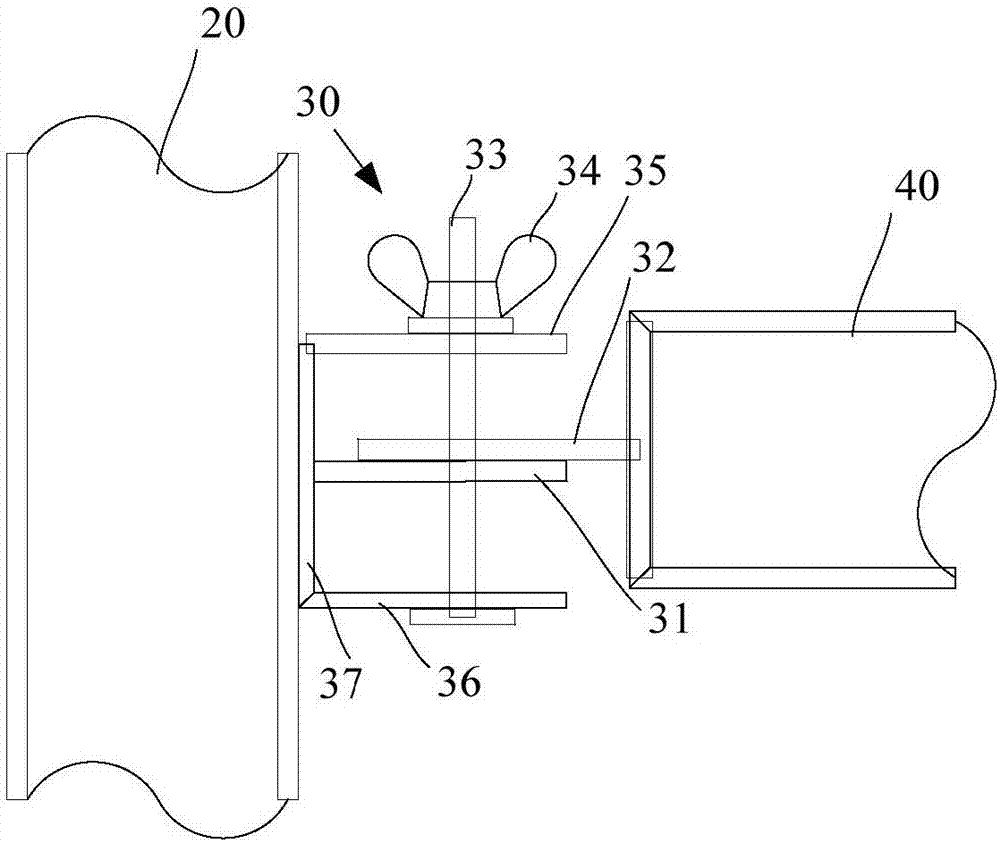

Inner support device of basement precast slab mold and construction method

ActiveCN107313451AGeometrically accurateStable structureArtificial islandsUnderwater structuresBasementCushion

The invention relates to an inner support device of a basement precast slab mold and a construction method. The device is used for supporting between a first precast slab and a second precast slab oppositely arranged; the first precast slab and the second precast slab are vertically arranged on the edge of a basement cushion layer; and the inner support device of the basement precast slab mold comprises at least one first stand column vertically arranged in a basement and bonded on the first precast slab, at least one second stand column vertically arranged in the basement and bonded on the second precast slab, at least one first hinge piece fixed on the first stand column, at least one second hinge piece arranged corresponding to the first hinge piece and fixed on the second stand column, and at least one support pipe capable of adjusting the length, connected between the first hinge piece and the second hinge piece and supported between the first stand column and the second stand column. The device is convenient in disassembly and capable of recycling.

