External-wall culture stone slab

A culture and slate technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as affecting aesthetics, hidden dangers, easy corrosion, etc., and achieve weight reduction, construction efficiency improvement, and good weather resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: An exterior wall cultural stone slab, including slurry, the slurry is composed of cement, plant fiber, toner, admixture, alkali-resistant yarn, fly ash, melamine and water.

[0042] The admixtures include air-entraining agents, expansion agents, coloring agents, antifreeze agents, waterproofing agents and pumping agents, etc., which are used to improve the corresponding performance of cultural stones.

[0043] The content of each component in the slurry is 100kg of cement, 12kg of plant fiber, 1.0kg of toner, 0.6kg of admixture, 0.2kg of alkali-resistant yarn, 5.2kg of fly ash, 3kg of melamine, and 35kg of water.

[0044] 12kg of the plant fiber, 1.0kg of toner, 0.6kg of admixture, 0.2kg of alkali-resistant yarn, 5.2kg of fly ash, and 35kg of water.

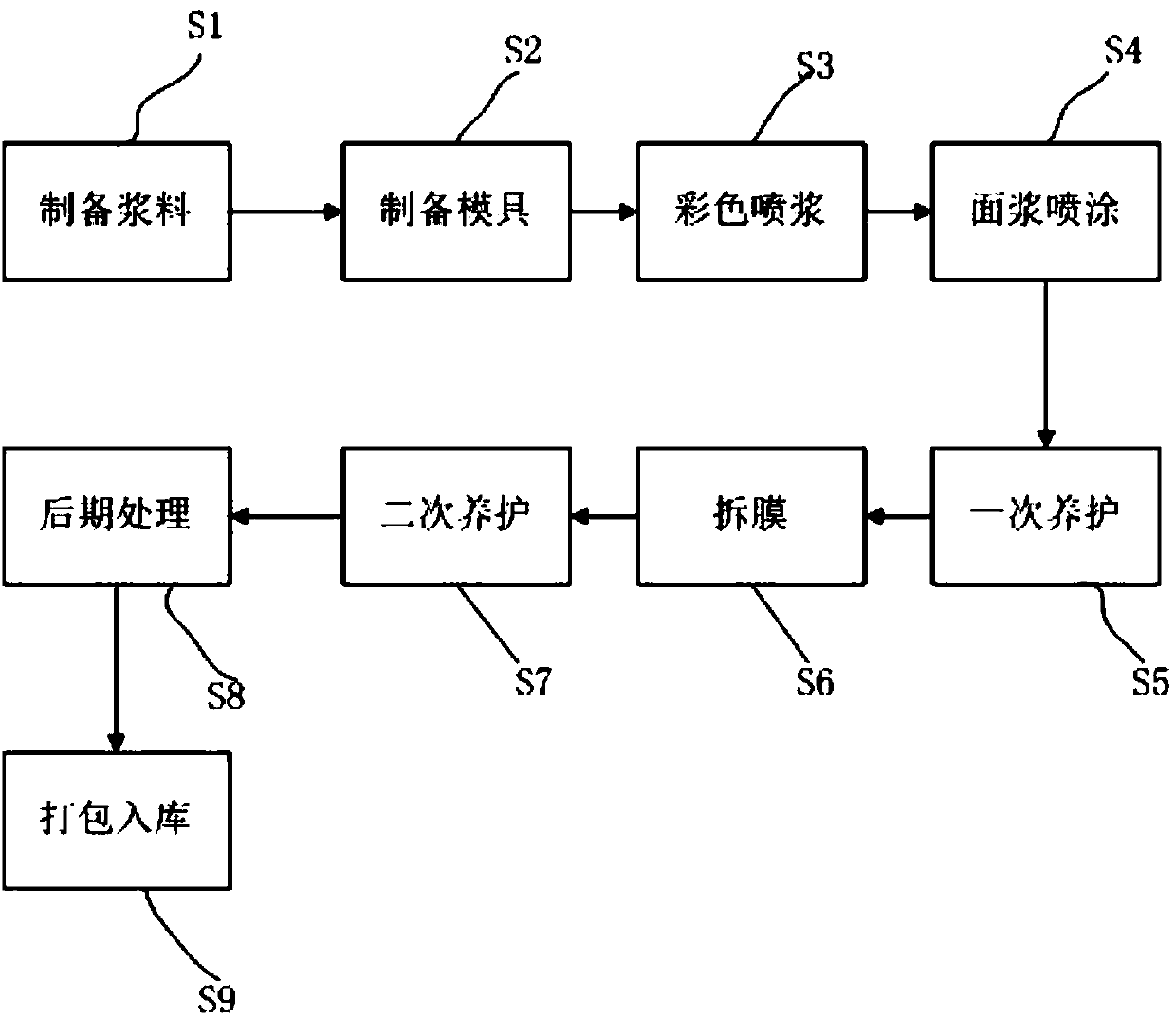

[0045] The present invention also provides a preparation method for the external wall cultural stone slab, which specifically includes the following steps:

[0046] S1. Preparation of slurry: mix cement, pla...

