Landscape model and method for making landscape model on ground or wall

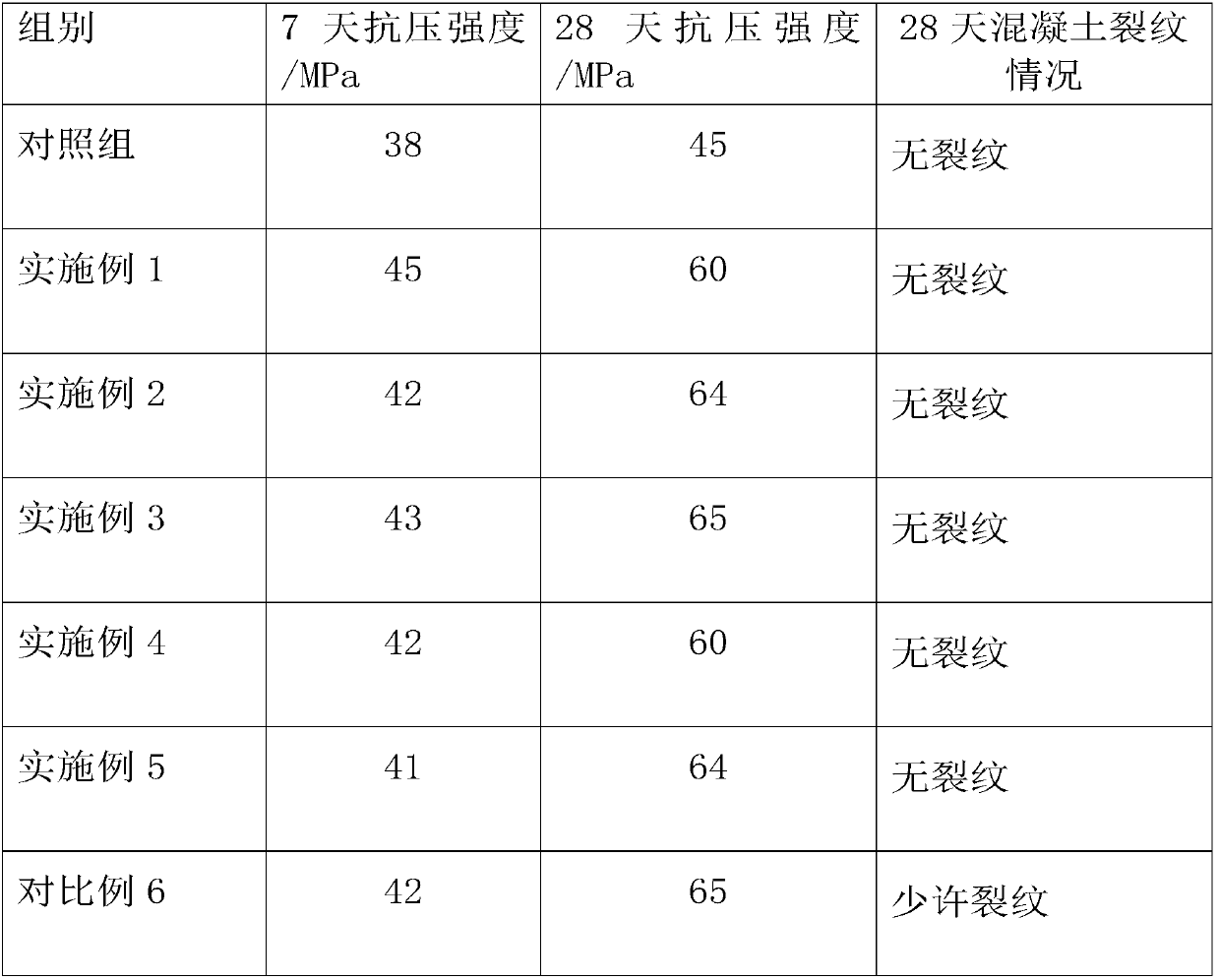

A landscape and ground technology, applied in the field of materials, can solve problems such as poor impact resistance and easy cracking, and achieve the effects of improving concrete performance, improving wear resistance and weather resistance, and improving impact resistance and fracture resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The preparation method of the landscape modeling provided by the embodiment of the present invention is to firstly mix the concrete raw materials and halve it, then lay the concrete and multi-layer grid cloth at intervals, and use a mold to form after the surface is dry. In this embodiment, the surface drying time is 2 hours, and the molding process uses tools such as hollow molds and rollers, and is directly constructed by hand. It can be made on the wall or the bottom surface without the need for release powder, saving materials and procedures.

[0051] Further, the raw materials of the above mixed anti-cracking rubber powder are reacted at 60-70° C. for 2 hours and then mixed with other raw materials to form concrete.

[0052] Further, the above also includes spraying the molded product with polyurea coating. Polyurea is produced by the reaction of isocyanate components and amino compound components, and has extremely high tensile impact strength, flexibility, abras...

Embodiment 1

[0057] This embodiment provides a kind of landscape modeling, and the concrete of landscape modeling is mainly made through the following steps:

[0058] Weighing raw materials: Portland cement 350g, bentonite 20g, lignocellulose 10g, quartz sand 400g; White powder 10g and sericite powder 5g.

[0059] Mix ethylene oxide-tetrahydrofuran copolyether and diphenylmethane diisocyanate, react at 60°C for 1 hour, then add sericite powder, fly ash and titanium dioxide and stir for 1 hour, then mix with other raw materials to make concrete.

Embodiment 2

[0061] This embodiment provides a kind of landscape modeling, and the concrete of landscape modeling is mainly made through the following steps:

[0062] Weighing raw materials: Portland cement 500g, bentonite 65g, lignocellulose 25g, quartz sand 700g; ethylene oxide-tetrahydrofuran copolyether 5g, diphenylmethane diisocyanate 10g, fly ash 12g, titanium dioxide 13g and silk Mica powder 8g.

[0063] Mix ethylene oxide-tetrahydrofuran copolyether and diphenylmethane diisocyanate, react at 60°C for 1 hour, then add sericite powder, fly ash and titanium dioxide and stir for 1 hour, then mix with other raw materials to make concrete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com