Owner:CHINA CONSTR EIGHTH ENG DIV CORP LTD ZHEJIANG CONSTR CO LTD

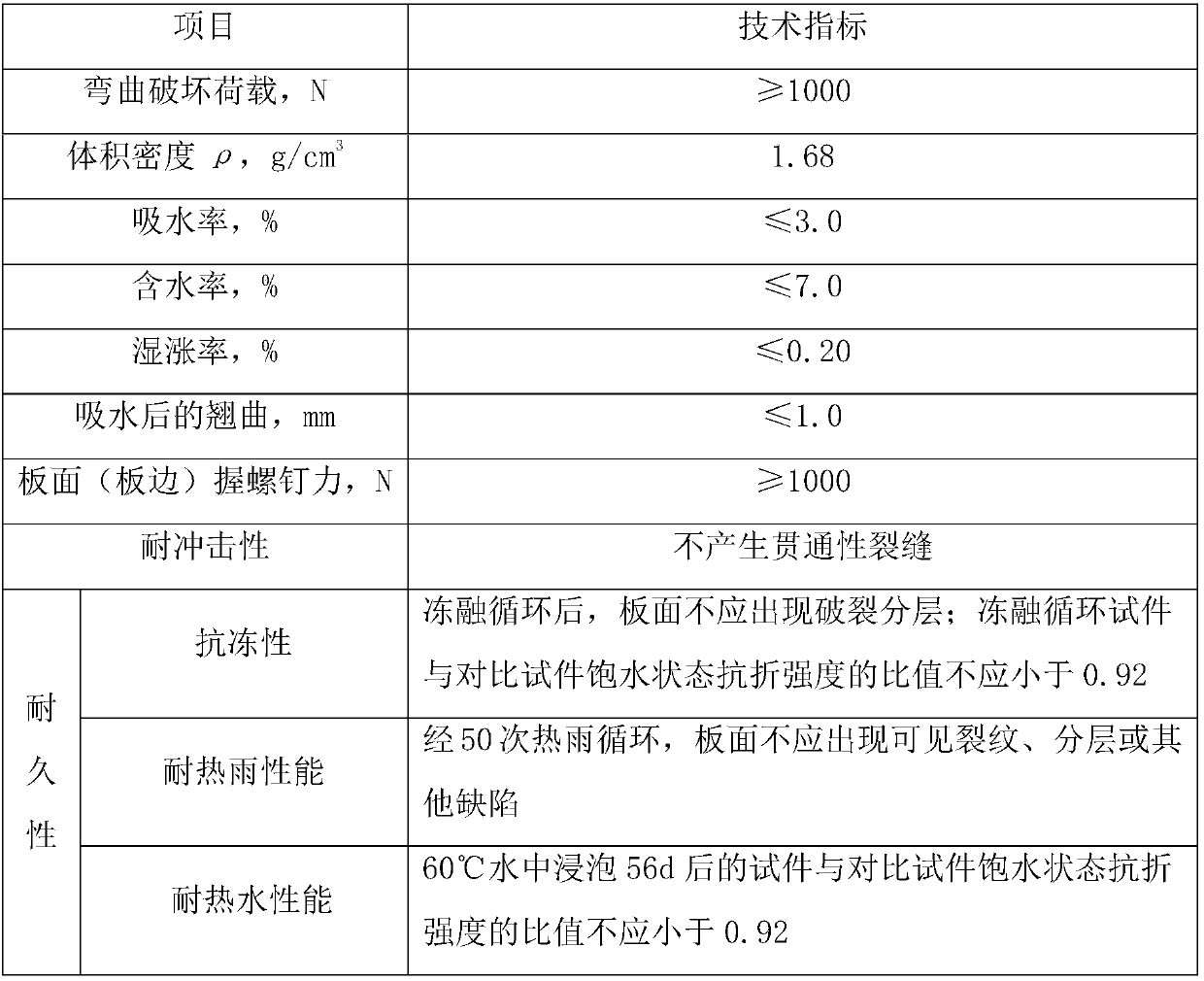

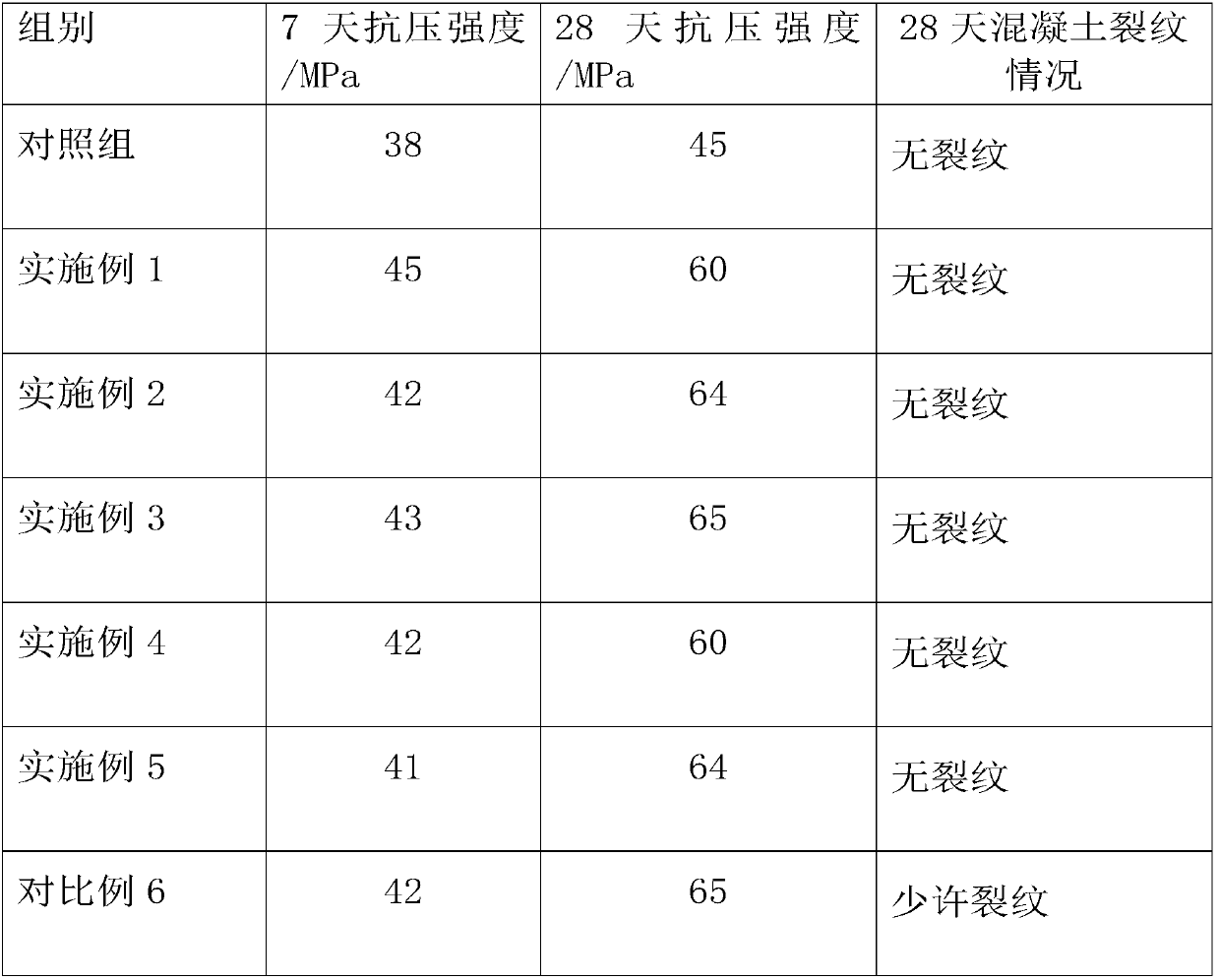

External-wall culture stone slab

PendingCN107555892AReduce usageEasy to viewSolid waste managementCeramic shaping apparatusYarnFreeze thawing

The invention discloses an external-wall culture stone slab. The external-wall culture stone slab is prepared from slurry and filler, wherein the slurry is prepared from cement, plant fiber, toner, anadditive, alkali-resisting yarn, fly ash, melamine and water; the filler is prepared from Portland cement, quick hardening cement, hydrogen peroxide, a naphthalene-based FDN-S superplasticizer, waterborne polyurethane, calcium stearate, lithium carbonate, silica fume, glass fiber, nylon fiber, redispersible latex powder and water. According to the external-wall culture stone slab, the problems that during freeze thawing, pores can be mutually communicated, strength is reduced gradually, culture stone is prone to corrosion and falling off, appearance is affected and potential safety hazard isgenerated due to filling particles produced in the culture stone and hard surface of the culture stone in the prior art are solved, stability is high, and the external-wall culture stone slab is moreeasily adaptive to severe environments such as low temperature and the like.

