Ecological treatment technology for construction waste

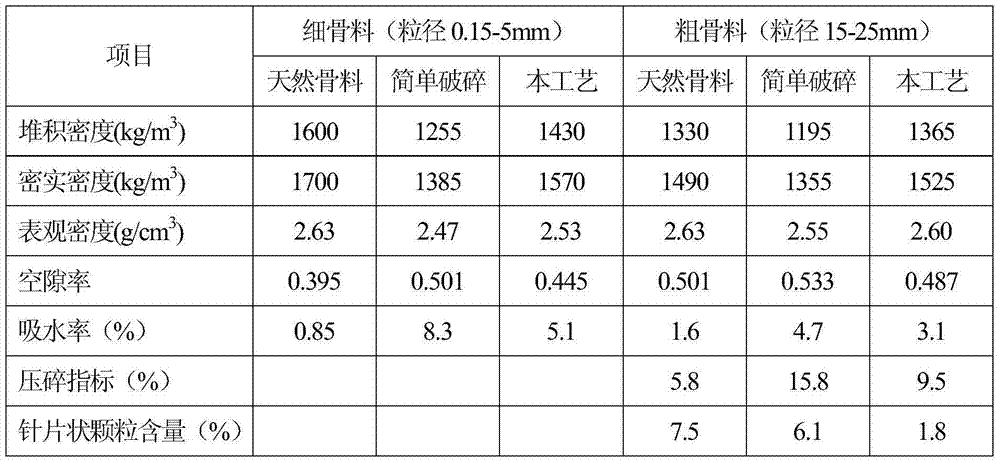

A construction waste and processing technology technology, which is applied in the fields of building materials, energy conservation and environmental protection, and construction waste recycling, can solve the problems of difficulty in preparation and high value-added utilization, and achieves low elastic modulus, high water absorption, The effect of high water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