Embodiment 2

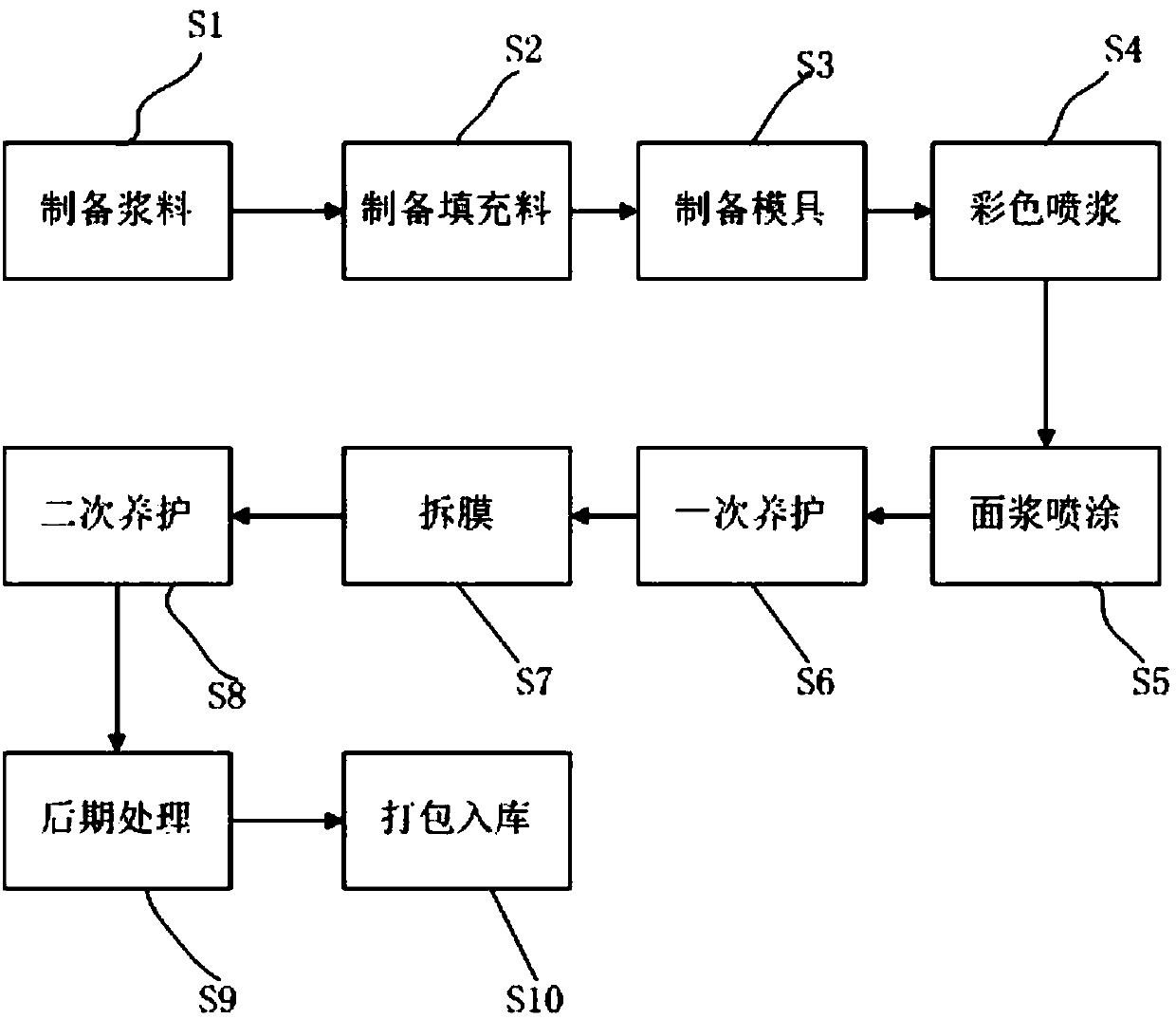

[0058] Embodiment 2: A kind of external wall cultural stone slab, including slurry and filler, described slurry is made up of cement, plant fiber, toner, admixture, alkali-resistant yarn, fly ash, melamine and water; The material consists of Portland cement, rapid hardening cement, hydrogen peroxide, naphthalene series FDN-S superplasticizer, water-based polyurethane, calcium stearate, lithium carbonate, silica fume, glass fiber, nylon fiber, redispersible latex powder and water composition.

[0059] The admixtures include various water reducing agents, air-entraining agents and pumping agents, etc., which are used to improve the rheological properties of the cultural stone mixture.

[0060] The admixtures include setting retarders, early strength agents and accelerators, etc., which are used to adjust the setting time and hardening performance of cultural stones.

[0061] The admixtures include air-entraining agents, waterproofing agents and rust inhibitors, etc., which are ...

Embodiment 3

[0080] Embodiment 3: A kind of external wall cultural stone slab, including slurry and filler, described slurry is made up of cement, plant fiber, toner, admixture, alkali-resistant yarn, fly ash, melamine and water; The material consists of Portland cement, rapid hardening cement, hydrogen peroxide, naphthalene series FDN-S superplasticizer, water-based polyurethane, calcium stearate, lithium carbonate, silica fume, glass fiber, nylon fiber, redispersible latex powder and water composition.

[0081] The admixtures include various water reducing agents, air-entraining agents and pumping agents, etc., which are used to improve the rheological properties of the cultural stone mixture.

[0082] The admixtures include setting retarders, early strength agents and accelerators, etc., which are used to adjust the setting time and hardening performance of cultural stones.

[0083] The admixtures include air-entraining agents, waterproofing agents and rust inhibitors, etc., which are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com