Owner:HEBEI ZHUODA BUILDING MATERIALS RES INST CO LTD

Lightweight air-entrained concrete block and its preparation method

InactiveCN103332915BImprove hydrophobicityReduce weightSolid waste managementCeramicwareSodium metasilicatePolyvinyl alcohol

Provided is a lightweight aerated concrete block. The aerated concrete block is characterized by comprising, by weight, 20-25 parts of cement, 15-20 parts of quicklime, 10-12 parts of gypsum, 10-15 parts of fly ash, 0.2-0.3 parts of aluminium powder, 8-10 parts of polypropylene fiber, 8-10 parts of mineral oil, 5-8 parts of clay, 30-35 parts of plant ash, 3-5 parts of ammonium persulfate, 10-12 parts of oil foot, 12-15 parts of sodium metasilicate and 3-5 parts of polyvinyl alcohol. The aerated concrete block takes plant ash as a main raw material, the plant ash is lightweight, so that the weight of block is reduced greatly, and the building load is reduced.

Owner:江西展业建材科技有限公司

Fire-resistant and flame-retardant aerated concrete block and preparation method thereof

ActiveCN103332921BImprove hydrophobicityNo water seepage was foundCeramicwareCelluloseSodium metasilicate

The invention relates to a fireproof and fire retardant aerated concrete block and a preparation method thereof. The fireproof and fire retardant aerated concrete block is prepared by the following raw materials by weight: 15-20 parts of cement, 10-15 parts of quicklime, 8-12 parts of gypsum, 20-25 parts of loess, 0.2-0.3 part of aluminum powder, 1-2 parts of cellulose ether, 20-25 parts of corn stalk powder,10-15 parts of chilli vine powder, 8-10 parts of oil residues, 3-5 parts of aluminium hydroxide, 3-5 parts of ammonium alum, 2-3 parts of ammonium persulfate and 10-15 parts of sodium metasilicate. The aerated concrete block produced by the method has increased hydrophobicity and greatly improved water permeability by adopting the oil residues and modifying by an initiator. No wall seepage phenomenon is found in over 3 years by using the block produced by the invention in external walls of small residential areas, while the seepage is found every spring in some residents whose walls are built by conventional aerated concrete blocks. Aluminium hydroxide and ammonium alum are used by the method, so that the aerated concrete block has relatively good fire retardance and can greatly reduce risks of fire.

Owner:TONGLING FENGZE BUILDING MATERIALS TECH

Tea seed episperm powder aerated concrete block and preparation method thereof

The invention provides a tea seed episperm powder aerated concrete block and a preparation method thereof. The tea seed episperm powder aerated concrete block is prepared by the following raw materials by weight: 30-35 parts of broken block slag, 20-25 parts of fly ash, 15-18 parts of cement, 12-16 parts of lime, 2-3 parts of sodium benzoate, 15-20 parts of gypsum, 1-2 parts of aluminum powder, 20-25 parts of the tea seed episperm powder, 8-10 parts of vermiculite powder, 4-8 parts of polyvinyl alcohol, 2-3 parts of borax, 2-3 parts of waste oil, 2-3 parts of sodium persulfate, 3-5 parts of asphalt, 1-2 parts of a silane coupling agent KH570 and a proper amount of water. By adopting the tea seed episperm powder as a raw material, the weight of the aerated concrete block is lightened, and wastes can be utilized.