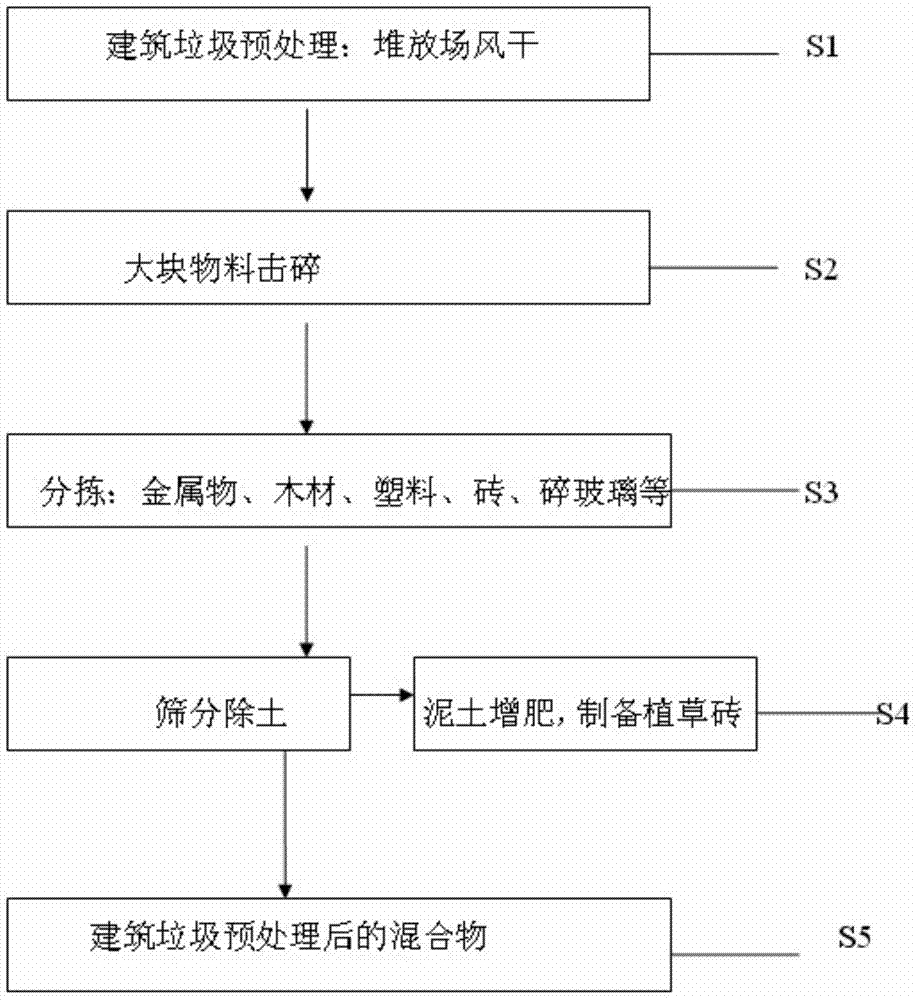

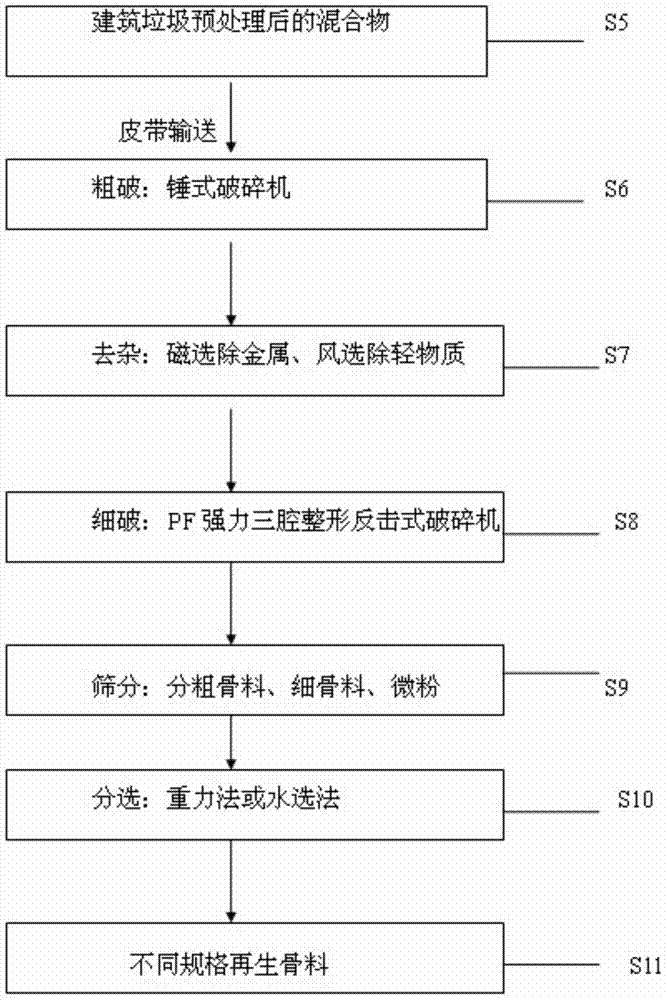

[0046] The construction waste ecological classification treatment technology of the present invention comprises the following steps:

[0047] 1. Pretreatment, carry out natural air-drying in the construction waste dump, and the site is equipped with a canopy:

[0048] a. For the initial selection, metal materials, wood materials and plastic materials are classified by manual and excavator (crushing and handling of bulk materials);

[0049] b. Sorting out waste bricks and broken glass and separating them from waste concrete;

[0050] c. Initial screening, the fine material (mainly soil) contained in the construction waste is separated through a vibrating screen, and the soil is fertilized for the production of grass planting bricks. The rest is the pre-treated mixture of construction waste, which will be used for later use.

[0051] As a further improvement, the pretreatment step of the construction waste is to classify metal materials, wood materials and plastic materials. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com