Owner:滨海县益彬新型建材有限公司

Aerated concrete block with good anticorrosion property, and preparation method thereof

ActiveCN103332951BImprove hydrophobicityNo water seepage was foundCeramicwareSodium bicarbonateHexamethylenetetramine

Owner:JIANGSU GOLDEN CUBE ENVIRONMENTAL TECH CO LTD

Low thermal conductive aerated concrete block and preparation method thereof

ActiveCN103332950BImprove hydrophobicityNo water seepage was foundCeramicwareBrickChlorinated paraffins

The invention relates to a low thermal conductive aerated concrete block and a preparation method thereof. The low thermal conductive aerated concrete block is prepared by the following raw materials by weight: 18-22 parts of cement, 15-18 parts of quicklime, 10-15 parts of gypsum, 0.25-0.4 part of aluminum powder, 20-30 parts of fly ash, 15-20 parts of floating beads, 20-25 parts of waste brick fragments, 10-15 parts of foamed polypropylene particles, 3-5 parts of sodium persulfate, 6-8 parts of oil residues, 3-5 parts of chlorinated paraffin, 5-8 parts of propylene glycol, 3-5 parts of 2-hydroxypropyl acrylate and 4-6 parts of borax. Foamed particles are used, so that the aerated concrete block has the characteristics of light weight and heat insulation. In summer, an indoor temperature of a room employing the block provided by the invention is 4-5 DEG C lower than a room employing conventional aerated concrete wall.

Owner:JIANGSU GOLDEN CUBE ENVIRONMENTAL TECH CO LTD

Landscape model and method for making landscape model on ground or wall

InactiveCN107628787AImprove frost resistanceGood shrinkage performanceRoads maintainenceSodium BentoniteThermal expansion

The invention relates to the material field, in particular to a landscape model and a method for making a landscape model on the ground or wall. The landscape model comprises the following raw materials by weight: 350-500 parts of Portland cement, 20-65 parts of bentonite, 10-25 parts of lignocellulose, 400-700 parts of quartz sand, and 37-45 parts of anti-crack rubber powder. Portland cement hasgood frost resistance and small dry shrinkage; bentonite has the functions of improving concrete performance, saving water, regulating the strength grade of concrete and the like, and can increase thefluidity, cohesiveness and water retention properties of concrete. Lignocellulose has the advantages of uniform thermal expansion, and no peeling or cracking, and can increase the support force and durability of the landscape model. The landscape model is in an environment exposed to the sun and rain and is constantly run over by automobiles, the anti-crack rubber powder improves the impact resistance and fracture resistance of the landscape model, and improves the wear resistance and weather resistance.

Owner:王慧同

Multilayer thin film sealing technology of organic light emitting display

ActiveCN101577317BHigh strengthImprove corrosion resistanceSolid-state devicesSemiconductor/solid-state device manufacturingOrganic filmOptoelectronics

Owner:YUNNAN NORTH OLIGHTEK OPTO ELECTRONICS TECH

Beryllia-containing aerated concrete block and preparation method therefor

Provided is a beryllia-containing aerated concrete block. The block is composed of the following raw materials comprising, by weight, 22-24 parts of cement, 14-16 parts of quicklime, 12-14 parts of gypsum, 20-25 parts of fly ash, 0.1-0.2 parts of aluminium powder, 30-35 parts of iron sand tailings, 12-15 parts of calcium chloride, 1-2 parts ofberyllia, 3-5 parts of sulfamate water reducing agents, 3-5 parts of zinc oxide, 2-3 parts of tributyl phosphate, 1-2 parts of dodecyl betaine, 3-5 parts of sodium persulfate, 2-3 parts of oil foot, 2-3 parts of silane coupling agent KH5502, 2-3 parts of cross-linking agent TAC and 6-8 parts of sodium tripolyphosphate. The aerated concrete block is advantaged by high compressive strength, light weight, sound insulation, heat insulation, good heat retaining property, good anti-frost property, less contraction and the like. The aerated concrete block overcomes the defects of low strength and easy cracking of traditional aerated concrete blocks. Beryllia in the block is a good refractory material and can be fire-retardant.

Owner:深圳绿景环保再生资源有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com